Heavy oil treating method and heavy oil treating system

a technology of heavy oil and treating method, which is applied in the direction of water treatment, physical/chemical process catalysts, supercritical conditions, etc., can solve the problems of increasing fuel cost, affecting the efficiency of oil treatment, and affecting the quality of oil treatmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

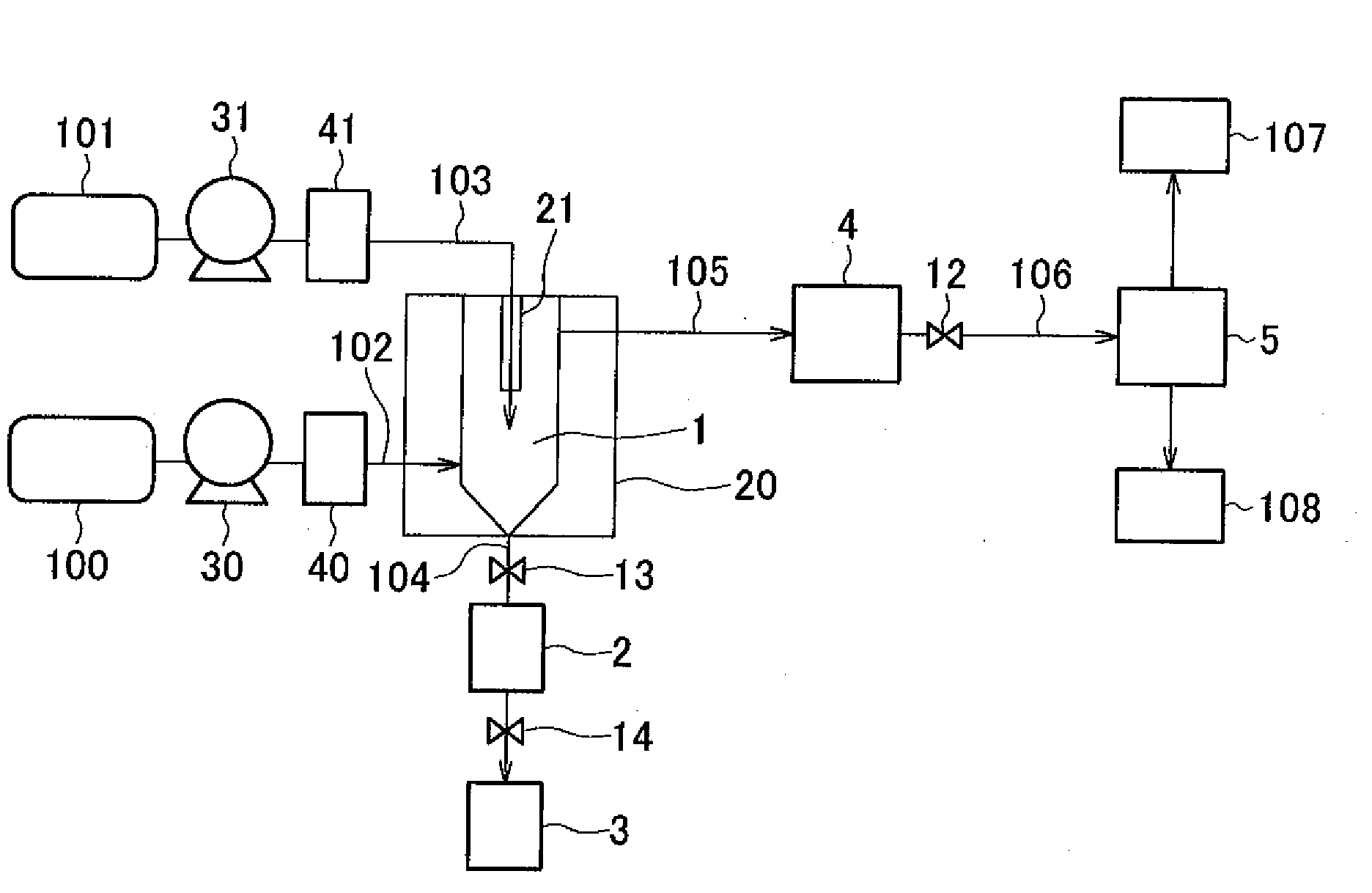

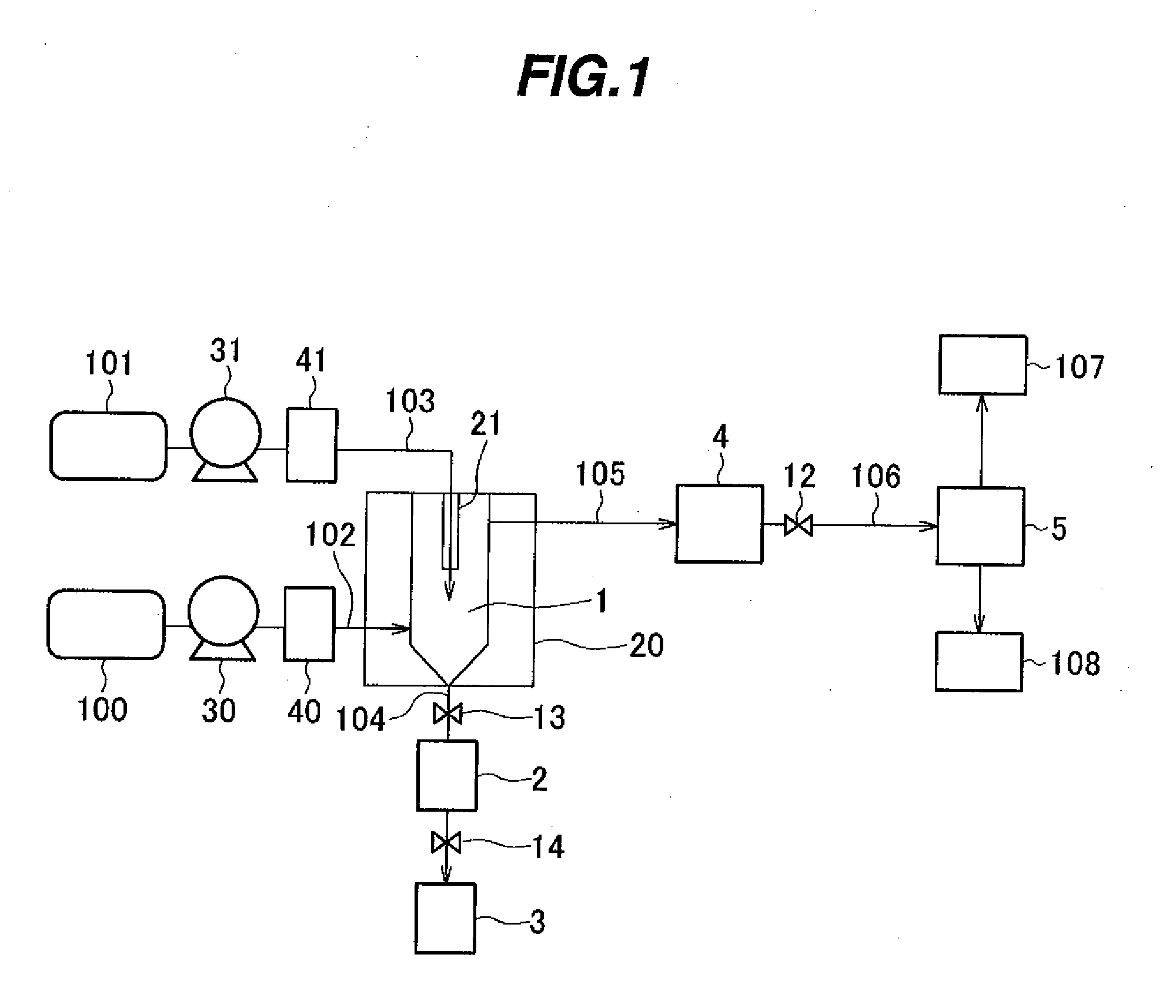

[0034]FIG. 1 shows a heavy oil treating system for treating heavy oil with high-temperature, high-pressure water, removing, from the heavy oil, metals contained in the heavy oil, such as vanadium, according to a first embodiment of the present invention.

[0035]In this system, water from supply 100 is pressurized to 20 MPa by a water supply pump 30 for supplying the water under pressure, and is then heated up to 480° C. by a water preheater 40, thereby producing high-temperature, high-pressure water 102. Similarly, heavy oil from supply 101 is pressurized to 20 MPa by a heavy oil supply pump 31 for supplying the heavy oil under pressure, and is then heated up to 350° C. by an oil preheater 41, thereby producing high-temperature, high-pressure heavy oil 103. While electric heaters are employed as the water preheater 40 and the oil preheater 41, the water and the heavy oil may be heated by heat exchangers using high-temperature steam.

[0036]A contact-reaction unit 1 is installed such tha...

second embodiment

[0045]This second embodiment represents a system for effectively utilizing waste heat of a gas turbine by supplying reformed oil, which is obtained by modifying heavy oil with high-temperature, high-pressure water, to a gas turbine combustor to generate electric power by the gas turbine, and by utilizing waste heat of combustion exhaust gas to produce the high-temperature, high-pressure water. The system of this embodiment will be described below with reference to FIG. 3.

