Rare earth ore leaching agent and leaching process

A rare earth ore and leaching technology, which is applied in the direction of improving process efficiency, can solve the problems of high leaching rate and high selectivity of rare earth leaching agents, and achieve high selectivity, reduced content, and low agent cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

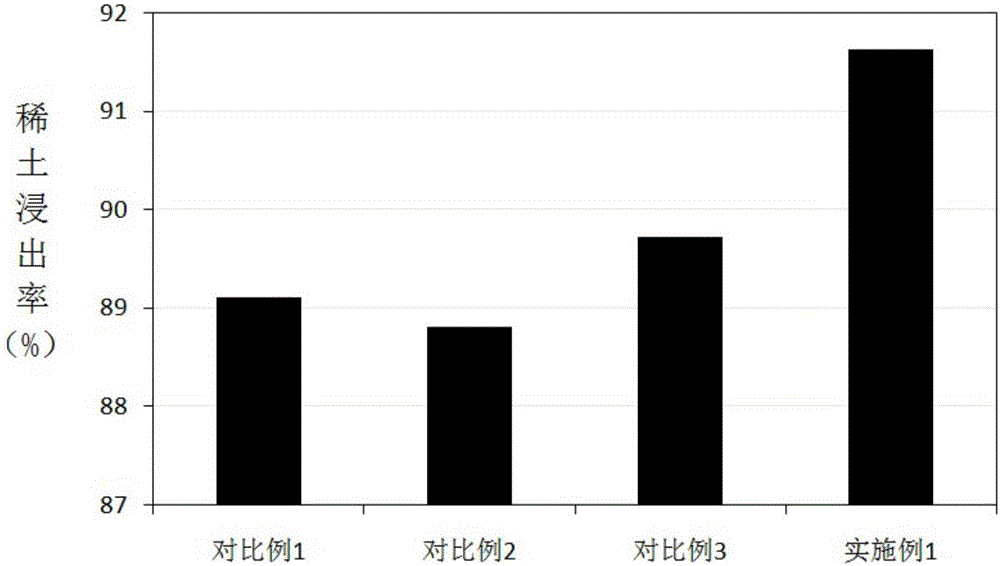

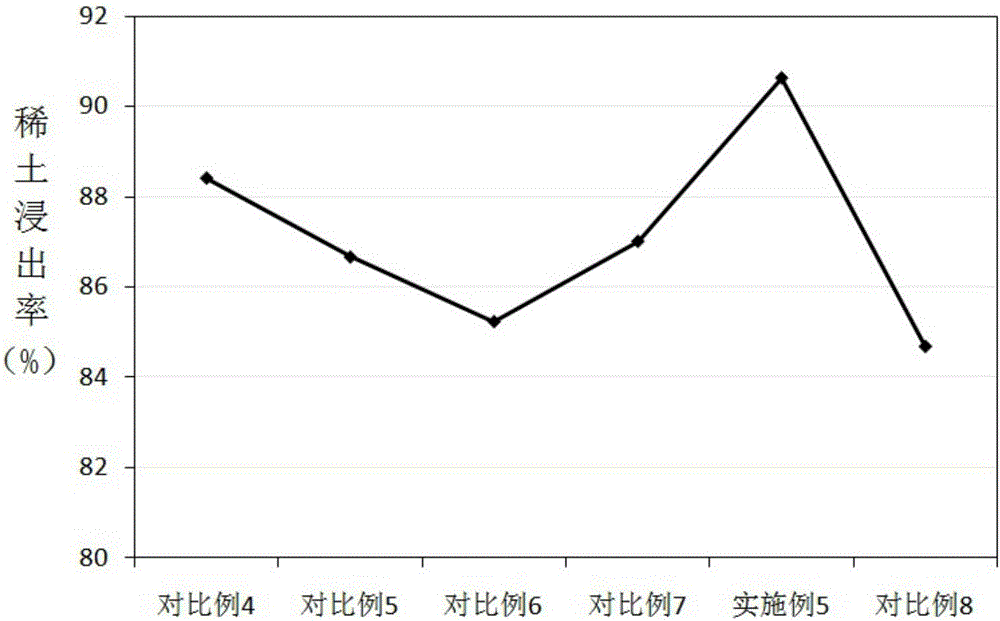

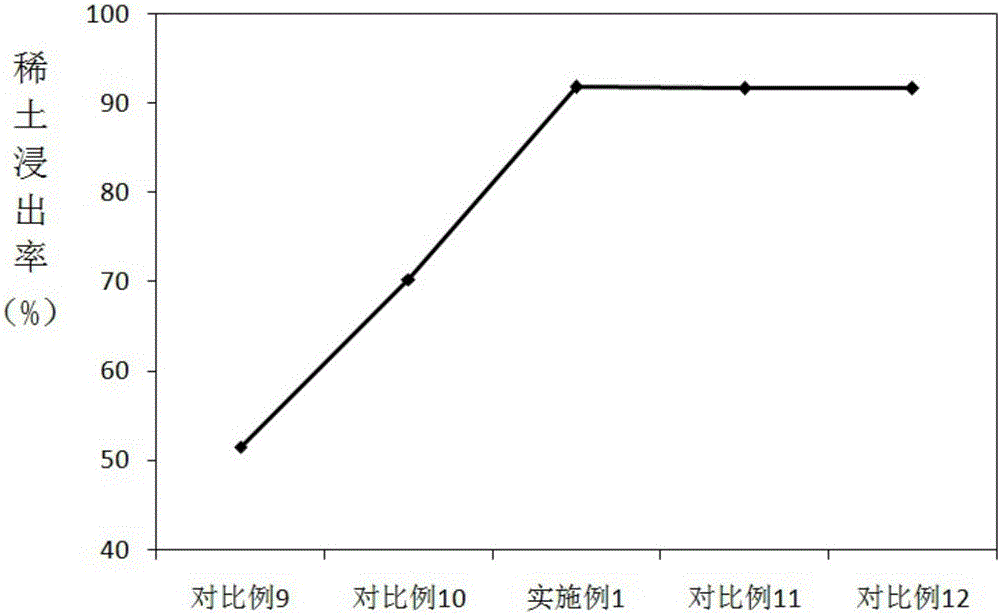

Examples

Embodiment 1

[0031] This embodiment provides a rare earth ore leaching agent, including ammonium thiosulfate, ammonium sulfate, ammonium chloride and water. The mass ratio of the ammonium thiosulfate, the ammonium sulfate and the ammonium chloride is 3:3:4, and the mass concentration of the leaching agent is 1.5wt%.

[0032] A kind of rare earth leaching technique described in the present invention comprises the following steps:

[0033] S1. Add 500g of ion-adsorbed rare earth ore to the leaching column, and the natural ore loading density of the leaching column is 1.4g / cm 3 ;

[0034] In this embodiment, the ion-adsorption type rare earth ore is a test ore sample from a rare earth company in Guangxi. The appearance of the ore sample is yellow sandy soil-like fine particles, and the rare earth grade in the ionic phase is 0.0556%. The rare earth content of the ion adsorption phase in the ion adsorption type rare earth ore accounts for 72.49% of the total rare earth content.

[0035] S2. ...

Embodiment 2

[0039] This embodiment provides a rare earth ore leaching agent, including ammonium thiosulfate, ammonium sulfate, ammonium chloride and water. The mass ratio of the ammonium thiosulfate, the ammonium sulfate and the ammonium chloride is 3:3:4, and the mass concentration of the leaching agent is 1.5wt%.

