Liquid milk and preparation method thereof

A technology for liquid milk and concentrated milk, which is applied in milk preparations, other dairy products, dairy products, etc., can solve the problem of neglecting calcium ion strengthening, increasing the number and activity of osteoblasts and osteoclasts, and affecting the stability of the milk system. , the taste of the product is sticky and other problems, to achieve the effect of good taste and flavor, increased quantity and activity, and easy digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

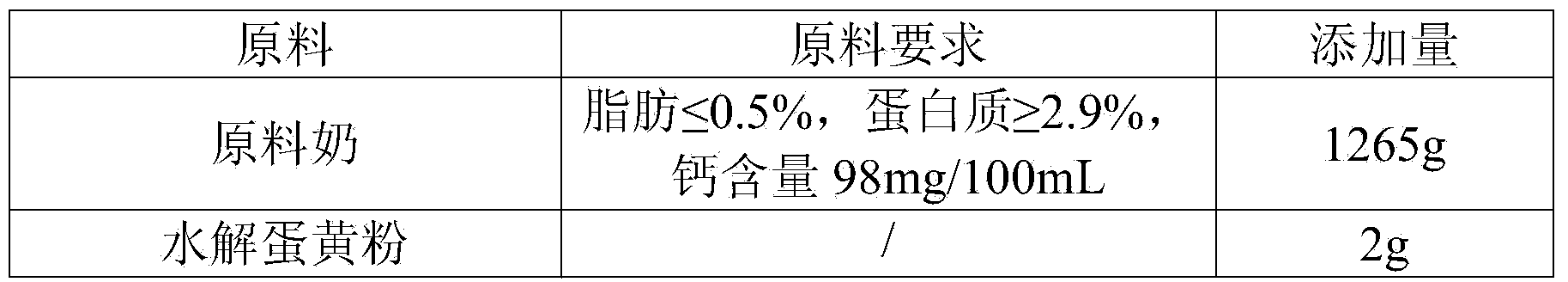

[0059] raw material:

[0060]

[0061]

[0062] Preparation Process:

[0063] (1) The raw milk is concentrated by falling film at low temperature to increase moisture to obtain concentrated milk, wherein the concentration temperature is 50°C, and the concentration pressure is 10000Pa;

[0064] (2) Mix the concentrated milk with hydrolyzed egg yolk powder, hydrolyzed collagen, casein phosphopeptide and vitamin D. When mixing, the stirring speed is 20rpm, and the stirring time is 10min. The protein and fat are standardized, and the standardized protein Content 3.9%, fat content 0.4%; then stir evenly;

[0065] (3) Two-stage homogenization: the homogenization temperature is 70°C, the first-stage homogenization pressure is 23MPa, and the second-stage homogenization pressure is 10MPa;

[0066] (4) Sterilization: the sterilization condition is 120°C, and the time is 15 seconds;

[0067] (5) After cooling to 2-6°C, fill it.

[0068] Each substance and its content in the obt...

Embodiment 2

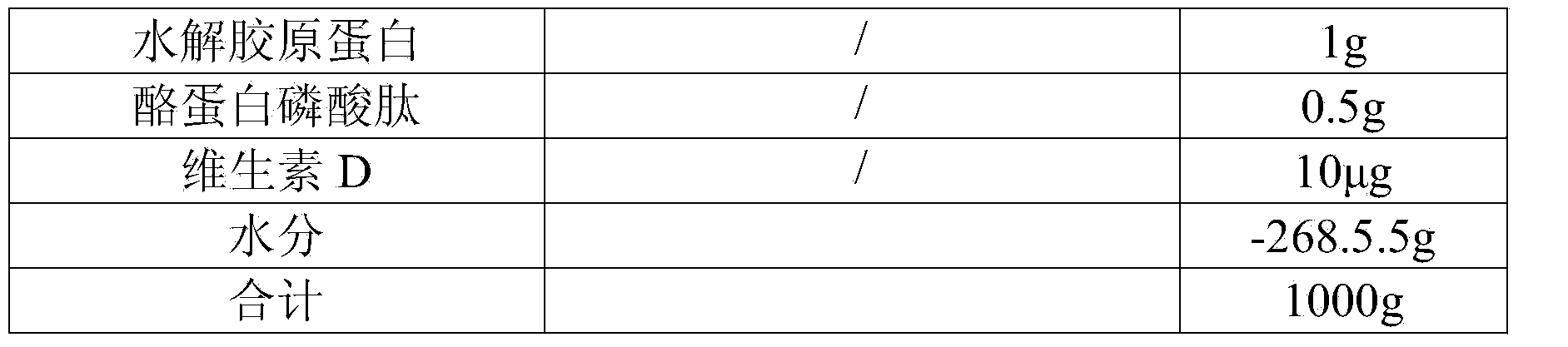

[0071] raw material:

[0072]

[0073]

[0074] Preparation Process:

[0075] (1) The raw milk is concentrated by falling film at low temperature to increase the water content to obtain concentrated milk, wherein the concentration temperature is 45°C, and the concentration pressure is 20000Pa;

[0076] (2) Add the stabilizer QSR-70 into the concentrated milk, stir for 10 minutes, then mix well with hydrolyzed egg yolk powder, hydrolyzed collagen, casein phosphopeptide and vitamin D. The stirring speed is 50rpm when mixing. The time is 15 minutes, and the protein and fat are standardized. After the standardization, the protein content is 4.0%, and the fat content is 4.3%; then stir evenly;

[0077] (3) Two-stage homogenization: Homogenization temperature: 65°C, the first stage is at 22MPa, and the second stage is at 8MPa;

[0078] (4) Sterilization: The sterilization condition is 85°C and the time is 15 seconds;

[0079] (5) After cooling to 2-6°C, fill it.

[0080] E...

Embodiment 3

[0083] raw material:

[0084]

[0085] Preparation Process:

[0086] (1) The raw milk is concentrated by falling film at low temperature to increase the water content to obtain concentrated milk, wherein the concentration temperature is 55°C, and the concentration pressure is 15000Pa;

[0087] (2) Add the stabilizer 9395-C to the concentrated milk, stir for 10 minutes, and then mix with hydrolyzed egg yolk powder, hydrolyzed collagen, casein phosphopeptide and vitamin D. The stirring speed is 1000rpm when mixing, and the stirring time For 10 minutes, carry out the standardization of protein and fat, after standardization, the protein content is 4.0%, and the fat content is 4.3%; then stir evenly;

[0088] (3) Two-stage homogenization: homogenization temperature: 70°C, the first stage is at 23MPa, and the second stage is at 10MPa;

[0089] (4) Add milk essence APG-07 and stir for 10 minutes;

[0090] (5) Sterilization: The sterilization condition is 137°C and the time is 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com