Preparation process and device of high functional whole egg powder

A preparation process and preparation device technology, which is applied in the field of high-functional whole egg powder preparation process and preparation device, can solve the problems of whole egg powder emulsification and low foaming performance, and achieve the improvement of foaming performance, reduction of impact, The effect of improving foaming and emulsifying properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

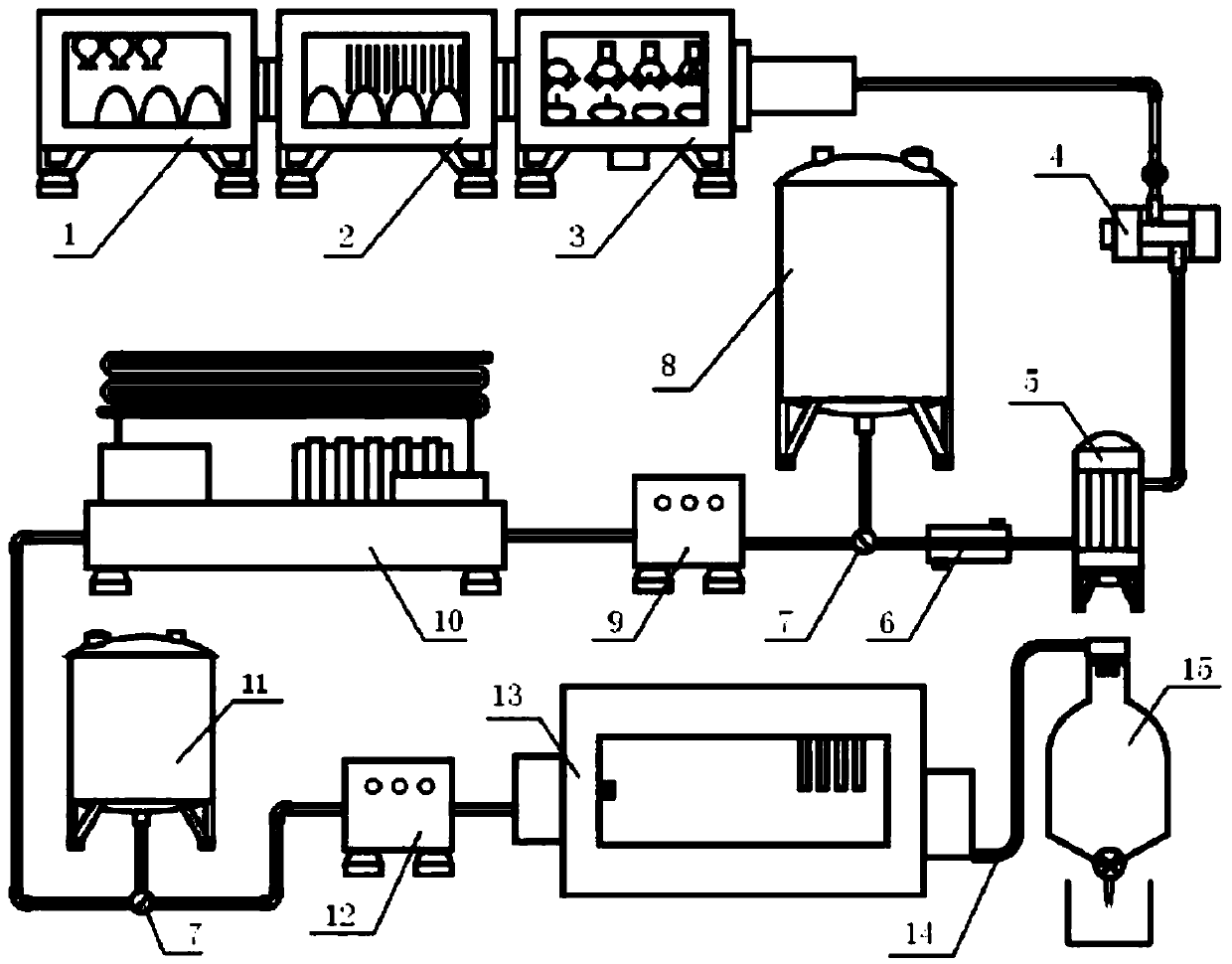

[0024] A preparation process for high-functional whole egg powder, comprising the following processes:

[0025] a. Egg cleaning: the sorted fresh eggs are placed in the egg tray of the egg loading machine 1, and are transported to the egg loading machine 1 by the conveyor belt. attached dirt;

