Method and apparatus for railway wheel ultrasonic testing apparatus

一种超声、车轮的技术,应用在铁路车辆测试、机械设备、使用声波/超声波/次声波分析固体等方向,能够解决车轮旋转偏移、不稳定等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Although this specification refers to testing of railway wheels, it should be understood that the testing apparatus and methods disclosed herein are equally applicable to other cast and forged wheels used in industries unrelated to the railway industry. Accordingly, the description of the new method and apparatus in relation to train wheels is for convenience only.

[0030] Ultrasonic testing equipment for train wheels

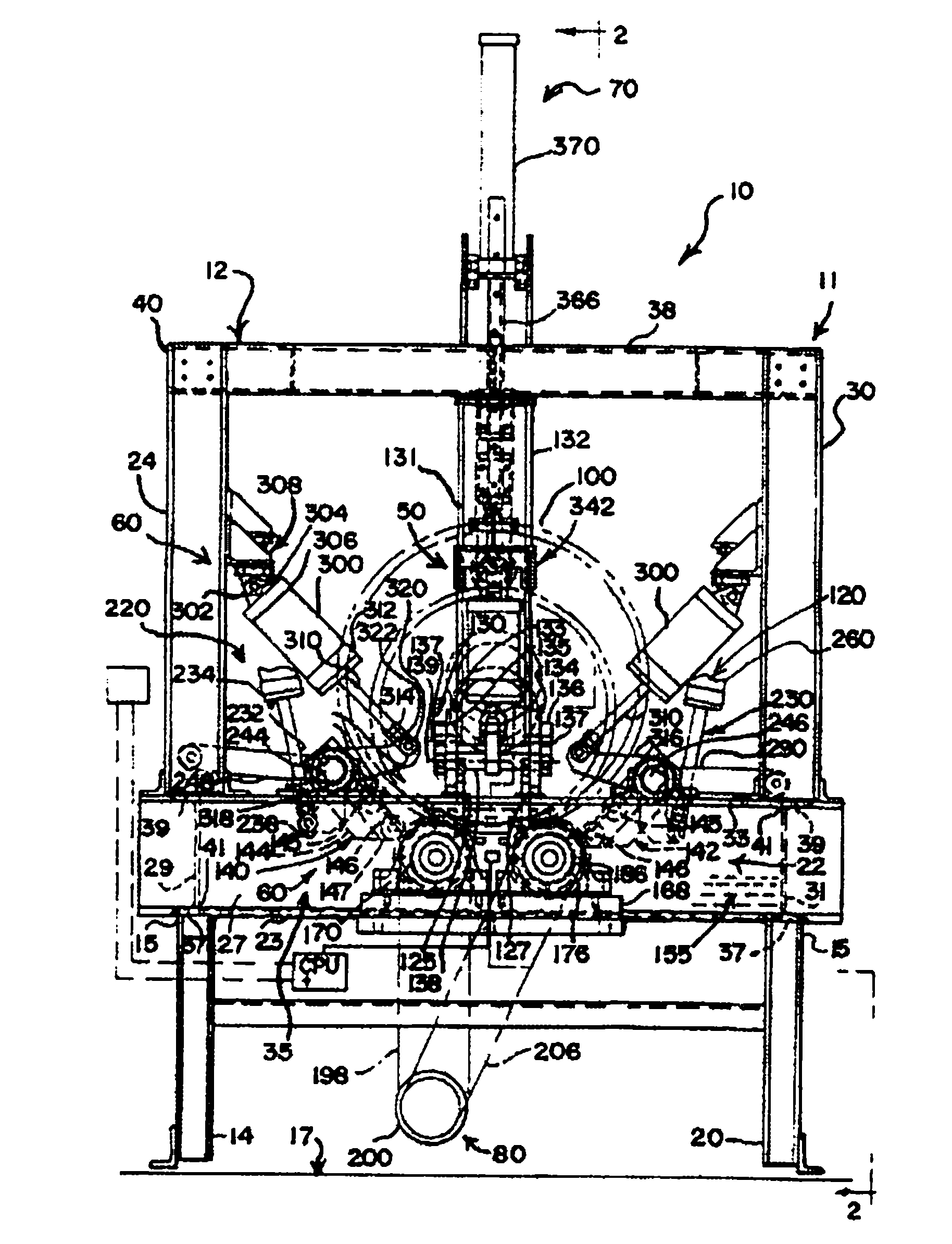

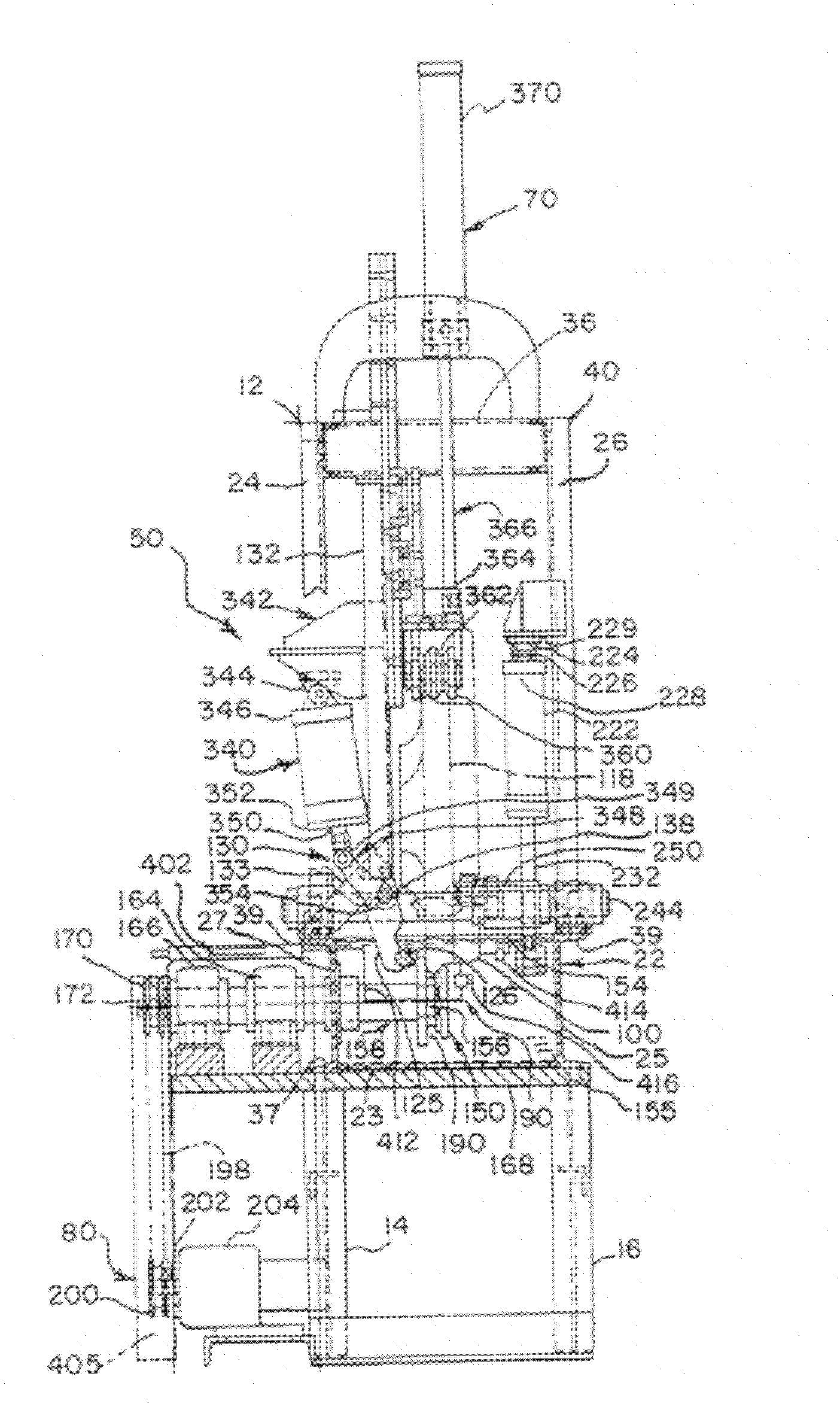

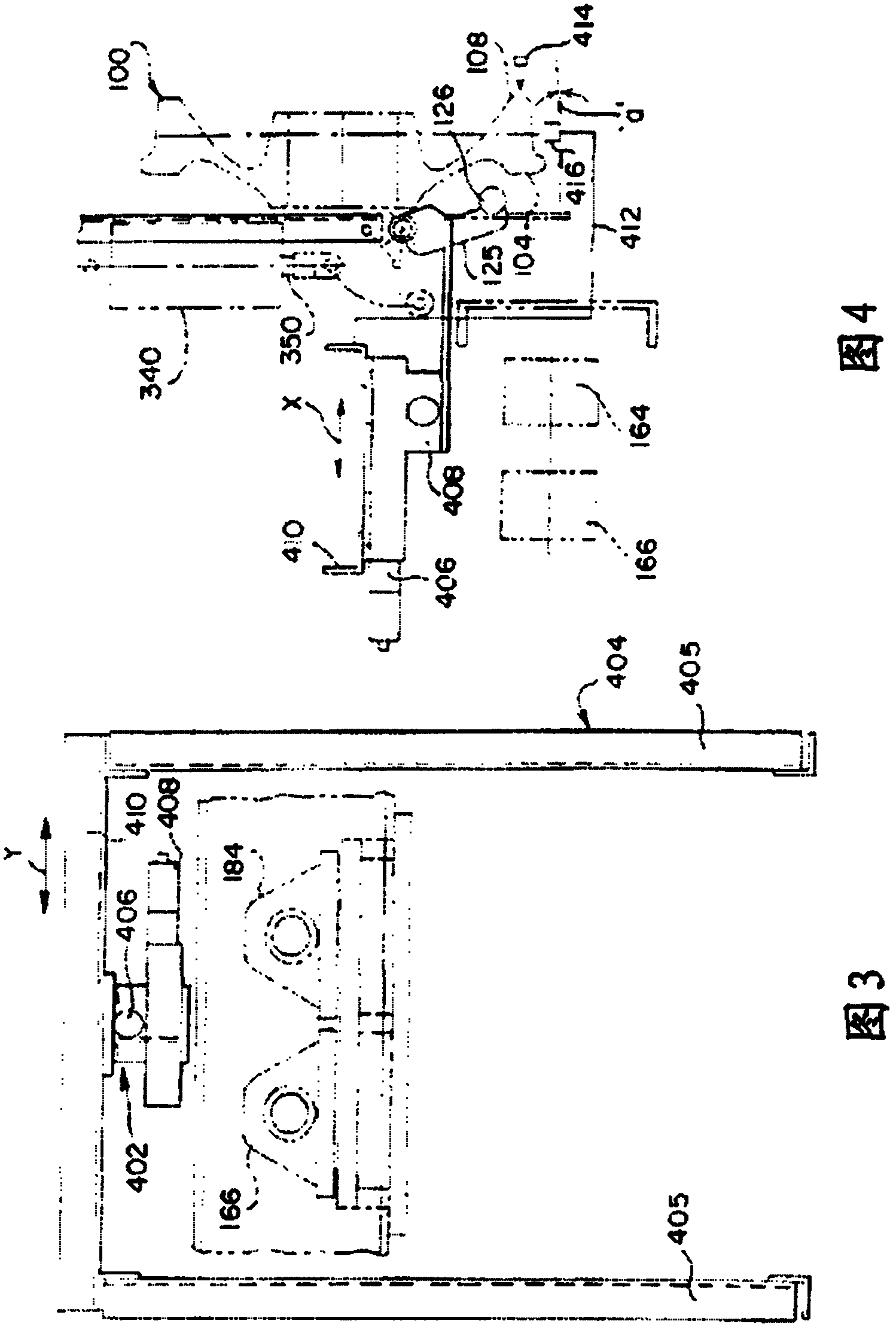

[0031] exist figure 1 in the front view of and figure 2 An embodiment of an ultrasonic testing device is shown in side view. Ultrasonic test equipment is designed to be used by Figure 9 Non-damaging evaluation and internal topography measurements of the structure of an exemplary type of railway wheel 100 are shown.

[0032] In one embodiment, the ultrasonic testing apparatus includes an ultrasonic testing fixture 11 and an ultrasonic sensing assembly 90 for capturing and rotating a wheel. Additionally, in some embodiments, a CPU (such as a progra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com