Patents

Literature

47 results about "Ultrasonic analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

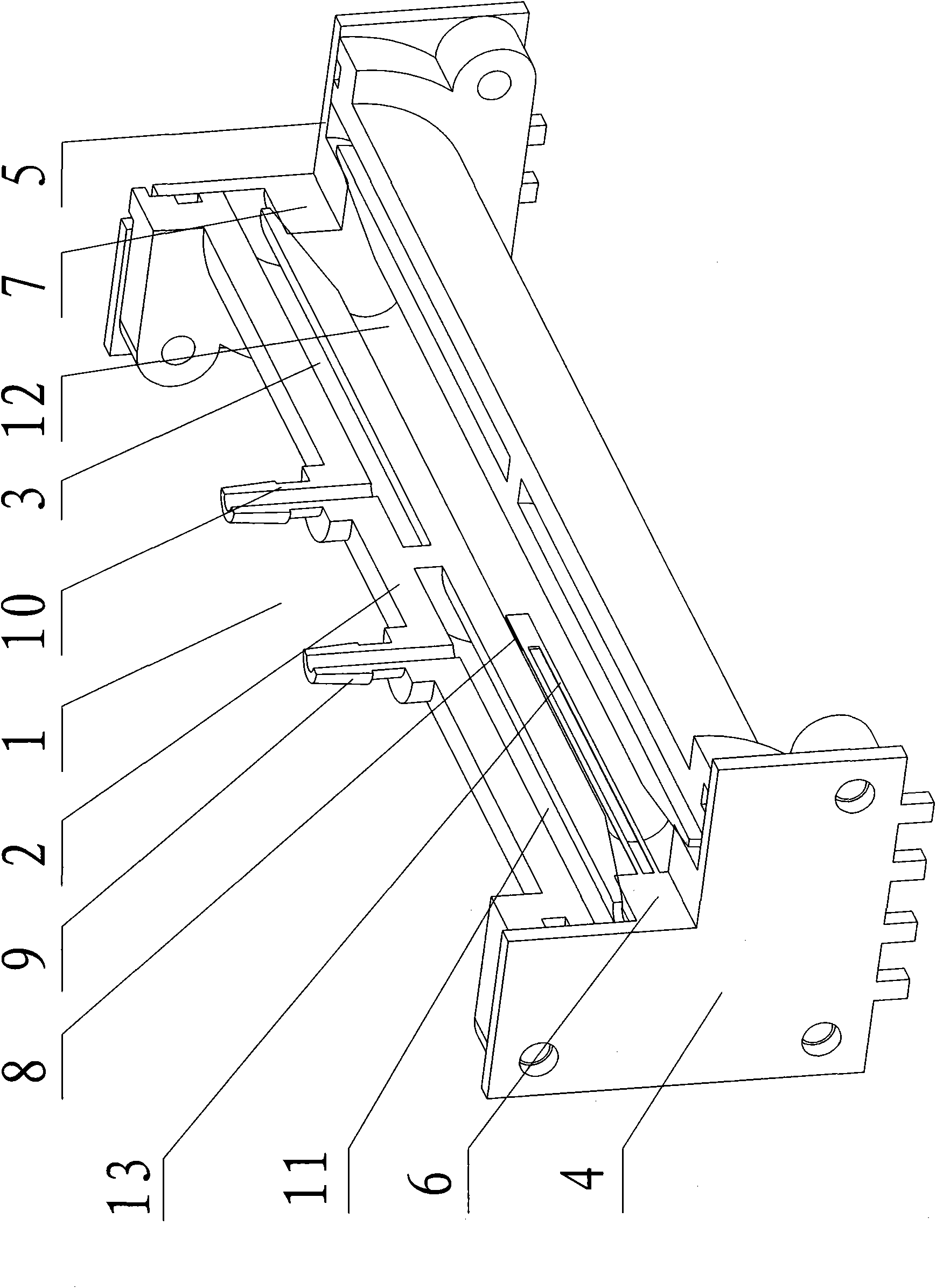

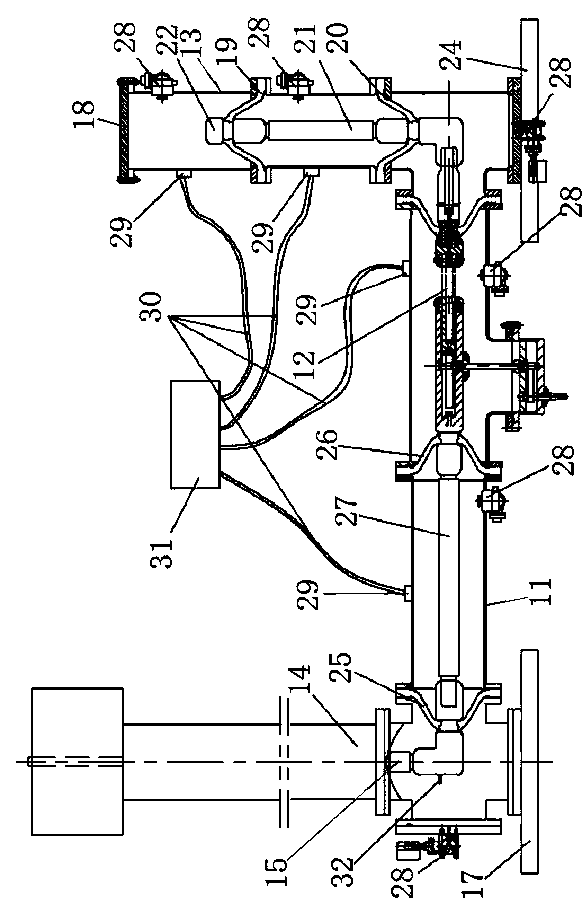

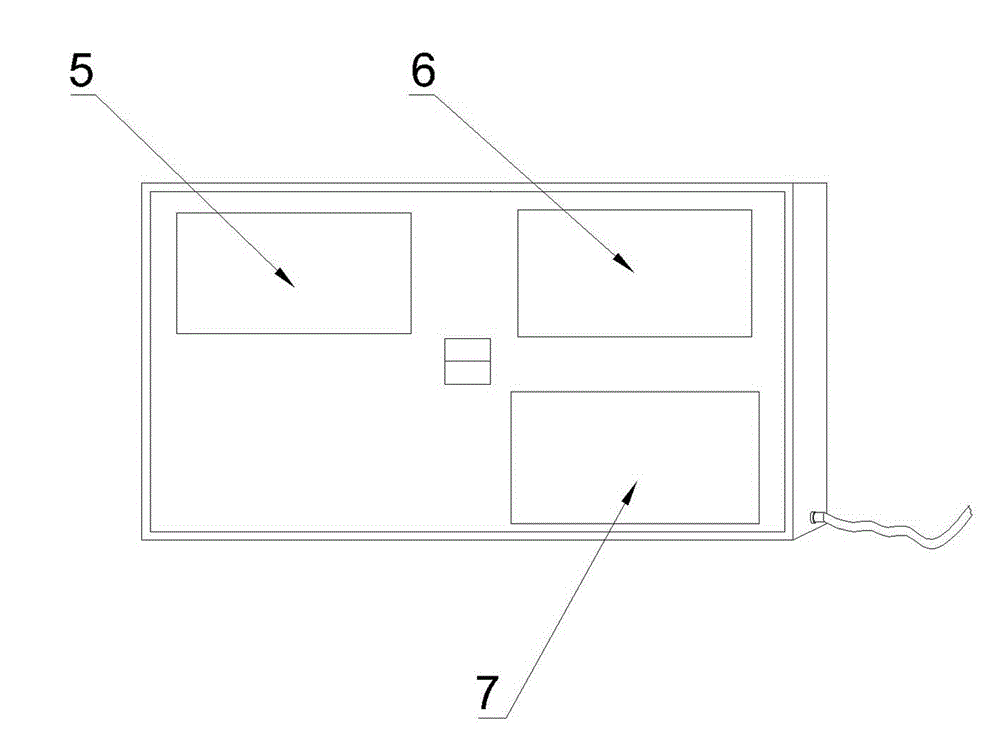

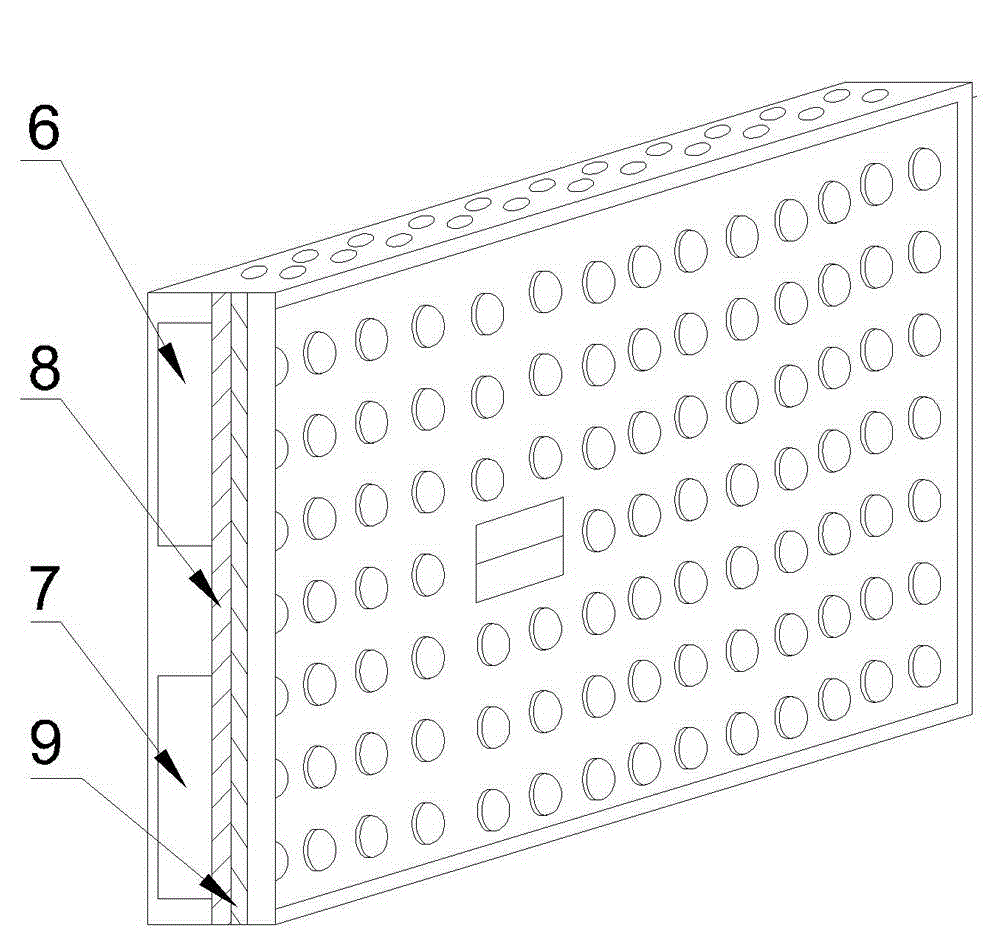

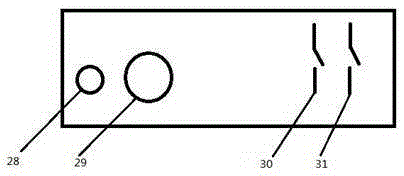

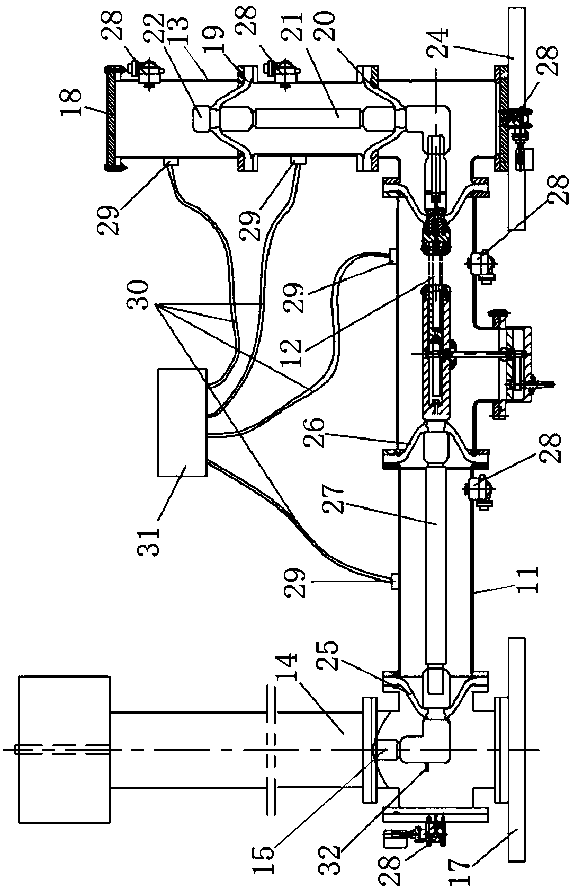

Portable full automatic resistance spot welding ultrasonic detecting instrument and detecting method

InactiveCN103822970ACompact structureReduce volumeAnalysing solids using sonic/ultrasonic/infrasonic wavesAnti jammingWater immersion

