Method for separating and enriching trace phthalates by using pyridine type ionic liquid aqueous two-phase system

A two-phase aqueous system and phthalic acid technology, applied in the preparation of test samples, etc., can solve the problems of difficulty in popularization, low sensitivity, and high cost, and achieve high recovery, wide linear range, and small standard deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

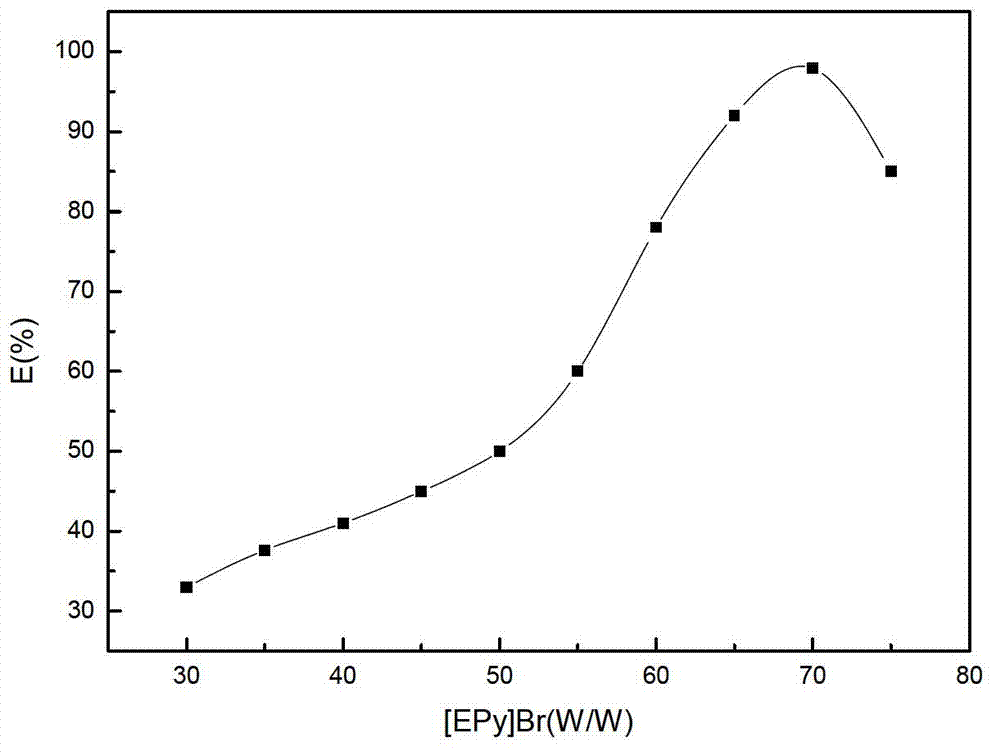

Embodiment 1

[0039] Take 39 g of [EPy]Br ionic liquid, place it in a 60 ml Erlenmeyer flask, add 10.89 g of C 4 o 6 h 4 KNa, add 2 ml dibutyl phthalate standard solution and 10 ml distilled water, mix well. At 25 °C and pH 5.0, vibrate and extract in a constant temperature oscillator for 2.5 h and then let it stand still. After the phase separation is clear, measure the concentration of residual dibutyl phthalate in the water phase, from the dibutyl phthalate in the water phase before and after extraction. The content of dibutyl formate calculates the extraction rate of dibutyl phthalate to be 94.67%.

Embodiment 2

[0041] Take 49 g of [EPy]Br ionic liquid, place it in a 60 ml Erlenmeyer flask, add 10.15 g of C 4 o 6 h 4 KNa, add 2 ml dibutyl phthalate standard solution and 10 ml distilled water, mix well. At 15 °C and pH 5.4, vibrate and extract in a constant temperature oscillator for 3 h and then let it stand still. After the phase separation is clear, measure the concentration of residual dibutyl phthalate in the water phase, from the dibutyl phthalate in the water phase before and after extraction. The content of dibutyl formate calculates the extraction rate of dibutyl phthalate to be 95.53%.

Embodiment 3

[0043] Take 39 g of [EPy]Br ionic liquid, place it in a 60 ml Erlenmeyer flask, add 7.96 g of C 4 o 6 h 4KNa, add 2 ml dibutyl phthalate standard solution and 10 ml distilled water, mix thoroughly. Under the conditions of 15 ℃ and pH 5.9, shake and extract in a constant temperature oscillator for 2.5 h and then let it stand still. After the phase separation is clear, the ionic liquid and the water phase are separated, and 39 g of [EPy]Br ionic liquid is added to the water phase , after repeating this three times, measure the concentration of residual dibutyl phthalate in the water phase, calculate the extraction rate of dibutyl phthalate from the content of dibutyl phthalate in the water phase before and after extraction to be 95.98 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com