Polycarbonate/ABS (acrylonitrile, butadiene and styrene) resin plastic alloy

A technology of polycarbonate resin and ABS resin, which is applied in the field of polycarbonate/ABS resin plastic alloy, can solve the problems of low impact strength of PC/ABS alloy and cannot meet the application requirements of high impact strength, etc., and achieve good mechanical properties, excellent Effects of mechanical properties, processability, and ultra-high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

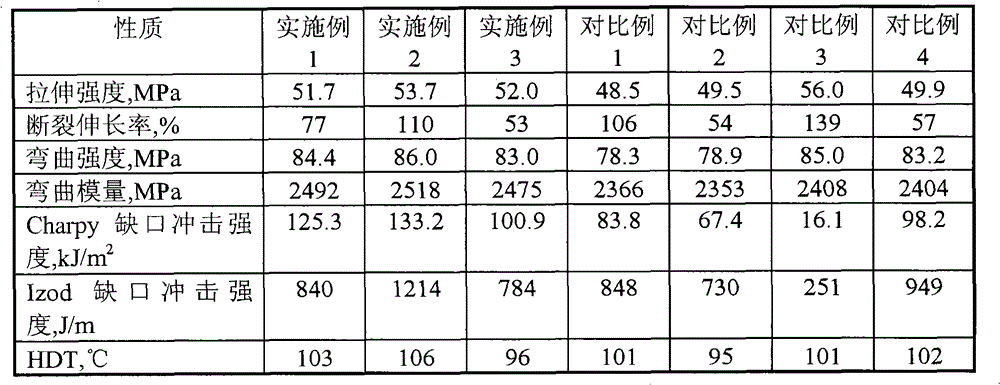

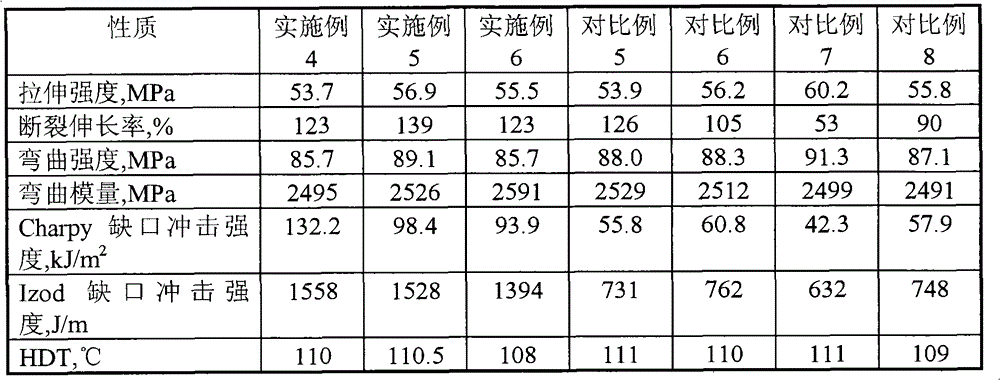

Examples

Embodiment 1

[0047] Weigh 2.475 kg of bisphenol A polycarbonate (PC-1) produced by Sabic Company with an MFR (300°C, 1.2kg) of 10.5g / 10min, an MFR (220°C, 10kg) of 16g / 10min, and an average 2.175 kilograms of bulk polymerization ABS resin (ABS-1) with a rubber particle diameter of 0.8 microns, MFR (230°C, 2.16kg) is 7g / 10min, 0.300 kilograms of SMA resin with maleic anhydride weight percent content of 18%. 25 grams of oxygen agent 1010, 25 grams of white oil (12#), put into a container and mix evenly with a stirrer, then add it to the feeder of the twin-screw extruder for subsequent use. Twin-screw extruder (screw diameter 27mm, length / diameter ratio 36, Germany Leistritz company) barrel temperature is set in ten sections from the feed inlet to the extrusion outlet at 200°C, 220°C, 230°C, 240°C, 245°C , 250°C, 250°C, 250°C, 250°C, 245°C, when the temperature of each section reaches the set value, turn on the screw of the main engine and the screw of the feeder at 150 rpm and 60 rpm Extrud...

Embodiment 2

[0051] Weigh 2.725 kg of bisphenol A polycarbonate (PC-2) produced by Sabic Company with an MFR (300°C, 1.2kg) of 7.0g / 10min, an MFR (220°C, 10kg) of 16g / 10min, and an average 1.975 kilograms of bulk polymerization ABS resin (ABS-1) with a rubber particle size of 0.8 micron, MFR (230°C, 2.16kg) is 7g / 10min, 0.250 kilograms of SMA resin with maleic anhydride weight percent content of 18%. Oxygen agent 1010 25 grams, white oil (12#) 25 grams, put into a container and mix homogeneously with agitator, then add in the twin-screw extruder feeder and prepare polycarbonate / ABS alloy by the same condition of embodiment 1 , Injection molded strips and test performance, the results are shown in Table 2.

Embodiment 3

[0053]Weigh 2.475 kg of bisphenol A polycarbonate (PC-1) produced by Sabic Company with an MFR (300°C, 1.2kg) of 10.5g / 10min, an MFR (220°C, 10kg) of 32g / 10min, and an average 2.275 kilograms of bulk polymerization ABS resin (ABS-2) with a rubber particle diameter of 0.8 microns, MFR (230°C, 2.16kg) is 7g / 10min, 0.200 kilograms of SMA resin with maleic anhydride weight percent content 18%, anti- Oxygen agent 1010 25 grams, white oil (12#) 25 grams, put into a container and mix homogeneously with agitator, then add in the twin-screw extruder feeder and prepare polycarbonate / ABS alloy by the same condition of embodiment 1 , Injection molded strips and test performance, the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com