Preparation method for high polymer composite zirconia mobile phone back cover

A technology of composite zirconia and mobile phone back cover, which is applied in the field of ceramics, can solve the problems of improving toughness and molding characteristics, and achieve the effects of increasing toughness and molding characteristics, reducing energy efficiency loss, and lowering sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

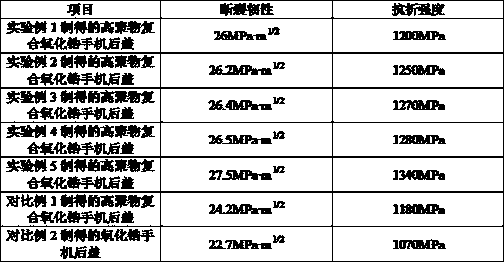

Examples

Embodiment 1

[0028] A method for preparing a high polymer composite zirconia mobile phone back cover, comprising the following steps:

[0029] (1) Prepare raw materials: The raw materials and parts by weight for preparing the polymer composite zirconia mobile phone back cover include: 5 parts of mullite whiskers, 50 parts of zirconia powder, 15 parts of high polymer, 5 parts of filler Parts, 5 parts of plasticizer; High polymer is the copolymer of polyethylene terephthalate and polybutylene terephthalate; Plasticizer is methyl oxide acetyl linoleate;

[0030] (2), adding the mullite whiskers in the parts by weight into 40wt% ethylene glycol aqueous solution, stirring evenly to form a suspension with a mass fraction of 8%, and then adding the zirconia powder in the parts by weight, Mix well to form a precursor suspension;

[0031] (3) Transfer the precursor suspension formed in (2) to a hydrothermal kettle, react for 1 hour at a temperature of 160ºC and a pressure of 0.2MPa, and wash and d...

Embodiment 2

[0035] A method for preparing a high polymer composite zirconia mobile phone back cover, comprising the following steps:

[0036] (1) Prepare raw materials: The raw materials and parts by weight for preparing the polymer composite zirconia mobile phone back cover include: 8 parts of mullite whiskers, 80 parts of zirconia powder, 30 parts of high polymer, 10 parts of filler Parts, 8 parts of plasticizer; High polymer is the copolymer of polyethylene terephthalate and polybutylene terephthalate; Plasticizer is epoxy butyl furfurate;

[0037] (2), adding the mullite whiskers in the parts by weight into a 60wt% ethylene glycol aqueous solution, stirring evenly to form a suspension with a mass fraction of 10%, and then adding the zirconia powder in the parts by weight, Mix well to form a precursor suspension;

[0038] (3) Transfer the precursor suspension formed in (2) to a hydrothermal kettle, react for 2 hours at a temperature of 180ºC and a pressure of 0.8MPa, and wash and dry ...

Embodiment 3

[0042] A method for preparing a high polymer composite zirconia mobile phone back cover, comprising the following steps:

[0043] (1) Preparation of raw materials: The raw materials and parts by weight for preparing the polymer composite zirconia mobile phone back cover include: 5.5 parts of mullite whiskers, 60 parts of zirconia powder, 18 parts of high polymer, and 6 parts of filler Parts, 6 parts of plasticizer; High polymer is the copolymer of polyethylene terephthalate and polybutylene terephthalate; Plasticizer is epoxy octyl soybean oleate;

[0044] (2), adding the mullite whiskers in the parts by weight into a 50wt% aqueous solution of ethylene glycol, stirring evenly to form a suspension with a mass fraction of 9%, and then adding the zirconia powder in the parts by weight, Mix well to form a precursor suspension;

[0045] (3) Transfer the precursor suspension formed in (2) to a hydrothermal kettle, react for 1.5 hours under the conditions of temperature 170ºC and pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com