Glazed tile with wallpaper or bark-shaped surface and concave and convex effect and preparation method

A technology of glazed tiles and bark, applied in the field of glazed tiles and their preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail below in conjunction with embodiment.

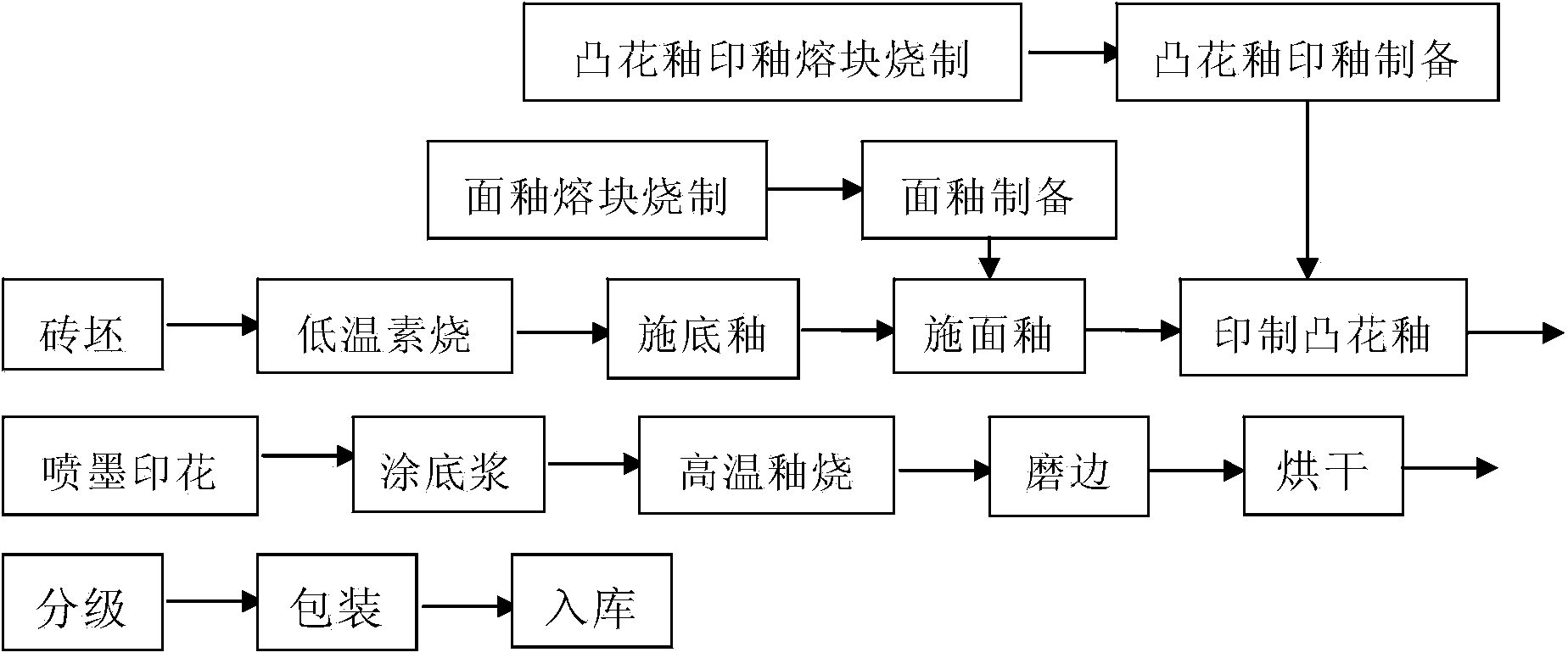

[0040] A kind of surface such as wallpaper, bark etc. of the present invention and have the glazed brick of concavo-convex effect and preparation method, it comprises following component preparation and steps:

[0041] A. Preparation of top glaze:

