Glass ceramic and preparation method thereof

A technology of glass ceramics and glass, applied in the field of glass ceramics and its preparation, can solve the problems that it is difficult to obtain glass ceramics with microscopic hierarchical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] This specific embodiment also proposes a kind of preparation method of glass-ceramic, comprises the following steps:

[0030] S1. Raise the temperature of the precursor glass to T1 at a rate of 1-10°C / min and keep it warm for 1-4h. T1 is 540-580°C;

[0031] S2. Cool the precursor glass at a rate of 1-20°C / min to T2 and keep it warm for 1-4h, where T2 is 480-560°C, T1>T2;

[0032] S3, repeat steps S1-S2, continue to raise the temperature of the precursor glass to T3 and keep it warm for 1-4h, T3 is 560-650°C, T3>T1>T2;

[0033] S4. Continue to raise the temperature of the precursor glass treated in step S3 to 700-800° C. and keep it warm for 0.1-4 hours to obtain the glass-ceramic.

[0034] In some embodiments, before step S4, it further includes raising the temperature of the precursor glass to T4 and keeping it warm for 1-4 hours, where T4 is 610-690° C., and T4>T3.

Embodiment 1

[0037] The present embodiment proposes a kind of glass-ceramic, is made by following steps:

[0038] S1. Raise the temperature of the precursor glass to 580°C at a rate of 1°C / min and keep it warm for 1h;

[0039] S2. Lowering the temperature of the precursor glass to 480° C. at a rate of 1° C. / min and keeping it warm for 4 hours;

[0040] S3. Repeat steps S1-S2 once, continue to raise the temperature of the precursor glass to 600° C. and keep it warm for 1 hour;

[0041] S4. Continue to raise the temperature of the precursor glass to 750° C. and keep it warm for 2 hours to obtain the glass-ceramic.

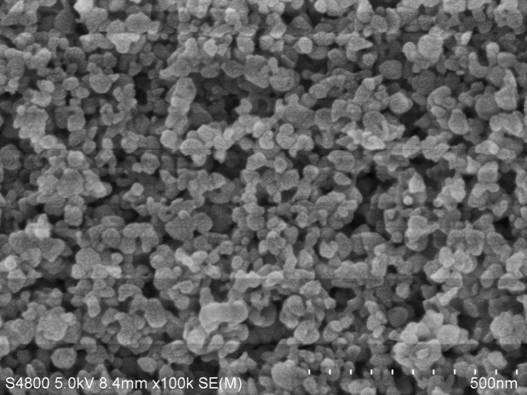

[0042] The fracture toughness of the prepared glass ceramics is 2.2Mpa·m 1 / 2 , with a haze of 0.12, combined with figure 1 , the glass-ceramic has two micro-level structures; the micro-level structure includes a higher level structure formed by three-dimensional connected skeleton pillars, and the diameter of the higher level structure is about 50-150nm; the micro-level struct...

Embodiment 2

[0044] The present embodiment proposes a kind of glass-ceramic, is made by following steps:

[0045] S1. Raise the temperature of the precursor glass to 550°C at a rate of 5°C / min and keep it warm for 2 hours;

[0046] S2. Lowering the temperature of the precursor glass to 490° C. at a rate of 5° C. / min and keeping it warm for 3 hours;

[0047] S3. Repeat steps S1-S2 once, continue to raise the temperature of the precursor glass to 560° C. and keep it warm for 4 hours;

[0048] S4. Continue to raise the temperature of the precursor glass to 700° C. and keep it warm for 0.1 h to obtain the glass-ceramic.

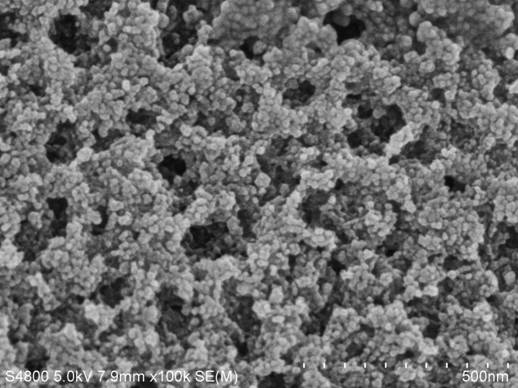

[0049] The fracture toughness of the prepared glass ceramics is 1.0Mpa m 1 / 2 , with a haze of 0.2; combined with figure 2 , the glass-ceramic has more than two micro-level structures; the micro-level structure includes a higher-level structure formed by three-dimensional connected skeleton pillars, and the diameter of the higher-level structure is about 30-200nm; The mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com