Technology of low temperature separation and concentration coal layer gas to produce methane

A coalbed methane, low temperature technology, applied in distillation purification/separation, petroleum industry, recovery of liquid hydrocarbon mixture, etc., can solve the problems of not getting methane product, unable to meet the requirement of rectification reflux ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

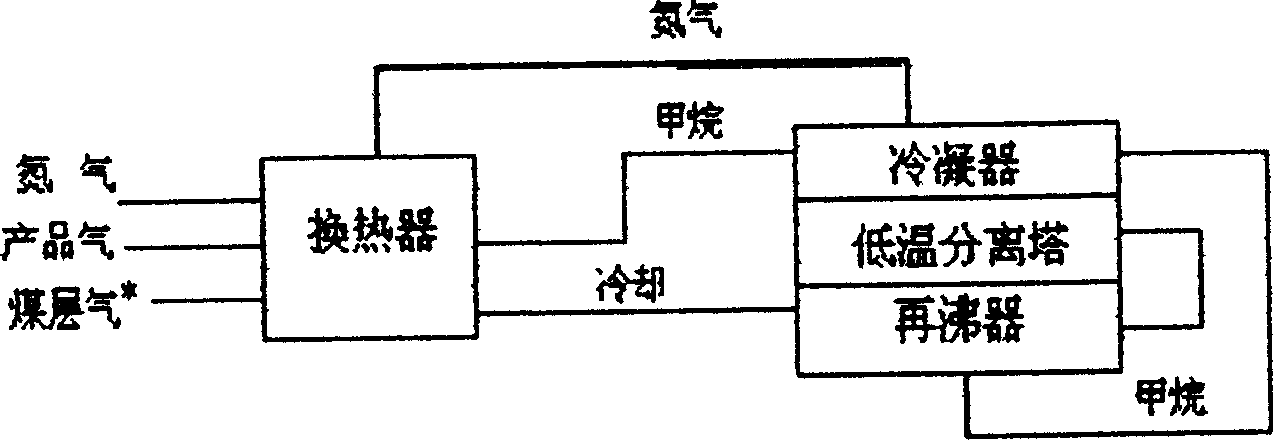

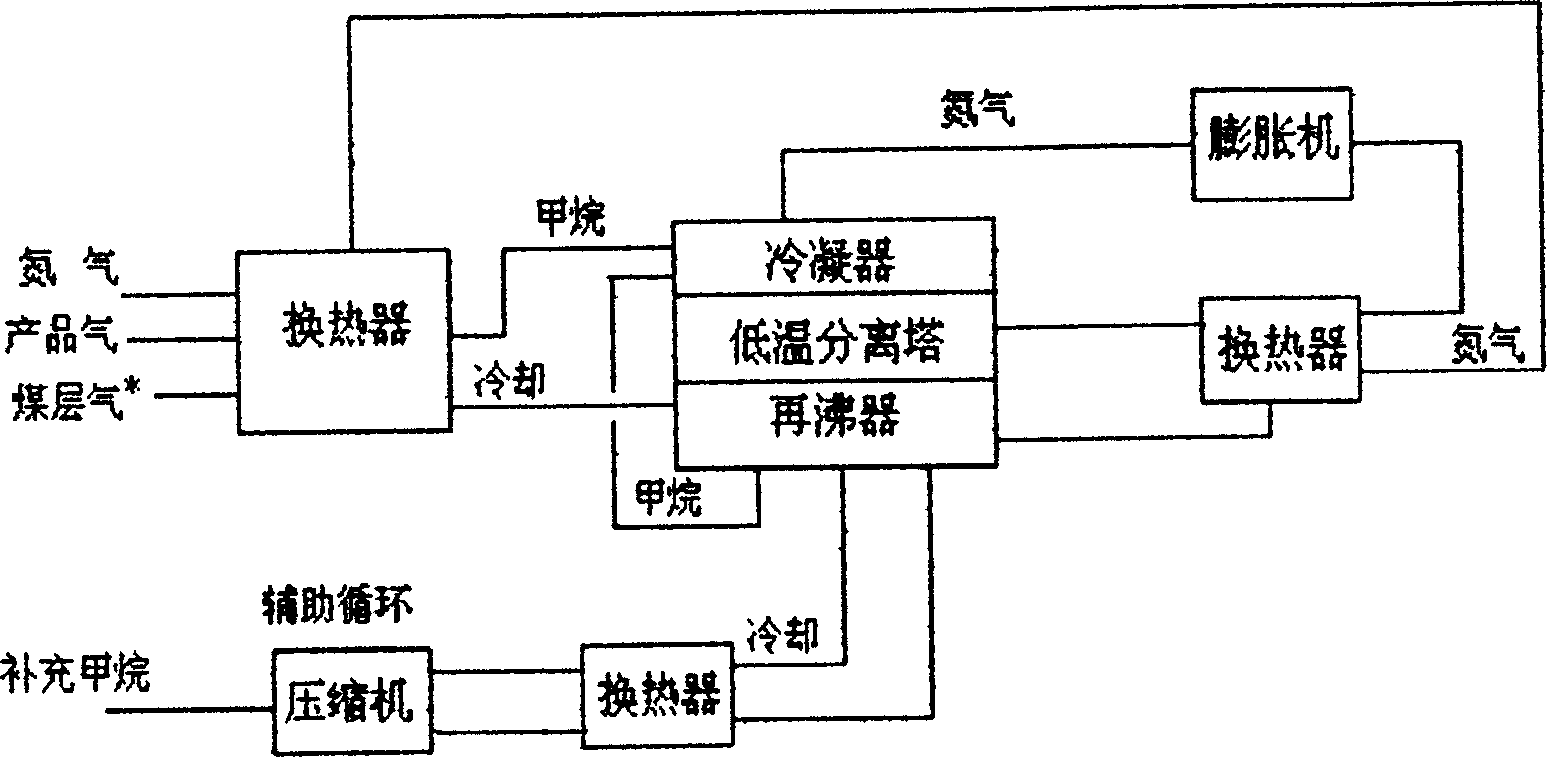

Method used

Image

Examples

Embodiment 1

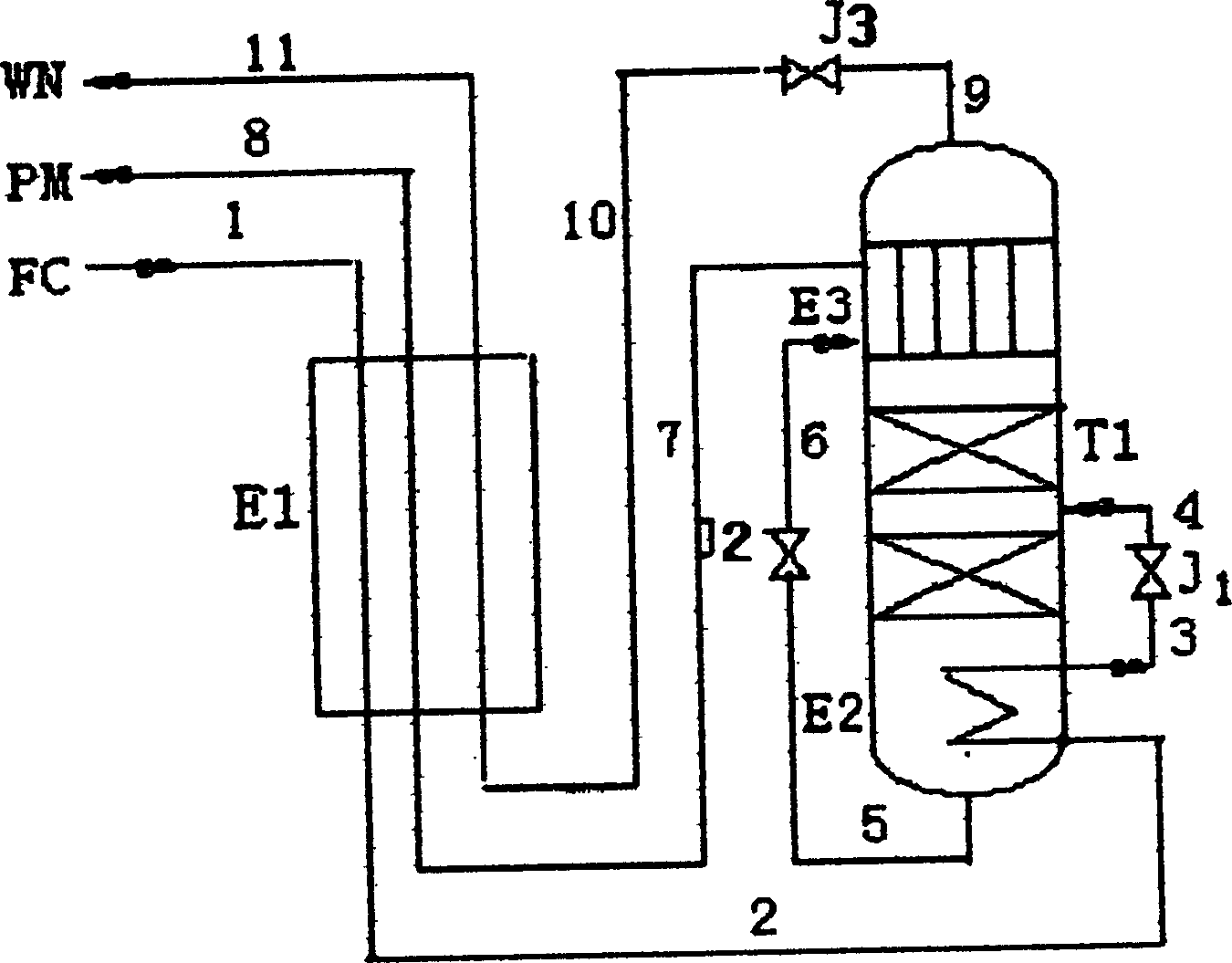

[0016] After desulfurization, oxygen removal, decarburization, and drying (water removal), coalbed methane forms CH 4 50% (the remainder is N 2 ). The raw material gas pressure is 4.0MPa(g), and the separation tower pressure is 2.0MPa(g). Product methane concentration is 99% (the remainder is N 2 ), yield 95%. The nitrogen content in the waste nitrogen gas at the top of the tower is greater than 95%. The temperature of the feed gas entering the tower is 139K, the temperature of the bottom of the tower is 164K, and the temperature of the top of the tower is <122K. The auxiliary circulation pressure is 2.4MPa(g), and the circulation volume is about 30% of the feed gas volume. The inlet temperature of the expander is 163K, the pressure after expansion is 0.5MPa(g), and the outlet temperature is 127K.

Embodiment 2

[0018] After desulfurization, oxygen removal, decarburization, and drying (water removal), coalbed methane forms CH 4 56% (the remainder is N 2 ). The raw material gas pressure is 4.0MPa(g), and the separation tower pressure is 2.0MPa(g). Product methane concentration is 95% (the remainder is N 2 ), yield > 97%. The temperature of the feed gas entering the tower is 140K, the temperature of the bottom of the tower is 155K, and the temperature of the top of the tower is 120K. The auxiliary circulation pressure is 2.4MPa(g), and the circulation volume is about 10% of the feed gas volume. The inlet temperature of the expander is 154K, the pressure after expansion is 0.5MPa(g), and the outlet temperature is 119K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com