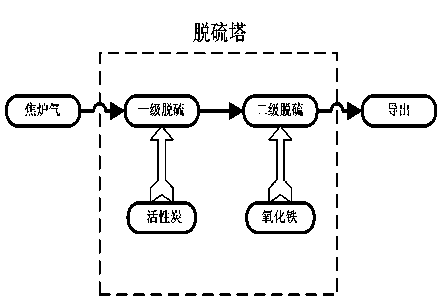

Desulfurization process and device for coke-oven gas automobile gas station

A desulfurization process and coke oven gas technology, which is applied in the petroleum industry, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of large desulfurization investment, threats to the health of operators, and environmental pollution, and achieve high desulfurization accuracy, The effect of low price and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

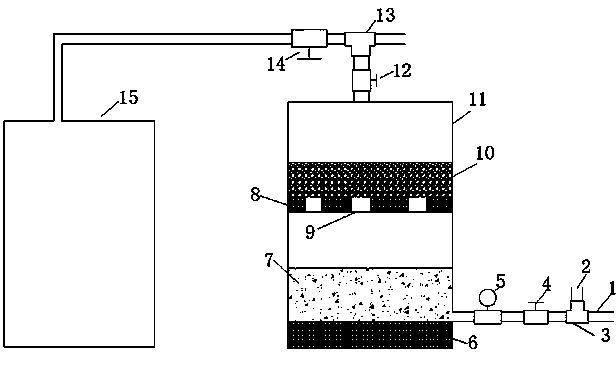

[0016] A vehicle-used coke oven gas desulfurization device, the coke oven gas gas inlet pipe 1 and the air inlet pipe 2 communicate with the lower part of the desulfurization tower 11 through the three-way interface A3, the stop valve A4 and the pressure gauge 5, and the top of the desulfurization tower 11 is provided with a gas outlet , the gas outlet at the top of the desulfurization tower 11 is connected to the tee pipe B13 through the stop valve B12, and one end of the three-way pipe B13 is connected to the recovery tank 15 through the stop valve C14. Fine desulfurizer 10. A heating device 6 is provided at the bottom of the desulfurization tower 11 .

[0017] After the coke oven gas containing impurities such as hydrogen sulfide enters the coke oven gas vehicle filling station, it needs to enter the desulfurization tower for desulfurization treatment. The coke oven gas enters through the intake pipe 1, mixes with the air entering from the intake pipe 2 at the three-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com