Continuous production equipment and production technology of powdered condiments

A technology of production equipment and production process, which is applied in the field of continuous production equipment and production process of powder condiments, which can solve the problems of large particles, insufficient mixing, and easy dissociation of raw material flavors, so as to achieve stable compound flavors, improve production efficiency, Fusion Tight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment, this patent will be further described.

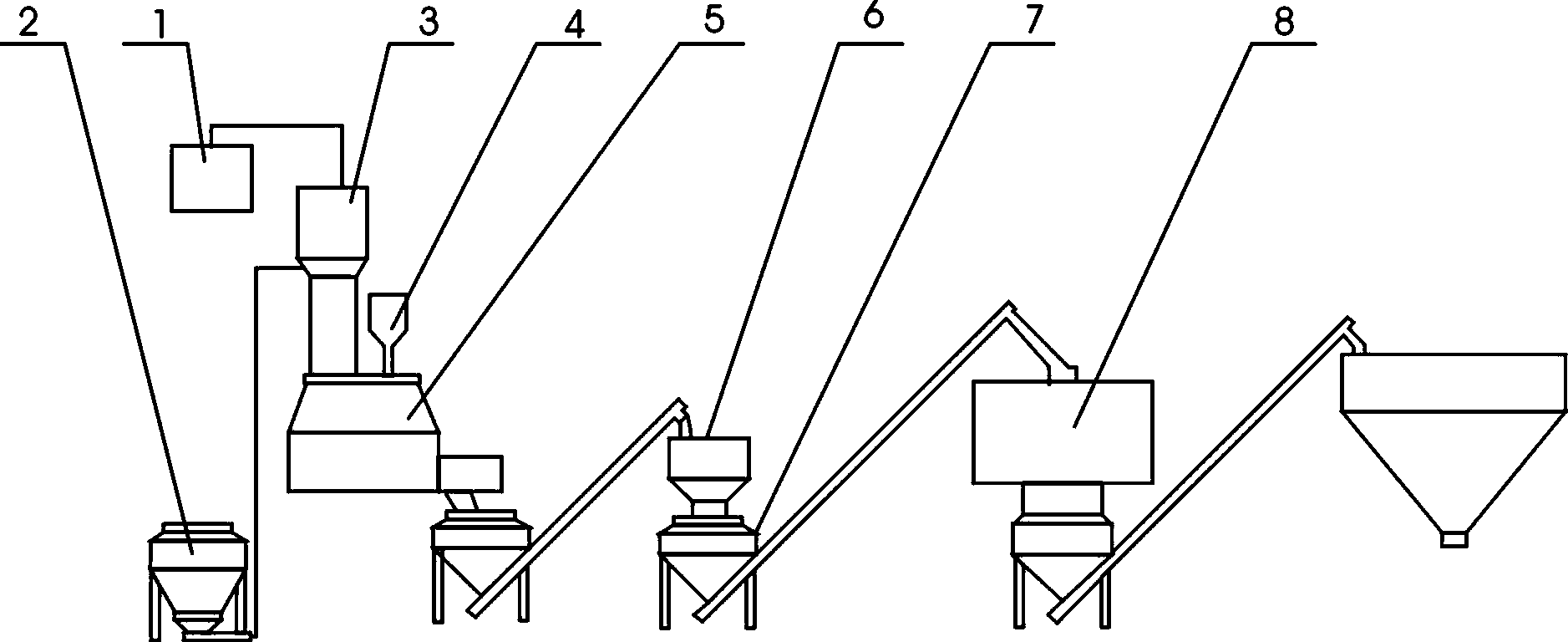

[0024] Continuous production equipment for powder condiments, consisting of a vacuum pump, hopper, vacuum feeder, atomizer, high-speed mixer, particle sieve, screw feeder, and trough mixer. The vacuum pump is connected to the top of the vacuum feeder, and the hopper is connected to the The inlet of the vacuum feeder, the outlet of the vacuum feeder is set at the inlet of the high-speed mixer, the top of the high-speed mixer is equipped with an atomizer, the outlet of the high-speed mixer is connected to the screw feeder, and the screw feeder The discharge end of the feeder is set above the granular sieve, the bottom outlet of the granular sieve is provided with a screw feeder, and the discharge end of the screw feeder is connected to a trough mixer.

[0025] The continuous production process of powder condiments is as follows:

[0026] A. The vacuum pump pumps the vacuum feeder to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com