Central region combustor with staged combustion function

A technology of staged combustion and central zone, applied in the combustion chamber, combustion method, combustion equipment, etc., can solve the problem that the combustion chamber is difficult to meet the requirements of high outlet temperature, and achieve the improvement of premix uniformity, optimization of emission performance, and flame temperature distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The exemplary embodiments will be described in detail here, and examples thereof are shown in the accompanying drawings. When the following description refers to the accompanying drawings, unless otherwise indicated, the same numbers in different drawings represent the same or similar elements.

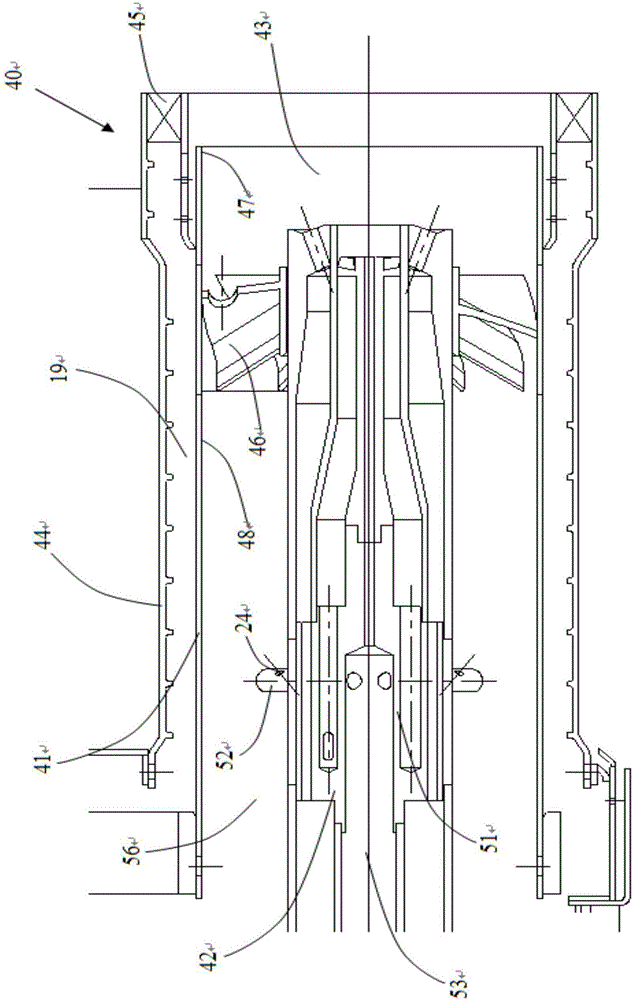

