Red fluoresent material, and preparing technique

A red phosphor powder and phosphor technology, applied in the preparation of the red phosphor powder, in the field of red phosphor powder, can solve the problems of difficult to achieve satisfactory particle size, influence of ball milling luminous efficiency, wide product particle size distribution, etc., and achieve easy operation control, Conducive to the expansion of large-scale production, the effect of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

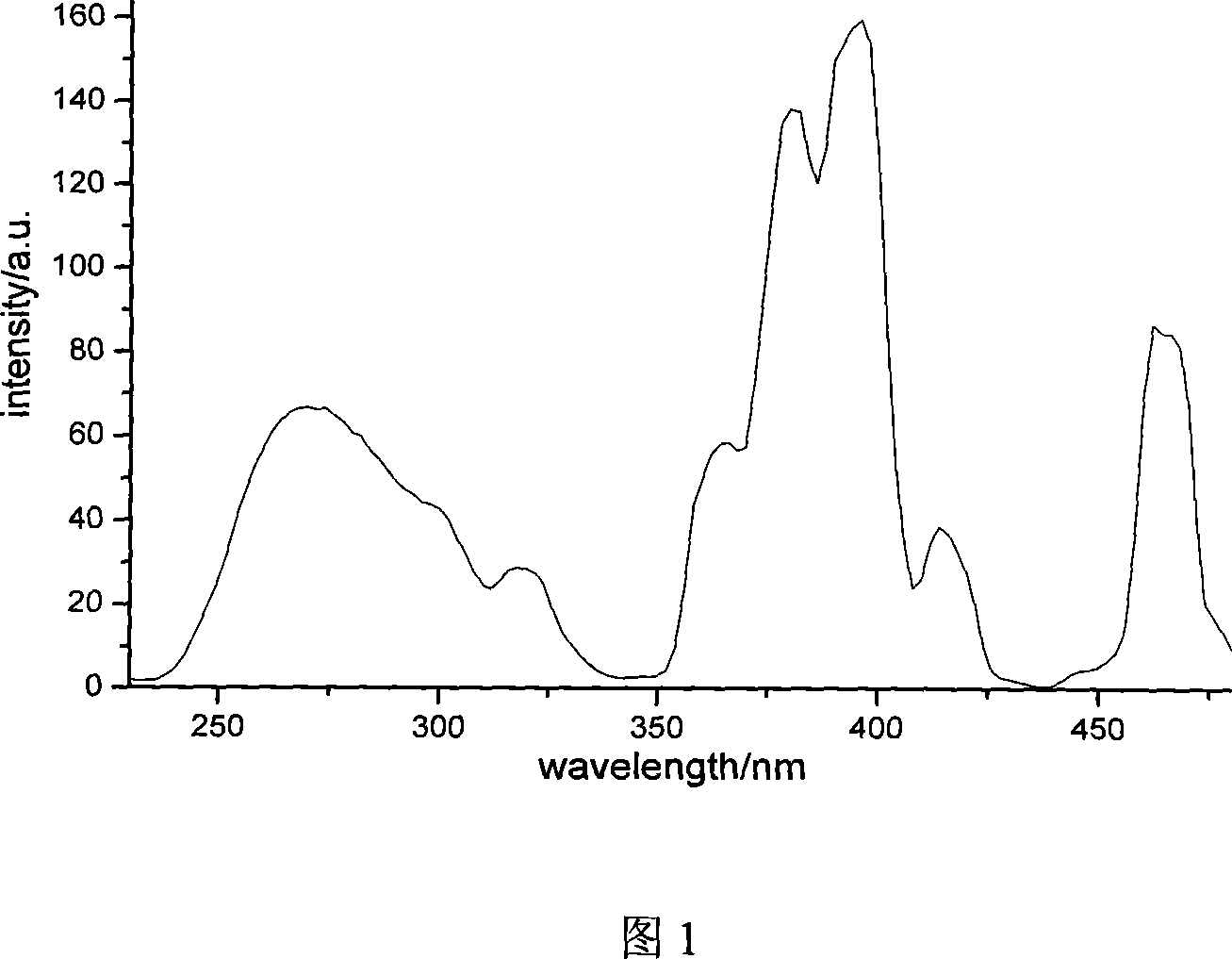

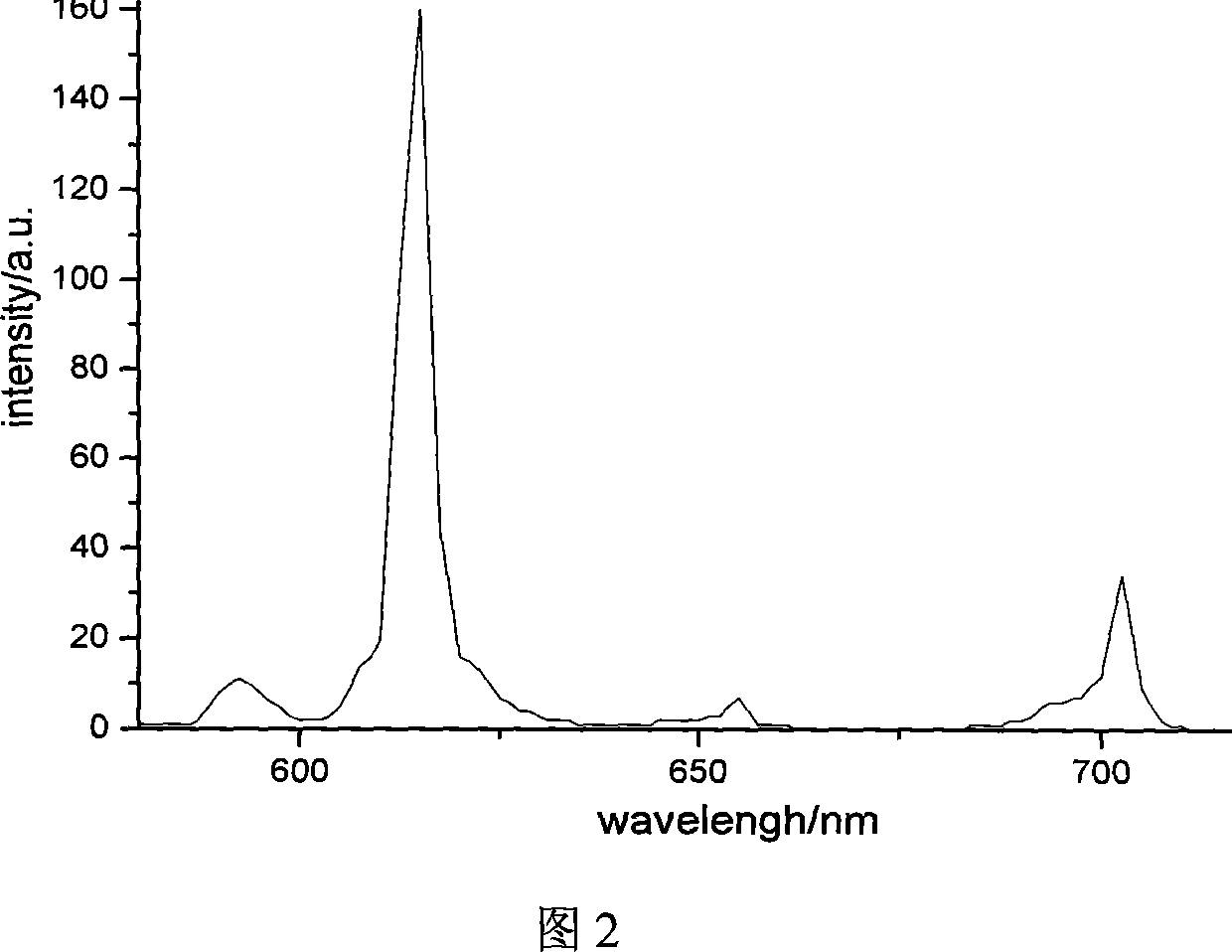

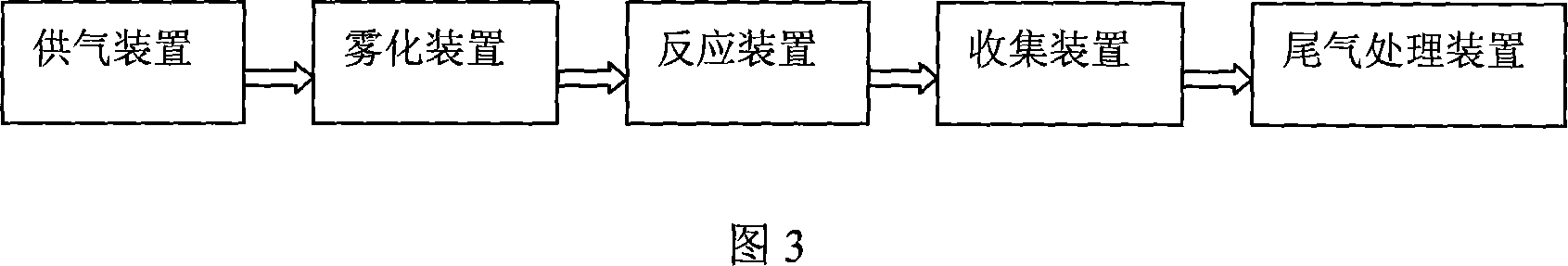

[0026] Embodiment 1: take by weighing 22.2g Li 2 CO 3 , 104.56g Eu 2 o 3 Dissolve in an appropriate amount of nitric acid to make a nitrate solution, weigh 331.08g H 4 SiW 12 o 40 ·nH 2 O is made into an aqueous solution, then the two are mixed, and diluted to 1000ml with deionized water to obtain a clear precursor solution, which has a pH value of 