High conduction and high voltage solar photovoltaic glass plate

A high-voltage, solar energy technology, applied in conductive materials dispersed in non-conductive inorganic materials, printed circuit dielectrics, glass/slag layered products, etc. Expensive, limited application occasions, etc., to achieve the effect of maintaining superconductivity, light weight, and preventing surface oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

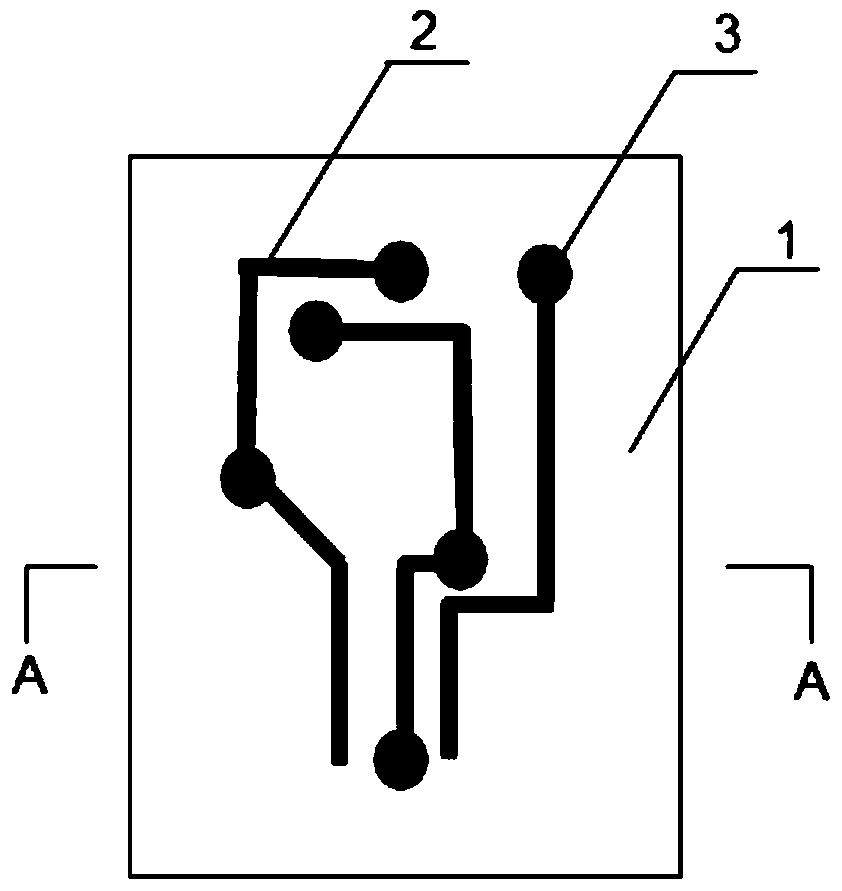

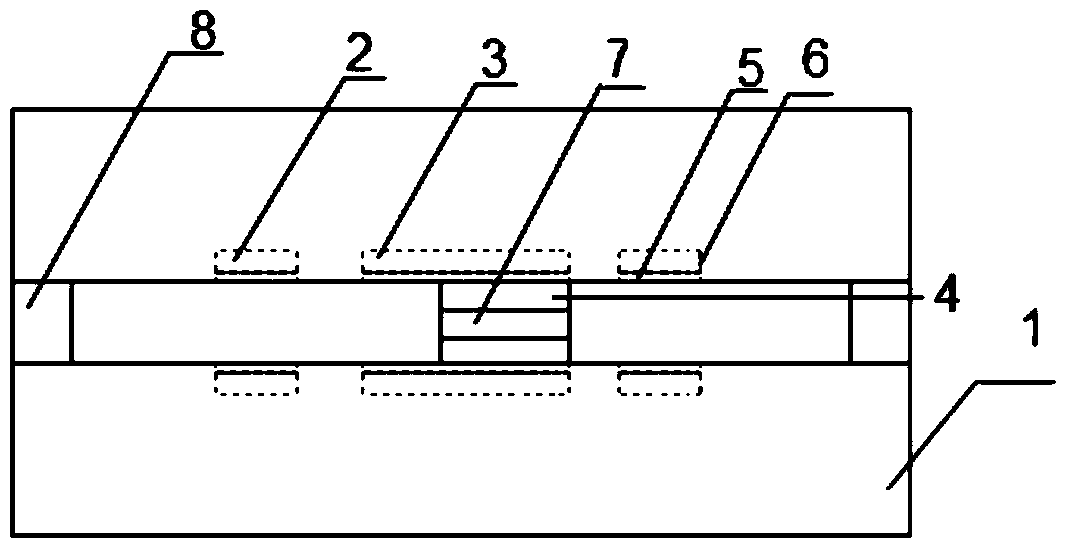

[0023] refer to figure 1 and figure 2 , the present invention provides a high-conduction high-voltage solar photoelectric glass plate, including a glass substrate 1, the glass substrate has two pieces, and the surface of the glass substrate is provided with a conductive paste printed on the air surface of the glass substrate. 1. Conductive circuit 2 fused with the surface of the glass substrate after heating and cooling, the conductive circuit is a graphene layer, or a metal layer 6 fused with the graphene layer 5 of the surface layer and the bottom layer and the glass substrate, the graphene layer and the metal layer The contact surfaces between the layers are mutually fused; between the two glass substrates, there is a solar chip 7 with electrodes on both sides, and the two electrodes of the solar chip are respectively connected to the pads of the conductive lines o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com