Surface treatment method for aluminum or aluminum alloy and product prepared thereby

A technology for surface treatment and aluminum alloy, which is applied in the field of surface treatment of aluminum or aluminum alloy and products obtained by the method, can solve the problem of falling off of chemical nickel plating layer, increase pollution of chemical nickel plating treatment, and shorten the service life of chemical plating solution And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Degreasing treatment: The degreasing liquid contains 30g / L sodium phosphate, 25g / L sodium carbonate and 8g / L sodium silicate, the treatment temperature is 70-75℃, and the treatment time is 2-5min.

[0030] The first activation treatment: the activation solution is hydrochloric acid solution, wherein the volume ratio of hydrochloric acid to water is 1:4, the temperature of the activation solution is room temperature, and the activation time is 6-30s.

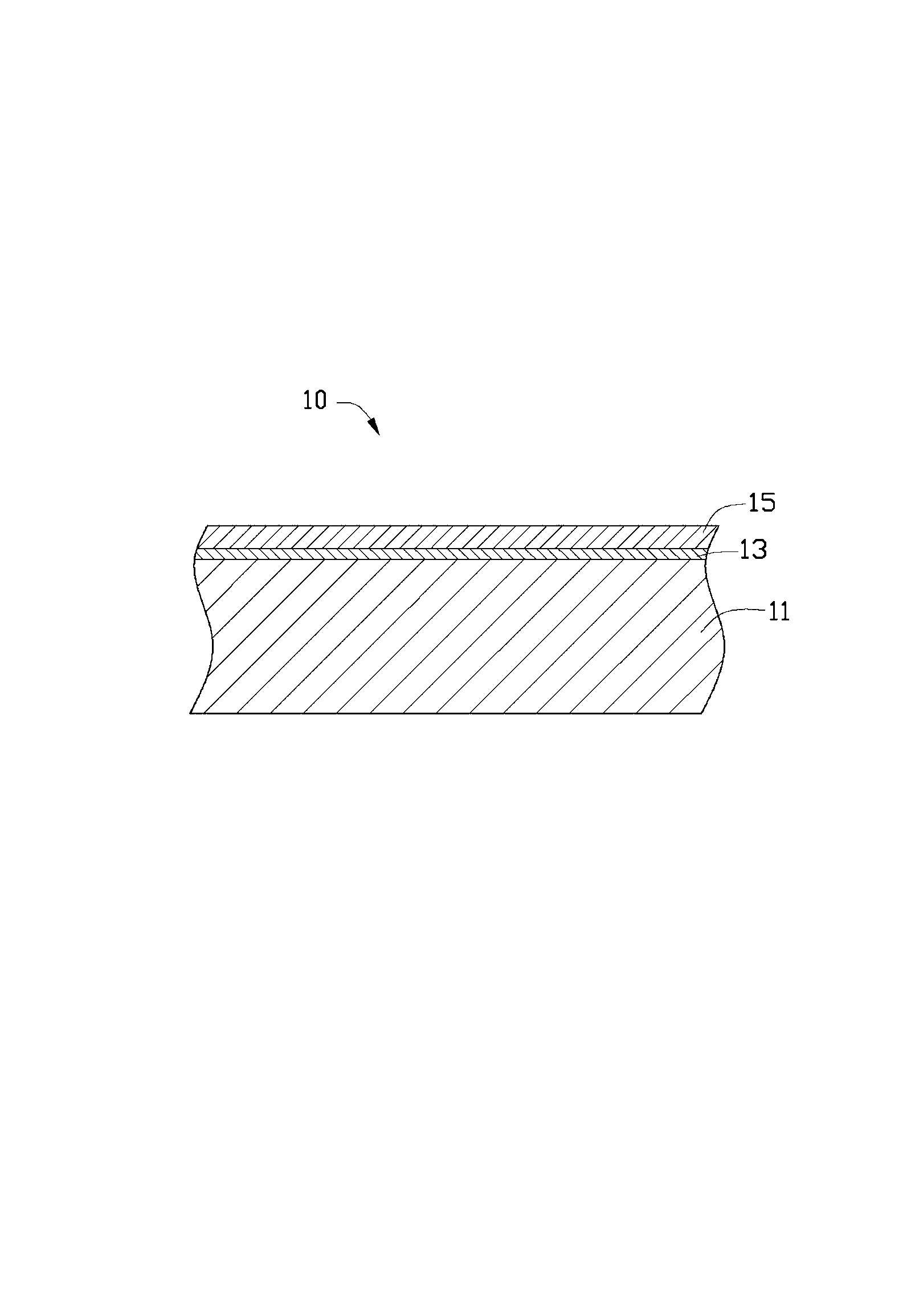

[0031] Acid etching treatment: immerse the aluminum or aluminum alloy substrate 11 in a nitric acid aqueous solution for 3 seconds, and the temperature of the nitric acid aqueous solution is room temperature. The volume ratio of nitric acid and water in the nitric acid aqueous solution is 1:3.

[0032] The method of the second activation treatment is: use sulfuric acid solution as the activation solution, the mass percentage of the sulfuric acid solution is 10%, the temperature of the activation solution is room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com