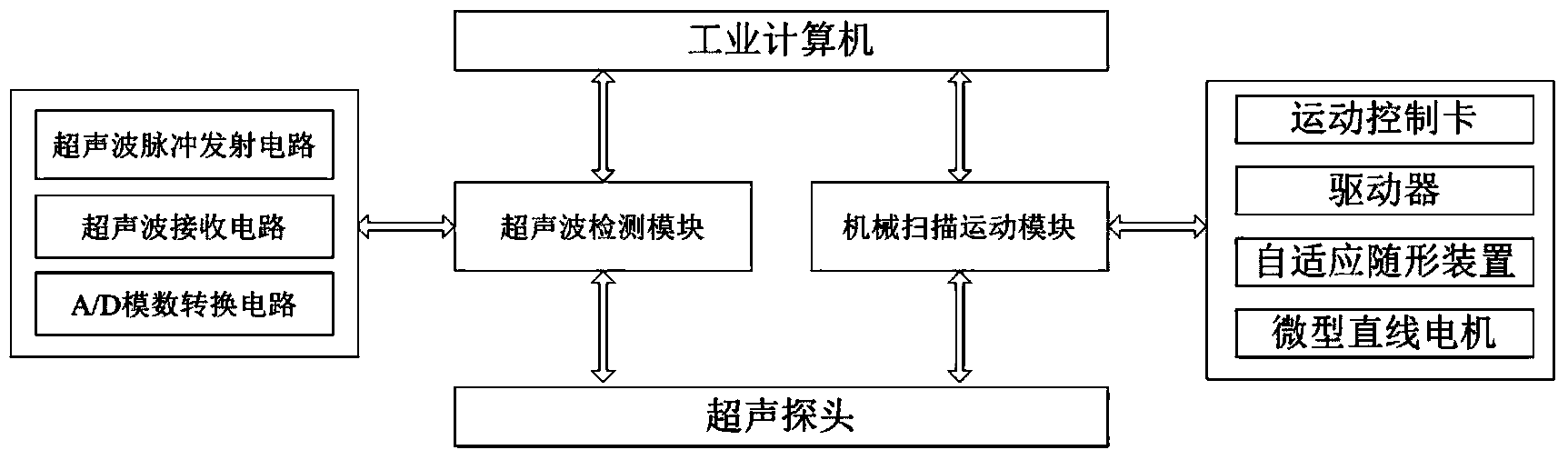

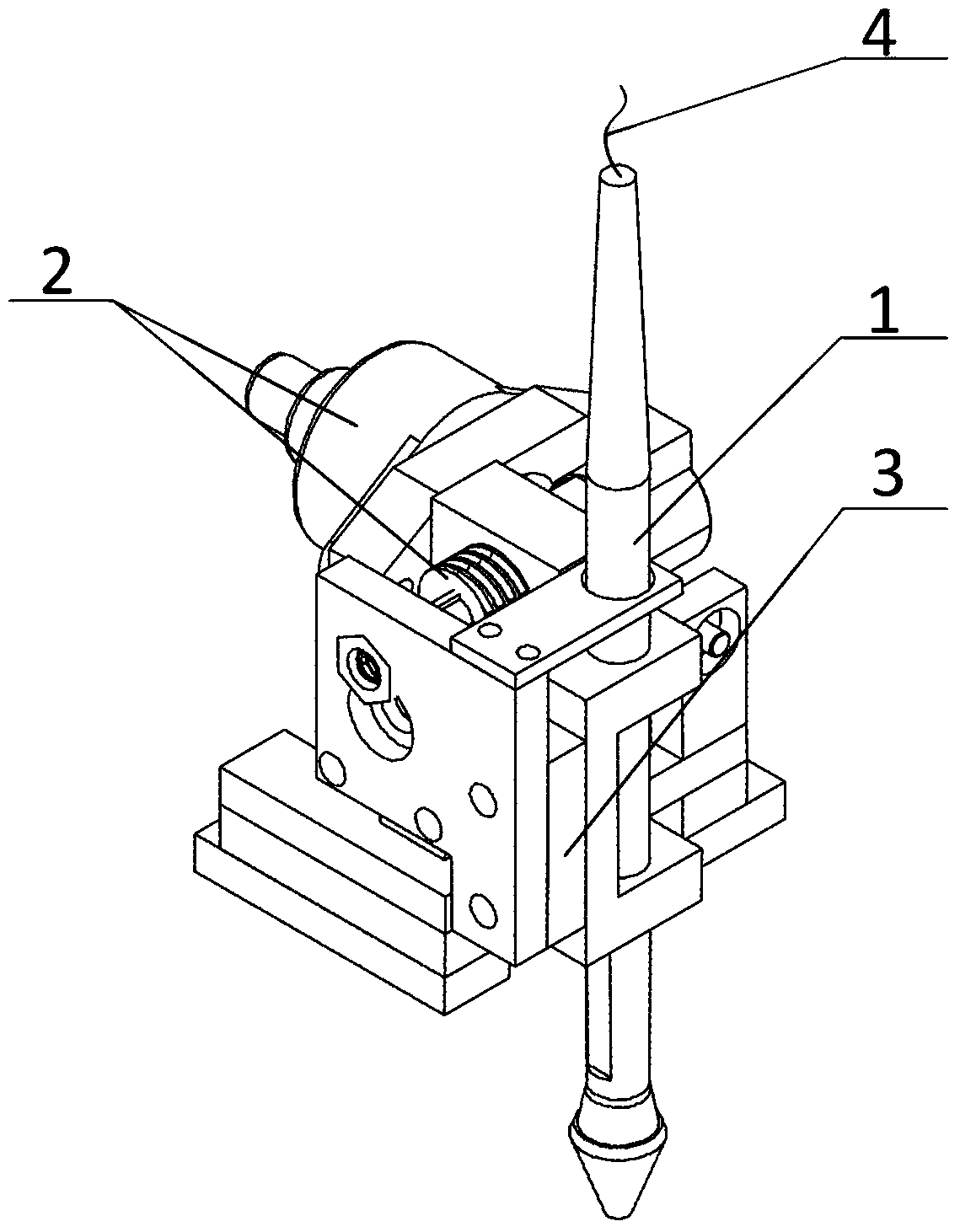

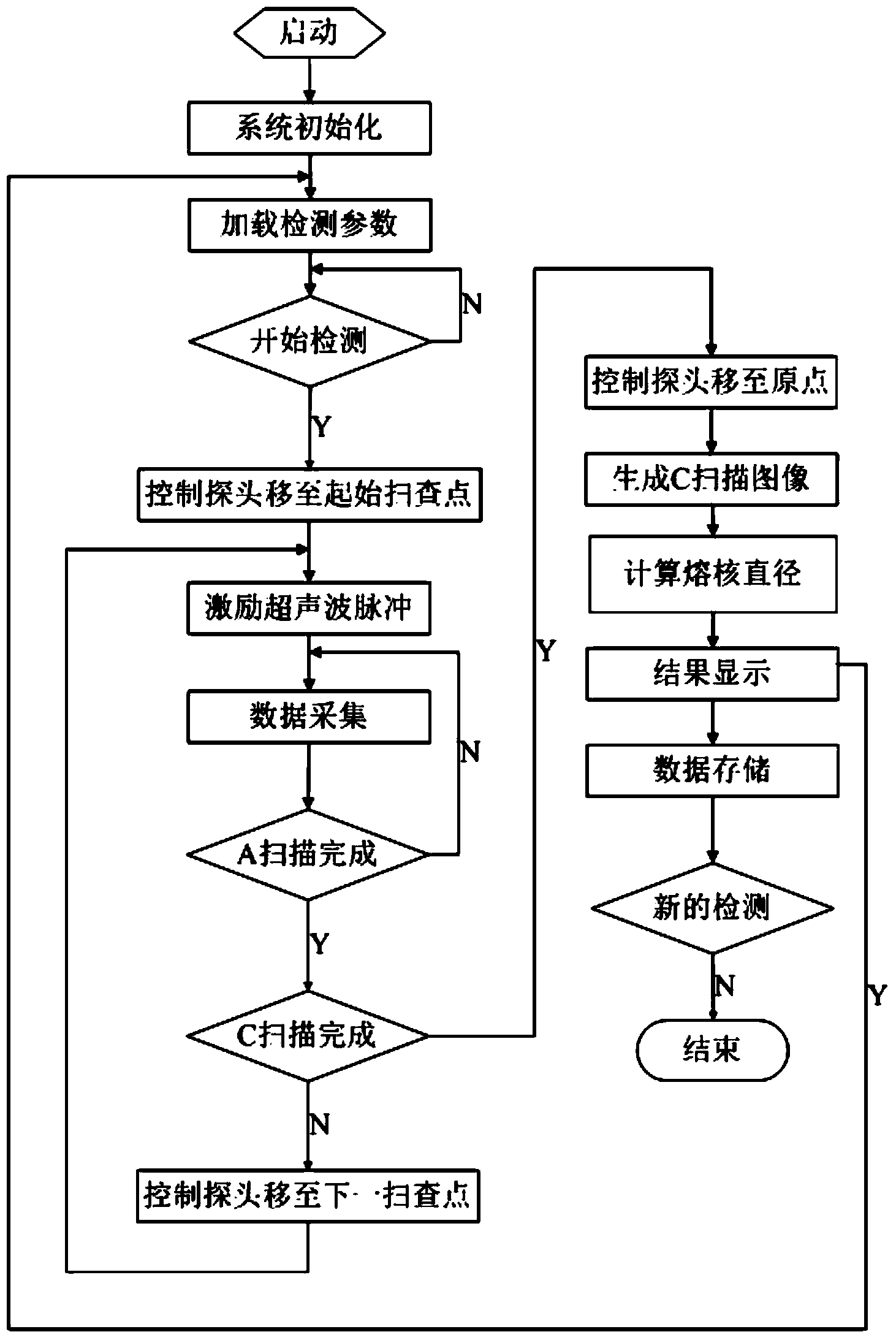

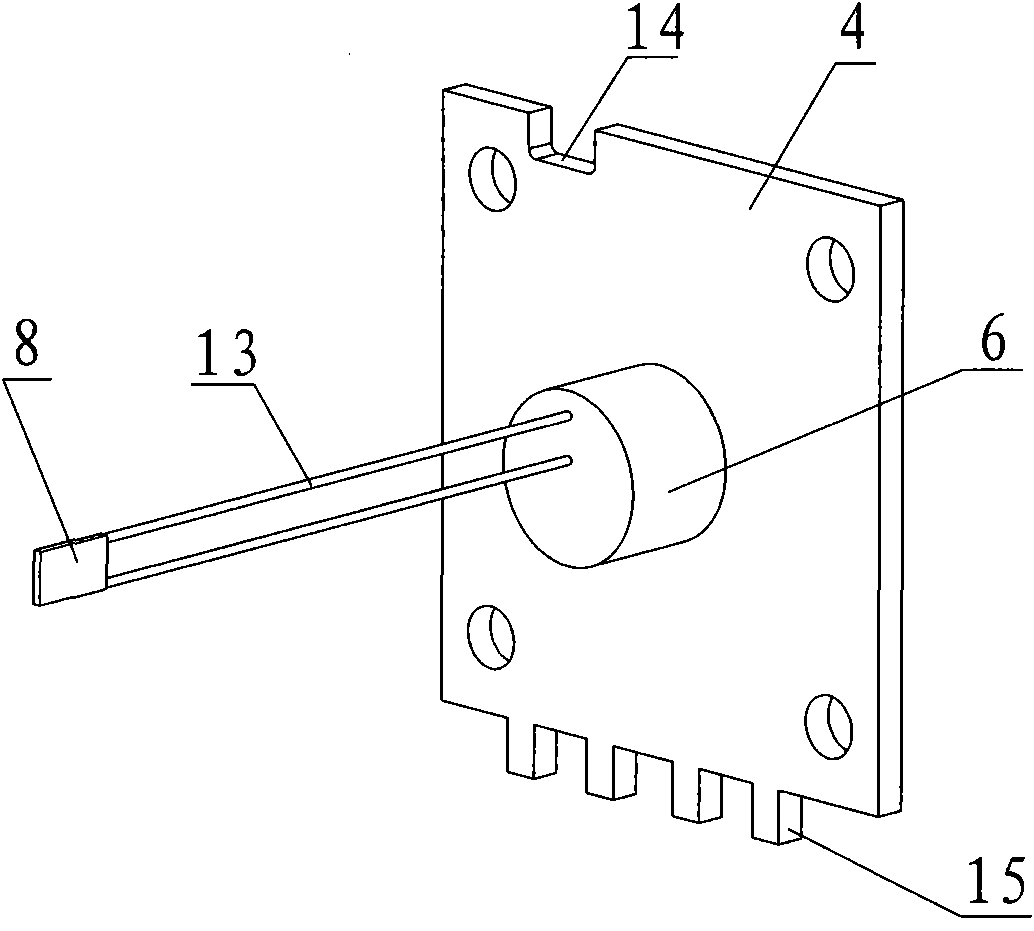

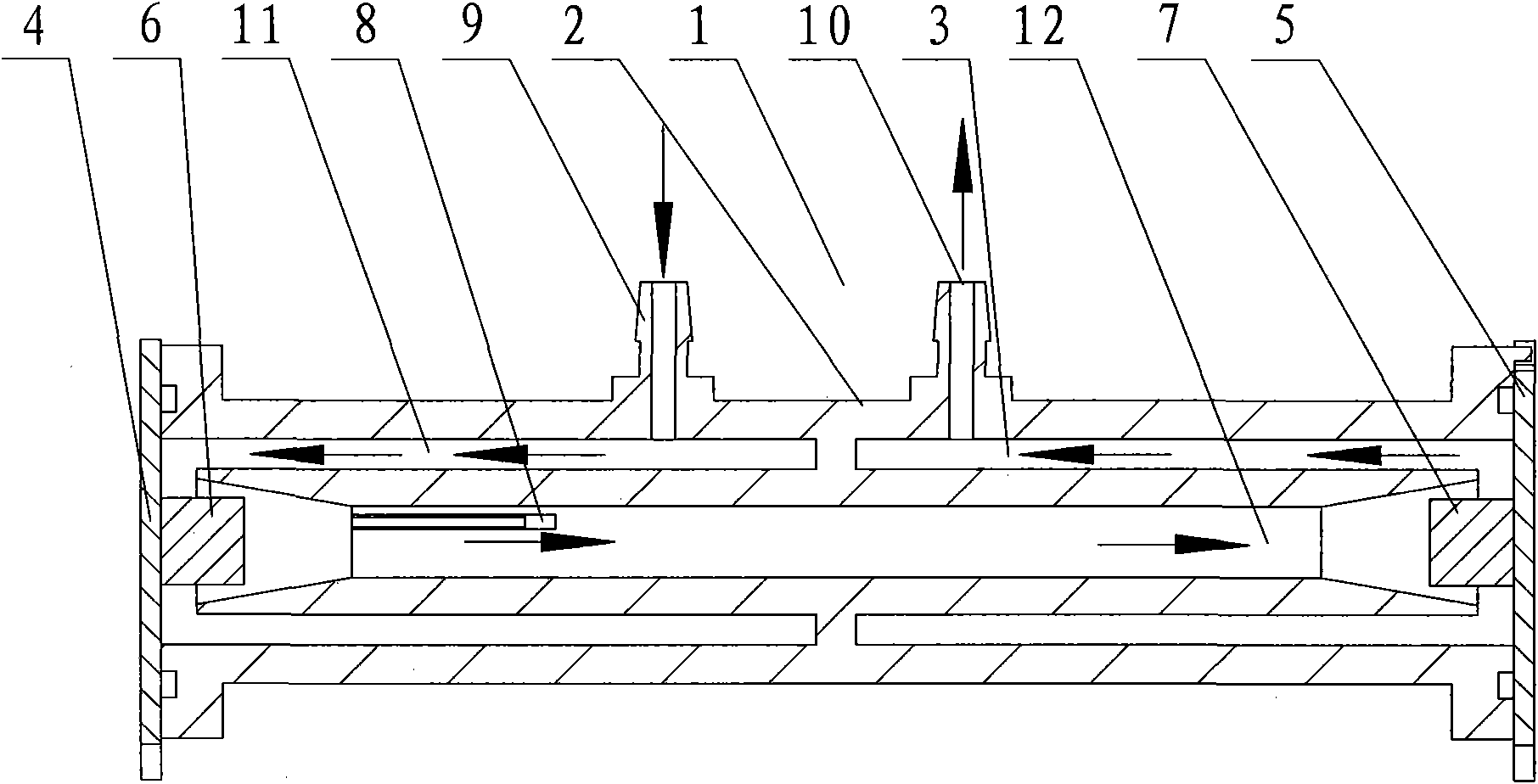

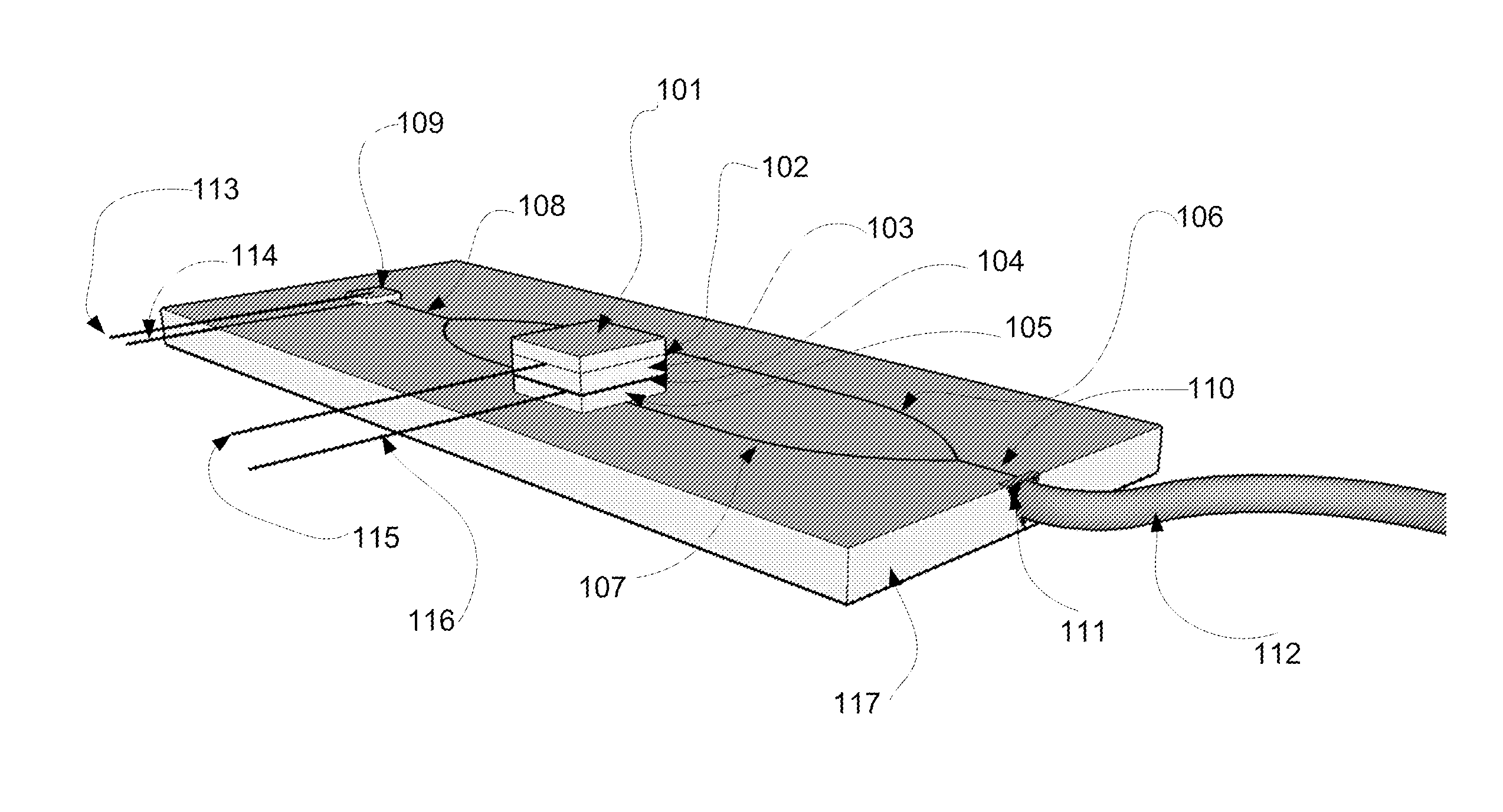

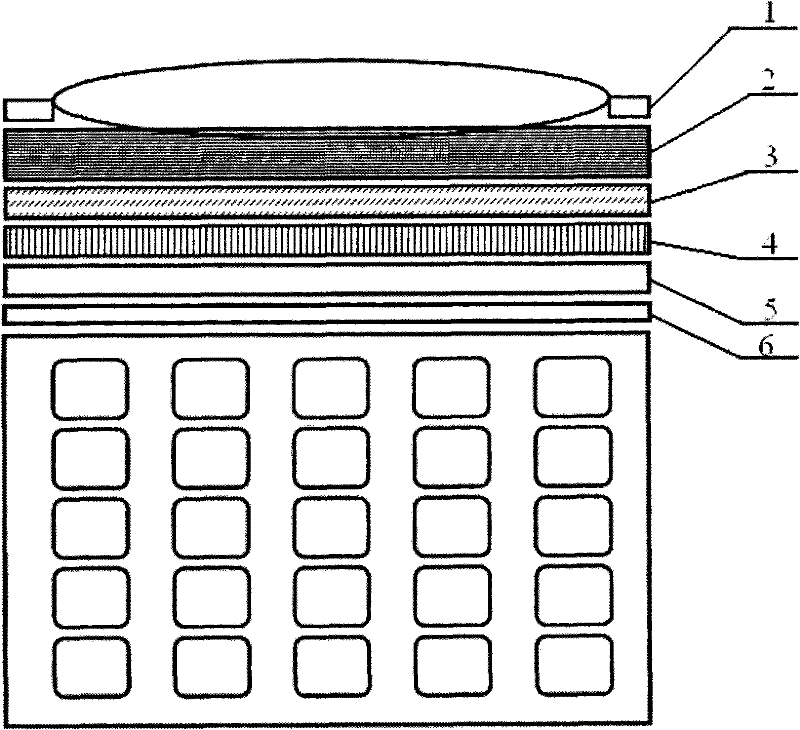

The invention relates to a portable full automatic resistance spot welding ultrasonic detecting instrument and a detecting method. The portable full automatic resistance spot welding ultrasonic detecting instrument comprises an industrial computer, an ultrasonic probe, an ultrasonic detecting module integrated in an IPC (Industrial Personal Computer), a compact-type two-dimension mechanical scanning motion module, and an ultrasonic analyzing module, wherein the ultrasonic detecting module comprises an ultrasonic pulse radiating circuit, an ultrasonic receiving circuit and an A / D conversion circuit; the compact-type two-dimension mechanical scanning motion module comprises a micro-scale linear motor, a driver, a motion control card, and a self-adaption profile-followed