3 and is added to the atomization device. Raise the intelligent temperature-raising reaction furnace to 1100°C, feed air into the reaction system, and control the gas flow rate at 15L / min. Start the atomization device, the aerosol generated by the precursor solution enters the reaction system with the airflow, and the LiEu(SiO 2 ) 1 / 6 W 2 o 8 The fluorescent powder is collected by the collection device, and the tail gas is discharged after being processed by the tail gas treatment device. The collected fluorescent powder is washed twice, dehydrated and dried to obtain the finished product. Observing its morphology with a...

Embodiment 2

[0027] Embodiment 2: take by weighing 19.98g Li 2 CO 3 , 3.08 g Na 2 CO 3 , 104.56g Eu 2 o 3 Dissolve in an appropriate amount of nitric acid to make a nitrate solution, weigh 331.08g H 4 SiW 12 o 40 ·nH 2 O is dissolved into an aqueous solution, then the two are mixed, and diluted to 1000ml with deionized water to obtain a clear precursor solution. The preparation method is the same as in Example 1, and the chemical formula is (Li 0.9 Na 0.1 )Eu(SiO 2 ) 1 / 6 W 2 o 8 phosphor, its luminous intensity is comparable to that of LiEu(SiO 2 ) 1 / 6 W 2 o 8 Compared with phosphor, there is a slight change, as shown in Table 1.

Embodiment 3

[0028] Embodiment 3: take by weighing 22.2g Li 2 CO 3 , 101.36g Eu 2 o 3 , 4.18g Sm 2 o 3 Dissolve in an appropriate amount of nitric acid to make a nitrate solution, weigh 331.08g H 4 SiW 12 o 40 ·nH 2 O is dissolved into an aqueous solution, then the two are mixed, and diluted to 1000ml with deionized water to obtain a clear precursor solution. The preparation method is the same as in Example 1, and the chemical formula is Li(Eu 0.96 SM 0.04 ) (SiO 2 ) 1 / 6 W 2 o 8 Phosphor powder, its luminous intensity is obviously improved compared with Example 1, and its main emission peak is shifted to the long wave direction. As shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com