Method for preparing sulfonated graphene material

A technology of sulfonated graphene and graphene, which is applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the constraints of large-scale application of graphene functionalization, high toxicity of reducing agent raw material hydrazine hydrate, and pH value control Higher requirements and other issues, to achieve the effect that is conducive to large-scale production, mild conditions, and low requirements for production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

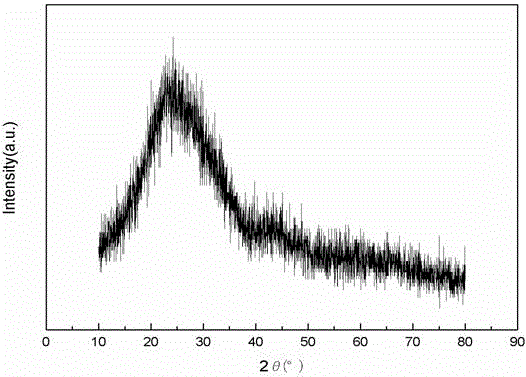

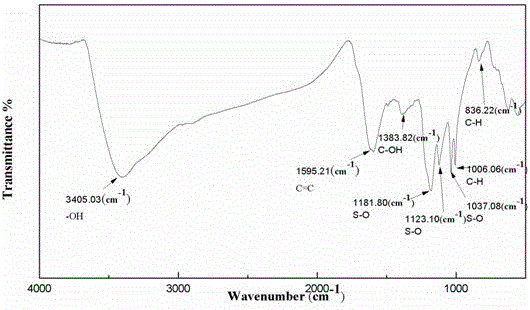

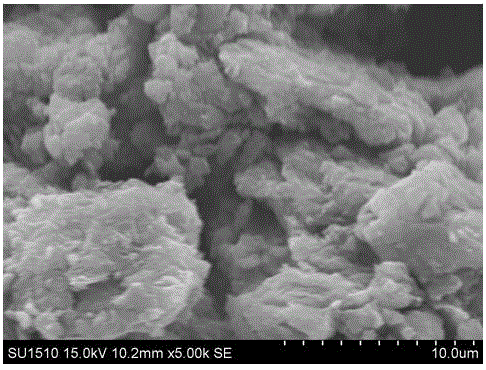

Image

Examples

Embodiment 1

[0026] A kind of preparation method of sulfonated graphene material, comprises following process:

[0027] 1. Preparation of rGO (reduced graphene oxide)

[0028] (1) Put 0.15 g of graphene oxide into a 250mL beaker and add 75mL of deionized water for 2 hours, and after 2 hours, use NH 3 •H 2 O adjust the pH to 10.0 and continue sonication for 2 hours.

[0029] (2) Set up the reaction device after the ultrasound, pour the dispersion liquid into a four-necked bottle, and add 2 g (NH 4 ) 2 S 2 o 3 Continue to heat to 70° C. and continue stirring at constant temperature for 10 hours.

[0030] (3) Vacuum filtration and washing, followed by washing with 50 mL methanol and 150 mL water, and drying to obtain the reduced graphene oxide powder.

[0031] 2. Diazonium salt configuration experiment plan

[0032] (1) Weigh 3 mmol of p-aminobenzenesulfonic acid, 0.5195 g;

[0033] (2) Measure 6mL (24 mmol) of 4 mol / L hydrochloric acid to dissolve p-aminobenzenesulfonic acid;

[00...

Embodiment 2

[0045] A kind of preparation method of sulfonated graphene material, comprises following process:

[0046] 1. Preparation of rGO

[0047] (1) Put 0.20 g of graphene oxide into a 250 mL beaker and add 200 mL of deionized water for 3 hours, and after 3 hours, use NH 3 •H 2 O adjust the pH to 10.0 and continue sonication for 3 hours.

[0048] (2) Set up the reaction device after the ultrasound, pour the dispersed liquid into a four-necked bottle, add 2.5 g (NH4)2S2O3 when the oil bath is heated and stirred to 30 °C, continue to heat to 80 °C and continue to react at a constant temperature for 12 Hour.

[0049] (3) Vacuum filtration and washing, washing with 50 mL methanol and 150 mL water, and drying to obtain the reduced graphene oxide powder.

[0050] 2. Diazonium salt configuration experiment plan

[0051] (1) Weigh 6 mmol, 1.039 g of p-aminobenzenesulfonic acid;

[0052] (2) Measure 6mL (24 mmol) of 4 mol / L hydrochloric acid to dissolve p-aminobenzenesulfonic acid;

[00...

Embodiment 3

[0065] A kind of preparation method of sulfonated graphene material, comprises following process:

[0066] 1. Preparation of rGO (reduced graphene oxide)

[0067] (1) Put 0.25 g graphene oxide into a 500 mL beaker and add 250 mL deionized water for 3.5 hours to sonicate. After 3.5 hours, use NH 3 •H 2 O adjusted the pH to 11.0 and continued sonication for 3.5 hours.

[0068] (2) Set up the reaction device after the ultrasound, pour the dispersion liquid into a four-neck bottle, and add 3 g (NH 4 ) 2 S 2 o 3 Continue heating to 90° C. and continue stirring at constant temperature for 14 hours.

[0069] (3) Vacuum filtration and washing, followed by washing with 50 mL methanol and 150 mL water, and drying to obtain the reduced graphene oxide powder.

[0070] 2. Diazonium salt configuration experiment plan

[0071] (1) Weigh 9 mmol of p-aminobenzenesulfonic acid, 1.5585 g;

[0072] (2) Measure 6mL (24 mmol) of 4 mol / L hydrochloric acid to dissolve p-aminobenzenesulfonic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com