Dragon spring celadon antibacterial agent and application thereof

A kind of antibacterial agent and celadon technology, applied in application, biocide, disinfectant, etc., can solve the problems of no antibacterial glaze technology, doping, etc., and achieve significant economic benefits and increase sales prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

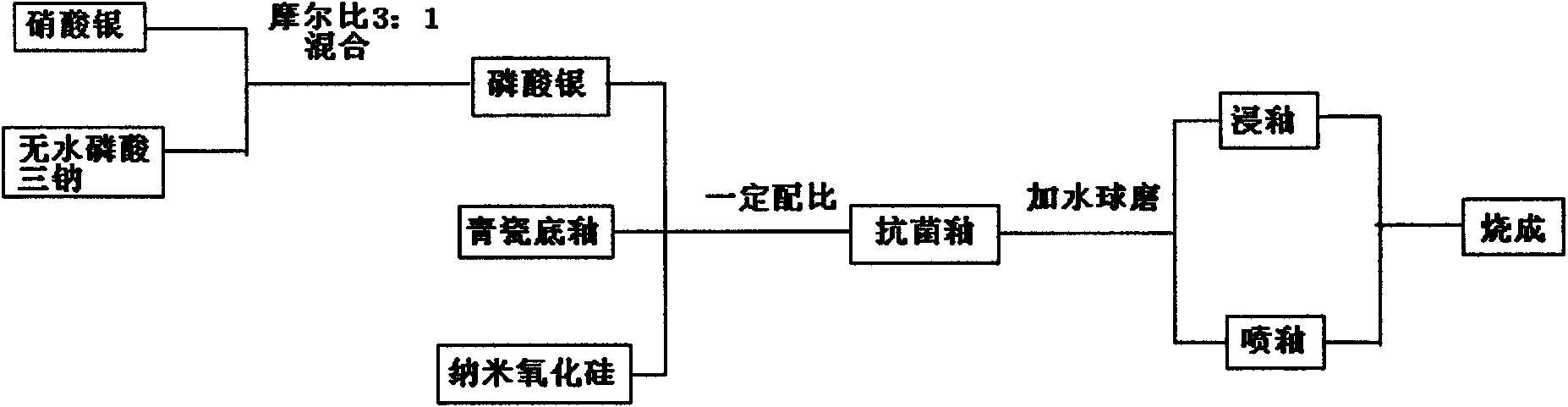

Method used

Image

Examples

Embodiment 1

[0035] In terms of weight percentage, mix 45% of Longquan celadon glaze, 35% of nano-silicon oxide and 20% of silver phosphate, mix evenly, grind finely, and pass through a 300-mesh sieve to obtain the Longquan celadon antibacterial agent.

[0036] The chemical composition of Longquan celadon glaze in this embodiment is:

[0037] SiO 2 69.95%

[0038] K 2 O 5.2%

[0039] Na 2 O 0.96%

[0040] Al 2 o 3 14.16%

[0041] Fe 2 o 3 1.95%

[0042] CaO 7.2%

[0043] MgO 0.34%

[0044] TiO 2 0.24%

[0045] Mix 28% of Longquan celadon antibacterial agent prepared above with 72% of traditional celadon underglaze to make antibacterial glaze dry agent. Dissolve the antibacterial glaze drying agent with water and ball mill it into glaze slurry, immerse the celadon carcass in the antibacterial glaze, dry it and then fire it at 1250-1350 degrees Celsius.

[0046] The antibacterial glaze obtained in this embodiment has a bactericidal rate of 95...

Embodiment 2

[0048] In terms of weight percentage, mix 47% of Longquan celadon glaze, 33% of nano-silicon oxide and 20% of silver phosphate, mix evenly, grind finely, and pass through a 300-mesh sieve to obtain the Longquan celadon antibacterial agent.

[0049] The chemical composition of Longquan celadon glaze in this embodiment is:

[0050] SiO 2 68.72%

[0051] K 2 O 5.1%

[0052] Na 2 O 1.1%

[0053] al 2 o 3 14.83%

[0054] Fe 2 o 3 2.1%

[0055] CaO 7.5%

[0056] MgO 0.37%

[0057] TiO 2 0.28%

[0058] Mix 25% of the Longquan celadon antibacterial agent prepared above with 75% of traditional celadon underglaze to make antibacterial glaze dry agent. Dissolve the antibacterial glaze dry agent with water and ball-mill it into a glaze slurry. First, dip the celadon carcass in a layer of celadon bottom glaze, and then use a spray gun to evenly spray the antibacterial glaze on the surface of ordinary celadon glaze. After drying, it is fire...

Embodiment 3

[0061] In weight percentage, mix 50% of Longquan celadon glaze, 30% of nano-silicon oxide and 20% of silver phosphate, mix evenly, grind finely, and pass through a 300-mesh sieve to obtain Longquan celadon antibacterial agent.

[0062] The chemical composition of Longquan celadon glaze in this embodiment is:

[0063] SiO 2 69.17%

[0064] K 2 O 4.8%

[0065] Na 2 O 1.2%

[0066] al 2 o 3 14.8%

[0067] Fe 2 o 3 1.9%

[0068] CaO 7.3%

[0069] MgO 0.57%

[0070] TiO 2 0.26%

[0071] Mix 35% of the Longquan celadon antibacterial agent prepared above with 65% of the traditional celadon underglaze to make antibacterial glaze dry agent. Dissolve the antibacterial glaze drying agent with water and ball mill it into glaze slurry, immerse the celadon carcass in the antibacterial glaze, dry it and then fire it at 1250-1350 degrees Celsius.

[0072] The antibacterial glaze obtained in this embodiment has a bactericidal rate of 96% fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com