Low-foam water-based diamond wire cutting liquid

A technology of cutting fluid and water soaking, which is applied in the petroleum industry, lubricating compositions, etc., and can solve problems such as fine powder agglomeration, edge defects, and line marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Low-foaming polyether, using propylene glycol or propylene glycol as the initiator, and then completes the addition polymerization with ethylene oxide, the molecular weight is about 2500, EO accounts for 70%, and the proportion is 8%;

[0025] Polyether-modified polysiloxane, the molecular weight of silicone oil is 100,000, the molecular weight of polyether is 500, and the content of EO is 30%, accounting for 5%;

[0026] The emulsifier uses isomeric tridecanol polyoxyethylene ether and isooctyl alcohol polyoxyethylene ether mixed in a ratio of 2:3, accounting for 5%;

[0027] The pH regulator is triethanolamine, adjusted to pH 6.5-7;

[0028] The complexing agent is sodium gluconate, accounting for 2%;

[0029] The extrusion agent is preferably sodium silicate, accounting for 0.2%-1.5%;

[0030] Water 70% ~ 95%.

Embodiment 2

[0032] Low-foaming polyether, using propylene glycol or propylene glycol as the initiator, and then completes the addition polymerization with ethylene oxide, the molecular weight is about 2360, EO accounts for 65%, accounting for 5%;

[0033] Polyether-modified polysiloxane, which is synthesized from silicone oil with a hydrogen content of about 1.5%, and a molecular weight of 2000 polyether, with a ratio of about 4%;

[0034] The emulsifier uses isomeric decanol polyoxyethylene ether, isomeric tridecyl alcohol polyoxyethylene ether, and isooctanyl polyoxyethylene ether, and the ratio is 1:2:1, accounting for about 2%;

[0035] The PH regulator uses amp-95 to maintain the PH value at about 6.5-7;

[0036] The complexing agent is sodium gluconate, accounting for 2%;

[0037] The extrusion agent is preferably sodium silicate, accounting for 0.2%-1.5%;

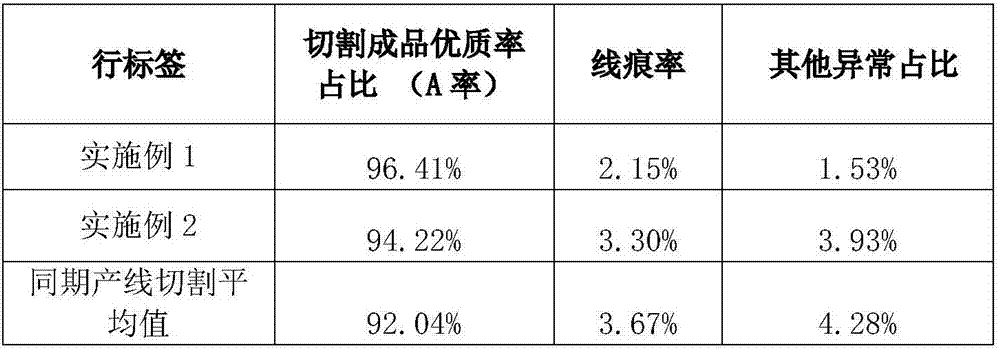

[0038] The use effect comparison of embodiment one and embodiment two is shown in the following table:

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com