Catalyst carbide carrier and its preparation method, regular catalyst and its preparation method

A photocatalyst and carbonization technology, applied in catalyst activation/preparation, catalyst carrier, chemical instruments and methods, etc., can solve the problem of excessive reduction of catalyst activity and surface area, hindering the practical application of photocatalytic technology, industrialized photocatalytic system development, adsorption Problems such as excessive loss of agent surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

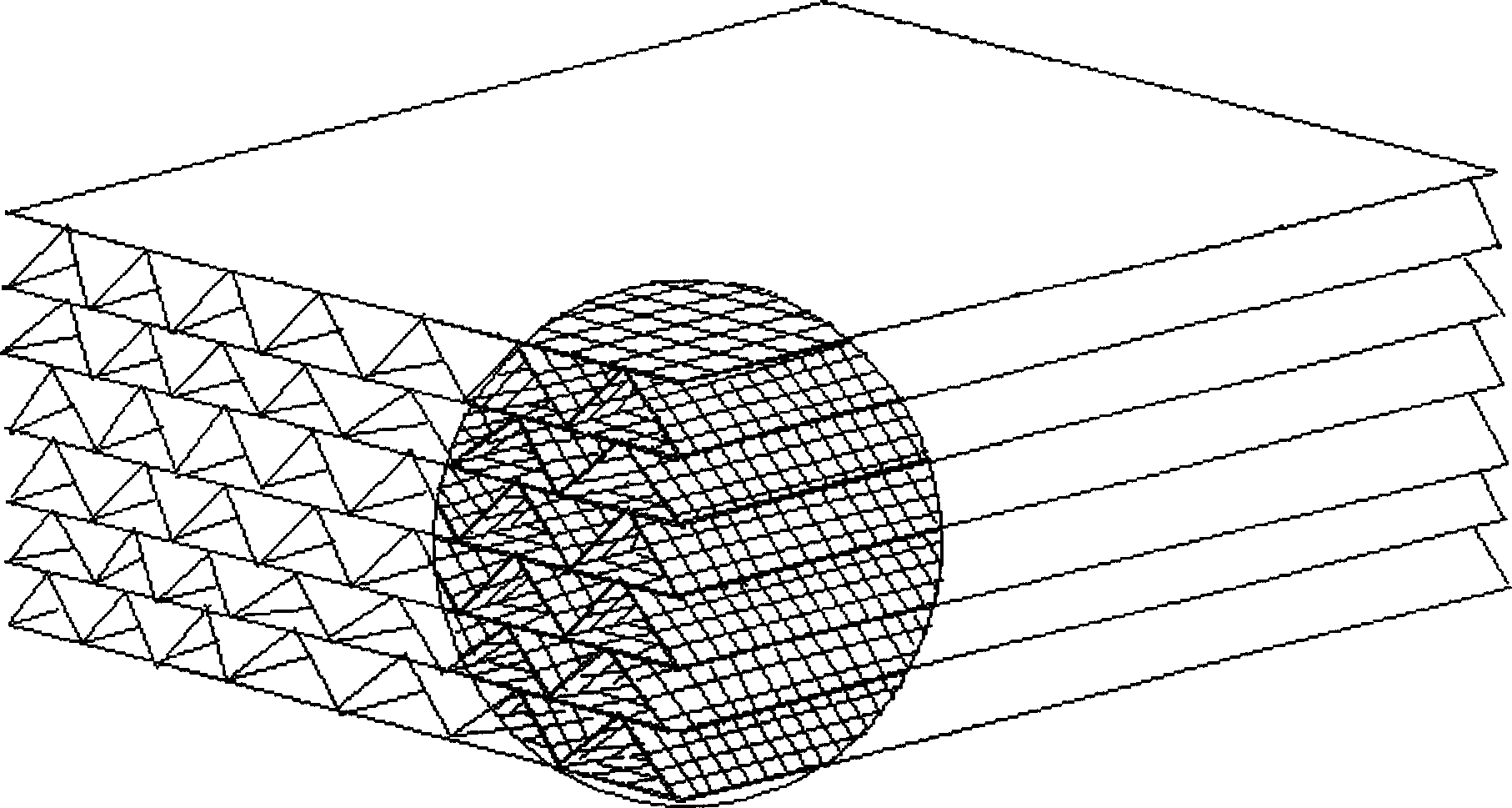

[0068] Example 1.1: A carbonized carrier of a catalyst, the precursor of the carrier is selected from thermoplastic phenolic resin, the curing agent is hexamethylene tetraammonium, and the support is selected as a rectangular plane mesh and rectangular corrugated plate with a high temperature resistance temperature greater than 1000 ° C Three-dimensional mesh 8 mesh iron wire mesh. 15% by mass of curing agent hexamethylenetetramine is mixed into the thermoplastic phenolic resin, and the mixture is uniform. The resin is evenly coated on the iron wire mesh, and the coating thickness is subject to the mesh hole not being blocked. The uniformly coated parts are successively subjected to curing process, carbonization process and activation process to obtain a regular mesh porous carbide carrier directly prepared on the iron wire mesh. The mesoporosity of the regular carbide carrier is 12%. Wherein the precursor can also be any one of thermosetting phenolic resin, amino resin, epox...

Embodiment 12

[0069] Embodiment 1.2: the preparation method of the carbonized carrier of the catalyst of embodiment 1.1, including:

[0070] (1) First, select a rectangular plane mesh and a rectangular corrugated plate three-dimensional mesh iron wire mesh with a high temperature resistance temperature greater than 1000 ° C, wash the wire mesh, and dry it for later use;

[0071] (2), select thermoplastic phenolic resin, mix the curing agent hexamethylenetetramine with a mass percentage of 15%, adjust the viscosity with acetone, until the thermoplastic phenolic resin mixed with the curing agent can be easily coated on the wire mesh Can;

[0072] (3), the thermoplastic phenolic resin prepared in (2) is evenly coated on the metal wire mesh for drying and standby, and do not block the mesh during coating;

[0073] (4), curing process: put the metal wire mesh coated with thermoplastic phenolic resin into the oven, uniformly heat up to 90 ° C, and maintain a constant temperature for 1 hour, so t...