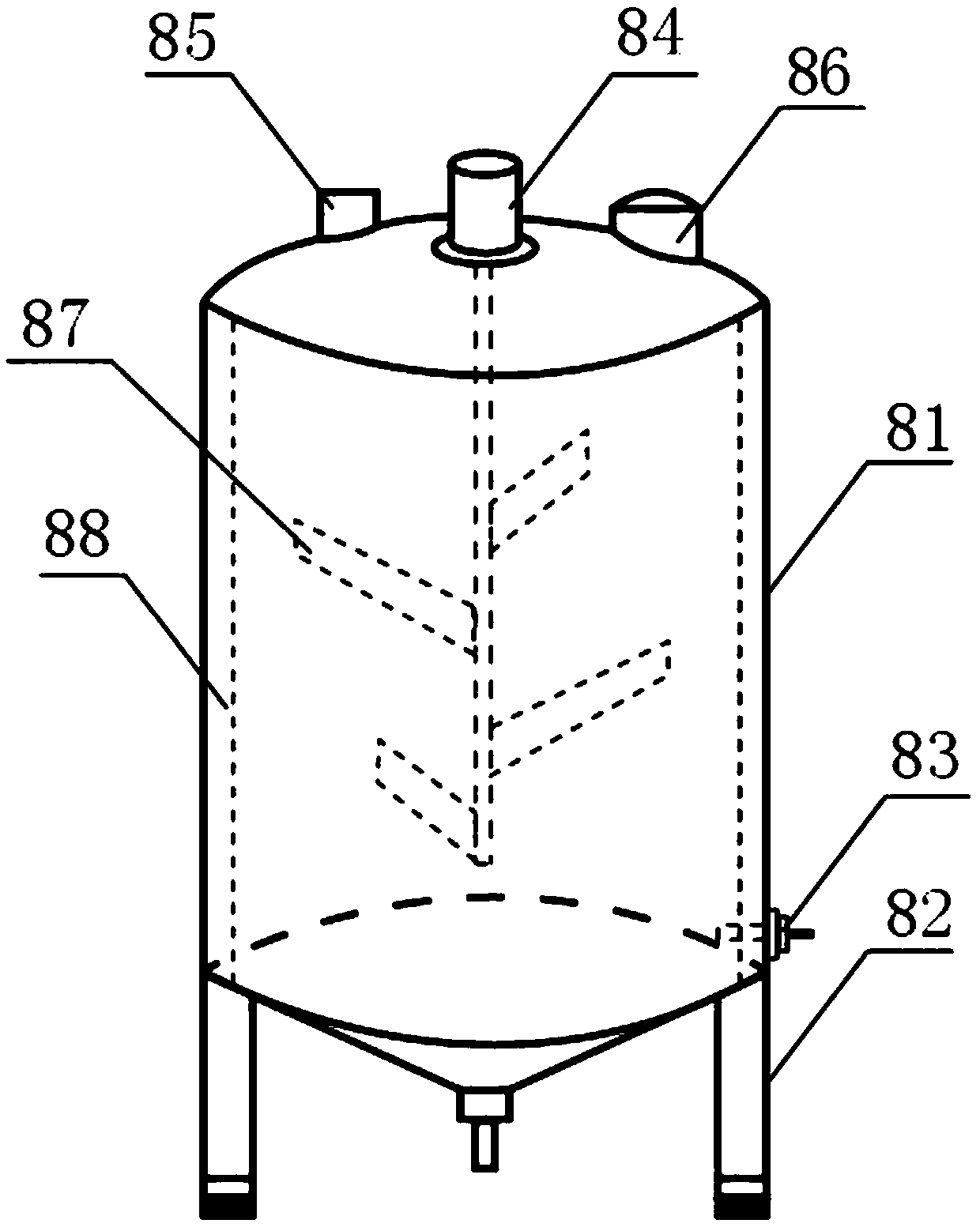

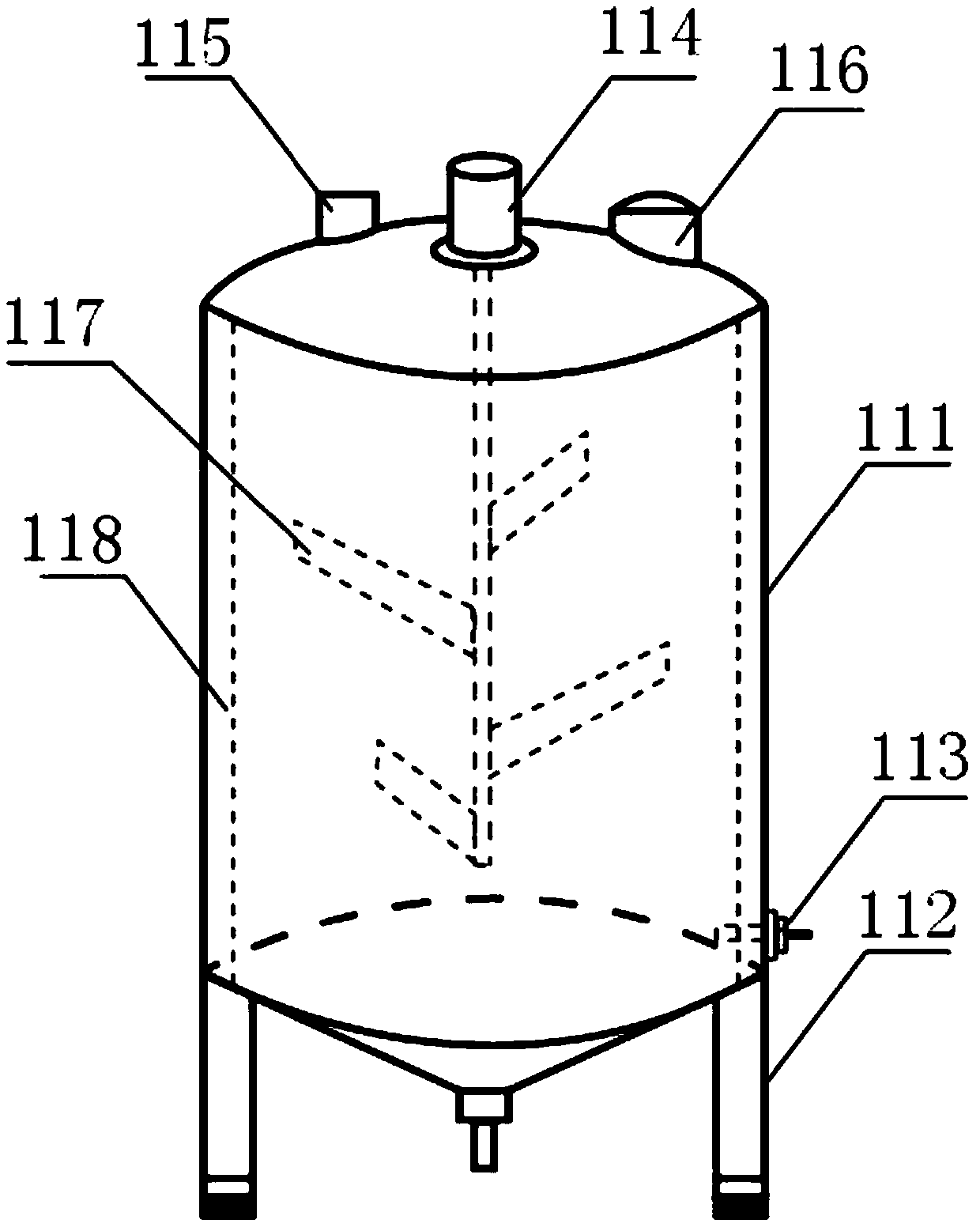

[0026] b. Shelling and separation: the shell is broken by the egg beater 3, the shell and the liquid are separated, and the egg liquid is filtered and stored in the fermenter 8;

[0027] c. Biological fermentation: Add yeast and protease to the fermenter 8 for storing egg liquid for fermentation. The total mass of yeast and protease added is 0.02% of the mass of the whole egg liquid, and the mass ratio of yeast and protease is 1:1 , the fermentation temperature is 28°C, and the fermentation time is 8 hours;

[0028] d. Homogenization: use a pressure type homogenizer 9, the homogenization pressure is 9MPa, and the processing time is 1s;

[0029] e. Low-temperature sterilization: the f...

Embodiment 2

[0032] A preparation process for high-functional whole egg powder, comprising the following processes:

[0033] a. Egg cleaning: the sorted fresh eggs are placed in the egg tray of the egg loading machine 1, and are transported to the egg loading machine 1 by the conveyor belt. attached dirt;

[0034] b. Shelling and separation: the shell is broken by the egg beater 3, the shell and the liquid are separated, and the egg liquid is filtered and stored in the fermenter 8;

[0035] c. Biological fermentation: add yeast and protease to the fermenter 8 storing the egg liquid for fermentation, the total mass of yeast and protease added is 0.05% of the mass of the whole egg liquid, and the mass ratio of yeast and protease is 2:1 , the fermentation temperature is 33°C, and the fermentation time is 10h;

[0036] d. Homogenization: use a pressure type homogenizer 9, the homogenization pressure is 11MPa, and the processing time is 1s;

[0037] e. Low-temperature sterilization: the ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com