device; the ultrasonic analyzing module comprises a data and image processing module, a database storage module, and a manual playback and analysis module. Functions such as self-adaption scanning and detecting to the resistance spot welding joint surface, automatic generation of a C scanning image, and quantitive calculation of nugget diameter of the ultrasonic probe in the situation of non-water immersion are realized; compared with the prior art, the portable full automatic resistance spot welding ultrasonic detecting instrument and the detecting method have the advantages of simplicity in operation, portability, reliability, strong anti-jamming capability, high detection and analyzing speed and the like.

Owner:JILIN UNIV

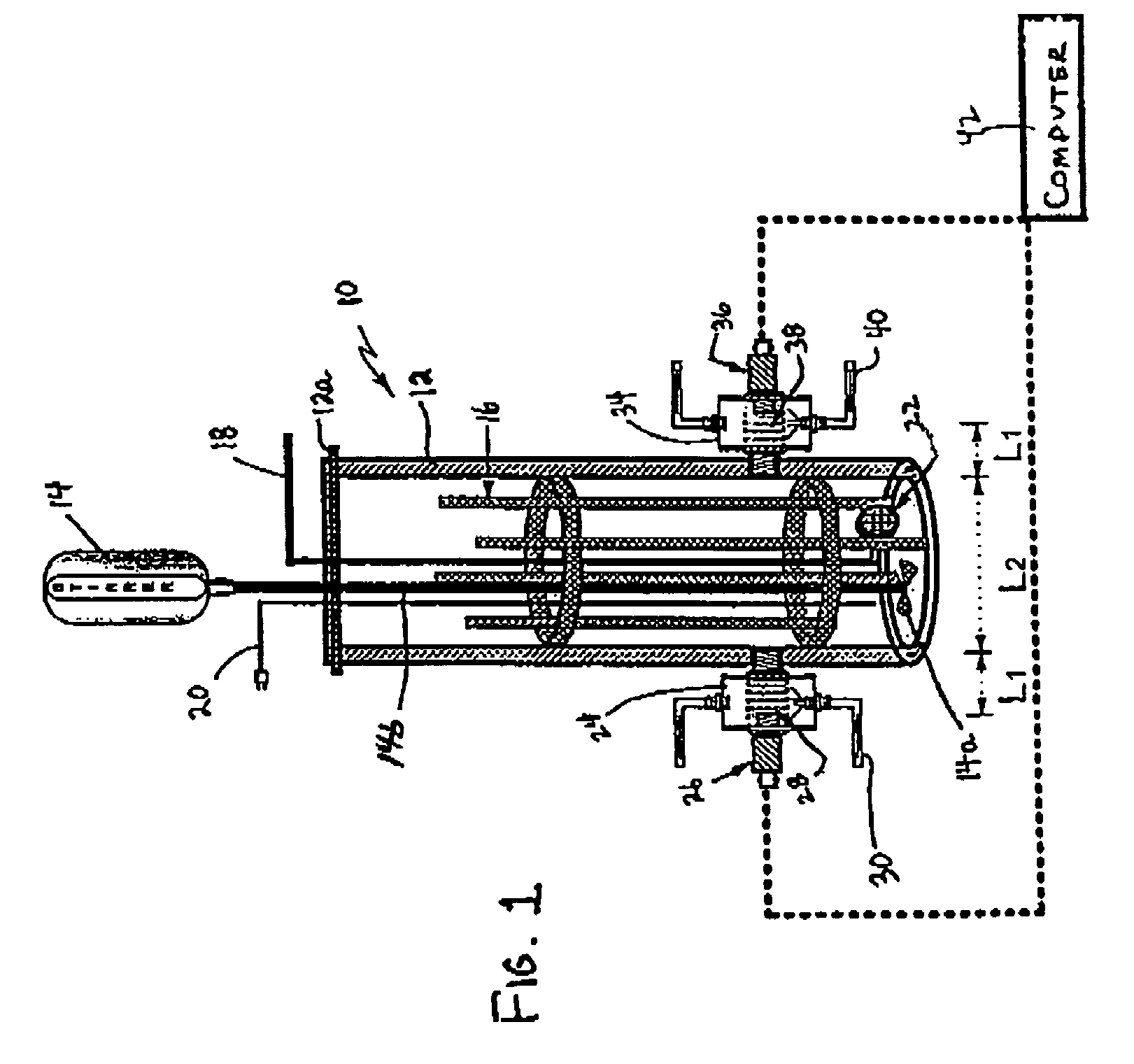

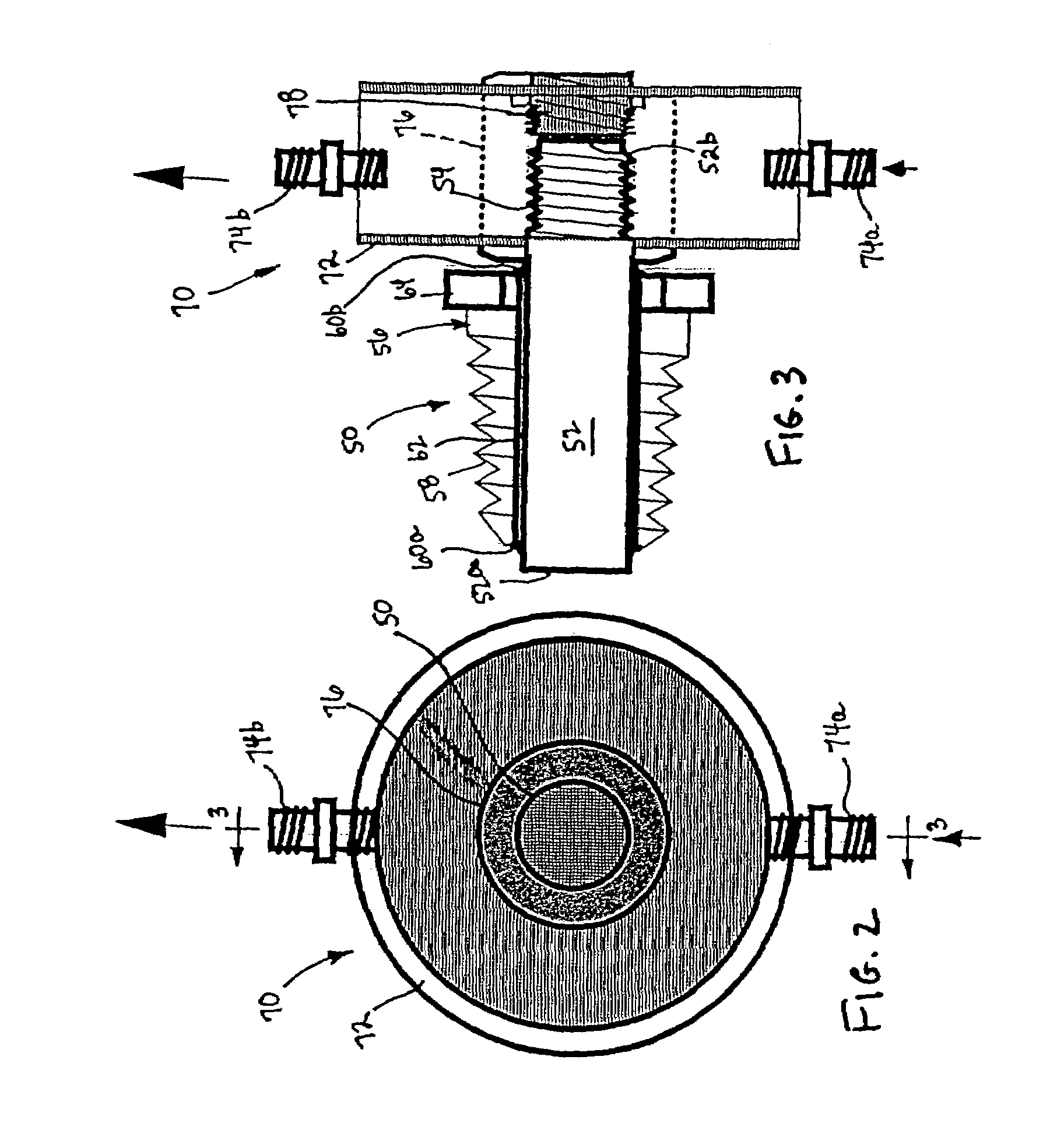

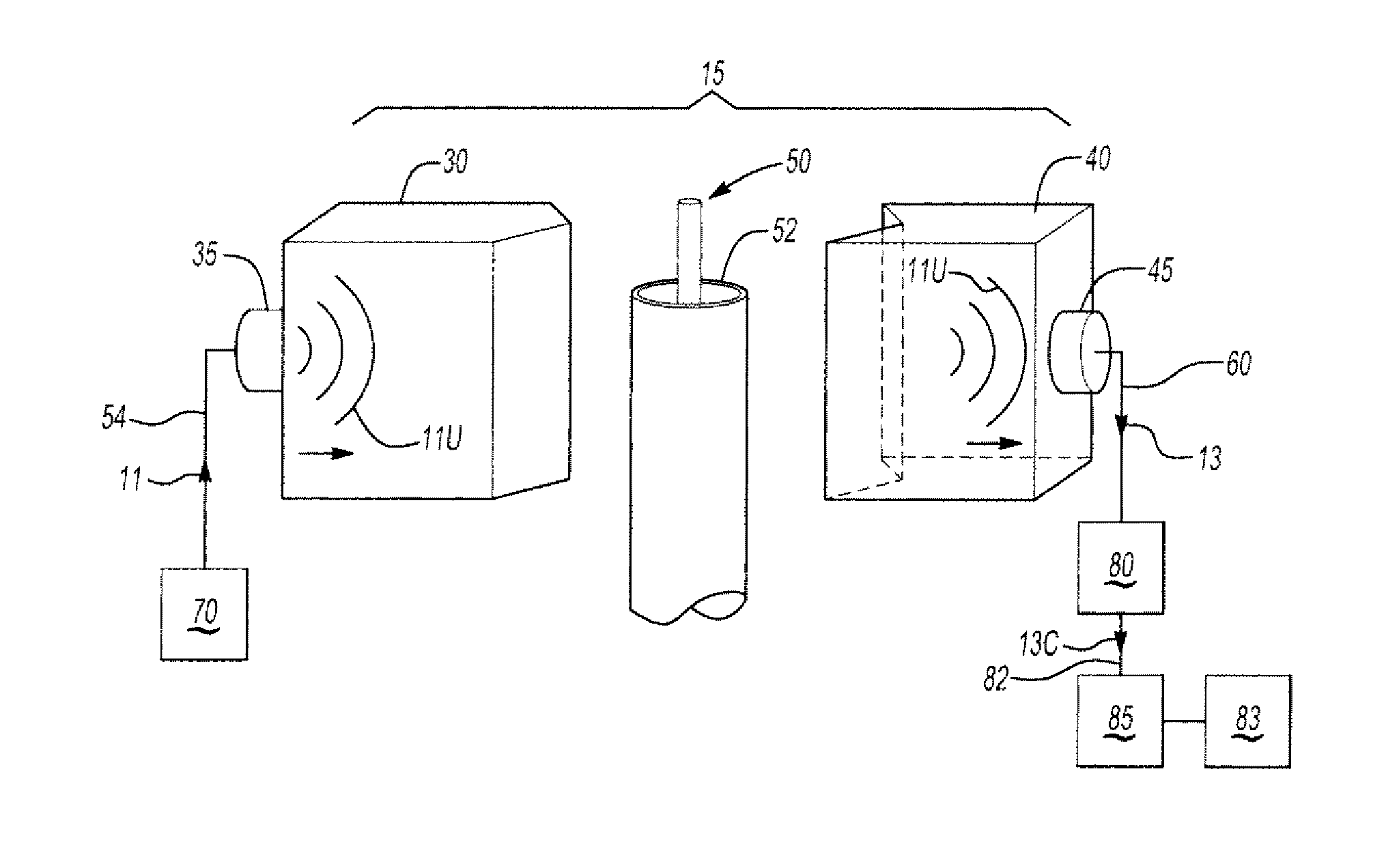

Ultrasound analysis of slurries

InactiveUS6959589B1Overcome limitationsMaintaining atmospheric pressureAnalysing fluids using sonic/ultrasonic/infrasonic wavesMultiple-port networksSonificationSlurry

