Rubber microwave regeneration linkage device

A linkage device, rubber technology, applied in recycling technology, plastic recycling, reagents, etc., can solve the problems of performance deterioration of recycled rubber, decomposition of compounding agents, scorch and carbonization, etc., to achieve high quality of recycled rubber, simple installation, and land occupation small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

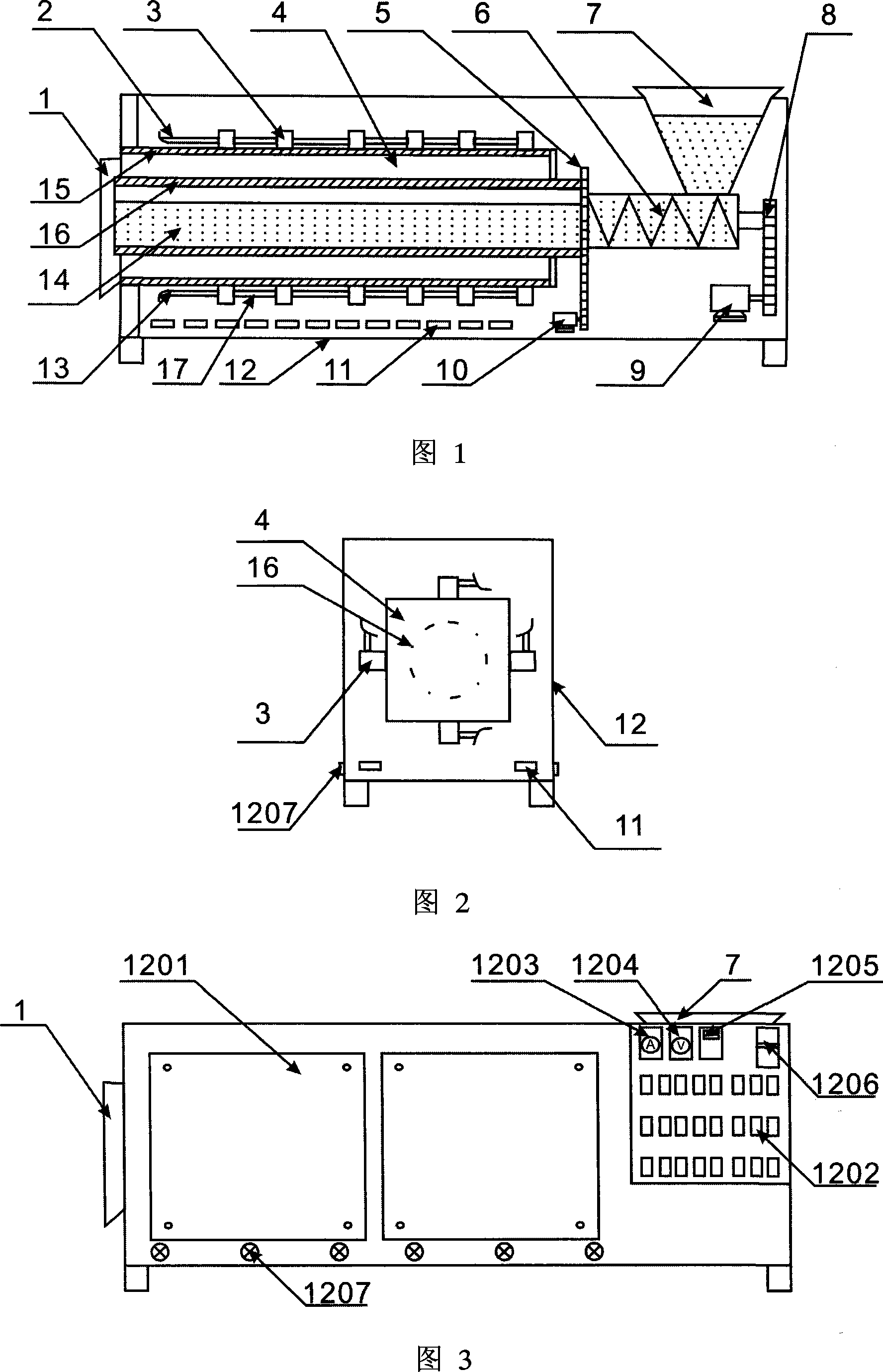

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] The essence of microwave desulfurization is that the polar groups in the cross-linked network absorb the microwave energy and convert it into kinetic energy of molecular thermal motion, or due to the internal friction between the polar group and the surrounding network due to orientation polarization, enough heat is generated to promote chemical bonds. A break occurs. Through the processing of literature data, the fracture time of different cross-linking points is calculated, and it is believed that microwave desulfurization can achieve carbon black aggregates, carbon black-rubber, carbon-hydrogen bonds, polysulfur cross-links, low-sulfur cross-links, carbon-carbon The bonds are broken in sequence to control the best desulfurization effect. The desulfurization process may be accompanied by side reactions such as thermo-oxidative aging, cyclization and re-crossl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com