Longquan celadon crackle glaze wine bottle and preparation method thereof

A technology of cracked glaze and celadon, applied in clay products, other household appliances, household appliances, etc., can solve the problems of cracked tire wall, cracked glaze wine bottle can not meet the long-term storage of wine, shrinking glaze and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

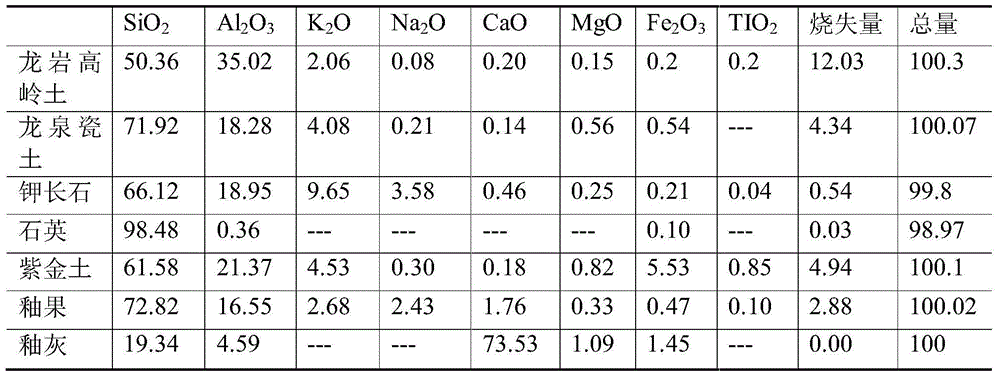

[0036] The Longquan celadon cracked glaze wine bottle of this embodiment uses mineral raw materials to prepare blanks and inner glazes, and uses mineral raw materials and adds industrial chemical raw materials to prepare outer glazes.

[0037] Specifically, the blank: the weight percentage of the formula is composed of 52% of Longyan kaolin, 20% of Longquan porcelain clay, 10% of potassium feldspar, 10% of quartz, and 8% of purple gold clay. Weigh according to the above ratio, mix the raw materials evenly, put them into a ball mill with a material:ball:water ratio of 1:2:0.6, and put them into a ball mill for 4 hours, pass the slurry through a 100-mesh sieve after being stale for 36 hours, and dehydrate, After practicing the mud process, it is made into a blank.

[0038] Inner glaze raw materials: The weight percentage of the formula is composed of glaze fruit 72%, glaze ash 20%, and purple gold soil 8%. Weigh according to the above ratio, mix the raw materials evenly, put th...

Embodiment 2

[0056] The Longquan celadon cracked glaze wine bottle of this embodiment uses mineral raw materials to prepare blanks and inner glazes, and uses mineral raw materials and adds industrial chemical raw materials to prepare outer glazes.

[0057] Specifically, the blank: the weight percentage of the formula is composed of 46% of Longyan kaolin, 20% of Longquan porcelain clay, 14% of potassium feldspar, 10% of quartz, and 10% of purple gold clay. After weighing the raw materials according to the billet formula and mixing them evenly, put them into a ball mill with a material:ball:water ratio of 1:2:0.6 and mill them for 4 hours. Pass the slurry through a 100-mesh sieve after aging for 36 hours. After the process, it is made into a blank.

[0058] Inner glaze raw materials: The weight percentage of the formula is composed of glaze fruit 74%, glaze ash 18%, and purple gold soil 8%. Weigh according to the above ratio, mix the raw materials evenly, put them into a ball mill with a ma...

Embodiment 3

[0073] The Longquan celadon cracked glaze wine bottle of this embodiment uses mineral raw materials to prepare blanks and inner glazes, and uses mineral raw materials and adds industrial chemical raw materials to prepare outer glazes.

[0074] Specifically, the blank: the weight percentage of the formula is composed of 46% of Longyan kaolin, 17% of Longquan porcelain clay, 15% of potassium feldspar, 12% of quartz, and 10% of purple gold clay. After weighing the raw materials according to the billet formula and mixing them evenly, put them into a ball mill with a material:ball:water ratio of 1:2:0.6 and mill them for 4 hours. Pass the slurry through a 100-mesh sieve after aging for 36 hours. After the process, it is made into a blank.

[0075] Inner glaze raw materials: The weight percentage of the formula is composed of glaze fruit 70%, glaze ash 20%, and purple gold soil 10%. Weigh according to the above ratio, mix the raw materials evenly, put them into a ball mill with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com