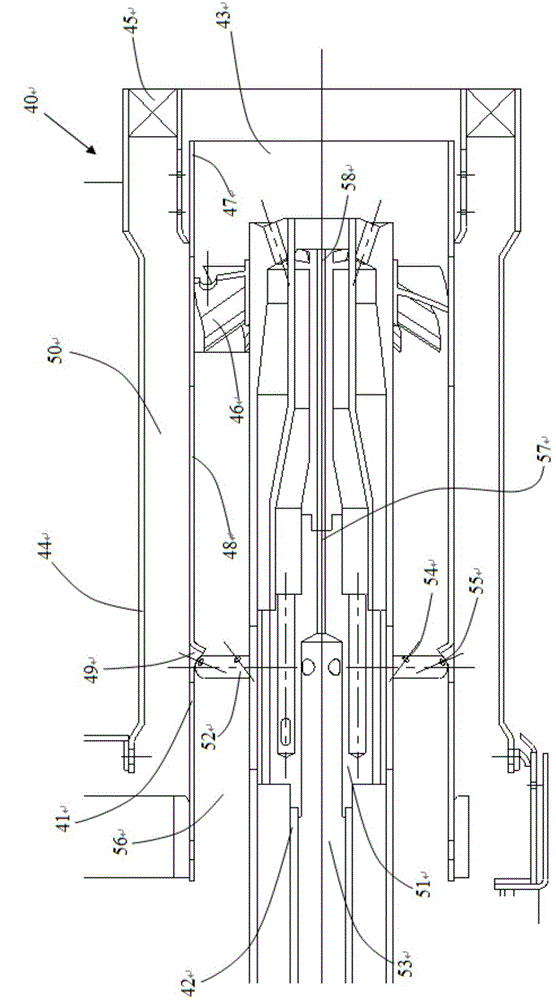

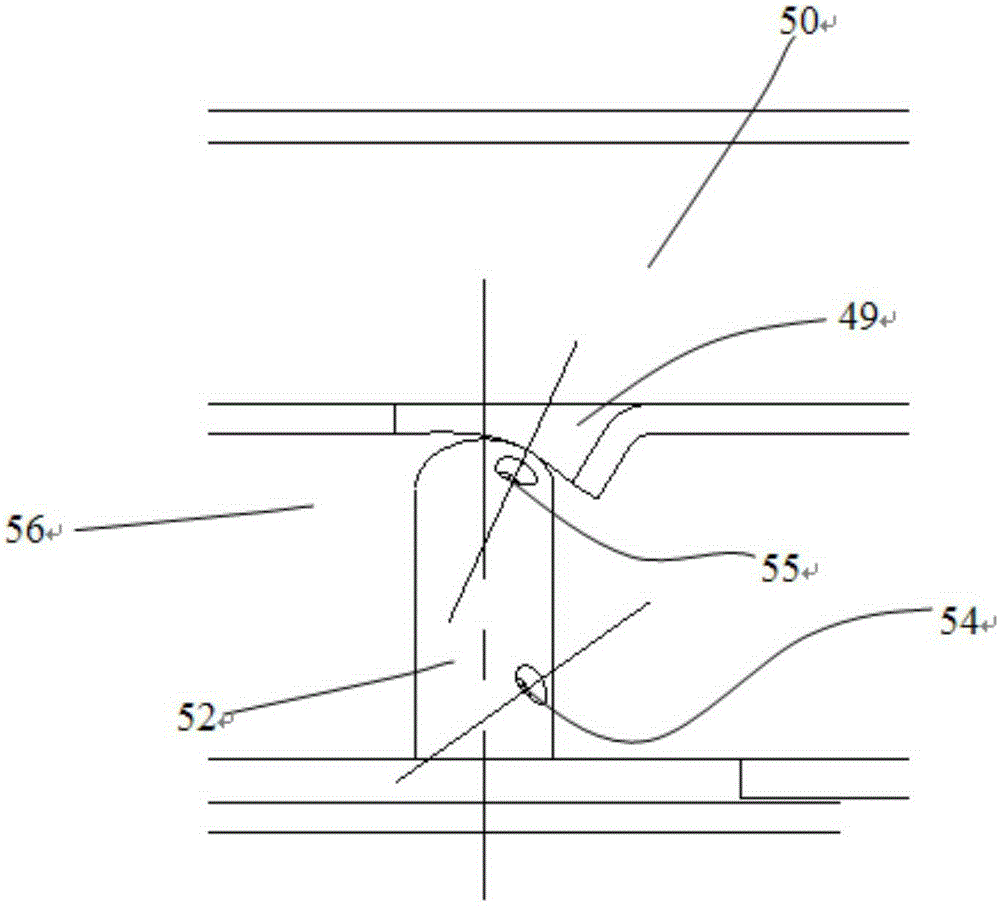

[0045] reference figure 1 As shown, the existing central zone combustor 40 is roughly shown, which includes a central body assembly 41 and a nozzle assembly 42. The central body assembly 41 includes a central cylinder 43, a central outer wall 44 and a primary cyclone 45. The central cylinder 43 includes a central swirler 46, an inner cylinder front wall 47, and an inner cylinder rear wall 48, which are fixedly connected back and forth by welding to form a main fuel passage 56 for sufficient premixing of fuel and air. The primary cyclone 45 is welded to the outer side of the downstream end of the inner cylinder front wall 47 of the central cylinder 43 to cool the central body asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com