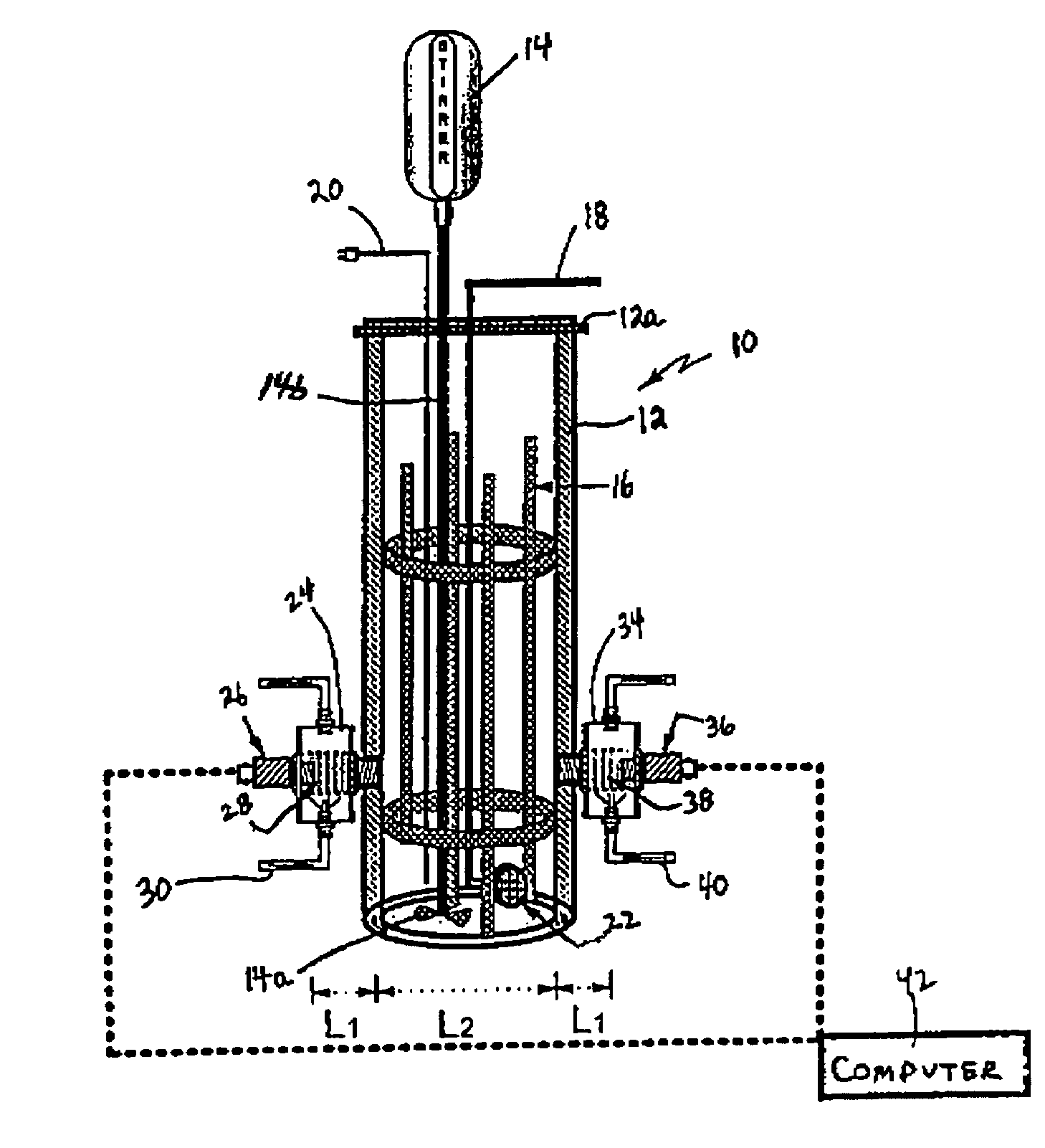

An autoclave reactor allows for the ultrasonic analysis of slurry concentration and particle size distribution at elevated temperatures and pressures while maintaining the temperature- and pressure-sensitive ultrasonic transducers under ambient conditions. The reactor vessel is a hollow stainless steel cylinder containing the slurry which includes a stirrer and a N2 gas source for directing gas bubbles through the slurry. Input and output transducers are connected to opposed lateral portions of the hollow cylinder for respectively directing sound waves through the slurry and receiving these sound waves after transmission through the slurry, where changes in sound wave velocity and amplitude can be used to measure slurry parameters. Ultrasonic adapters connect the transducers to the reactor vessel in a sealed manner and isolate the transducers from the hostile conditions within the vessel without ultrasonic signal distortion or losses.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Vacuum pulse type method of extracting and purifying ursolic acid of rosemary

The invention discloses a vacuum pulse type method of extracting and purifying ursolic acid of rosemary. The method comprises the following steps: (1) drying and crushing a raw material medical material rosemary; (2) carrying out vacuum pulse type reflux extraction on the material by taking 20-90% of ethanol as a solvent, and concentrating the extracting liquor for later use; and (3) carrying out ultrasonic analysis on the concentrated ursolic acid extracting liquor after being adsorbed by D101 macroporous resin, and then, concentrating, crystallizing twice and drying to obtain a 90-98% ursolic acid product. The method provided by the invention efficiently and greenly extracts ursolic acid in the whole technical process under a condition that no organic solvents except ethanol are used, and the finally obtained ursolic acid product has the activities of bacteriostatic action, tumor resistance, inflammation dimishing and the like and is wide in application prospect.

Owner:JISHOU UNIVERSITY

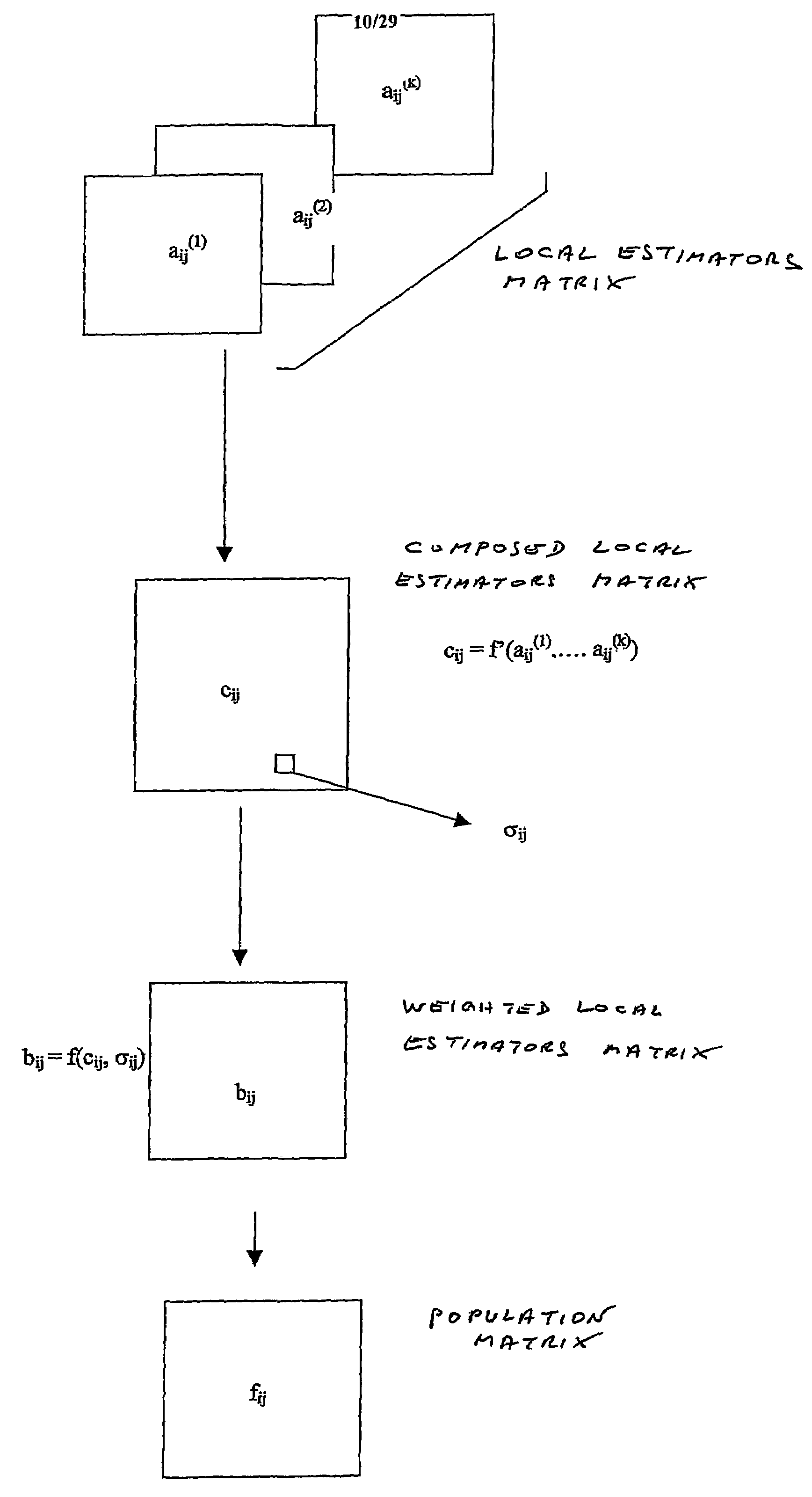

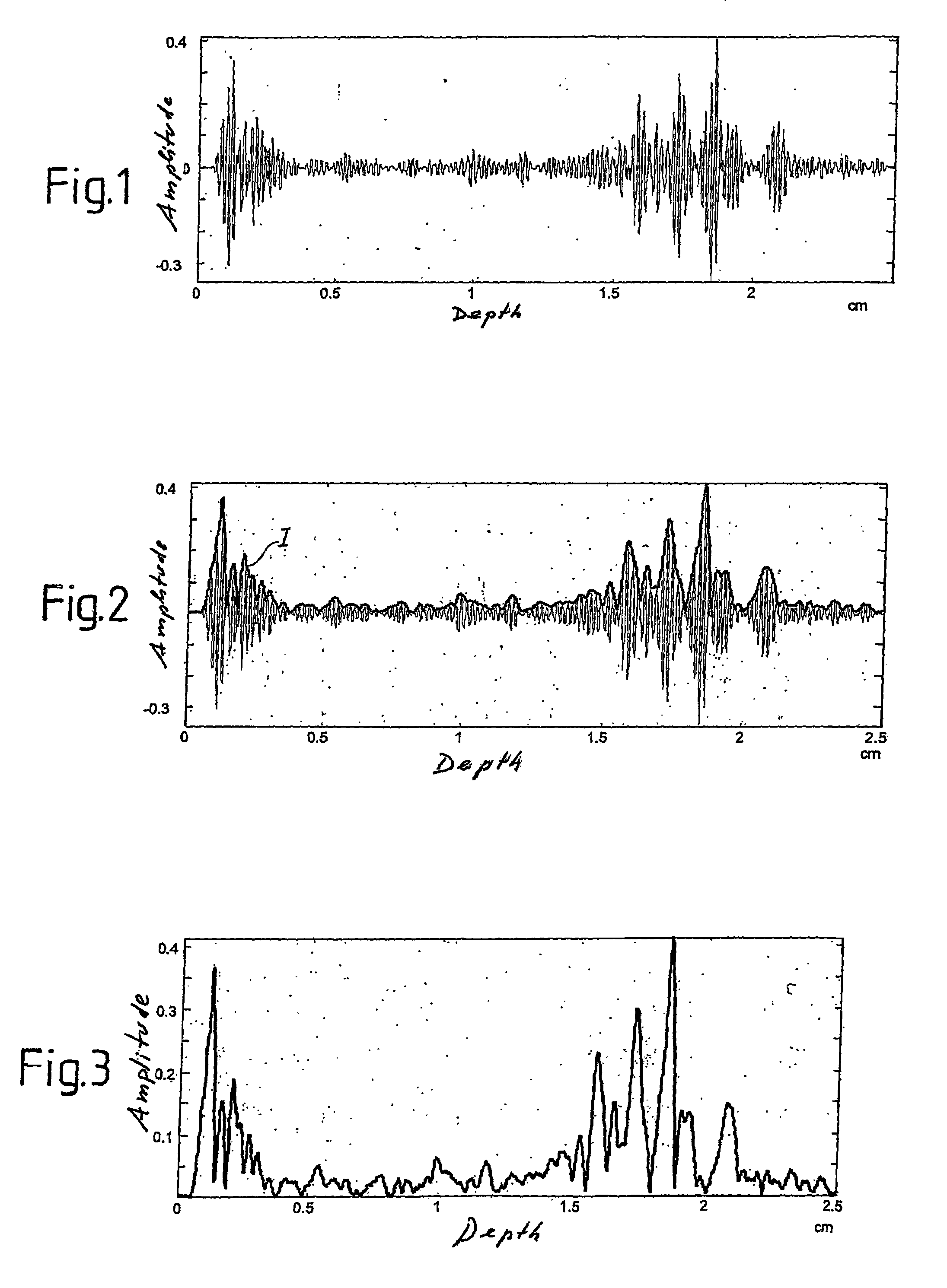

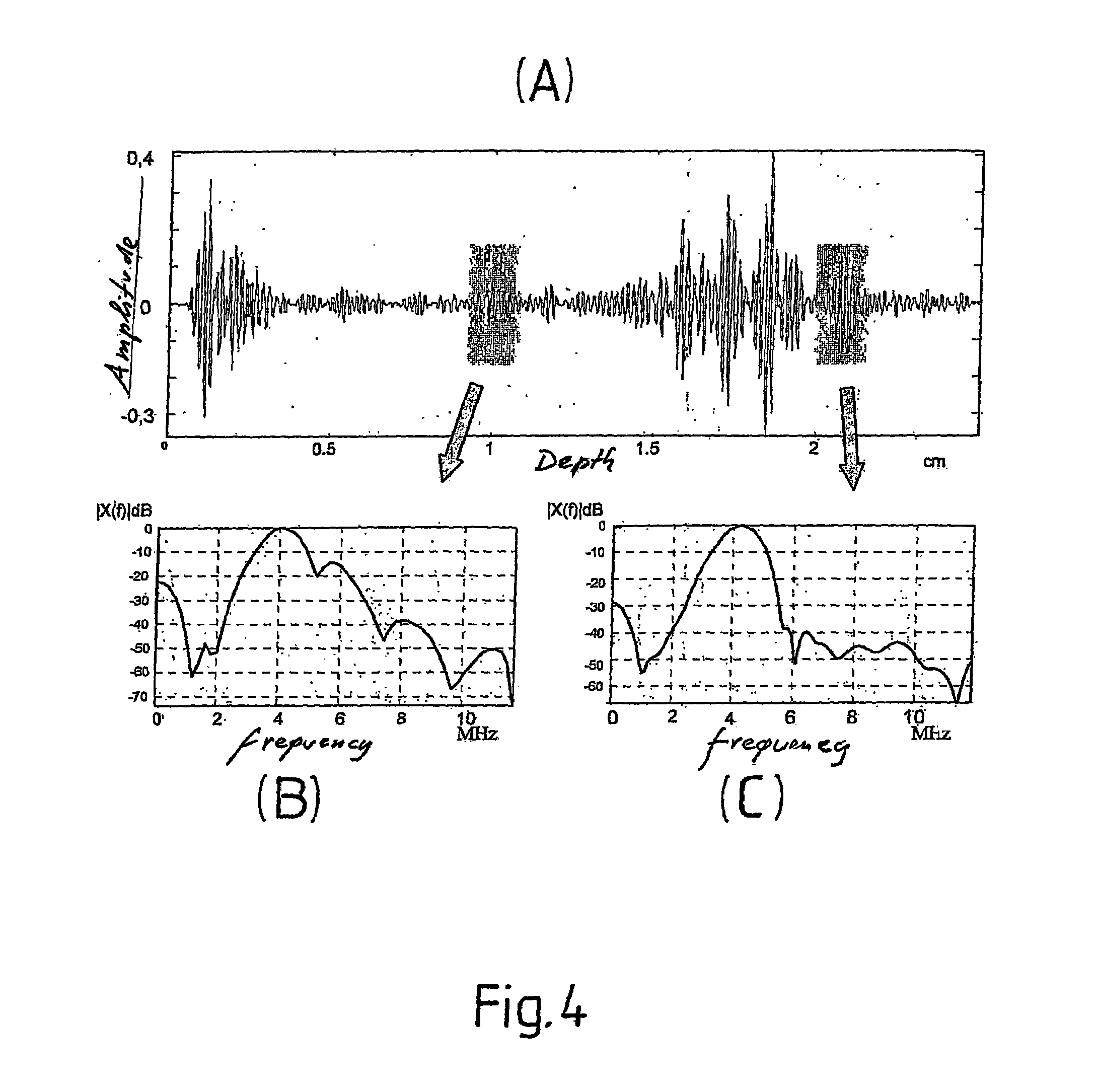

Method and device for local spectral analysis of an ultrasonic signal

InactiveUS7509861B2Great and precise informationEasy to useVibration measurement in solidsUltrasonic/sonic/infrasonic diagnosticsSonificationFrequency spectrum

The method decomposes the radio frequency signal into sub-bands by filtering, for example with a time-frequency transform. From the coefficients acquired through decomposition a matrix of spectral coefficients is obtained, from which local estimators are obtained, constituted in particular by the coefficients of the interpolating polynomials. The statistical distribution of the local estimators is evaluated in windows overlaid on the ultrasound frame. The conformation of the distribution histograms of the spectral coefficients provides a parameter which, combined with the local estimators, provides weighted local estimators, which contain spectral information useful in the identification of specific structures in the organ subjected to ultrasound analysis.

