High-efficiency treatment method of ballast water in ship

A technology of ship ballast water and treatment method, applied in water treatment device, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of saving floor space, simple process route, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

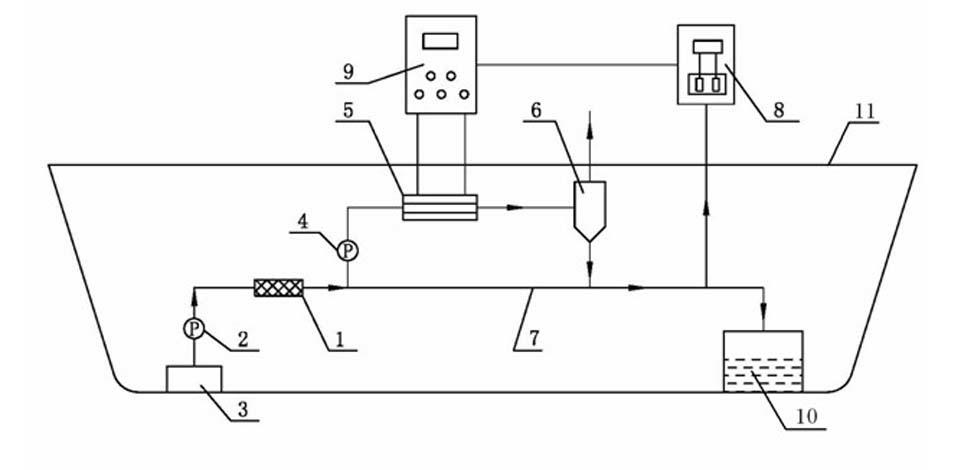

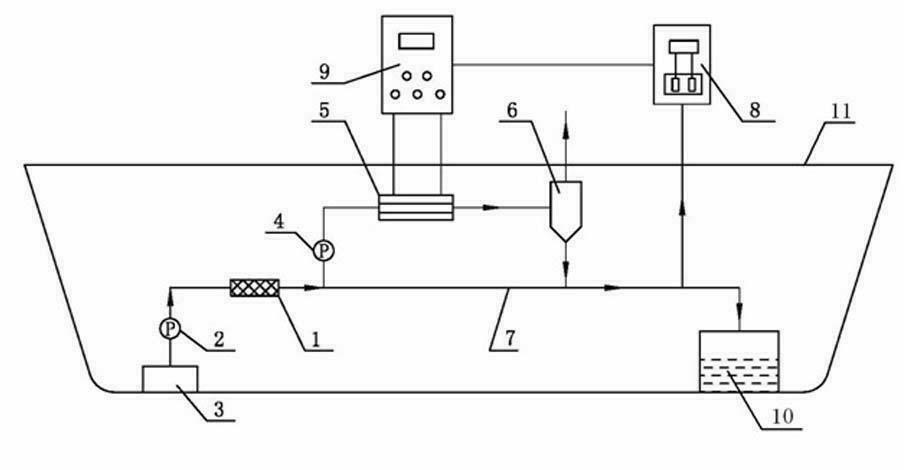

Method used

Image

Examples

Embodiment 1

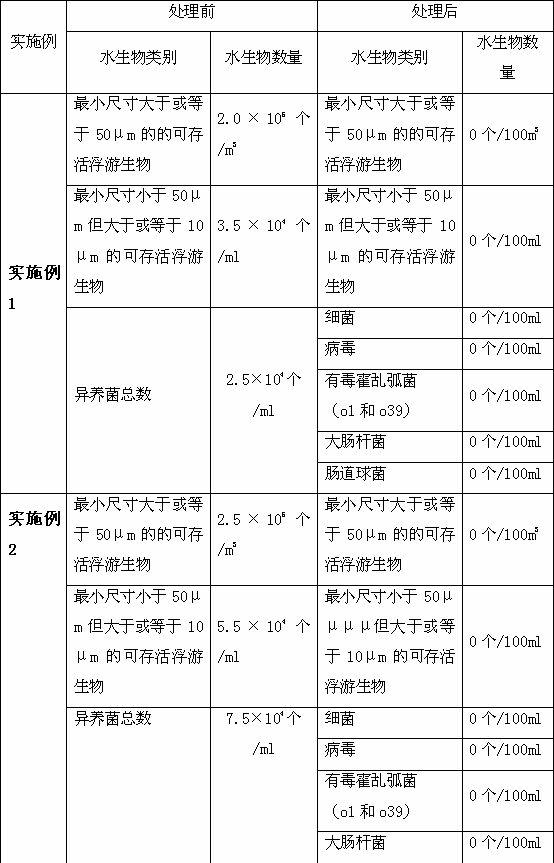

[0046] Example 1: First use an automatic backwash filter with a filtration precision of 30 μm for filtration, and then use 10 mg / L sodium hypochlorite generated by electrolysis for inactivation.

Embodiment 2

[0047] Example 2: First use an automatic backwash filter with a filtration precision of 40 μm for filtration, and then use 15 mg / L sodium hypochlorite generated by electrolysis for inactivation.

Embodiment 3

[0048] Example 3: First use an automatic backwash filter with a filtration precision of 35 μm for filtration, and then use 12 mg / L sodium hypochlorite generated by electrolysis for inactivation.

[0049] Table 1 Ballast water treatment effect of three examples

[0050]

[0051] In order to overcome the shortcomings in the existing ship ballast water treatment technology, the present invention adopts a treatment method of "high-efficiency filtration + branch electrolysis inactivation treatment". The process route of the method is simple, the volume of the system is small, and the occupied area is more than 30% less than that of the existing system. Due to the branch electrolysis, all the hydrogen can be removed, which eliminates potential safety hazards and is easy to install. Experiments have verified that the method of the present invention can completely kill aquatic organisms in ballast water, and the number of remaining survivable organisms of various sizes is zero, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com