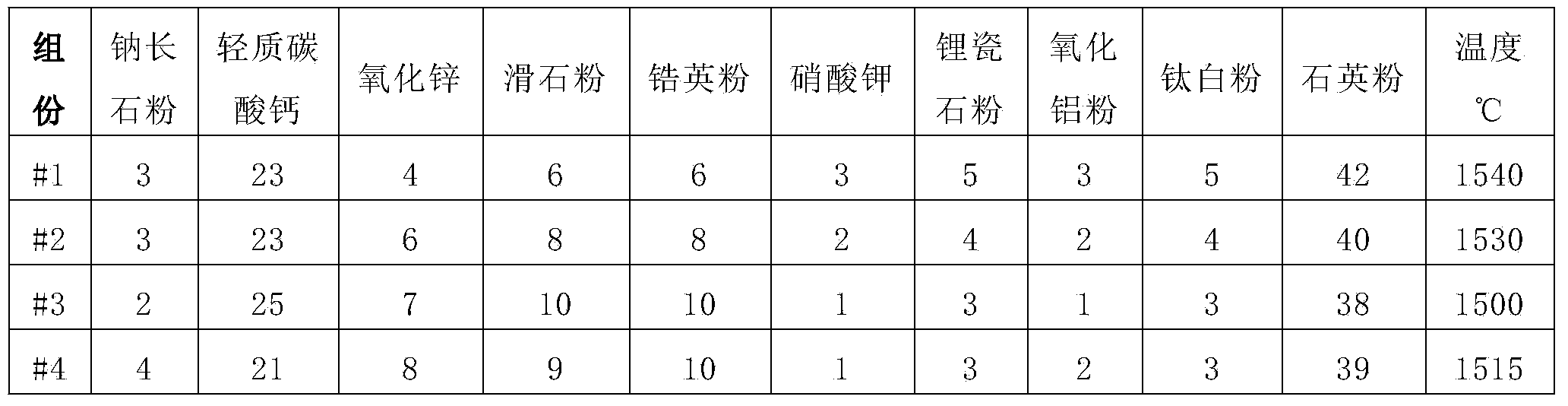

[0042] a. Preparation of surface glaze frit a: The composition of surface glaze frit is shown in Table 1:

[0043] Table 1: Composition (parts by weight) of glaze frit a

[0044]

[0045] The above-mentioned raw materials with a particle size of less than 150 mesh are batched according to the parts by weight in Table 1, mixed evenly, melted in a frit furnace, and water-quenched to form a transparent frit a for later use.

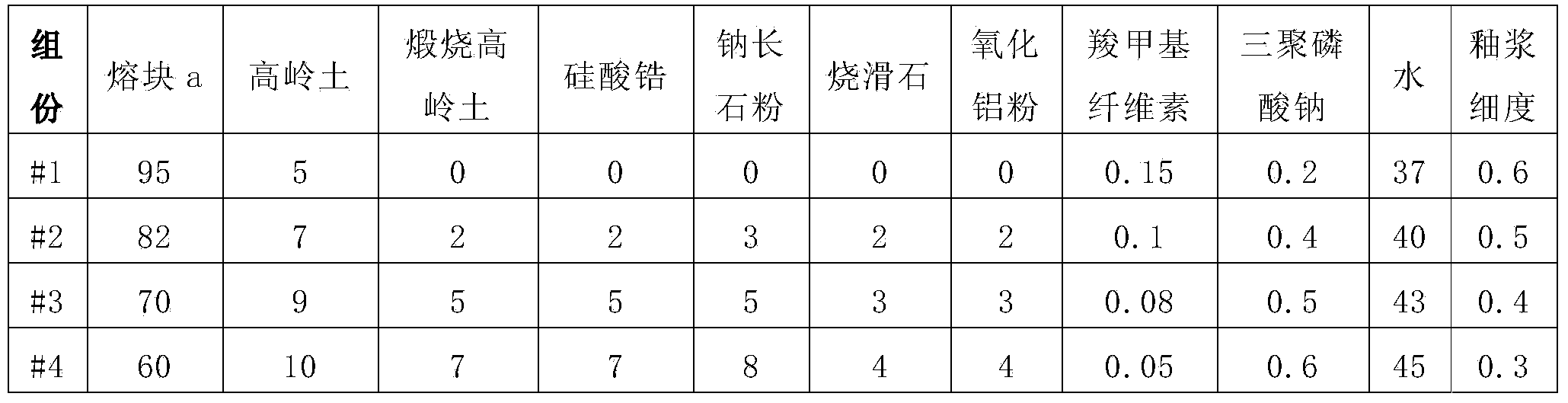

[0046] B. Preparation of top glaze:

[0047] The composition of the surface glaze is shown in Table 2:

[0048] Table 2: Composition of top glaze (parts by weight)

[0049]

[0050] According to the weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com