Ultra-low liquid ratio rice sample recoloring instrument

A technology of ultra-low liquid and recoloring instrument, which is applied in the direction of textile material dyeing device, textile and paper making, vibration treatment, etc. It can solve the problems of high maintenance cost, easy damage of machines, noise pollution, etc., and achieve the reduction of mechanical equipment and strengthening structure, the effect of reducing the amount of water used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

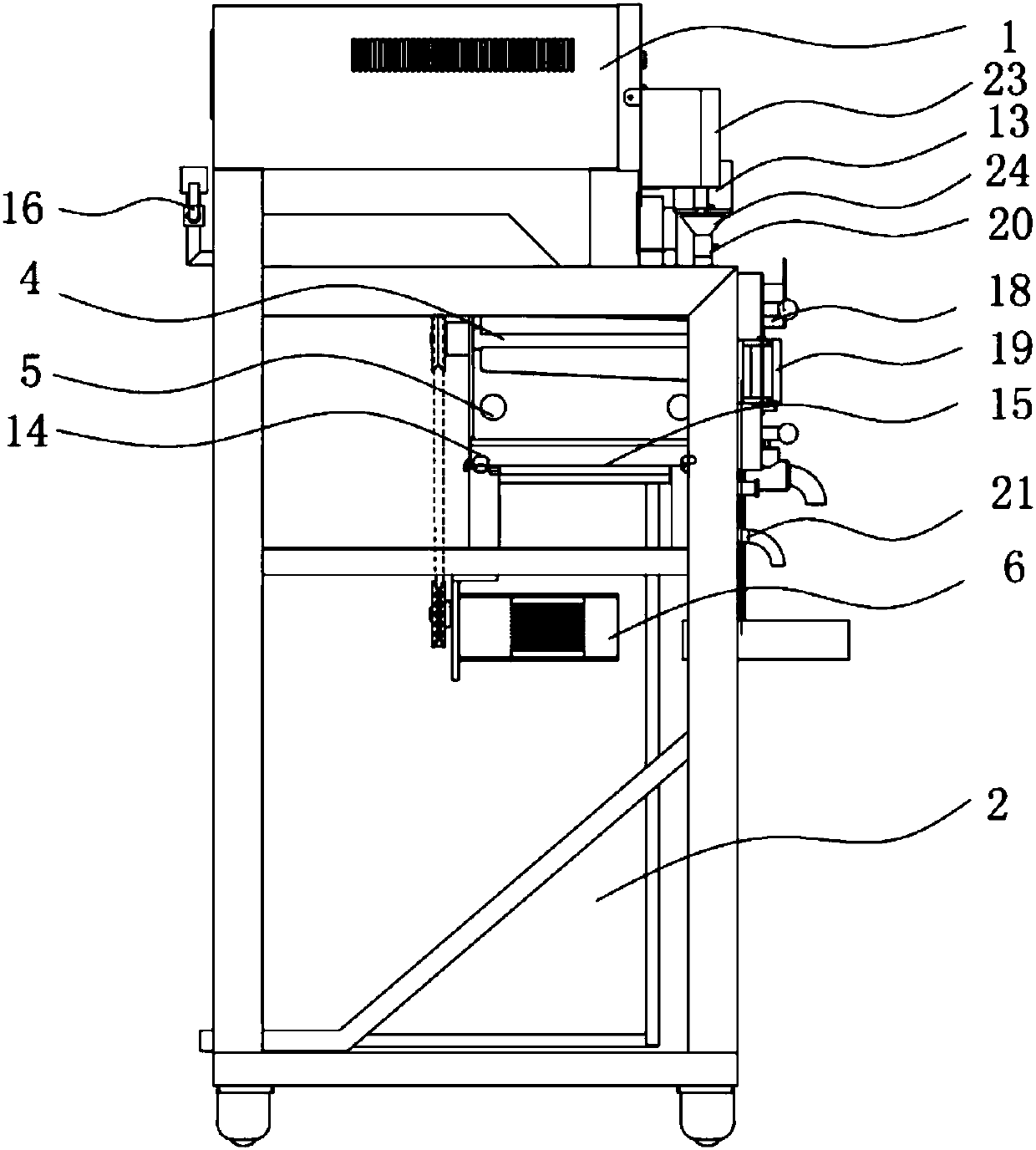

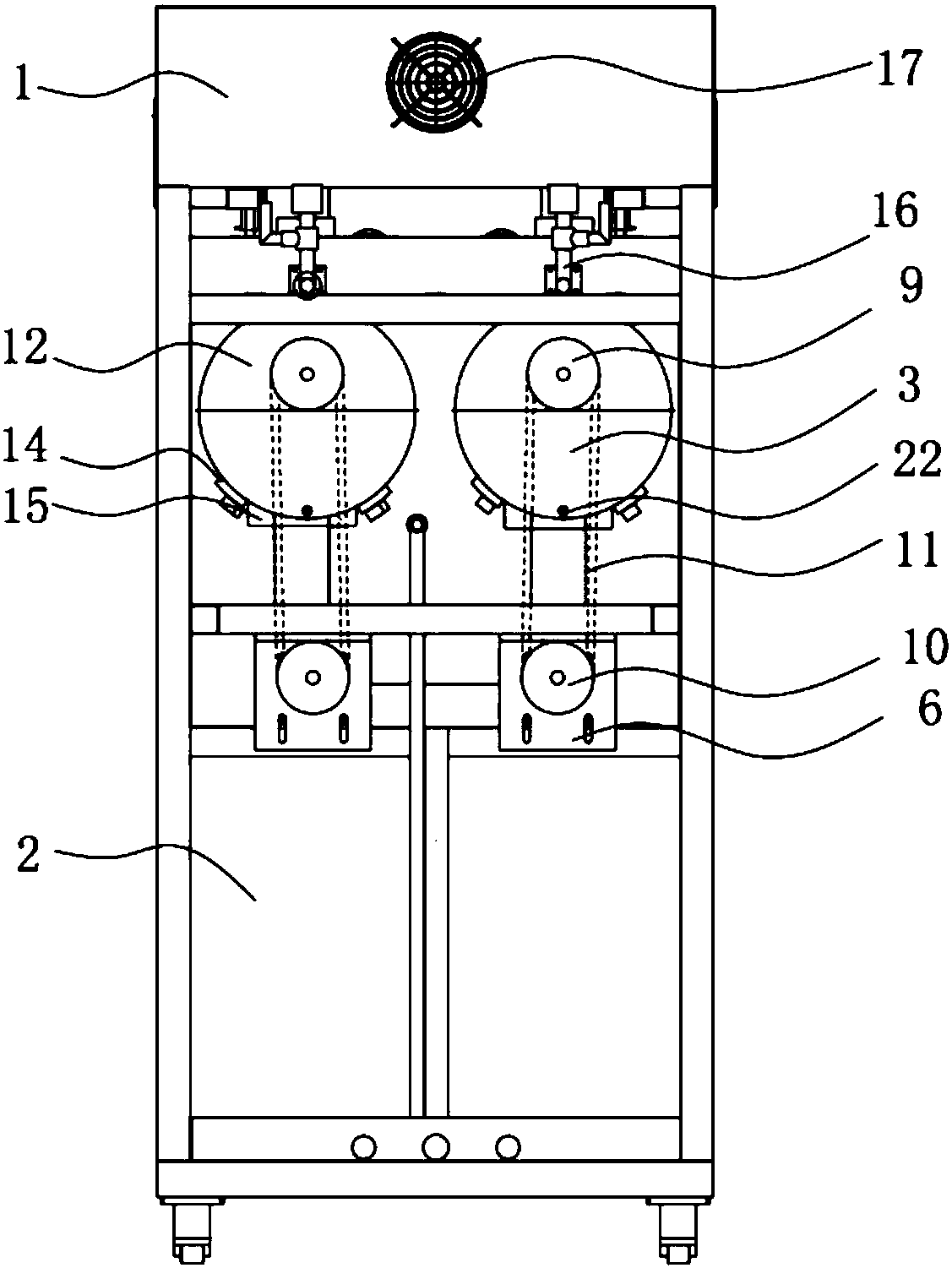

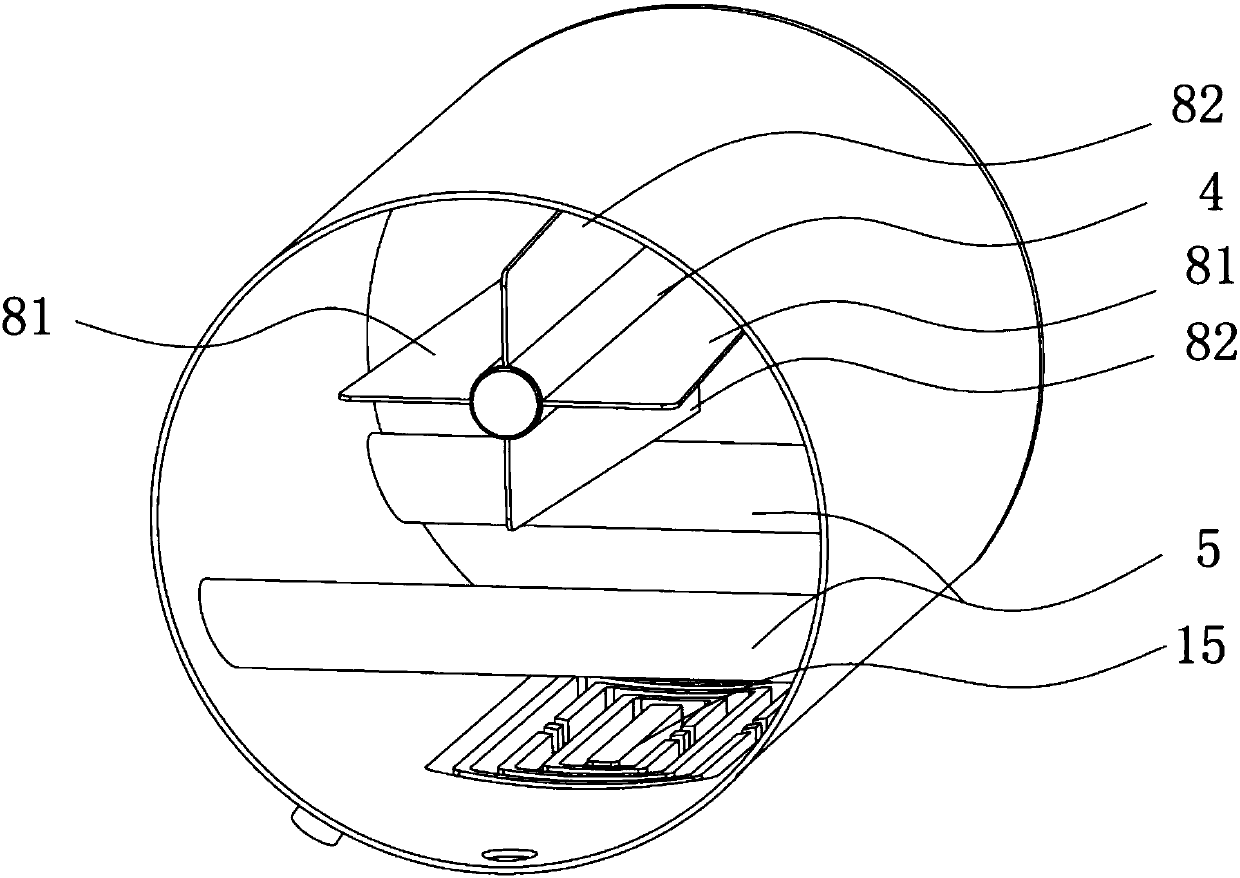

[0033] A kind of ultra-low liquid ratio rice sample complex color instrument of the present invention, it comprises ultra-low liquid ratio rice sample complex color instrument, described ultra-low liquid ratio rice sample complex color instrument comprises control box 1 and fuselage 2, so The control box 1 is fixedly connected with the fuselage 2 .

[0034] The fuselage 2 is provided with a cloth guiding mechanism (not shown), a transmission mechanism (not shown), a heating and cooling mechanism (not shown), and the like.

[0035] Include exhaust fan 17 in described control box 1, alarm device controller (not shown), stop operation device controller (not shown), transmission mechanism control switch (not shown), cloth guiding mechanism control switch (not shown) )Wait.

[0036] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with specific em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com