[0046]In this system, water from supply 100 is pressurized to 20 MPa by a water supply pump 30 for supplying the water under pressure, and is then heated up to temperature of 450-480° C. by a water heat exchanger 50, thereby producing high-temperature, high-pressure water. Similarly, heavy oil from supply 101 is pressurized to 20 MPa by a heavy oil supply pump 31 for supplying the heavy oil under pressure, while steam extracted from the high-temperature, high-pressure water in a high-temperature, high-pressure water...

third embodiment

[0055]This third embodiment represents a control method for a system wherein reformed oil, which is obtained by reforming heavy oil with high-temperature, high-pressure water, is supplied to a gas turbine combustor to generate electric power by a gas turbine. The system and the control method will be described below with reference to FIG. 4. The system of this embodiment includes a gas oil tank 113 and a gas oil pump 32 for supplying gas oil to the combustor. The gas oil is burnt in the gas turbine combustor at startup of the gas turbine, and a water heat exchanger 50 is heated by combustion exhaust gas produced after driving the gas turbine.

[0056]In this system, as in the second embodiment, water from supply 100 is pressurized to 20 MPa by a water supply pump 30 for supplying the water under pressure, and is then supplied to the water heat exchanger 50. The pressurized water is heated up to temperature of 450-480° C. by the water heat exchanger 50, thereby producing high-temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical point | aaaaa | aaaaa |

| weight % | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com