A kind of hybrid polyester resin for indoor thermal transfer matt powder coating and preparation method thereof

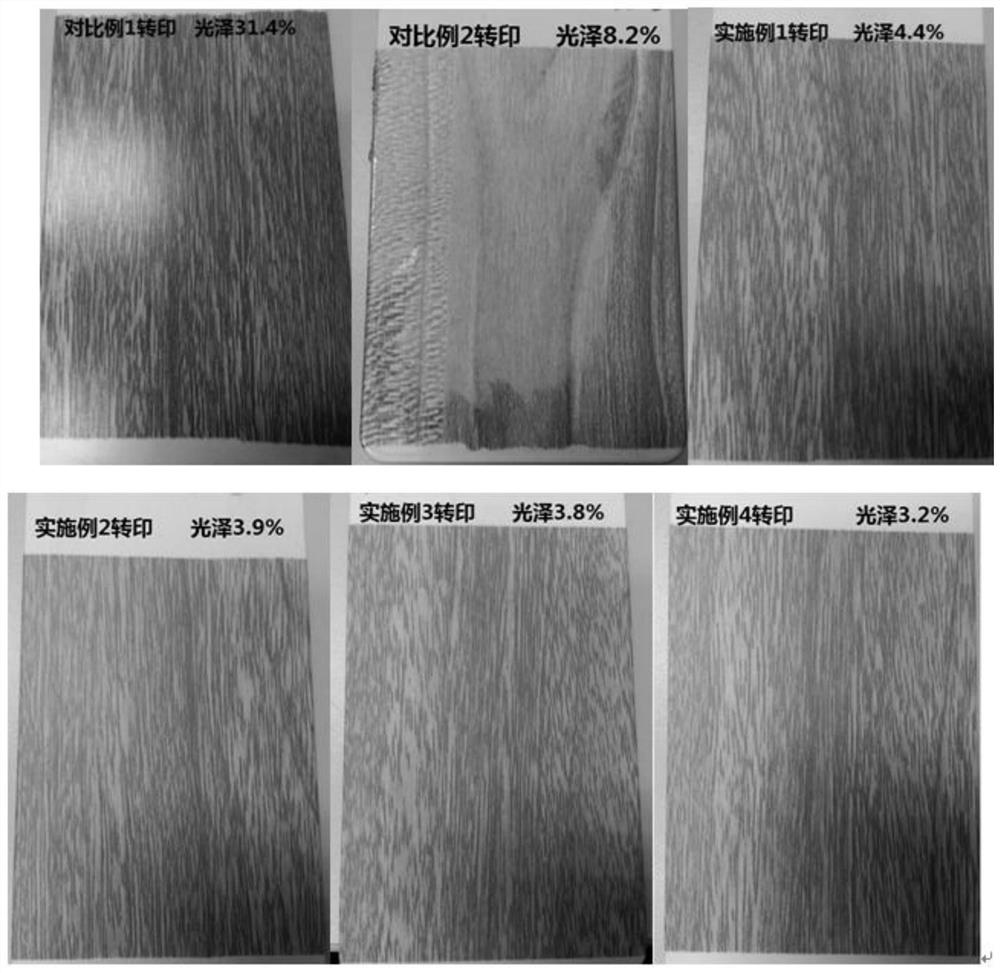

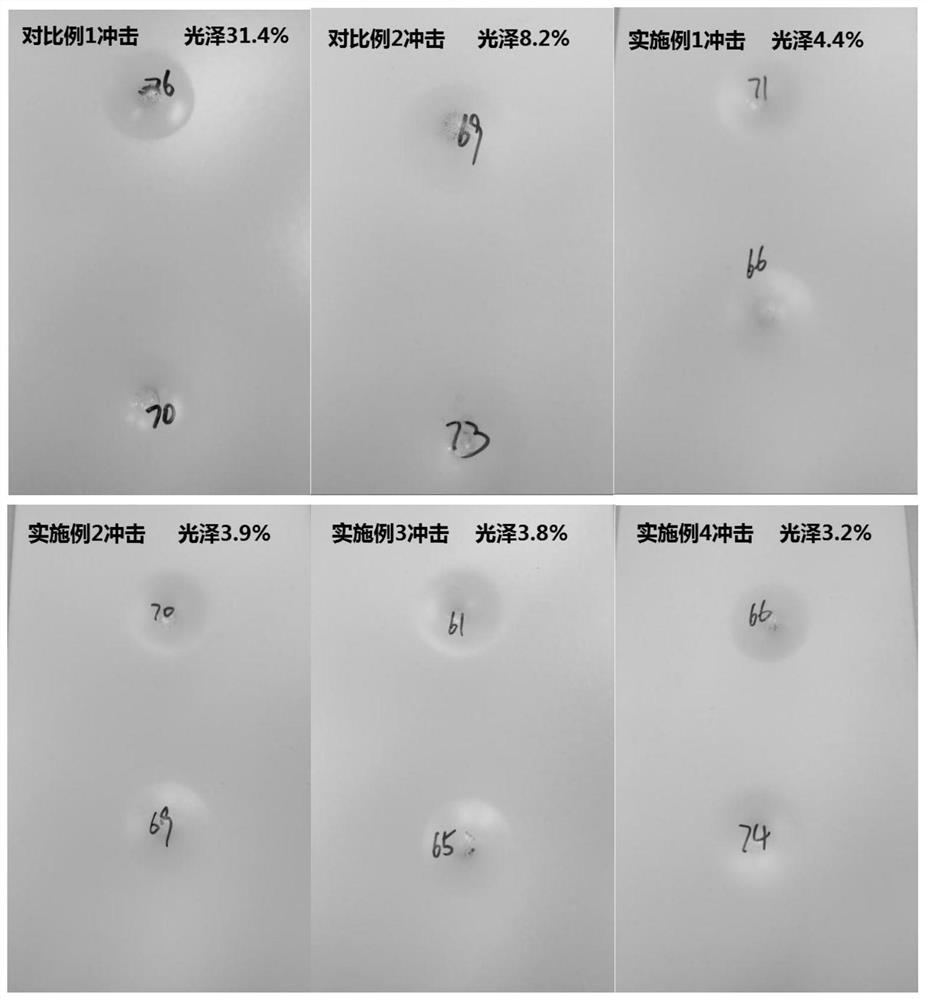

A powder coating and polyester resin technology, applied in the field of polyester resin, can solve the problems of unusable thermal transfer printing, poor impact resistance of coating, poor matting performance, etc., and achieve excellent transfer effect and stable matting performance , low gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are only used to illustrate the present invention, and do not limit the protection scope of the present invention. Those skilled in the art can achieve the purpose of the present invention according to the scope disclosed above.

[0028] The present invention will be described below with reference to the examples, and Table 1 is the examples of polyester resins. The monomer components and their amounts are shown in Table 1.

[0029] The preparation method of mixed polyester resin for indoor thermal transfer matt powder coating is as follows:

[0030] In the reactor, add neopentyl glycol, ethylene glycol, diethylene glycol and trimethylolpropane in the proportions listed in table 1, heat and heat up to the melting of the material; then add terephthalic acid, stearic acid or hexamethylene glycol Diacid, butyl tin oxide, pass nitrogen and continue to heat up the reaction, esterification water starts to generate and distill out at about 180 ° C, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com