Regeneration method of aluminum chloride for denitration

A technology of aluminum chloride and denitrification, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve problems such as high operating costs, low absorption efficiency, and low solubility, and achieve low operating costs, large processing capacity, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

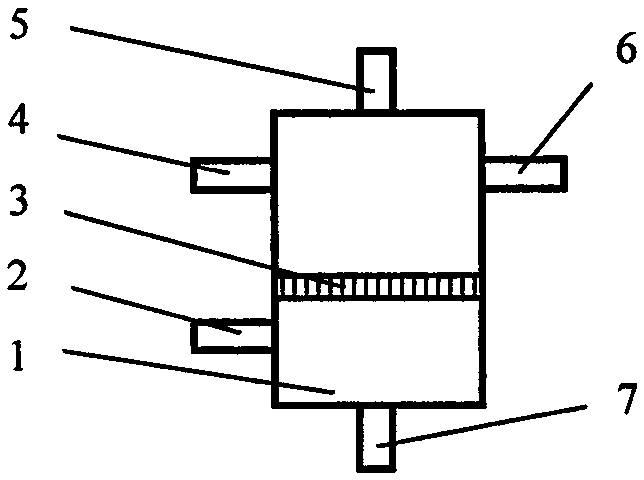

[0022] Embodiment 1: A schematic diagram of a fixed-bed device for the regeneration method of aluminum chloride for denitrification is as follows figure 1 shown. The aluminum chloride regeneration furnace is a tubular type with a size of Φ60mm×600mm. About 100g of the solid product after the denitrification reaction is added to the gas-solid reaction tower. The protective inert gas of the regeneration furnace is nitrogen, and the flow rate is about 1-3L / min. It adopts a tubular type Electric furnace heating, the temperature of the regeneration furnace is about 100°C, 150°C, 180°C, 250°C and 350°C respectively, and the reaction time is about 90min, 45min, 20min, 10min and 5min respectively, and the solid product is decomposed to release nitrogen oxides The material process is basically completed, and when the temperature is higher than 180°C, the aluminum chloride will be gasified, and it needs to be condensed to recover solid aluminum chloride. Then introduce hydrogen chlorid...

Embodiment 2

[0023] Embodiment 2: In the above-mentioned embodiment 1, the heating temperature of the regeneration furnace is 180°C, and the reaction time is about 20 minutes. Introduce about 50mL of hydrochloric acid with a content of about 5%, 15% and 36% respectively to the aluminum chloride regeneration furnace, make the solid product soak in the hydrochloric acid, then import hydrogen chloride gas with a content of about 15% into the aluminum chloride regeneration furnace, and keep The temperature of the regeneration furnace is about 98°C, and the reaction time is about 60 minutes, 40 minutes and 30 minutes respectively, and the basic aluminum chloride and aluminum hydroxide contained in the solid product are converted into aluminum chloride. Other conditions are the same as example 1.

Embodiment 3

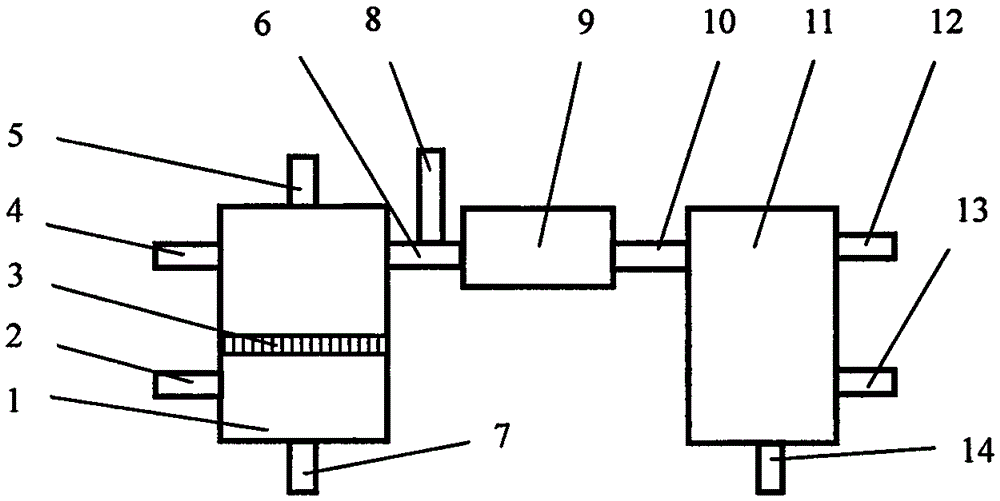

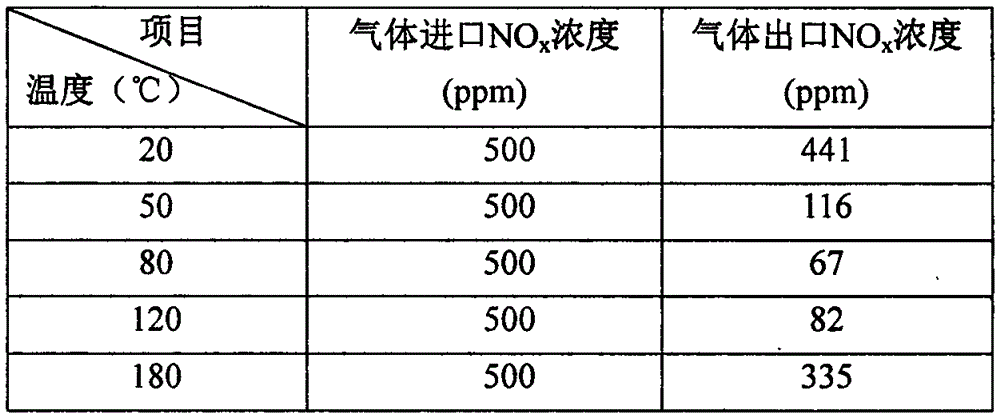

[0024] Embodiment 3: a kind of described denitrification uses the regenerative furnace of aluminum chloride as the device schematic diagram of aluminum chloride solid particle gasification furnace as figure 2 shown. The solid aluminum chloride obtained in the regeneration furnace of Example 1 is heated in the regeneration furnace at a heating temperature of about 180°C-210°C. The cooler is a tubular type with a diameter of Φ40mm and a length of 1000mm. Cool naturally, and the gas after cooling The outlet temperature is about 40°C-80°C (determined according to the reaction temperature of the gas-solid reaction tower), the protective gas of the regeneration furnace is nitrogen, the carrier gas is also nitrogen, the diameter of the gas-solid reaction tower is Φ60mm, and the effective contact height of the reaction is About 1000mm, empty tower, tower body material is 316L stainless steel. The concentration of nitrogen oxides (nitric oxide about 90%) in the gas stream is 500ppm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com