Method and device for removing hydrogen sulfide in gas phase through oxidation

A hydrogen sulfide, gas phase technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of blockage of the outer layer of the rotor, large regeneration equipment, low efficiency, etc., to reduce the concentration of hydrogen sulfide and the size of the equipment The effect of shrinking and reducing the amount of fluid circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

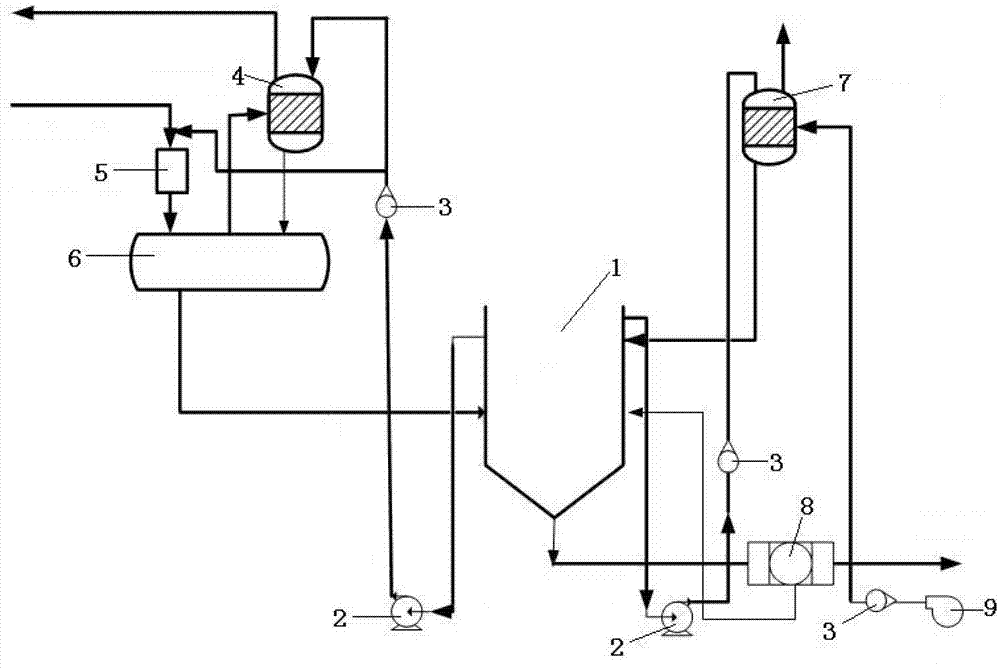

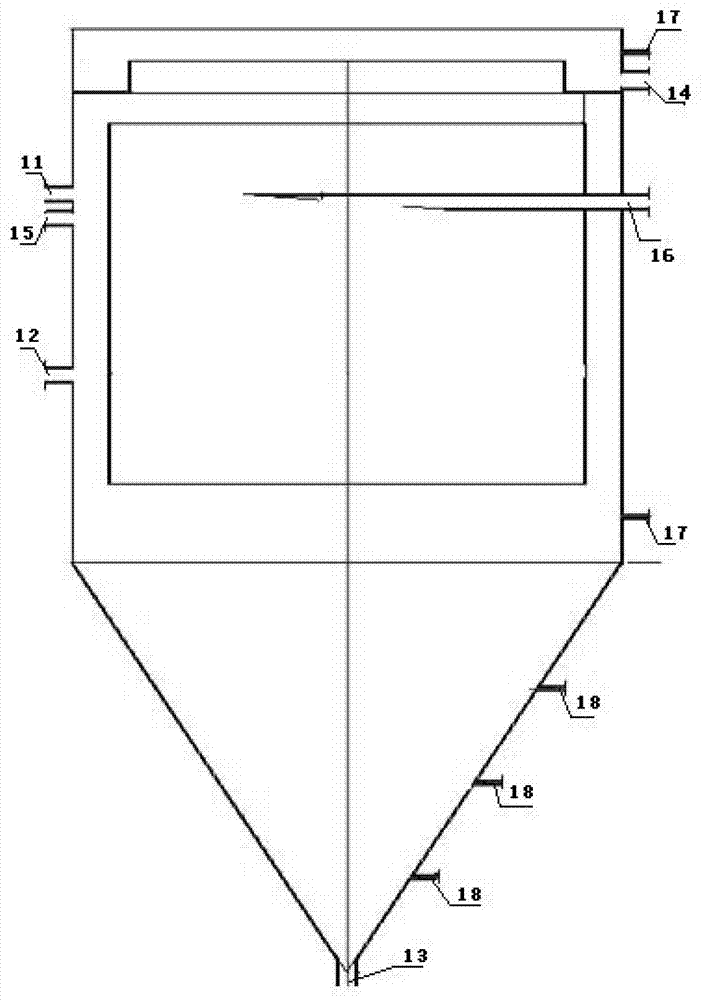

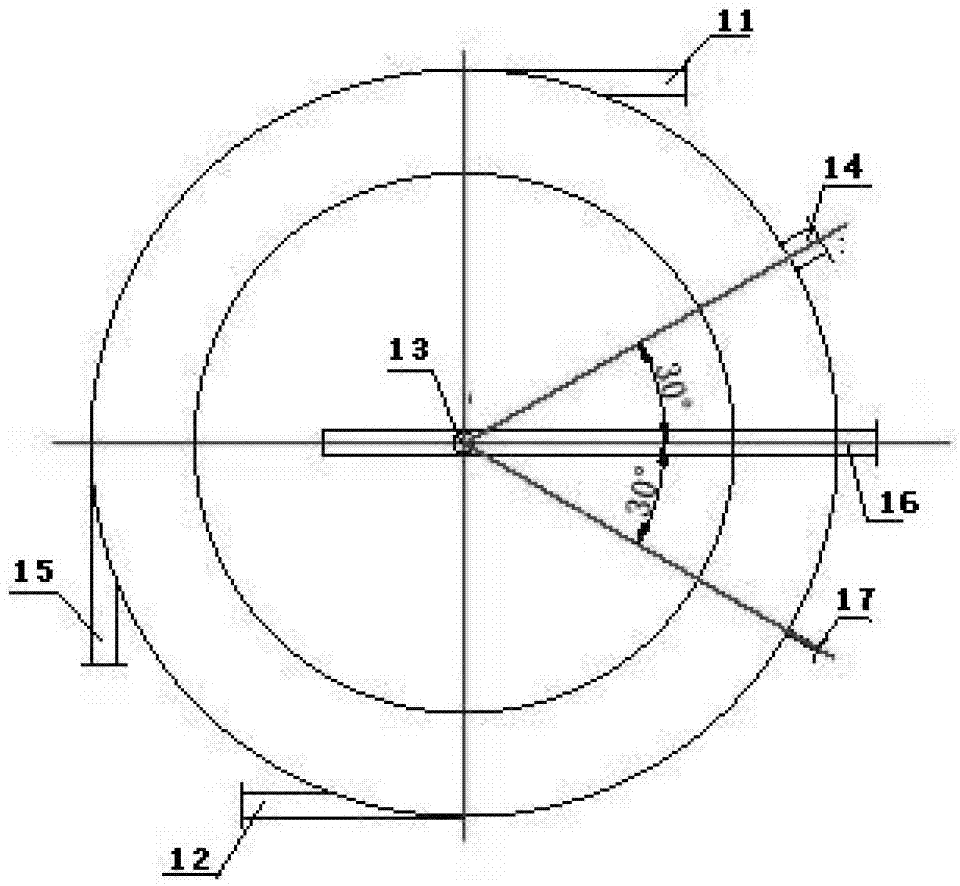

[0027] A device for oxidizing and removing hydrogen sulfide in the gas phase, the device includes a settling tank 1, an extraction pump 2, a filter membrane 3, a supergravity rotating packed bed 4, a separator 5, a balance tank 6 and a regenerative supergravity machine 7; An extraction pump 2 and a filter membrane 3 are sequentially connected between the tank 1 and the high-gravity rotating packed bed 4; a balance tank 6 is connected between the settling tank 1 and the separator 5; the high-gravity rotating packed bed 4 communicates with the balance tank 6, Settling tank 1 and separator 5 are sequentially connected with extraction pump 2 and filter membrane 3, and between settling tank 1 and regeneration supergravity machine 7 are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com