Owner:ACTIS ACTIVE SENSORS +1

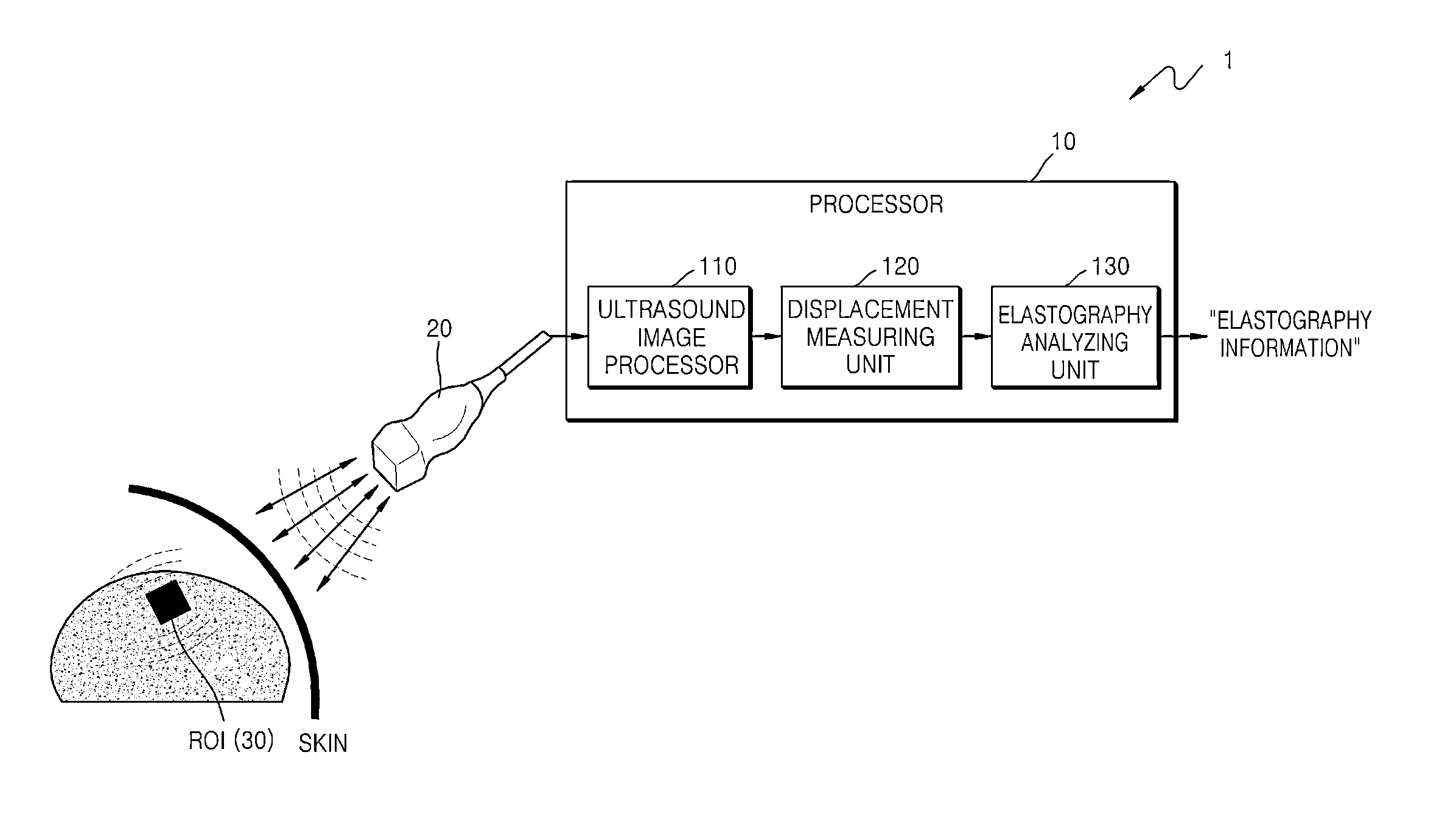

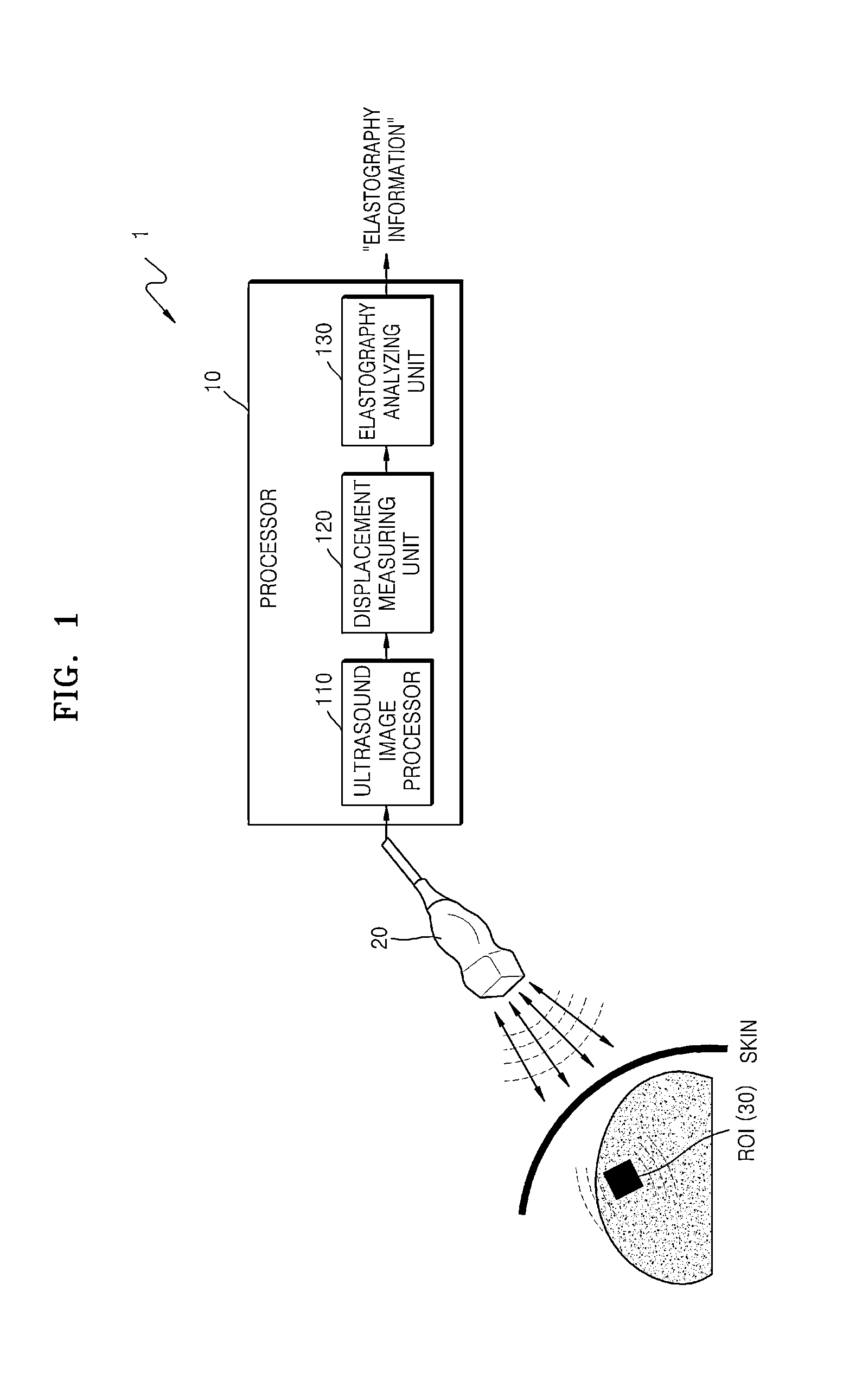

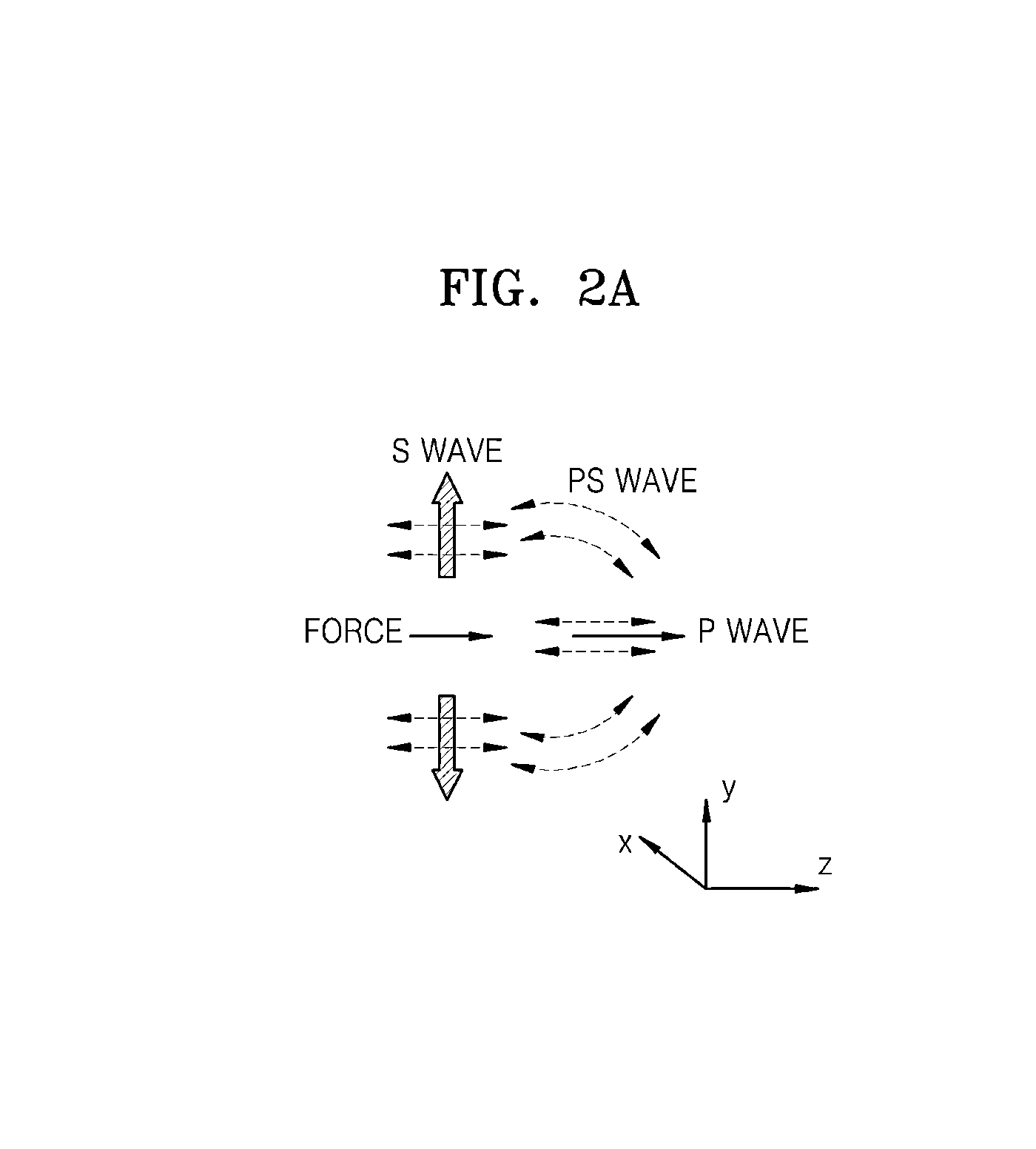

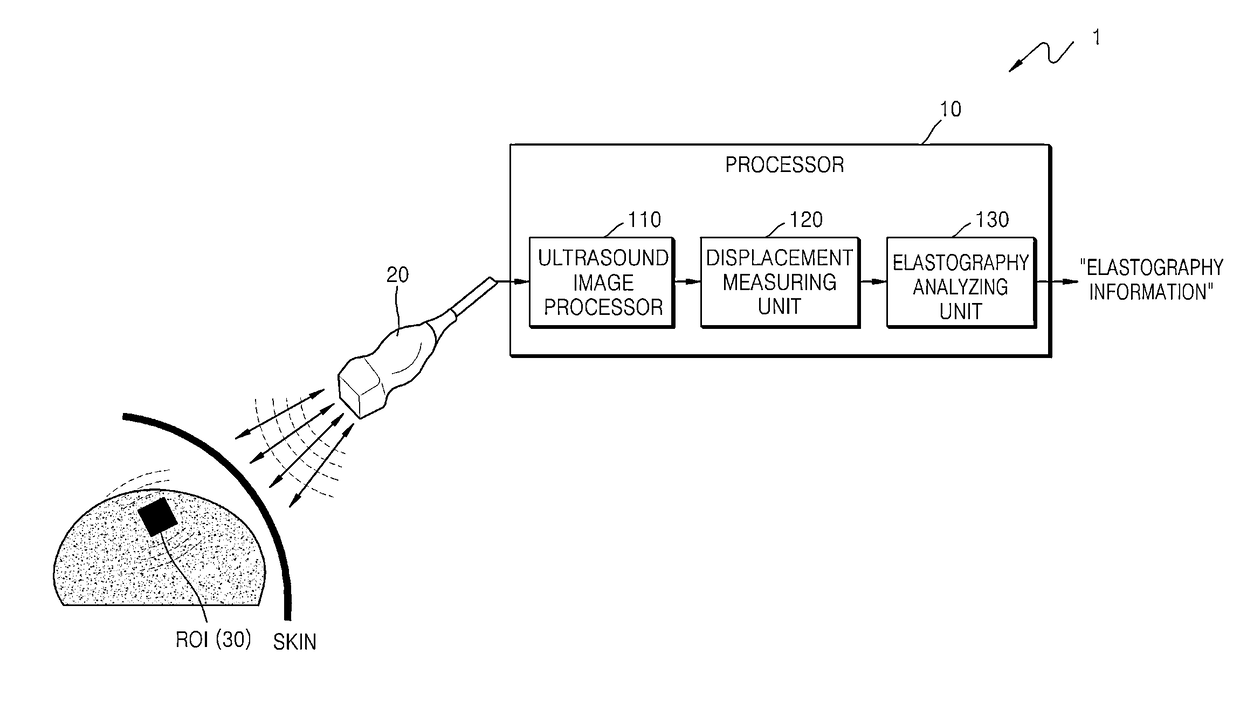

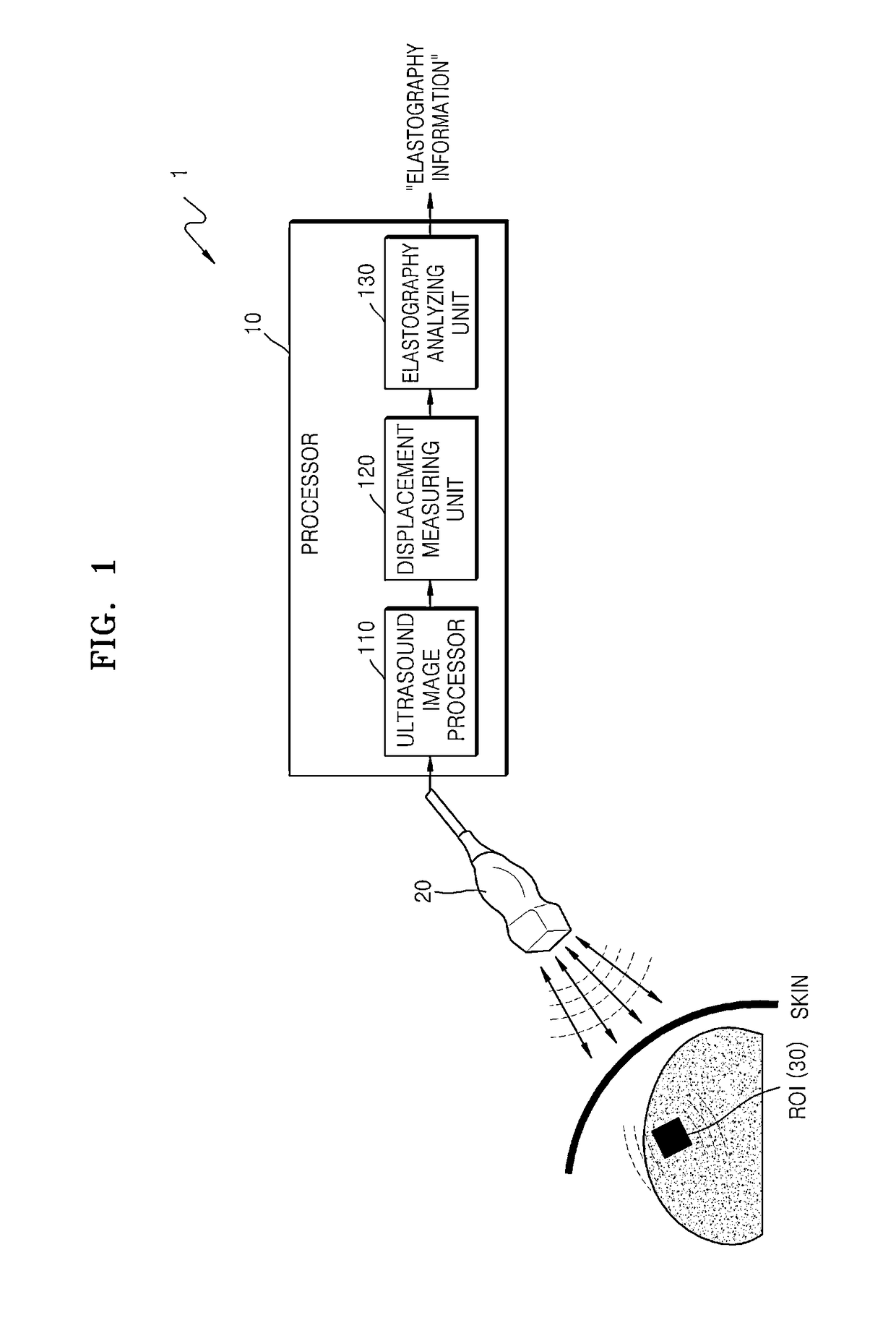

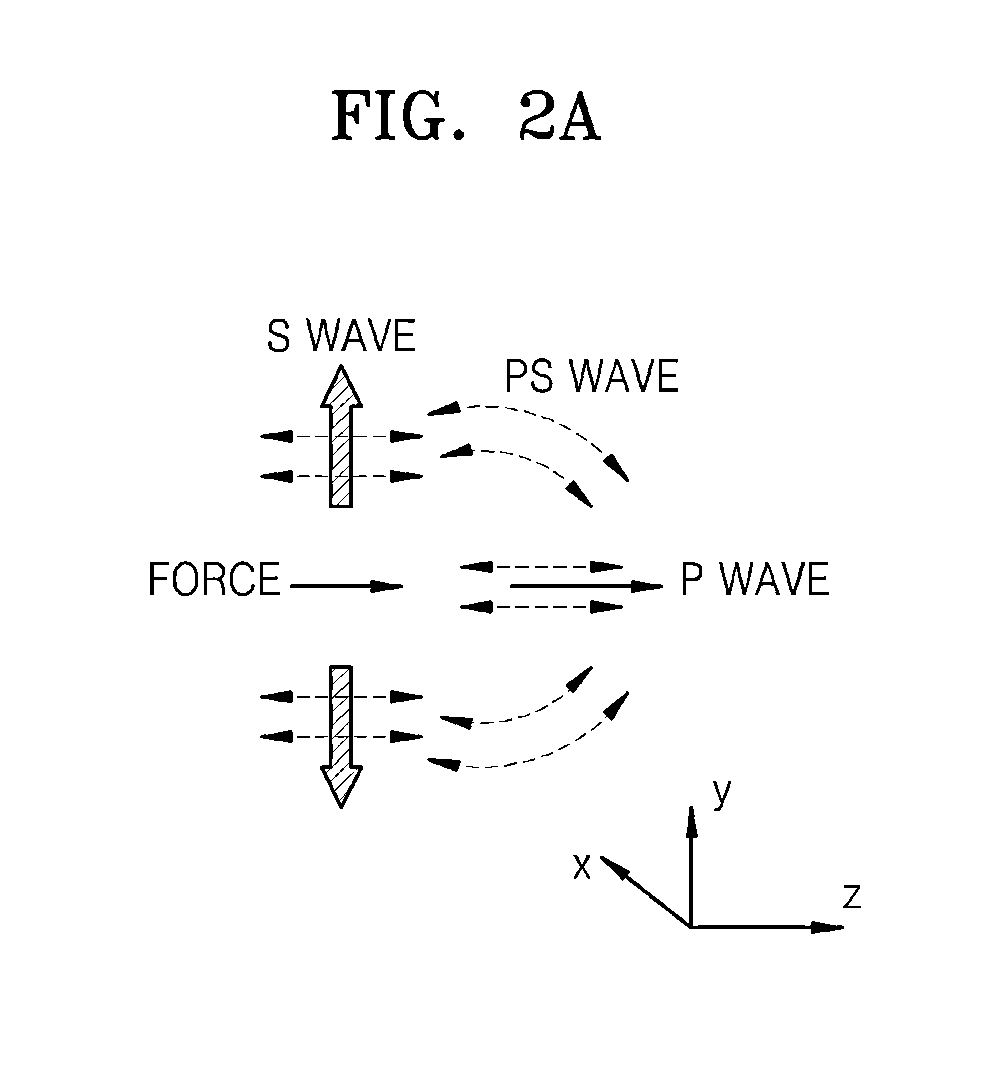

Method and apparatus for analyzing elastography of tissue using ultrasound waves

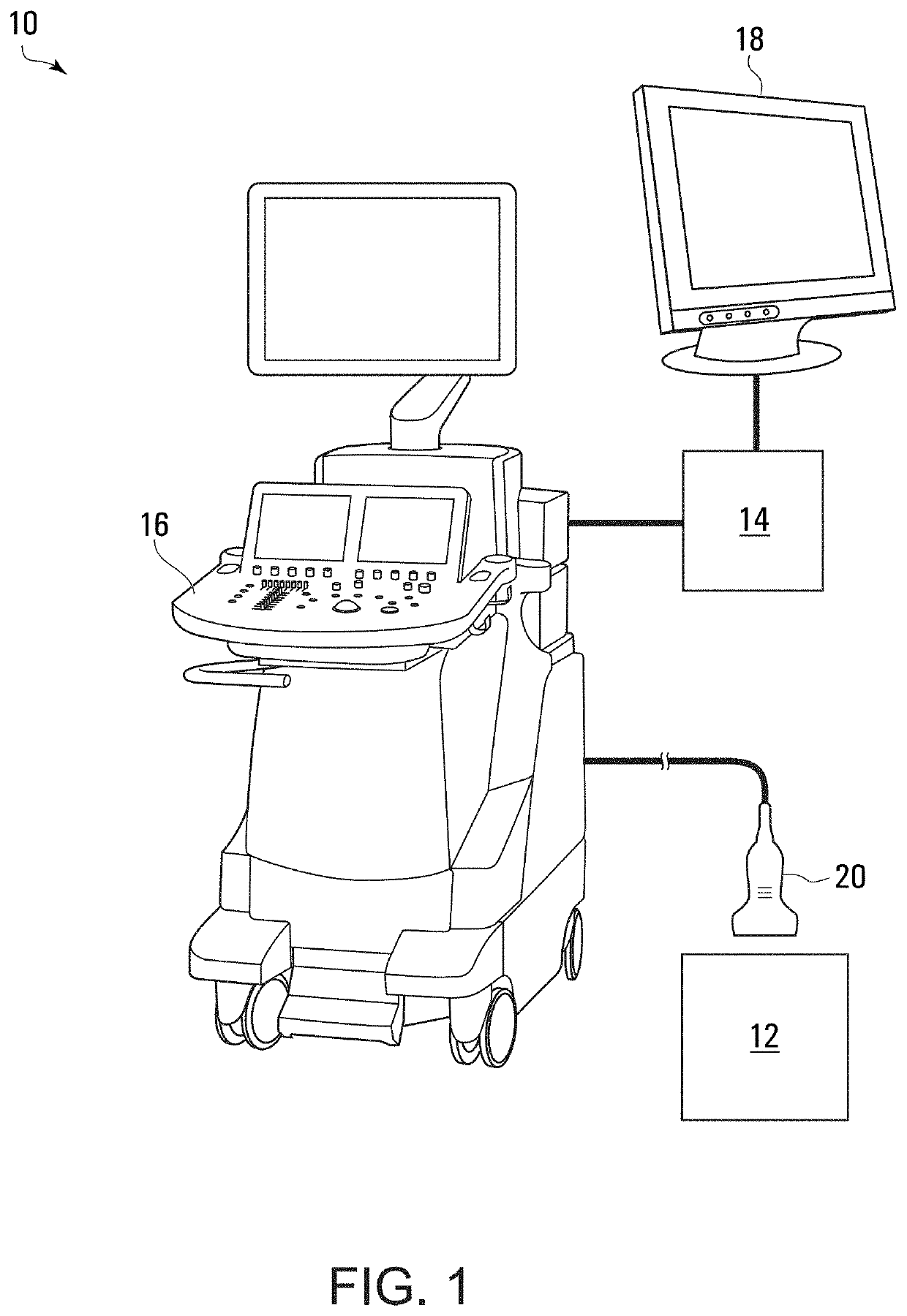

A method and apparatus for analyzing elastography of tissue using ultrasound waves, wherein elastography information of tissue in a region of interest (ROI) is analyzed by irradiating ultrasound waves for diagnosis towards the ROI to which a shear wave is induced from an ultrasound probe, receiving echo ultrasound waves, and acquiring three-dimensional (3D) ultrasound images with respect to the ROI.

