Underglaze five-color polished and glazed tile and preparation method thereof

An underglaze multicolored and glazed tile technology is applied in the field of underglaze multicolored polished glazed tiles and their preparation, which can solve the problems of colorful underglaze color tone, dark red color, gray color, insufficient color gamut, etc. Clear and natural, high brightness and wide color gamut, the effect of increasing the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

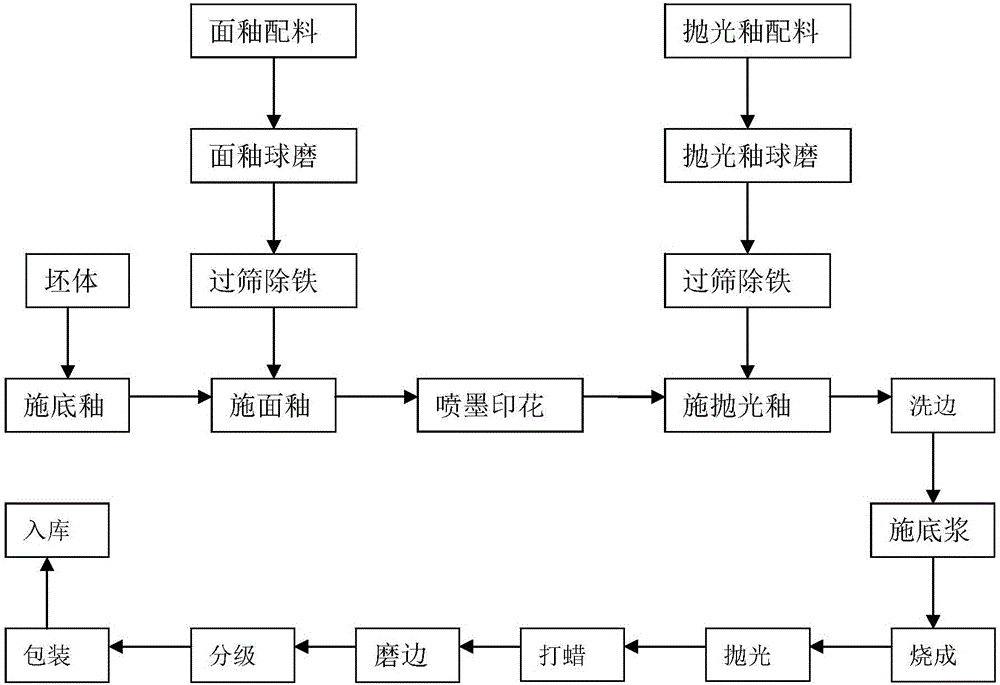

Method used

Image

Examples

Embodiment 1

[0040] A preparation method for underglaze multicolored polished glazed tiles, comprising the following steps:

[0041] A. Preparation of glaze:

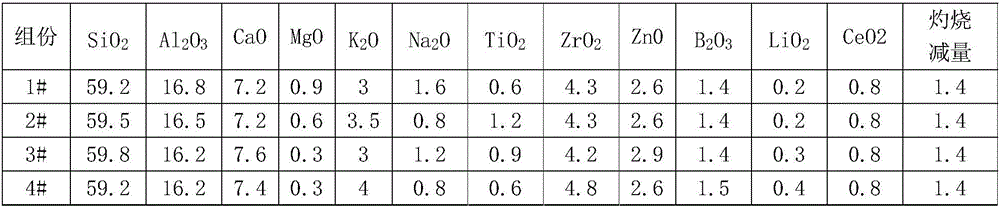

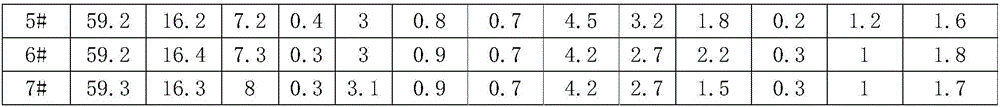

[0042] The chemical composition of the surface glaze is shown in Table 1:

[0043] Table 1, the chemical composition list of surface glaze (weight percent, %)

[0044]

[0045]

[0046] Prepare the surface glaze: select the corresponding proportion of frit, feldspar powder, spodumene powder, quartz powder, calcined alumina powder, calcium carbonate, calcined talc, titanium dioxide, zirconium silicate, cerium oxide, boric acid according to the chemical composition of Table 1 Zinc, kaolin and auxiliary raw materials with an additional weight percentage of 0.2% to 0.4% are used for batching, and then an appropriate amount of water is added to be finely ground by ball milling to form a fineness of 325 mesh. The sieve residue is 0.2% to 0.4% by mass and contains The glaze slurry with 28% to 30% moisture, after removing iron and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com