System and method for separating oil product by using deep eutectic solvent

A deep eutectic solvent and oil technology, applied in hydrocarbon oil treatment products, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of continuous and stable operation of polycyclic aromatic hydrocarbons, solvent-free regeneration system, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Build the system of described deep eutectic solvent separation oil product, specifically as follows:

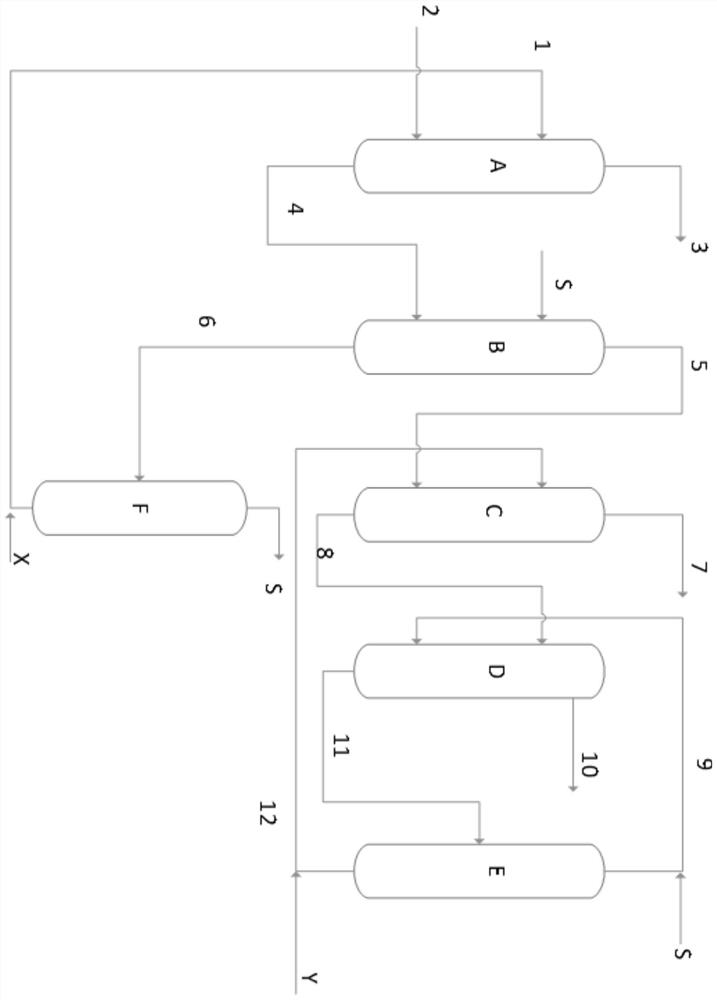

[0064] The system of the described deep eutectic solvent separation oil product comprises the following units: non-aromatic removal tower A, aromatics separation tower B, single-ring aromatics separation tower C, polycyclic aromatics separation tower D, deep eutectic solvent regeneration tower E and low eutectic solvent separation tower Eutectic solvent regeneration tower F; each unit is built according to the following connection relationship:

[0065] Wherein, the outlet of the non-aromatic separation tower A is connected to the bottom of the aromatics separation tower B through the pipeline 4 and the inlet, and the top of the aromatics separation tower B is connected to the bottom of the single-ring aromatics separation tower C through the pipeline 5. an entrance;

[0066] The single-ring aromatics separation tower C-bottom outlet is connected to the polycyclic aro...

Embodiment 2

[0084] The same system as in Example 1 was used.

[0085] Carrying out the method for deep eutectic solvent separation oil product can specifically comprise the following steps:

[0086] The raw material is hydrocracking of catalytic diesel from a refinery, and the analysis results show that the mass composition of the catalytic diesel hydrocracking oil is 44% of non-aromatics, 41% of single-ring aromatics, and 15% of polycyclic aromatics. The separation process is as follows:

[0087] i) The raw oil product is introduced into the non-aromatic removal tower A through the pipeline 2, and the deep eutectic solvent X is introduced into the tower A through the pipeline 1, and the two carry out a liquid-liquid extraction process of reverse contact in the tower A, and the non-aromatics are extracted from The overhead line 3 is taken out, and the mixture of the remaining mixed aromatics and the deep eutectic solvent X flows through the pipeline 4 and enters the aromatics separation ...

Embodiment 3

[0099] The same system as in Example 1 was used.

[0100] Carrying out the method for deep eutectic solvent separation oil product can specifically comprise the following steps:

[0101] After hydrocracking of heavy diesel oil from a refinery as raw material, the analysis results show that the mass composition of diesel hydrocracked oil with this catalyst is 35% of non-aromatics, 38% of single-ring aromatics, and 27% of polycyclic aromatics. The separation process is as follows:

[0102] i) The raw oil product is introduced into the non-aromatic removal tower A through the pipeline 2, and the deep eutectic solvent X is introduced into the tower A through the pipeline 1, and the two carry out a liquid-liquid extraction process of reverse contact in the tower A, and the non-aromatics are extracted from The overhead line 3 is taken out, and the mixture of the remaining mixed aromatics and the deep eutectic solvent X flows through the line 4 and enters the aromatics separation to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com