Dust filtration system of mixed gas of high-temperature oil gas, water vapour and carbonaceous easy-precipitation substances

A technology of dust filtration and water vapor, which is applied in membrane filter, dispersed particle filtration, transportation and packaging, etc. It can solve the problems of filter cake thickening, production stoppage, economic loss, etc., so as to increase speed, increase service life and reduce investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

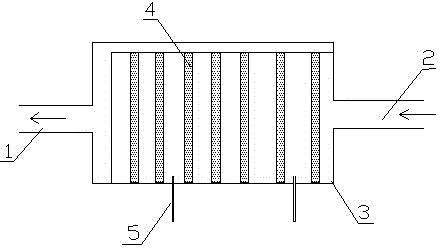

[0018] Such as figure 1 Shown: a dust filtration system for a mixture of high-temperature oil gas, water vapor, and carbon-containing easily precipitated substances, including a closed separation chamber 3 connected to an air intake pipe 2 and an exhaust pipe 1, and the airtight separation chamber 3 is provided with a A large number of filter mechanisms 4, the outer surface of the filter mechanism 4 communicates with the intake pipe 2, and the inner surface communicates with the exhaust pipe 1, and a filter body regeneration mechanism 5 is arranged in the sealed separation chamber 3, and the filter body regeneration mechanism It is used to control the intake and exhaust control components of the filter regeneration material, such as controlling the intake and exhaust control components of oxygen-containing gas, or the gas after combustion of the intake and exhaust control components of the intake and exhaust control components containing carbon dioxide, water vapor gas or a mix...

Embodiment 2

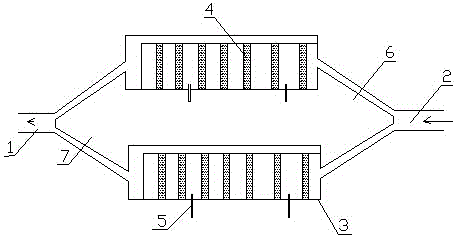

[0020] Such as figure 2 Shown: a dust filtration system for a mixture of high-temperature oil gas, water vapor, and carbon-containing easily precipitated substances, including a closed separation chamber 3 connected to an air intake pipe 2 and an exhaust pipe 1, and the airtight separation chamber 3 is provided with a A large number of filter mechanisms 4, the outer surface of the filter mechanism 4 communicates with the intake pipe 2, and the inner surface communicates with the exhaust pipe 1, and a filter body regeneration mechanism 5 is arranged in the sealed separation chamber 3, and the filter body regeneration mechanism It is used to control the intake and exhaust control components of the filter regeneration material, such as controlling the intake and exhaust control components of oxygen-containing gas, or the gas after combustion of the intake and exhaust control components of the intake and exhaust control components containing carbon dioxide, water vapor gas or a mi...

Embodiment 3

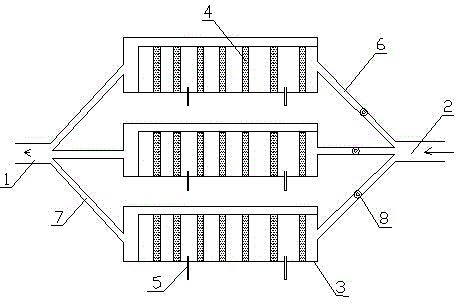

[0022] Such as image 3 Shown: a dust filter system for a mixture of high-temperature oil gas, water vapor, and carbon-containing easily precipitated substances, including a closed separation chamber 3 connected to an air intake pipe 2 and an exhaust pipe 1, and the airtight separation chamber 3 is provided with a A large number of filter mechanisms 4, the outer surface of the filter mechanism 4 communicates with the intake pipe 2, and the inner surface communicates with the exhaust pipe 1, and a filter body regeneration mechanism 5 is arranged in the sealed separation chamber 3, and the filter body regeneration mechanism It is used to control the intake and exhaust of the regenerated material of the filter body, such as the control component for controlling the intake and exhaust of gas containing carbon dioxide and water vapor, and the effective gas content is 5 to 11%. There are multiple airtight separation chambers 3 between the air intake pipe 2 and the exhaust pipe 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com