Owner:SAMSUNG ELECTRONICS CO LTD

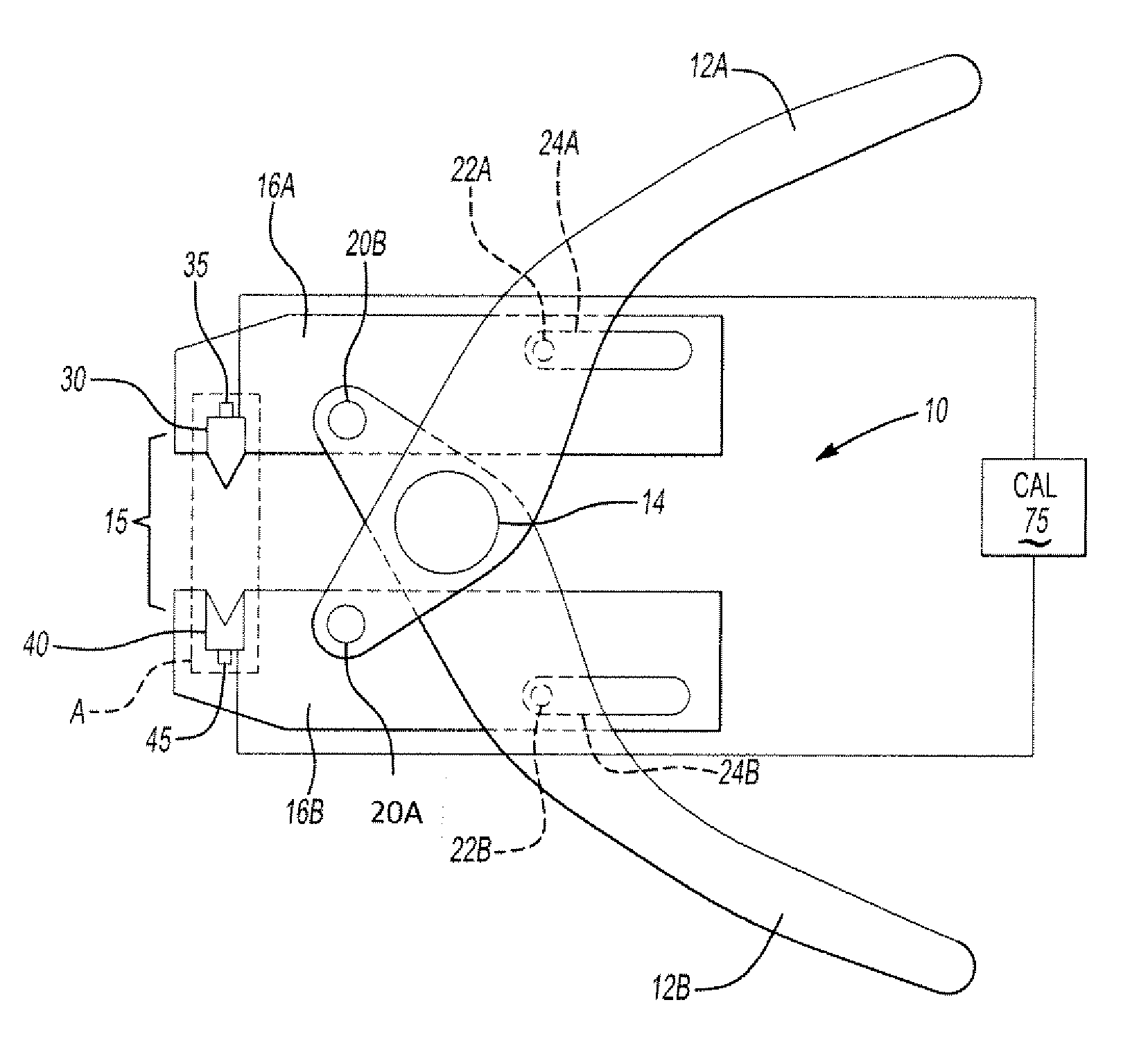

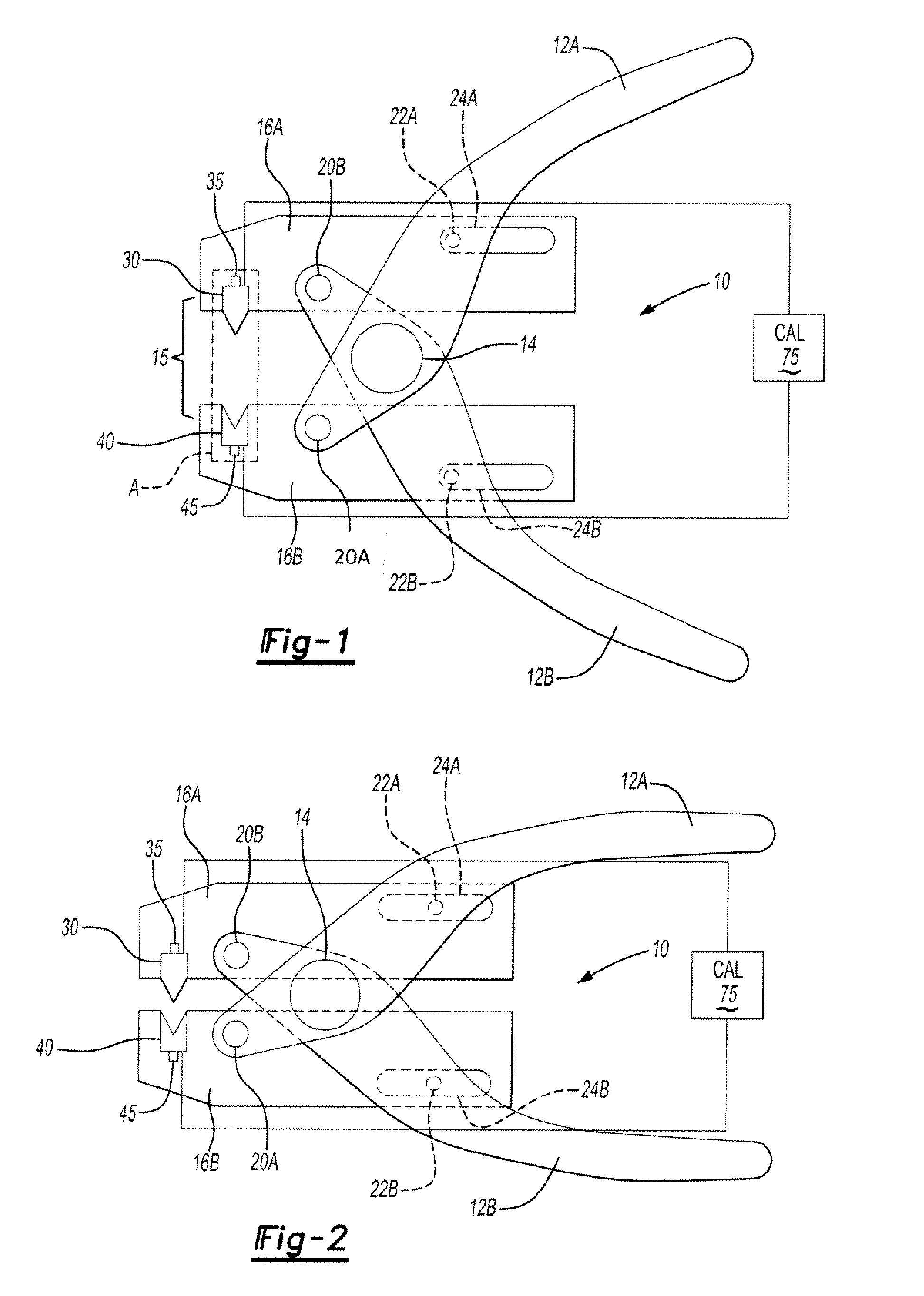

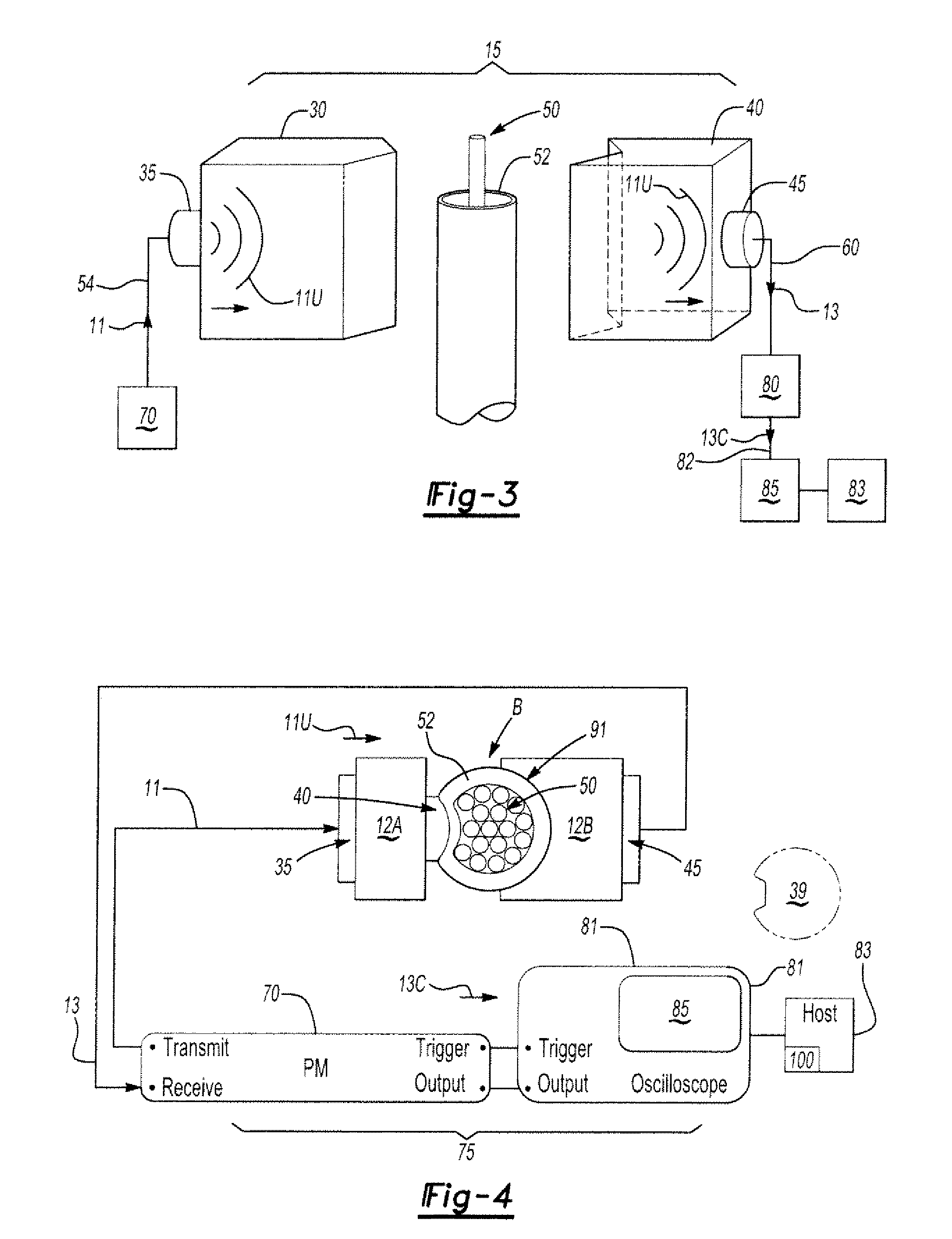

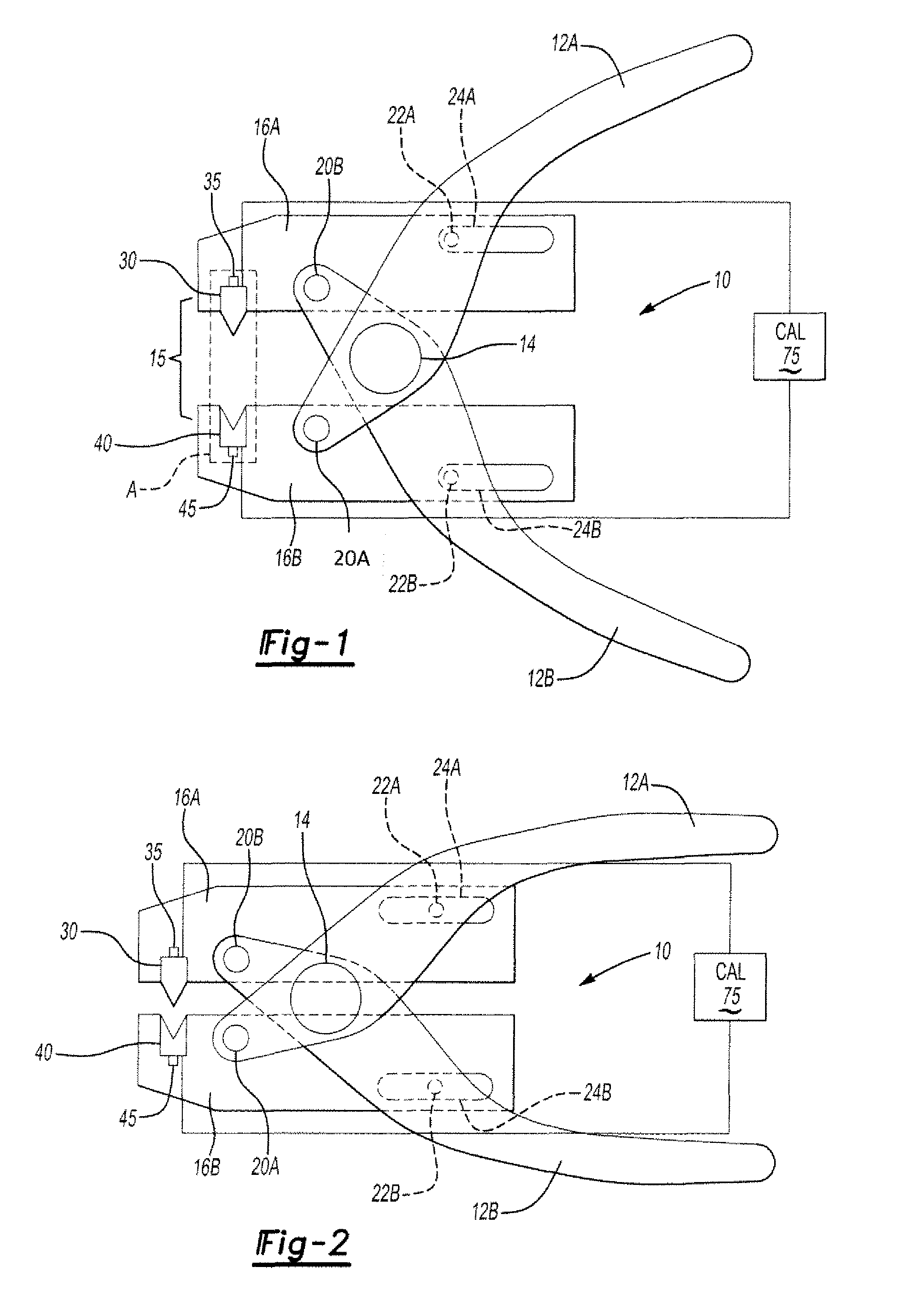

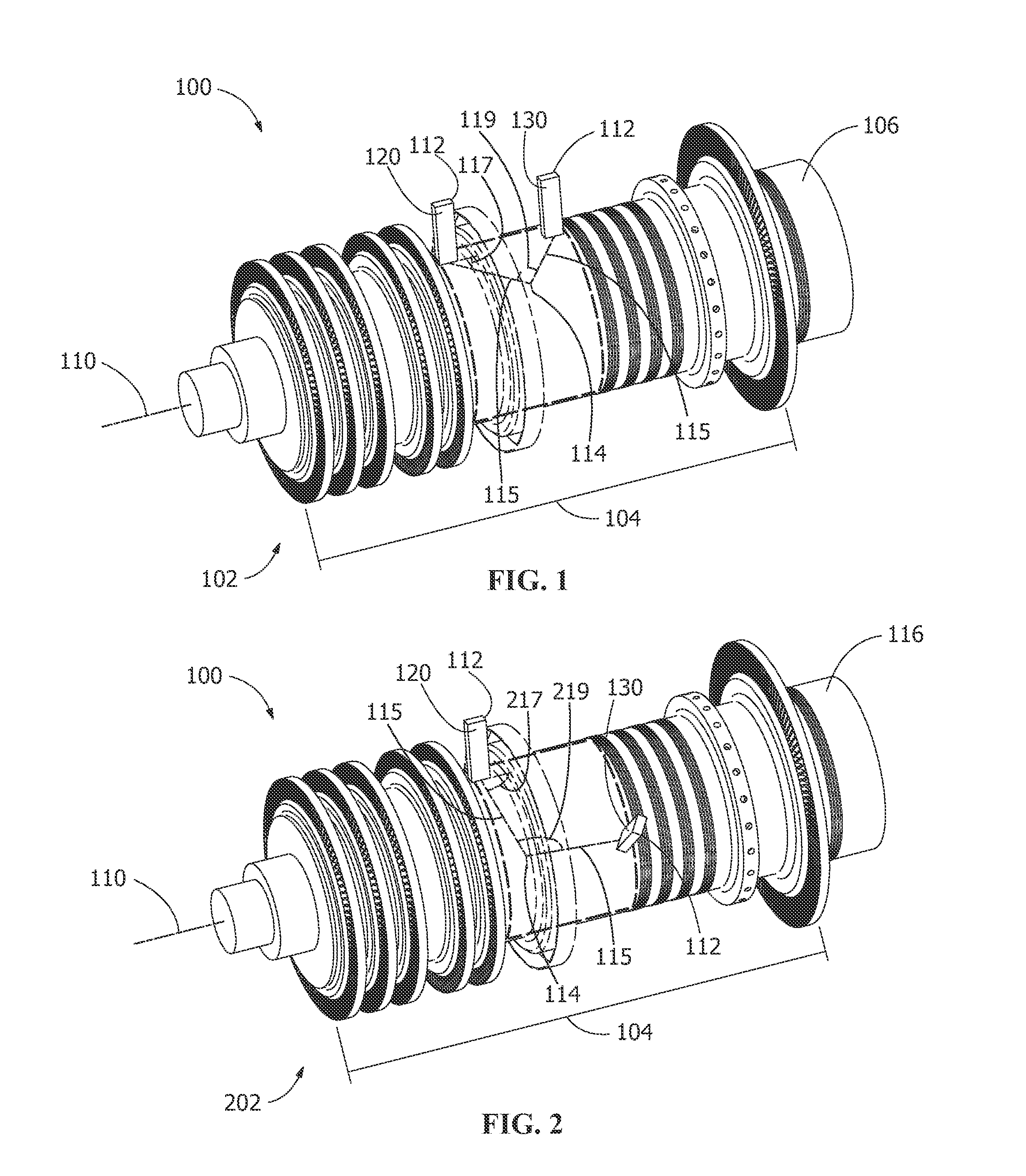

Assessment and Calibration of a Crimp Tool Equipped with Ultrasonic Analysis Features

InactiveUS20120060585A1Precise alignmentImprove performanceAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricitySonification

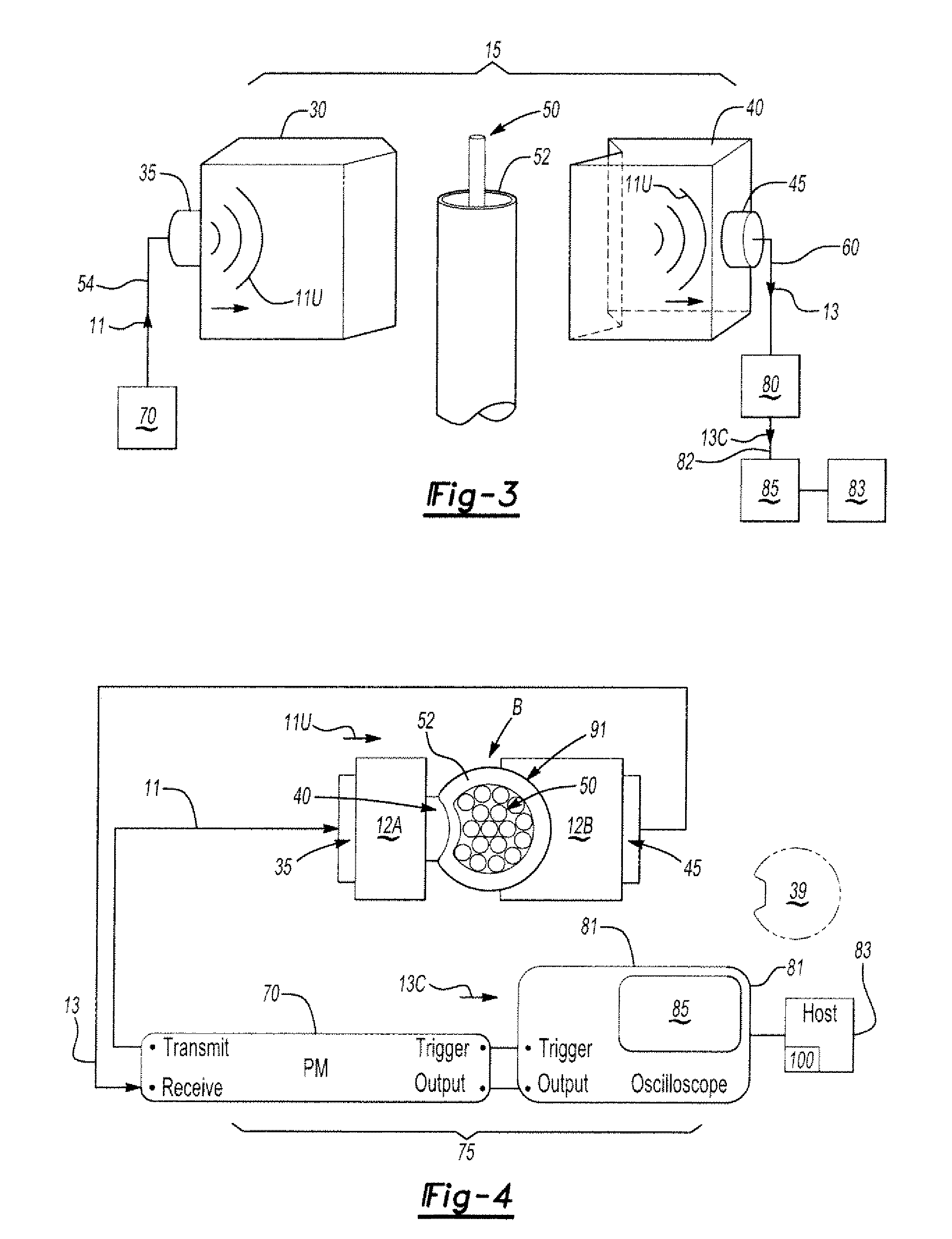

A method is provided for calibrating ultrasonic signals passed through a crimp formed with respect to a deformable body via an ultrasonically-equipped crimp tool (UECT). The UECT verifies a crimp quality using the ultrasonic signals. The method includes forming the crimp, transmitting a first signal, e.g., a pulse, to a first transducer of the UECT, and converting the first signal, using the first transducer, into a second signal which defines an ultrasonic pulse. This pulse is transmitted through the UECT into the crimp. A second transducer converts the second signal into a third signal, which may be further conditioned, and the ultrasonic signals are calibrated using the third signal or its conditioned variant. An apparatus for calibrating the ultrasonic signals includes a pulse module (PM) electrically connected to the first and second transducers, and an oscilloscope or display electrically connected to the PM for analyzing an electrical output signal therefrom.

