Solvent and method for removing carbon dioxide from Fischer-Tropsch synthesis circulation gas

A technology of carbon dioxide and Fischer-Tropsch synthesis, which is applied in combustible gas purification, combustible gas purification/transformation, liquid hydrocarbon mixture recovery, etc., can solve the problems of activator consumption, serious corrosion, solution deterioration, etc., to overcome high regeneration heat consumption, Reduced regeneration heat consumption and good solution stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

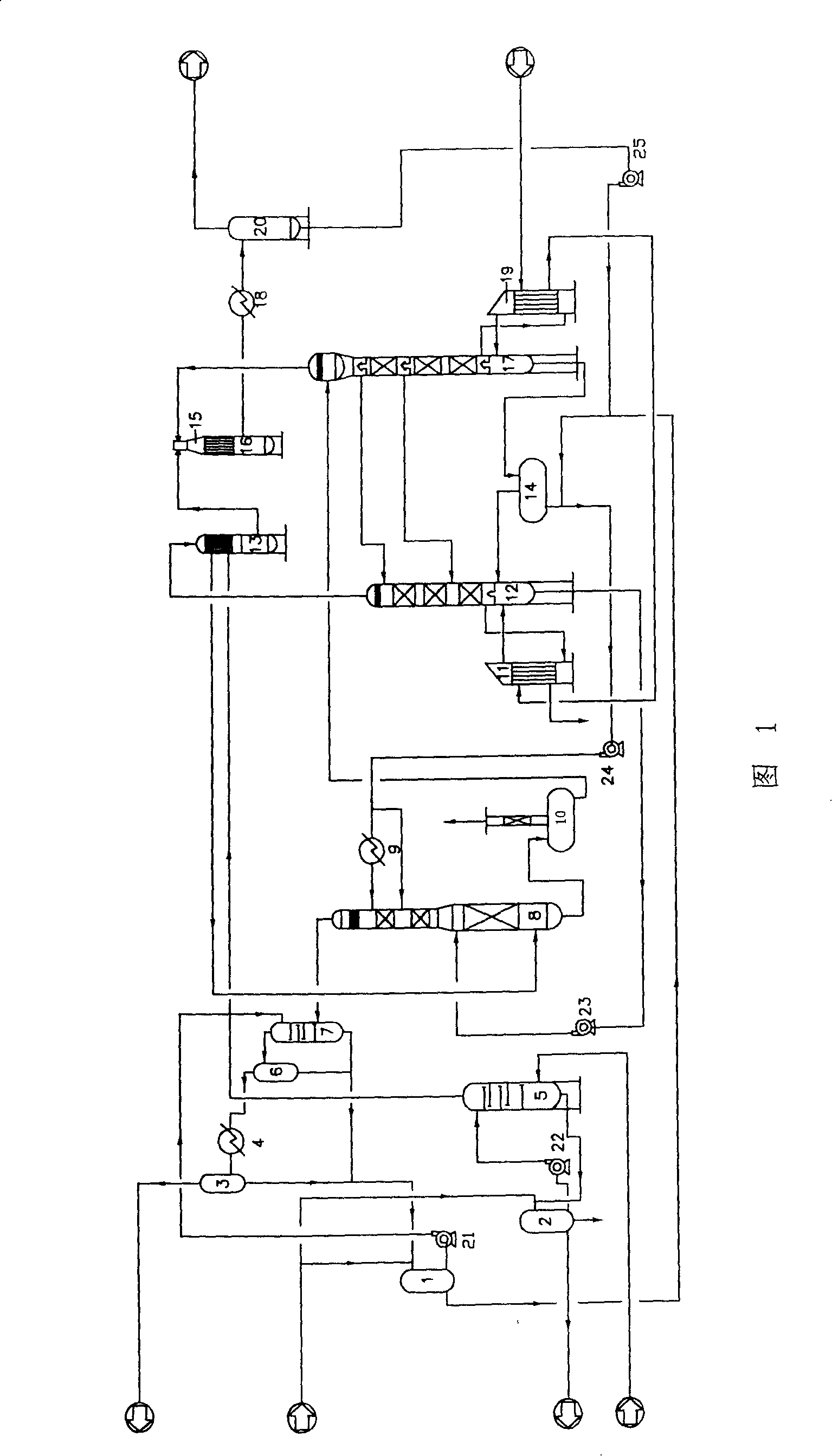

Image

Examples

Embodiment 1

[0022] A coal-water slurry as raw material, Texaco furnace for gas production, iron-based catalyst, Fischer-Tropsch synthesis slurry bed reactor, decarburization of circulating gas with potassium carbonate concentration of 28 (m)%, corrosion inhibitor pentoxide The concentration of vanadium is 5%, the concentration of the mixture of inorganic activators boric acid, selenous acid and vanadium pentoxide is 9%; the temperature of the absorption operation is 90°C at the top of the tower, 115°C at the bottom of the tower, the pressure is 2.7Mpa, and the CO2 content in the circulating gas is 22% , the residual CO2 in the absorption tower is less than 0.6%, the hydrocarbon consumption is less than 1.0%, and the absorption capacity of the solution is about 22Nm3CO2 / m3 solution, which can meet the decarburization requirements of the designed Fischer-Tropsch synthesis cycle gas, and the regeneration heat consumption of the solution is less than or equal to 3330 kJ / Nm3 CO2.

Embodiment 2

[0024] A pulverized coal as raw material, using Shell pulverized coal furnace to generate gas, using iron-manganese composite catalyst, Fischer-Tropsch synthesis slurry bed reactor, decarburization of circulating gas with potassium carbonate concentration of 26 (m)%, corrosion inhibitor pentoxide The concentration of vanadium is 5%, the concentration of the mixture of inorganic activators boric acid, antimonic acid and vanadium pentoxide is 9%; the temperature of the absorption operation is 90°C at the top of the tower, 116°C at the bottom of the tower, the pressure is 2.6 Mpa, and the CO2 content in the circulating gas is 20%. The residual CO2 in the absorption tower is less than 1.0%, the hydrocarbon consumption is less than 0.6%, and the solution absorption capacity is about 20Nm3CO2 / m3 solution, which can meet the designed Fischer-Tropsch synthesis cycle gas decarburization requirements, and the regeneration heat consumption of the solution is ≤3330 kJ / Nm3 CO2 .

Embodiment 3

[0026] One uses crushed coal as raw material, uses Lurgi furnace to generate gas, uses iron-based composite catalyst, and Fischer-Tropsch synthesis slurry bed reactor. The decarburization of circulating gas uses potassium carbonate concentration of 27 (m)%, corrosion inhibitor pentoxide The concentration of vanadium is 5%, the concentration of the mixture of inorganic activators boric acid and telluric acid is 5%, the concentration of organic activators, the mixture of glycine, methylimidazole and 2 amino-2 methyl-1 propanol is 3%; absorption operation temperature The top of the tower is 90°C, the bottom of the tower is 108°C, the pressure is 2.7Mpa, the CO2 content in the circulating gas is 19%, the residual CO2 out of the absorption tower is <1.0%, the hydrocarbon consumption is <0.5%, and the absorption capacity is about 29Nm3CO2 / m3 solution, which meets the Fischer-Tropsch Synthetic cycle gas decarbonization requirements, solution regeneration heat consumption ≤ 3320kJ / Nm3C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com