Heat preservation pipe and combination method for combining foamed polyurethane spraying with outer protective pipe winding

A technology of polyurethane and outer protective pipes, which is applied in the direction of heat preservation, heat insulation protection of pipes, pipes/pipe joints/pipe fittings, etc. It can solve the problems of material differences, manufacturing process differences, etc., and achieve sustainability, life synchronization and prolongation The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

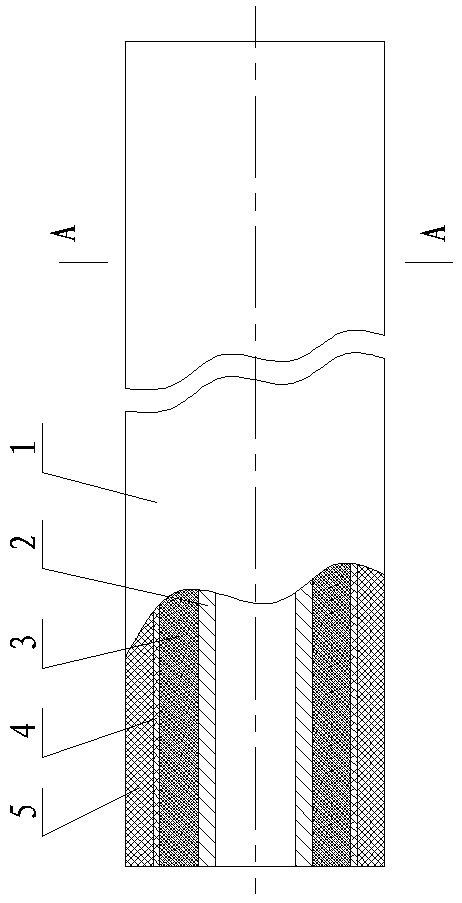

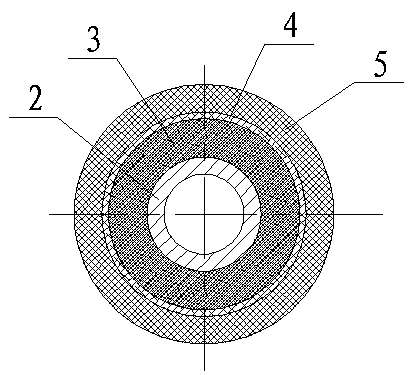

[0018] A thermal insulation pipe combined with spray-foamed polyurethane and a wound outer protective tube, comprising: a thermal insulation tube 1, the thermal insulation tube includes a working tube 2, and a polyurethane thermal insulation layer 3 is installed on the outer diameter of the working tube, The outer side of the polyurethane insulation layer is sprayed with a coating of polyethylene particles 4 through a spray gun, and the polyethylene particles are uniformly inlaid into the outer layer of the polyurethane insulation layer, and the inlay depth is 0.5-1 mm. The polyethylene outer protective tube 5 is wound on the outside of the ethylene particles.

Embodiment 2

[0020] According to the thermal insulation pipe combined with sprayed foamed polyurethane and winding outer protective tube described in Example 1, the polyurethane thermal insulation layer is a polyurethane plastic foam thermal insulation layer, and its working state is a soft state, and the polyethylene particles are not Regular granular structure, its surface is non-smooth, non-spherical polygonal pulverized material, particle size is 0.5-3 mm, the temperature when the polyethylene outer protective tube is wound is 200-230 degrees, the working tube The caliber is DN200-2000mm.

Embodiment 3

[0022] According to the method for combining the polyurethane foamed by spraying and the thermal insulation pipe wrapped around the outer protective pipe described in embodiment 1-4, the method may further comprise the steps:

[0023] (1) First install the working tube on the special equipment, and spray the foamed polyurethane insulation layer on the outer diameter of the working tube as the working tube rotates at a constant speed, and then use a spray gun to evenly spray polyethylene particles on the polyurethane For the outer layer of the insulation layer, before using the spray gun, adjust the pressure of the spray gun so that the polyethylene particles sprayed out are inlaid in the outer layer of the polyurethane insulation layer and the inlay depth reaches 0.5-1 mm, forming a fusion of polyurethane and polyethylene bridging substances layer;

[0024] (2) Then tightly wrap the polyethylene outer protective tube with a temperature of 200-230 degrees on the outside of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com