Preparation method and application of three-dimensional carbon aerogel with porous tube wall nanotubes

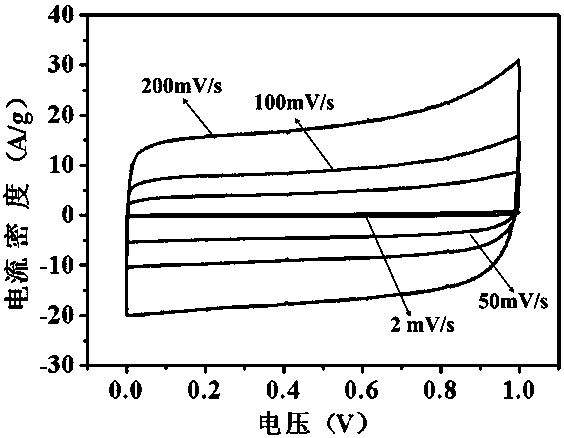

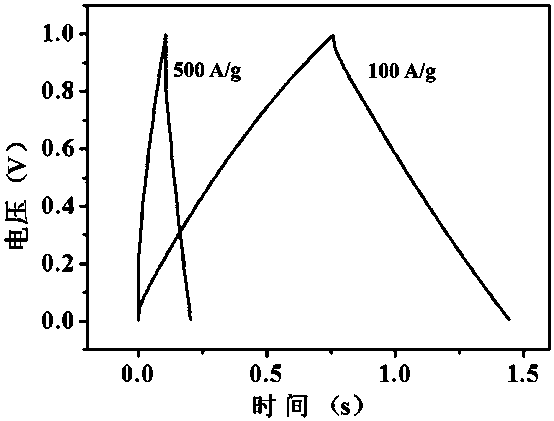

A carbon aerogel and nanotube technology, applied in the field of carbon materials, can solve the problems of non-uniformity, pores as small as sub-nanometers, pores as large as tens of nanometers or even hundreds of nanometers, and weak pore size controllability. , to achieve the effect of large specific surface area, broad application prospects and excellent fast charging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing a three-dimensional carbon aerogel with porous tube-walled nanotubes, and the method is implemented according to the following steps:

[0036] 1. Preparation of silver nanowires:

[0037] Using 150mL of ethylene glycol as the reducing agent, 6.9 mg of sodium chloride as the initiator, and under the action of 1.36g of polyvinylpyrrolidone, 1.02g of silver nitrate was heated at 160°C for 6 hours by hydrothermal method, and then the product was centrifugally cleaned. obtain silver nanowires;

[0038] 2. Preparation of silver nanowire / polypyrrole three-dimensional porous airgel:

[0039] Take 1 mL of pyrrole monomer and add it into a mixed solution of 150 mL of ethanol and deionized water (the volume ratio of the two is 1:1) containing 1 g of silver nanowires under stirring, and use 1.23 g of silver nitrate as the oxidant to polymerize the pyrrole monomer For polypyrrole, obtain a three-dimensional hydrogel of silver nanowir...

Embodiment 2

[0046] This embodiment provides a method for preparing a three-dimensional carbon aerogel with porous tube-walled nanotubes, and the method is implemented according to the following steps:

[0047] 1. Preparation of silver nanowires:

[0048] Using 150mL of ethylene glycol as a reducing agent, 6.9g of sodium chloride as an initiator, and under the action of 1.36g of polyvinylpyrrolidone, 1.02g of silver nitrate was heated at 160°C for 6h by hydrothermal method, and then the product was centrifugally cleaned. obtain silver nanowires;

[0049] 2. Preparation of silver nanowire / polypyrrole three-dimensional porous airgel:

[0050] Take 2 mL of pyrrole monomer and add it into a mixed solution of 150 mL of ethanol and deionized water (the volume ratio of the two is 1:1) containing 1 g of silver nanowires under stirring, and use 2.46 g of silver nitrate as the oxidant to polymerize the pyrrole monomer For polypyrrole, obtain a three-dimensional hydrogel of silver nanowires / polypyr...

Embodiment 3

[0056] This embodiment provides a method for preparing a three-dimensional carbon aerogel with porous tube-walled nanotubes, and the method is implemented according to the following steps:

[0057] 1. Preparation of silver nanowires:

[0058] Using 150mL of ethylene glycol as the reducing agent, 6.9 mg of sodium chloride as the initiator, and under the action of 1.36g of polyvinylpyrrolidone, 1.02g of silver nitrate was heated at 160°C for 6h by hydrothermal method, and then the product was centrifugally washed to obtain silver nanowires;

[0059] 2. Preparation of silver nanowire / polypyrrole three-dimensional porous airgel:

[0060] Take 0.5 mL of pyrrole monomer and add it into a mixed solution of 150 mL of ethanol and deionized water (the volume ratio of the two is 1:1) containing 1 g of silver nanowires under stirring, and use 0.615 g of silver nitrate as the oxidant to make the pyrrole monomer Polymerize into polypyrrole to obtain a three-dimensional hydrogel of silver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com