Embodiment 13

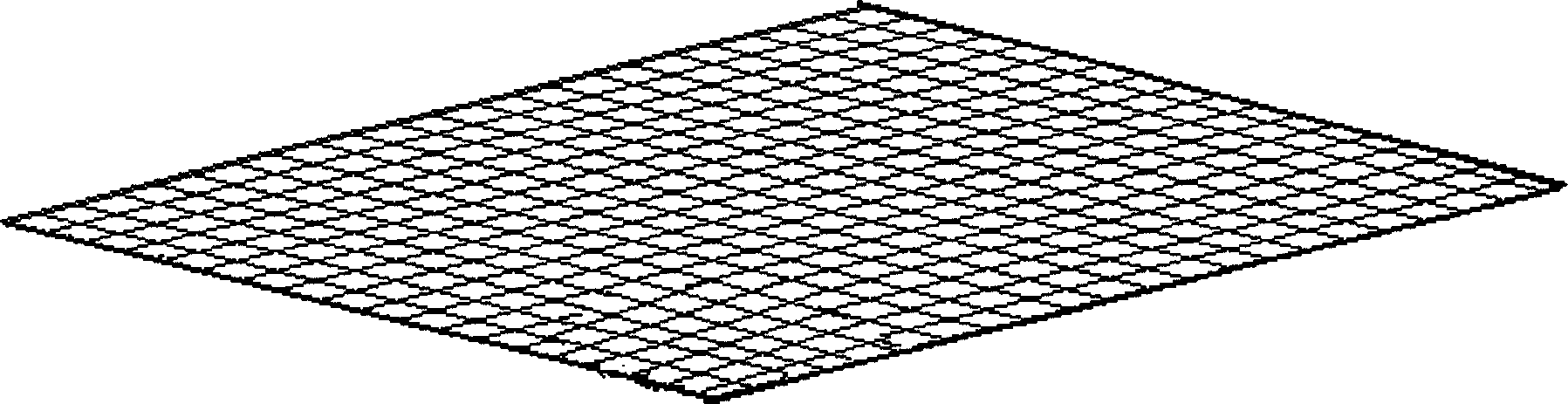

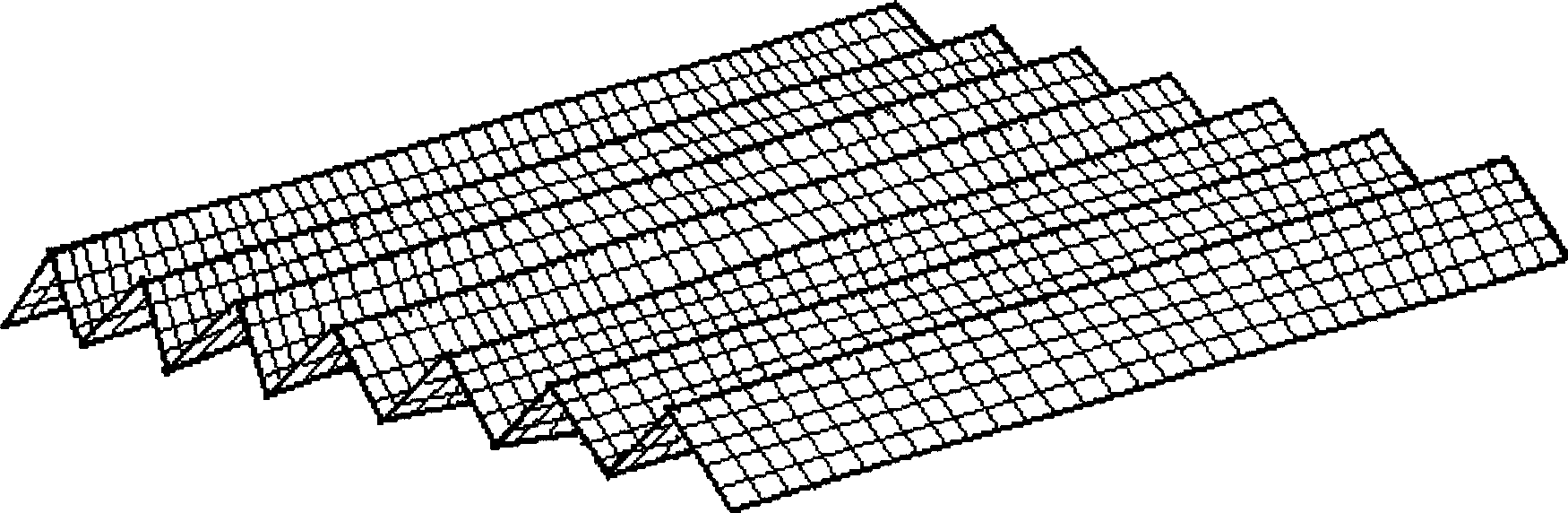

[0085] Example 1.3: Preparation of regular photocatalyst by using the reticulated porous carbide supports obtained in Example 1.1 and Example 1.2, which is to support the titanium dioxide with photocatalytic activity on the above-mentioned rectangular planar mesh or rectangular corrugated plate-shaped three-dimensional mesh. On the porous carbide support, they are combined into a regular whole to obtain a single regular network photocatalyst: such as figure 1 , one is a single regular photocatalyst with a rectangular planar network, such as figure 2 , and the other is a single regular photocatalyst with a rectangular corrugated plate-shaped three-dimensional network. The substance with photocatalytic activity can also be any one or a mixture of two or more of tungsten trioxide, antimony trioxide, zirconium dioxide, magnesium oxide, and zinc oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh diameter | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com