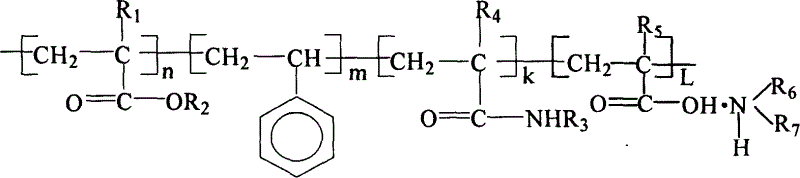

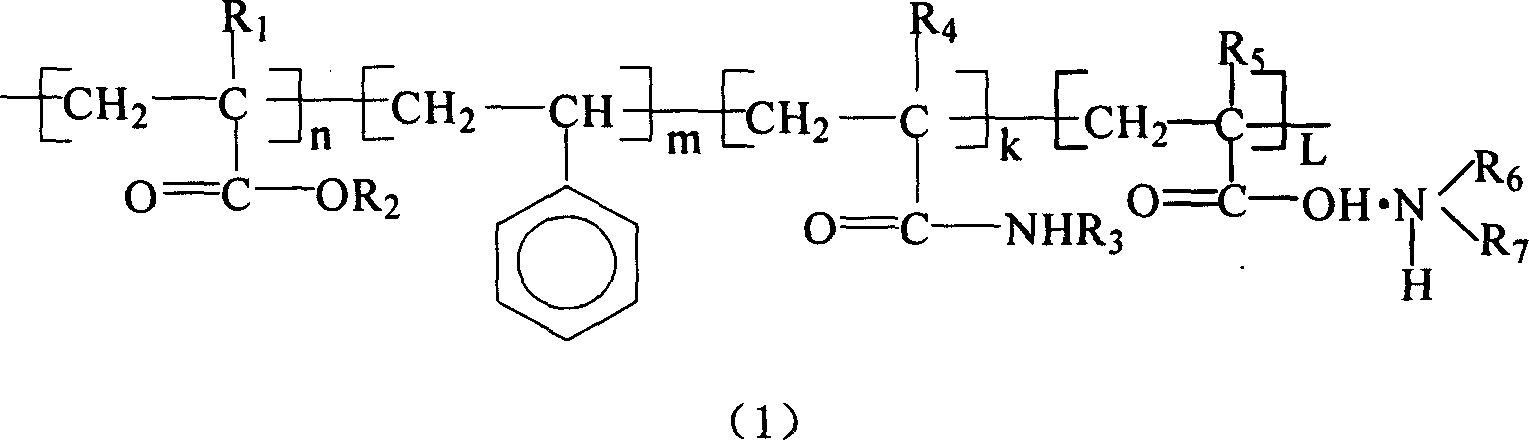

Copolymer for diesel low temperature flow promoter and its preparing method

A technology of low-temperature fluidity and copolymers, applied in the direction of lubricating compositions, etc., can solve the problems of complex preparation methods of copolymers, pollute the environment, etc., and achieve the effect of reducing cold filtration point and freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 3 mol of butyl acrylate, 1 mol of acrylic acid, 1 mol of styrene, toluene or ethanol as solvent, in Co 60 Under radiation source irradiation, polymerize at 50-80°C for 4 hours, lauryl alcohol, 16 amine, 1% by weight (relative to the total mass of reactants) of p-toluenesulfonic acid or strongly acidic ion exchange resin at 120-140°C After esterification and amidation for 8 hours, the water generated by the amine salification reaction is azeotropically distilled off with the solvent. The number average molecular weight is several hundred to 15,000, and the molecular weight distribution is 2.10 to 2.30. Acrylate copolymer infrared spectrum (coating method) data are as follows: main absorption peaks: 2956.5, 2918.6, 2849.3cm -1 , ν C-H (CH 3 , CH 2 ); 1739.5cm -1 , ν C=O (ester); 1656.6, v C=O (amide); 1617.0, v C=O (Amine salt part); 1471.9, 1462.6, ν of benzene ring C=C ;720cm -1 , δ of C-C .

[0023] To obtain 5 parts of acrylate copolymer, add 5 parts of E...

Embodiment 2

[0026] 2 mol of styrene, 7 mol of butyl acrylate, 6 mol of methyl methacrylate, 3 mol of acrylic acid, toluene, benzene or n-hexane, Co 60 , 50 ~ 80 ℃ polymerization reaction 5 ~ 6hr. Lauryl alcohol, 16-18 alcohol, 16 amine, 1% p-toluenesulfonic acid or strong acid ion exchange resin, 120°C-140°C, esterification, amidation, amine salification to remove the corresponding moisture. The number-average molecular weight of the obtained copolymer is 10000-30000, and the molecular weight distribution is 2.0-3.0.

[0027] C 16 ~C 18 Alcohol carbon number distribution: C 14 5%, C 16 20%, C 18 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com