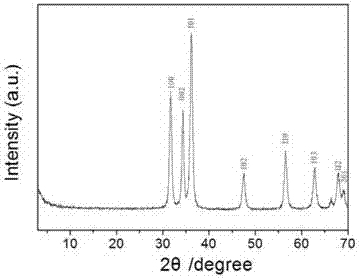

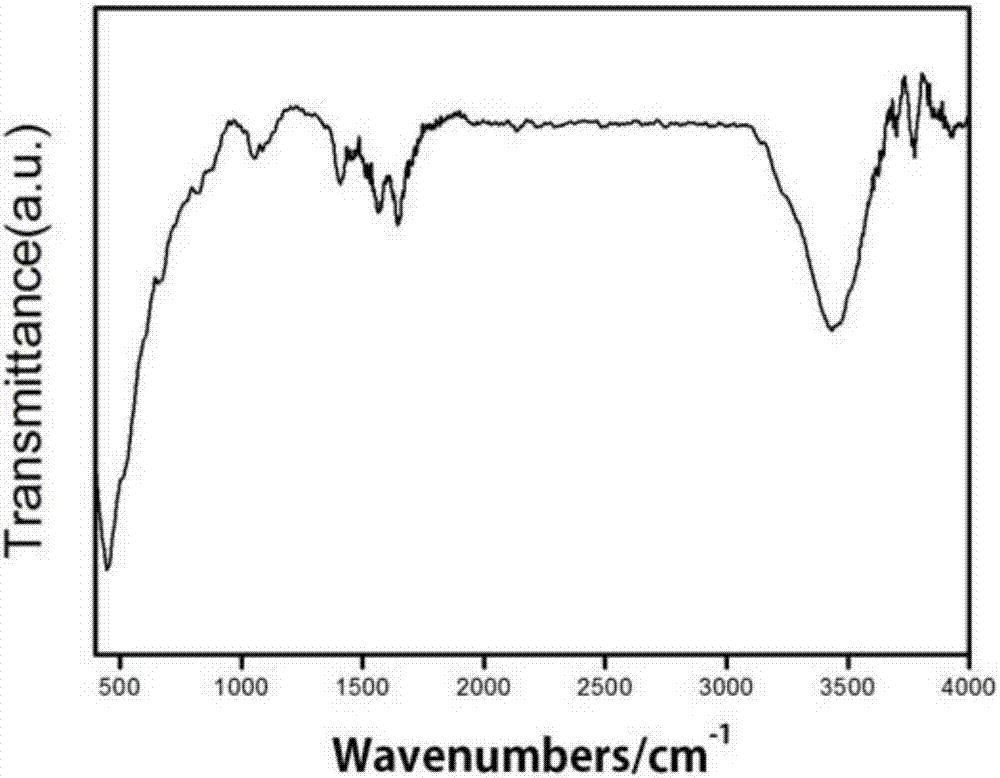

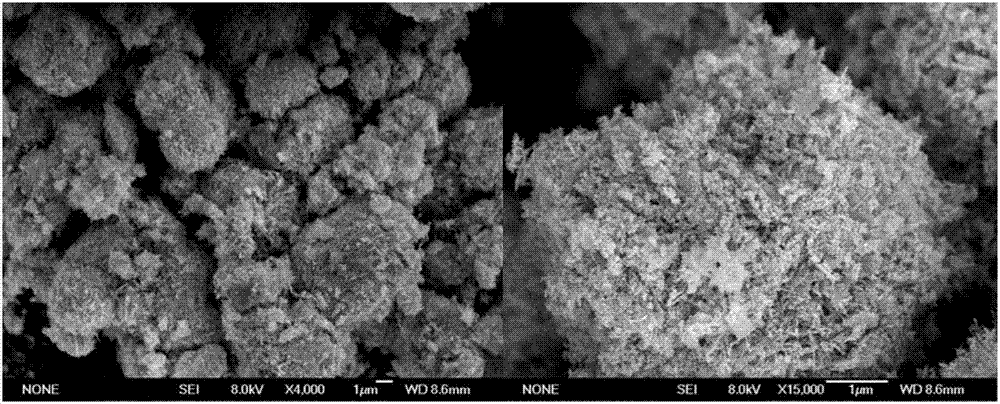

g-C3N4/ZnO nano-sheet multi-level heterogeneous structure photocatalyst and preparation method thereof

A heterogeneous structure, photocatalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as difficult preparation of g-C, achieve high catalytic efficiency, low cost, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Dissolve 1.0 g of acidified carbon nitride in water, add 0.007 g of potassium sodium tartrate, 0.28 g of zinc acetate, and 0.4 g of urea, react at 90°C for 12 hours, separate and wash;

[0016] (2) After drying the product obtained in step (1), raise the temperature to 300°C at a heating rate of 1°C / min and keep it warm for 0.5h to obtain g-C 3 N 4 / ZnO Nanosheet Hierarchical Structured Photocatalyst.

Embodiment 2

[0018] (1) Dissolve 0.5 g of acidified carbon nitride in water, add 0.007 g of potassium sodium tartrate, 0.28 g of zinc acetate, and 0.4 g of urea, react at 90°C for 12 hours, separate and wash;

[0019] (2) After drying the product obtained in step (1), raise the temperature to 300°C at a heating rate of 1°C / min and keep it warm for 0.5h to obtain g-C 3 N 4 / ZnO Nanosheet Hierarchical Structured Photocatalyst.

Embodiment 3

[0021] (1) Dissolve 2.0 grams of acidified carbon nitride in water, add 0.007 grams of potassium sodium tartrate, 0.28 grams of zinc acetate, and 0.4 grams of urea, react at 90°C for 12 hours, separate and wash;

[0022] (2) After drying the product obtained in step (1), raise the temperature to 300°C at a heating rate of 1°C / min and keep it warm for 0.5h to obtain g-C 3 N 4 / ZnO Nanosheet Hierarchical Structured Photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com