Polyester resin with high acid value and low acid value for environment-friendly dry blended low-gloss powder coating and preparation method thereof

A technology of powder coatings and polyester resins, applied in powder coatings, polyester coatings, coatings, etc., to achieve good mechanical properties, excellent matting effects, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

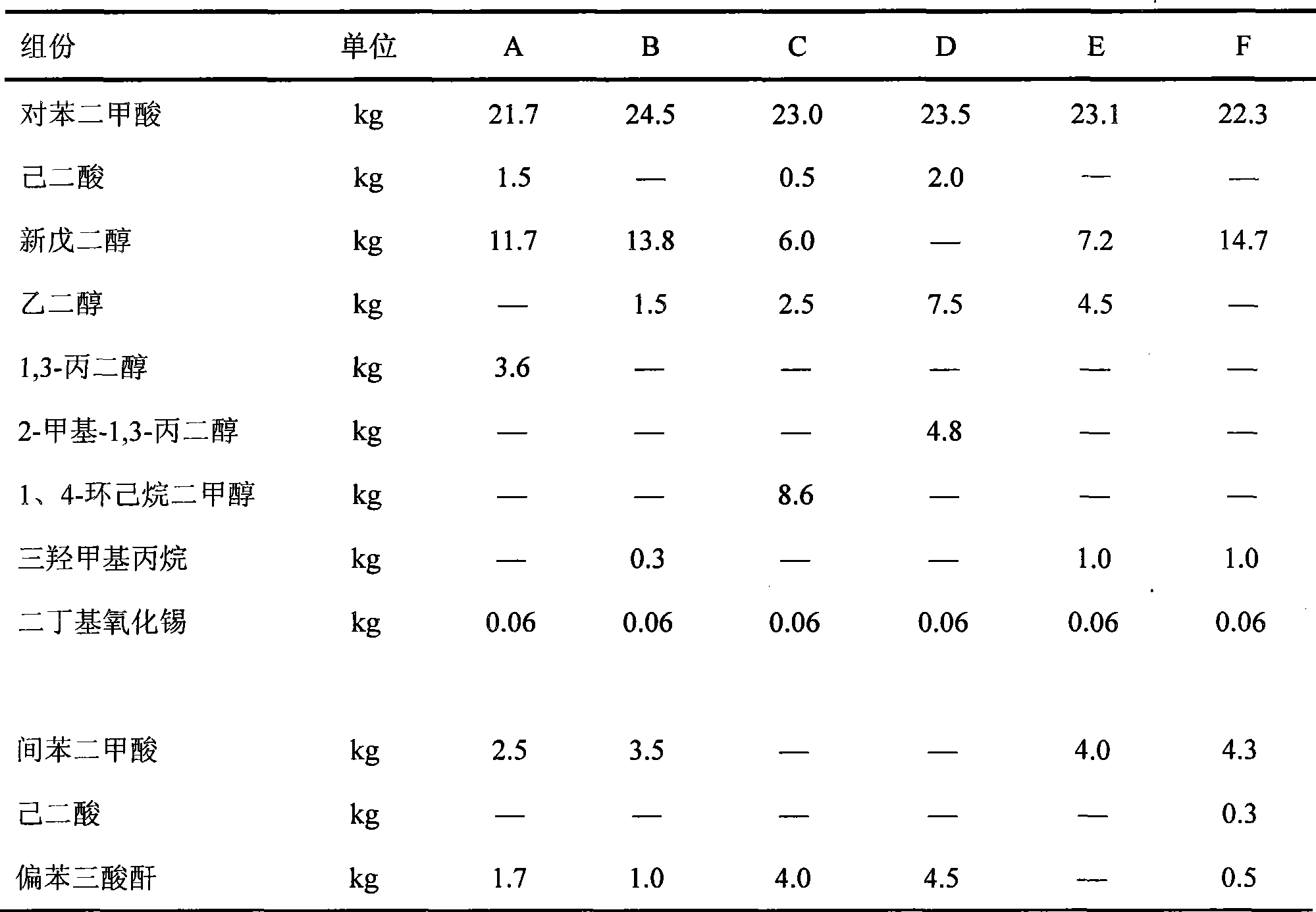

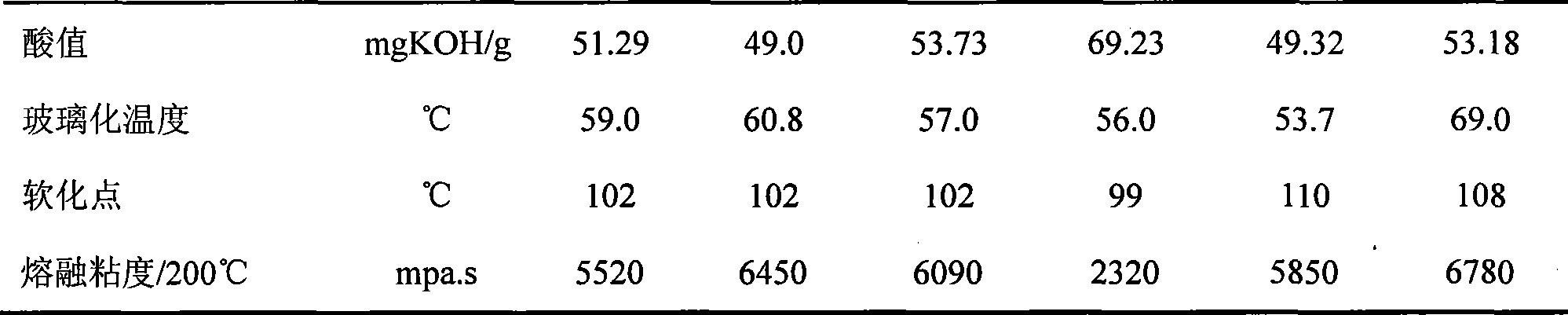

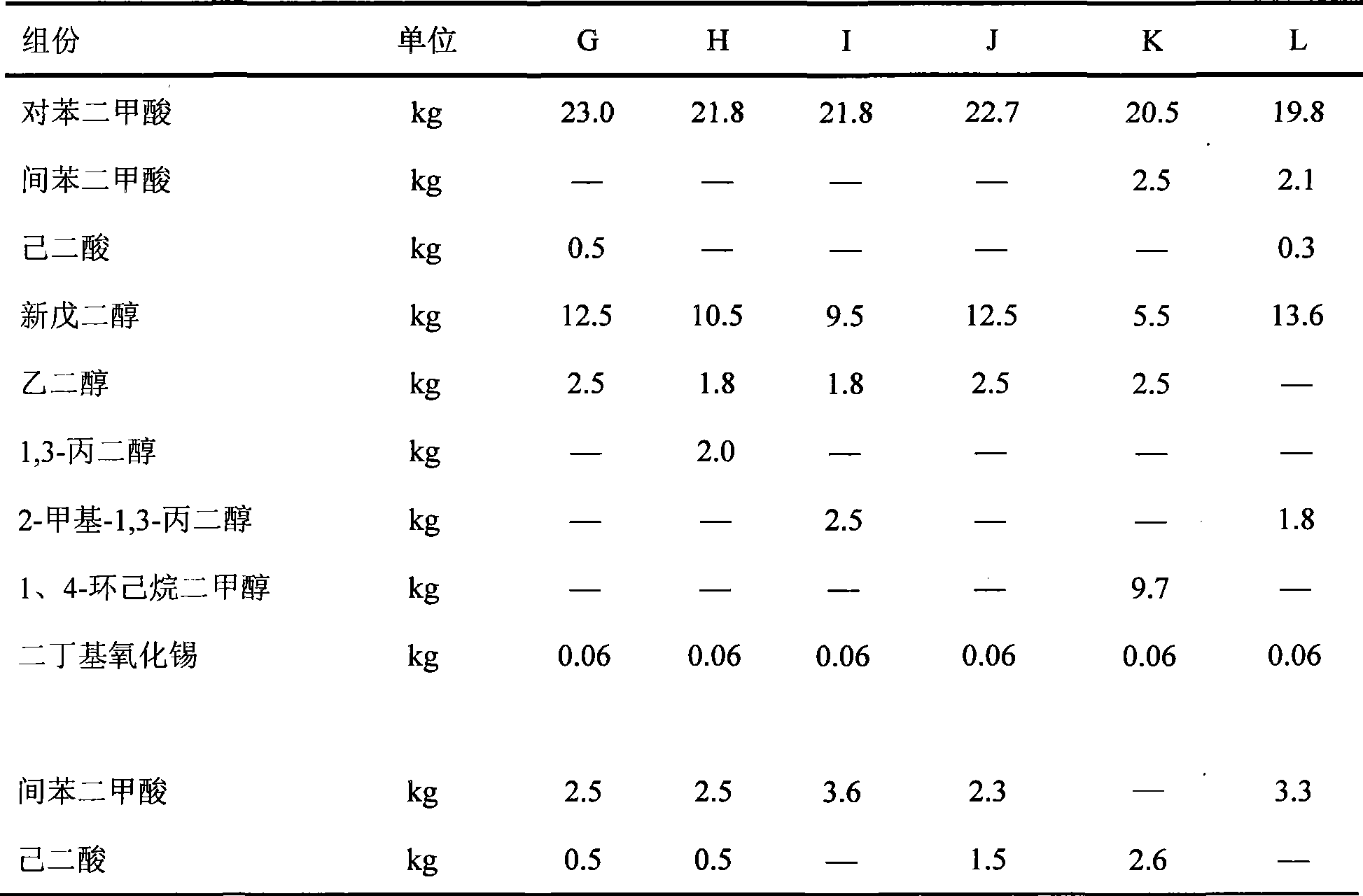

[0015] Some specific examples are listed below to illustrate the present invention. Table 1 is an example of high acid value polyester resin, and A to F are comparative examples of different monomers and process combinations. In a 50-liter reactor, add neopentyl glycol, 1,3-propanediol, 2-methyl-1,3-propanediol, ethylene glycol, 1,4-cyclohexanediol in the ratio listed in Table 1 Methanol and trimethylolpropane are heated until the materials are melted; then terephthalic acid, adipic acid, and dibutyltin oxide are added in sequence, and the reaction is continued with nitrogen gas, and esterification water begins to be formed and distilled out at about 180°C. Then gradually raise the temperature to 250°C, react for 5-10 hours until 95% of the esterified water is discharged, the acid value reaches 9-27 mgKOH / g, A-B, add isophthalic acid, react for 3-5 hours, the acid value reaches 40~50mgKOH / g, vacuum polycondensation for about 1~4h, the acid value reaches 28~35mgKOH / g, add trime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com