Integral lining of continuous casting tundish

A continuous casting tundish and integral technology, which is applied in casting equipment, casting melt containers, metal processing equipment, etc., can solve the problems of high temperature of the tundish shell, serious sintering of the surface of the permanent layer, and limited use time. Erosion loss control, extended service life, uniform quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 2

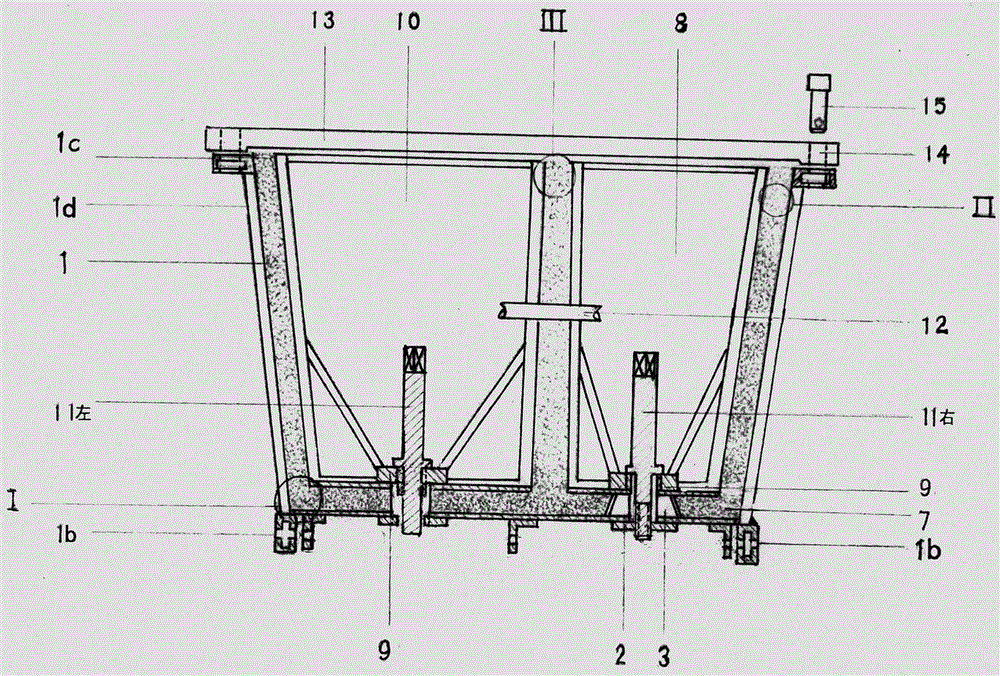

[0053] In actual manufacturing, 6, 8, and 10 are prepared in advance, and it only takes 20-30 minutes to put them into 1a and fix them, and the raw materials laid on 1e have not yet "solidified". 8, 8-10, 10-1 The "solidification" time of the raw materials in the gaps is a little longer than that of the bottom laying pins. For the first injection, the height of the raw materials in each part is uniformly about 300mm. The two vibrating rods start from the gap in the middle part, then the longitudinal ends and other parts. The head of the first round of vibrating rods should touch the bottom of the paving. Among the raw materials, every time you insert, lift, and move, the distance between left and right is 200mm, and the vibration time of each contact is 5-7 seconds. Follow up by analogy for each subsequent cycle, and the continuation time cannot be prolonged. When the raw material rises to a distance of 150mm from the upper edge of the lateral center point, the slag liquid dis...

Embodiment ( 3

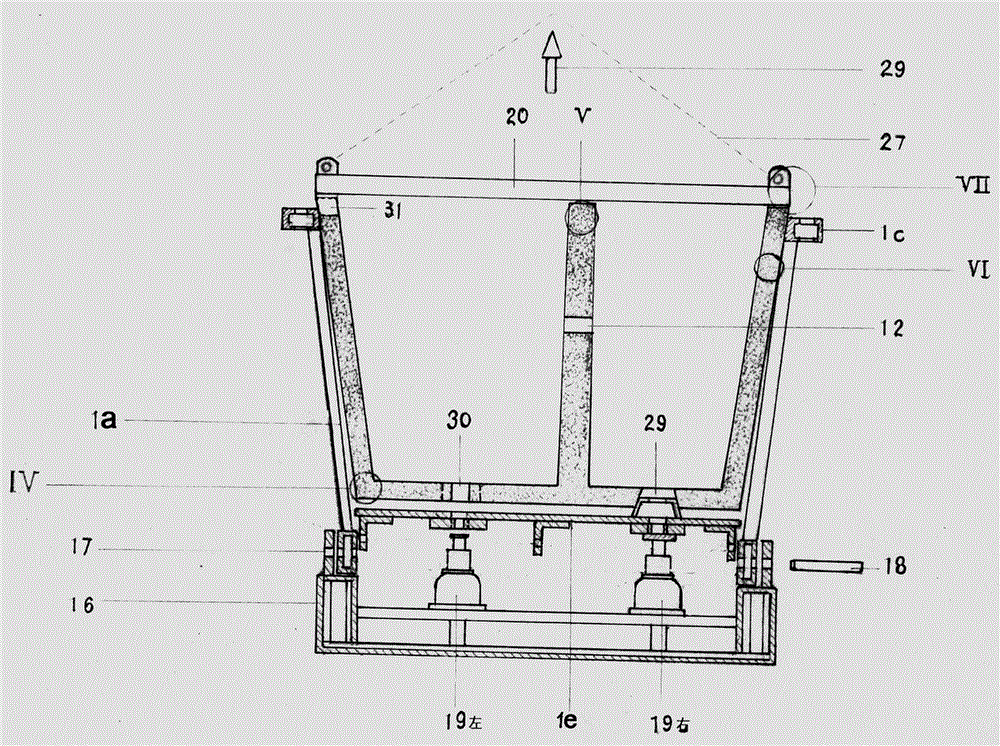

[0055] 16. Refers to the further steps of the special demoulding frame including: using 120# national standard channel steel 75# angle steel and 30mm thick steel plate to weld three pieces of concave rectangular special demoulding frame, and welding the upper plane edge of each piece to the height 200mm, wide 200mm, thick 30mm steel plate 17, and drill 25mm diameter round hole at respective center points. One of 16 is in the state of the lower end of the transverse center, and the other two pieces have the same shape, but the length is shortened along with the change of the specified position before and after the transverse center of the 1 upper mouth. After the three pieces of special demoulding frame are made, they are placed on the level ground according to their reasonable distance from the mold for preparation.

[0056] 18. The further step of specifying the positioning pins includes: hoisting the molds that have finished baking and placing them on the planes at the two e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com