[0040] A kind of rare earth leaching technique described in the present invention comprises the following steps:

[0041] S1. Add 500g of ion-adsorbed rare earth ore to the leaching column, and the natural ore loading density of the leaching column is 1.4g / cm 3 ;

[0042] In this example, the ion-adsorption type rare earth ore is the Dingnan ion-adsorption type rare earth test ore sample provided by a rare earth company in Ganzhou. Low-yttrium two-rich rare earth ore; the rare earth content of the ion adsorption phase in the ion adsorption rare earth ore accounts for 55.71% of the total rare earth content.

[0043] S2. Leach the ion-adsorption type rare earth ore in the le...

Embodiment 3

[0047] This embodiment provides a rare earth ore leaching agent, including ammonium thiosulfate, ammonium sulfate, ammonium chloride and water. The mass ratio of the ammonium thiosulfate, the ammonium sulfate and the ammonium chloride is 3:3:4, and the mass concentration of the leaching agent is 1.5wt%.

[0048] A kind of rare earth leaching technique described in the present invention comprises the following steps:

[0049] S1. Add 500g of ion-adsorbed rare earth ore to the leaching column, and the natural ore loading density of the leaching column is 1.4g / cm 3 ;

[0050] In this example, the ion-adsorption type rare earth ore adopts the Xinfeng ion-adsorption type rare earth test ore sample provided by a rare earth company in Ganzhou. Low, medium, and medium-sized rare earth ores (in which the rare earth content is low, Eu 2 o 3 and Y 2 o 3 The distribution content is medium); the rare earth content of the ion adsorption phase in the ion adsorption type rare earth ore ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com