Circuit board glass substrate manufactured from alkali-free glass fiber waste silk and preparation method thereof

A technology of alkali-free glass fiber and glass substrate, which is applied in the direction of circuit substrate materials, printed circuits, printed circuit components, etc., and can solve the problems of inability to place components on substrates, high wiring density of glass substrates, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Using non-alkali glass fiber waste silk as raw material, the percentage of chemical composition is as follows, SiO 2 :60%;TiO 2 :3%;Al 2 o 3 : 15%; Fe 2 o 3 : 0.35%; CaO: 18%; LiO 2 : 1.0%; MgO: 2.5%; Na 2 O: 0.25%; K 2 O: 0.25%; CeO 2 :0.5%, GeO 2 :0.5%.

[0025] The chemical composition weight percent of described non-alkali glass fiber waste silk is SiO 2 :60%;TiO 2 :3%;Al 2 o 3 : 15%; Fe 2 o 3 : 0.35%; CaO: 18%; LiO 2 : 1.0%; MgO: 2.5%; Na 2 O: 0.25%; K 2 O: 0.25%; CeO 2 :0.5%, GeO 2 :0.5%.

[0026] The preparation method of the circuit board glass substrate made of alkali-free glass fiber waste silk as described in this embodiment is as follows:

[0027] 1) Weigh the glass chemical composition raw materials except alkali-free glass fiber waste silk according to the above ratio requirements, and after preliminary mixing, use ND7-2L planetary ball mill for wet ball milling (60-100 rpm, 3h) to make the raw materials Mix evenly; after drying, put ...

Embodiment 2

[0031] Using non-alkali glass fiber waste silk as raw material, the percentage of chemical composition is as follows, SiO 2 : 57%; TiO 2 : 1.5%; Al 2 o 3 : 8%; Fe 2 o 3 : 0.3%; CaO: 15%; LiO 2 : 1.5%; MgO: 2.5%; Na2 O: 0.3%; K 2 O: 0.5%; CeO 2 :0.2%, GeO 2 :0.2%.

[0032] The processing method is the same as in Example 1, and the obtained circuit board glass substrate sample made of alkali-free glass fiber waste is marked as sample B.

Embodiment 3

[0034] Using non-alkali glass fiber waste as raw material, the percentage of chemical composition is as follows, SiO 2 : 65%; TiO2: 3.5%; Al 2 o 3 : 17%; Fe 2 o 3 : 0.4%; CaO: 25%; LiO 2 : 2.5%; MgO: 3%; Na 2 O: 1.5%; K 2 O: 1.5%; CeO 2 : 0.5%, GeO 2 : 0.5%.

[0035] The processing method is the same as in Example 1, and the obtained circuit board glass substrate sample made of alkali-free glass fiber waste is marked as sample C.

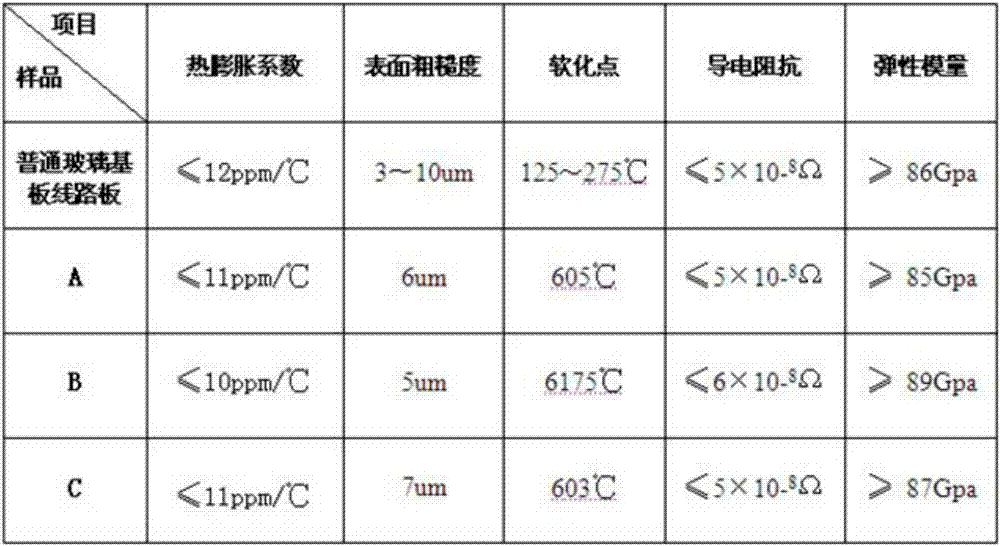

[0036] The following table shows the test comparison of various performances of the glass substrate circuit board in the experiment

[0037]

[0038] It can be seen from the table that the electrical conductivity and other indicators of the circuit boards made of glass fibers in these three cases are better than ordinary glass-based circuit boards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com