Technological process of preparing diesel oil fraction selectively with Fischer-tropsch synthetic gas

A technology for Fischer-Tropsch synthesis and synthesis gas, which is used in the petroleum industry, recovery of liquid hydrocarbon mixtures, etc., and can solve problems that have not yet been seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

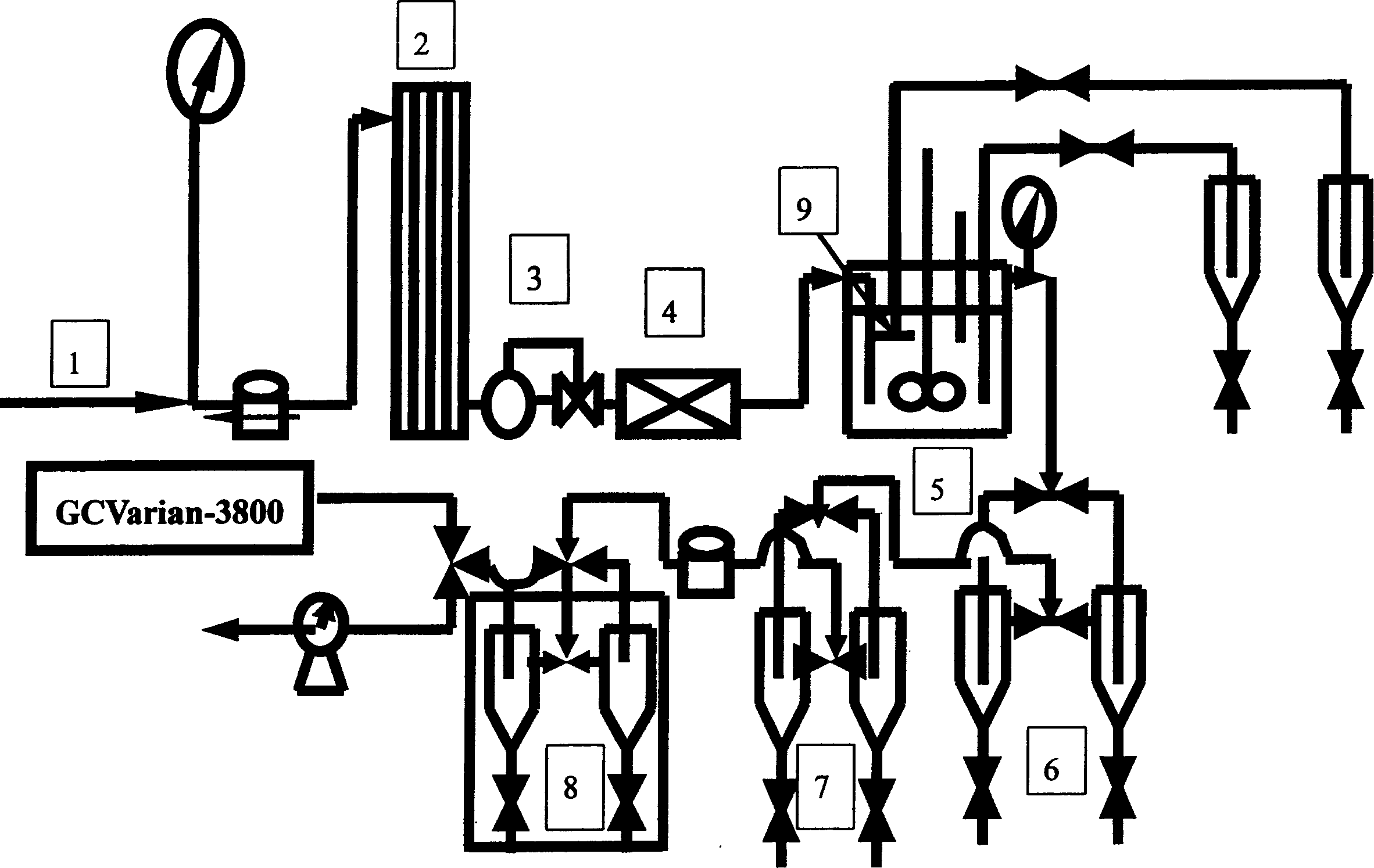

[0044] use figure 1 In the process flow, the reaction is carried out under the following reaction conditions.

[0045] The production method of the present invention adopts a one-stage method to directly prepare a product mainly composed of diesel fraction alkanes from the synthesis gas. Syngas is mainly composed of H 2 And CO, and H 2 / CO volume ratio is 1.0~4.0; the Fischer-Tropsch synthesis catalyst is a metal-containing cobalt / activated carbon carrier catalyst; the reaction conditions for Fischer-Tropsch synthesis are: reaction temperature is 120-400℃, reaction pressure is 0.05-10Mpa, and synthesis gas space velocity is 100~5000h -1 .

[0046] In addition, in figure 1 In the process shown, CO and H in a certain appropriate ratio 2 The synthesis gas comes from the pipeline (1). The gas is first purified by the purification pipe (2), and its flow is controlled by the mass flow meter (3). After being preheated by the preheater (4), it enters the FT synthesis reactor (5). The reac...

Embodiment 2

[0048] 40% (weight) of the 180-245℃ boiling range fraction, which comes from the Fischer-Tropsch synthesis thermal separation tank, and 60% (weight) of the heavy fraction (250-380℃ boiling range), this part of the product must The diesel fuel obtained by regular pressure filtration through a microporous filter (50μm) and mixed is called diesel fuel A. Therefore, the boiling range of this mixed diesel fuel is 180-380°C. Diesel fuel A is used in the present invention. The described cobalt-based catalyst supported by activated carbon directly synthesizes a representative of a complete typical diesel fuel through Fischer-Tropsch synthesis.

Embodiment 3

[0050] 45% (weight) of the 180~245℃ boiling range fraction, which comes from the thermal separation tank of the Fischer-Tropsch synthesis, and 55% (weight) of the heavy fraction (250~380℃ boiling range), this part of the product must The diesel fuel obtained by regular pressure filtration through a microporous filter (50μm) and mixed is called diesel fuel B. Therefore, the boiling range of this mixed diesel fuel is 180-380°C. Diesel fuel B is used in the present invention. A representative example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com