Gluing cardboard and processing technology thereof

A technology for gluing cards and pallets, which is applied to wood processing equipment, adhesive application devices, manufacturing tools, etc., can solve the problems of easy production accidents, increased production costs, and slow production efficiency, so as to avoid parts falling off and improve bonding effect, the effect of reducing the number of layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

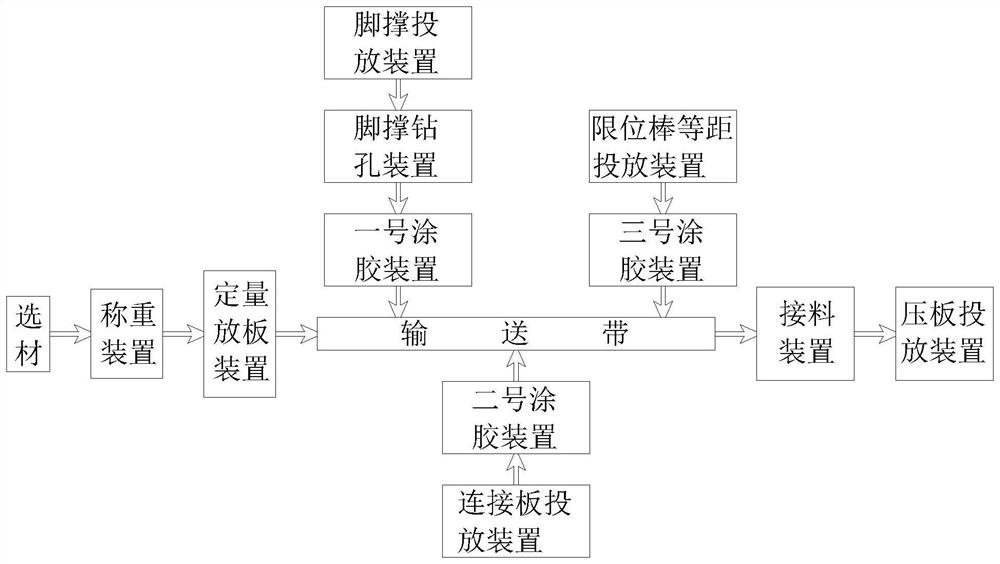

Method used

Image

Examples

Embodiment Construction

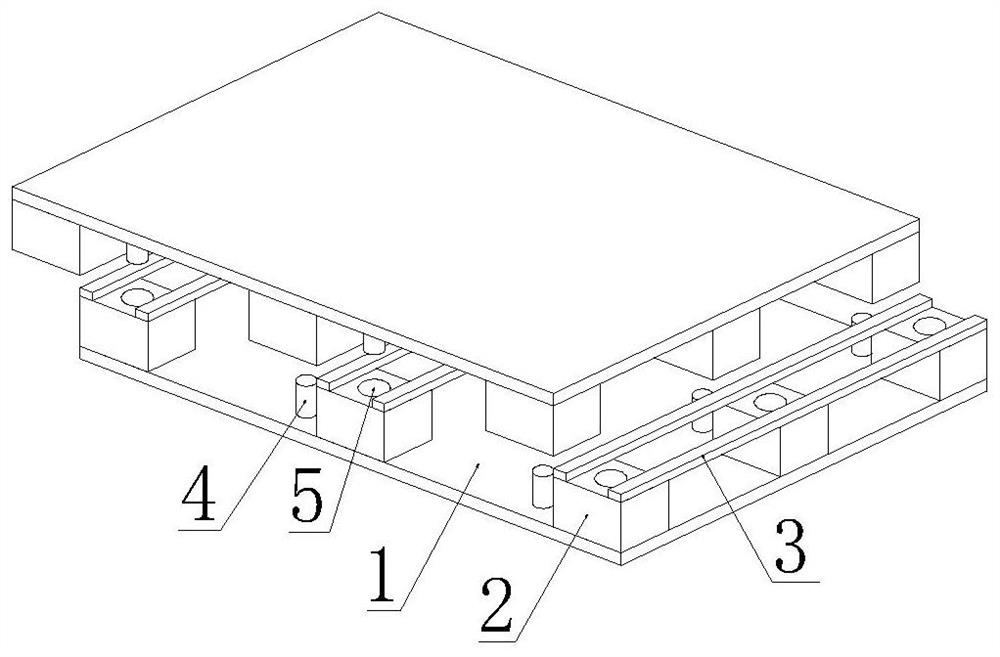

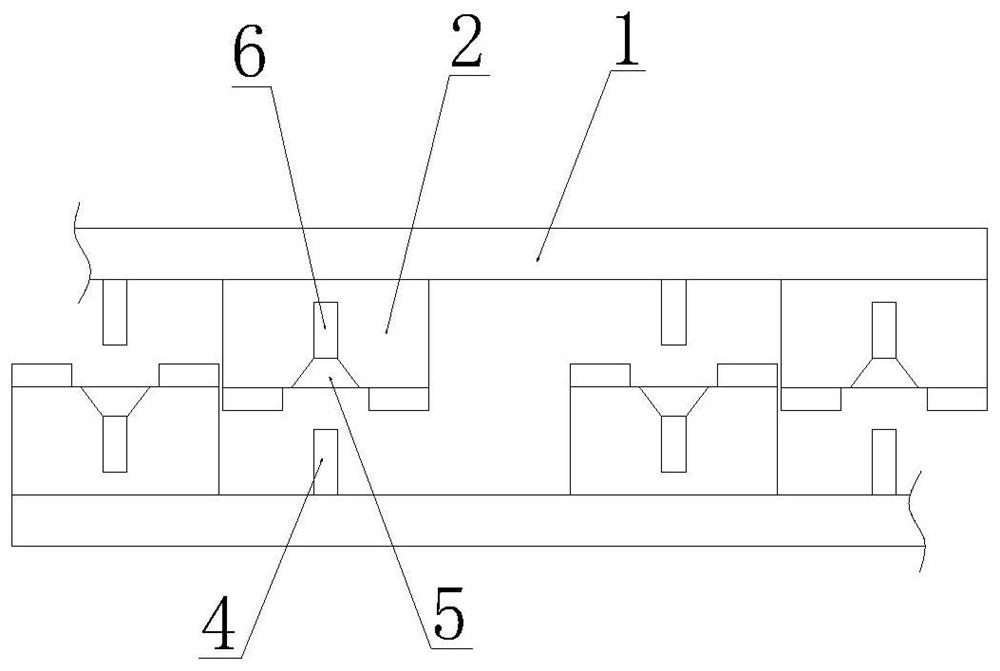

[0020] like Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: a glued cardboard and its processing technology, including a panel 1, the bottom of the panel 1 is fixedly connected with three rows of support blocks 2 at equal distances, and each row of support blocks 2 is equidistant. For the three provided, the bottom of the panel 1 and on the same side of the support block 2 are fixedly connected to the limit posts 4 , and the distance between each limit post 4 and the adjacent support blocks 2 is equal.

[0021] Among them, the center of the bottom end of the support block 2 is drilled with a conical groove 5, the bottom of the conical groove 5 is drilled with a limit insertion hole 6, and the limit column 4 is inserted into the conical groove 5 and the limit insertion hole 6, When the pallets are not stacked and stored, the two opposite pallets can be connected to form a relative whole, which reduces the number of layers of pallets, avo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com