Owner:NASA

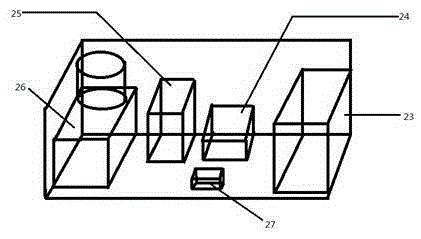

Device for analyzing oxygen density and flow rate and analysis method thereof

ActiveCN101592630ACompact structureEasy CalibrationRespiratorsMaterial analysis using sonic/ultrasonic/infrasonic wavesMicrocontrollerEngineering

The invention relates to a device for analyzing the oxygen density and the flow rate by utilizing ultrasonic and an analysis method thereof. The device comprises a container; two ends of the container are respectively provided with a circuit board, and the container is internally provided with a container internal cavity; the external part of the container internal cavity is provided with an inlet external cavity and an outlet external cavity; an air inlet and an air outlet are arranged on the container, and are respectively communicated with the inlet external cavity and the outlet external cavity; and both circuit boards are respectively provided with an ultrasonic transducer, any one of which is provided with a temperature sensor inserted into the container internal cavity through long tube leg pins. The method comprises the following steps: a transmission unit is used for controlling one of the ultrasonic transducers to transmit ultrasonic and the other one to receive the ultrasonic; a switching network switches over and controls the transmission and receiving of the ultrasonic transducers, and simultaneously the temperature sensor is used for measuring oxygen temperature T; a receiving unit sends signals to a microcontroller to obtain the forward conduction time and reverse conduction time tf and tr; and then the density P and the flow rate Q of oxygen being measured are calculated through a function relationship. The invention has the advantages of fast response speed to density change, compact structure, and the like.

Owner:SYSMED CHINA CO LTD

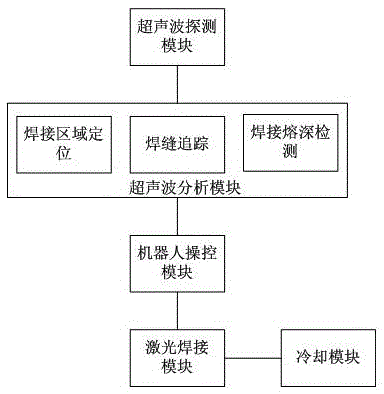

Brush type seal robot welding system based on ultrasonic detection technology

InactiveCN105562929AGuarantee welding qualityGuaranteed fine controlLaser beam welding apparatusWeld seamEngineering

The invention discloses a brush type seal robot welding system based on the ultrasonic detection technology. The brush type seal robot welding system based on the ultrasonic detection technology comprises an ultrasonic detection module. An ultrasonic analysis module is electrically connected with and communicates with the ultrasonic detection module and a robot control module. A laser welding module is fixedly connected with the robot control module. The ultrasonic analysis module scans a welding surface of a row wire root of a brush type seal through ultrasonic flaw detection equipment and sends wave signals obtained after scanning to the ultrasonic analysis module to carry out welding area positioning, welding seam tracking and welding penetration detection. Operation parameters are determined and sent to the robot control module. The robot control module works in cooperation with the laser welding module to complete welding operation. Welding area positioning, welding seam tracking and welding penetration monitoring are carried out through the ultrasonic detection technology, and automatic welding is realized in combination with a robot welding system, so that the welding quality is fully guaranteed, and meanwhile the welding work efficiency is improved.

Owner:江苏拓平密封科技有限公司

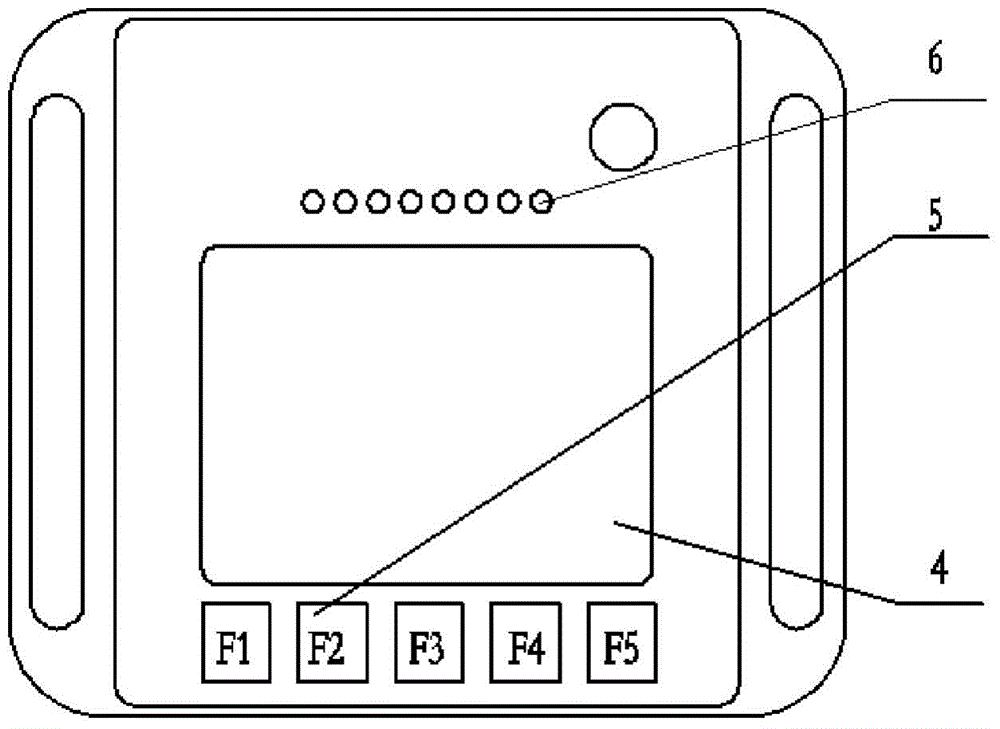

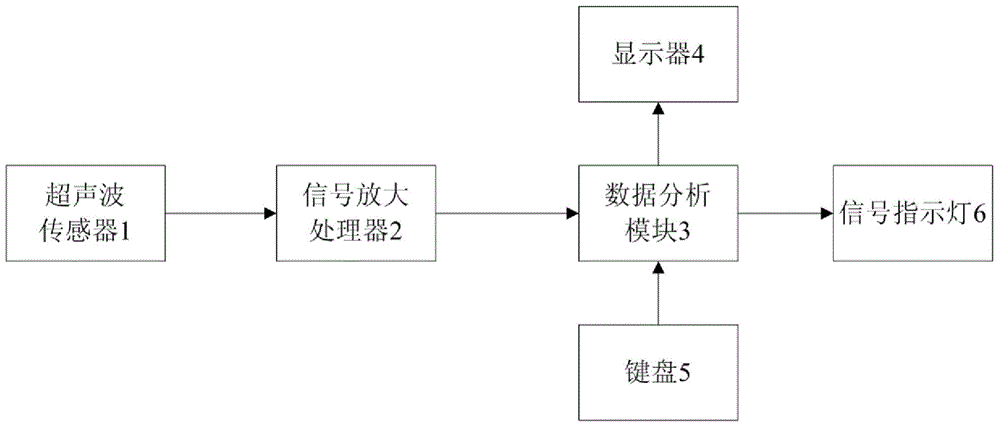

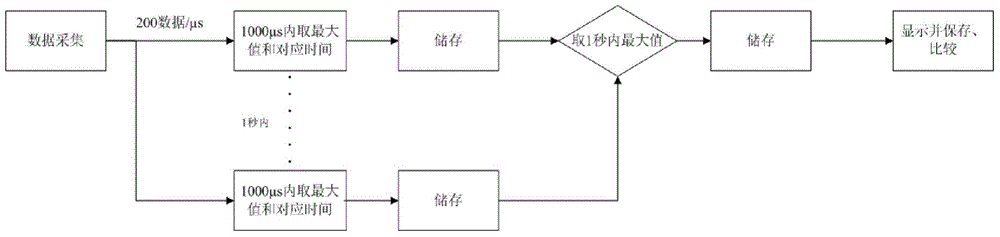

Ultrasonic wave analysis device and system for GIS breakdown positioning in electric system

InactiveCN104459490AAvoid Inductive Electrical InterferenceAvoid failureTesting dielectric strengthElectric power systemDisplay device

The invention discloses an ultrasonic wave analysis device and system for GIS breakdown positioning in an electric system. The device comprises an ultrasonic sensor, a signal amplification processor, a data analysis module, a display, a keyboard and a signal indication lamp. The ultrasonic sensor is connected with the signal amplification processor, the signal amplification processor is connected with the data analysis module, and the display, the keyboard and the signal indication lamp are all connected with the data analysis module. The ultrasonic sensor is used for receiving ultrasonic signals generated by GIS breakdown discharge in the electric system, and the ultrasonic signals are transmitted to the data analysis module after being amplified in a multistage mode and filtered and tuned by the signal amplification processor. The data analysis module analyzes data and obtains breakdown data, and then captures data values and the moment corresponding to GIS breakdown. The device can detect breakdown discharge portions of GIS equipment. The invention simultaneously discloses the system being composed of a plurality of independent ultrasonic wave analysis devices.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Cable defect detecting system based on induction power supply

InactiveCN109557426ADefect detectionDefect safetyCircuit arrangementsFault location by conductor typesElectricityAcoustic wave

The invention discloses a cable defect detecting system based on induction power supply. A clamping portion is used to clamp a cable; an ultrasonic sensor is disposed outside a safe distance from thecable, and the ultrasonic sensor conducts, through an optical fiber, a pressure wave signal generated during partial discharge of the online running cable caused by a cable core defect, sends the detected signal to an ultrasonic analyzer for detection and analysis; and finally the detection and analysis result is compared with a pre-calibrated result to determine the degree of cable defect. The system, by adopting a special cable clamp, can safely detect the defects of the cable when the cable is running online, and can conduct sound waves through the optical fiber, with a detection success rate much higher than the test result under the cable offline state. At the same time, the power supply circuit realizes the power supply from the cable, which can meet the long-term work under complicated conditions.

Owner:南京龙贞自控科技发展有限公司

Assessment and calibration of a crimp tool equipped with ultrasonic analysis features

InactiveUS8490463B2Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricitySonification

A method is provided for calibrating ultrasonic signals passed through a crimp formed with respect to a deformable body via an ultrasonically-equipped crimp tool (UECT). The UECT verifies a crimp quality using the ultrasonic signals. The method includes forming the crimp, transmitting a first signal, e.g., a pulse, to a first transducer of the UECT, and converting the first signal, using the first transducer, into a second signal which defines an ultrasonic pulse. This pulse is transmitted through the UECT into the crimp. A second transducer converts the second signal into a third signal, which may be further conditioned, and the ultrasonic signals are calibrated using the third signal or its conditioned variant. An apparatus for calibrating the ultrasonic signals includes a pulse module (PM) electrically connected to the first and second transducers, and an oscilloscope or display electrically connected to the PM for analyzing an electrical output signal therefrom.

Owner:NASA

Optical ultrasound device

InactiveUS20090097012A1Minimizes electronic interferenceIncreased signal noiseMaterial analysis using sonic/ultrasonic/infrasonic wavesPhase-affecting property measurementsUltrasound deviceSonification

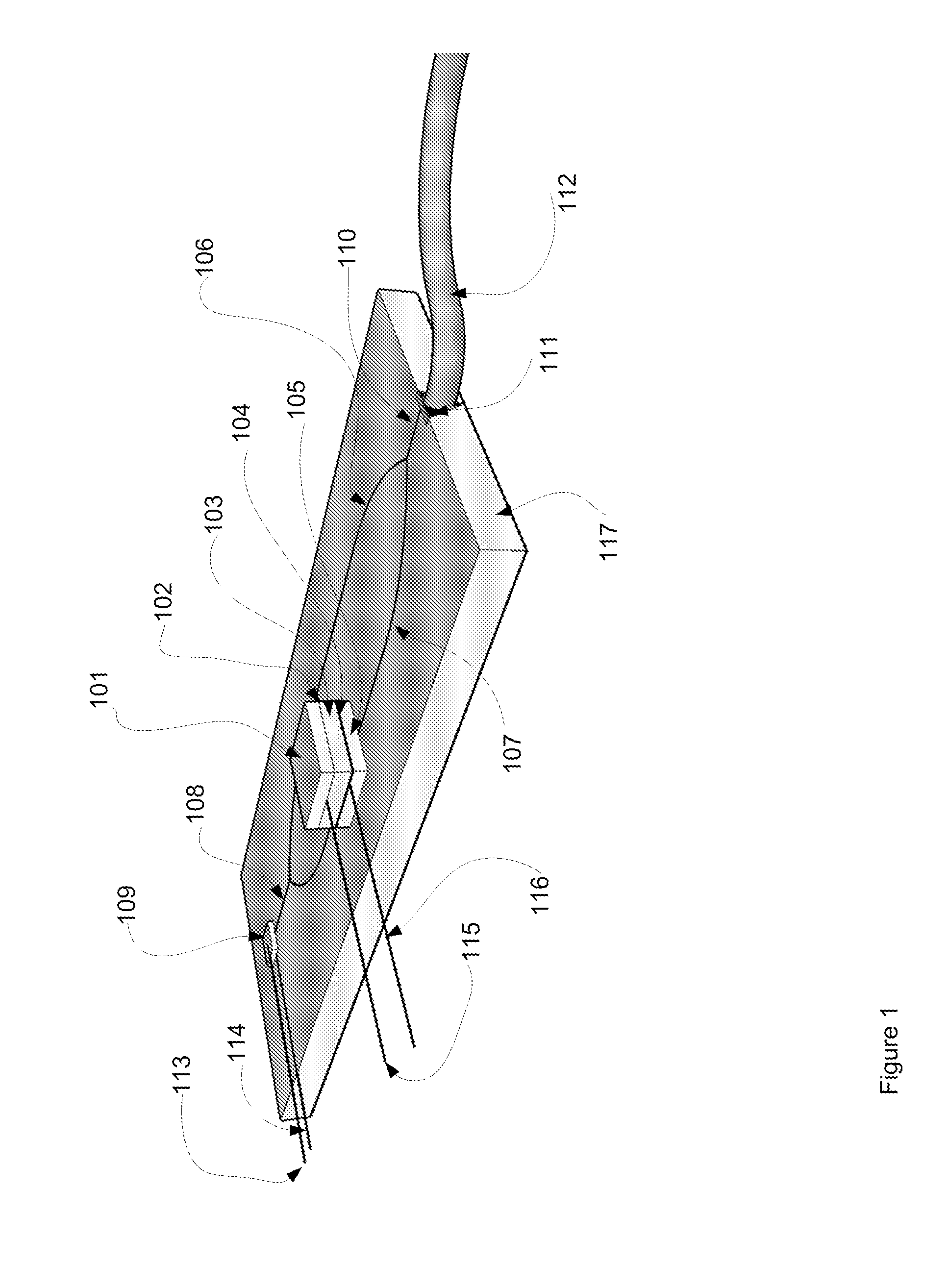

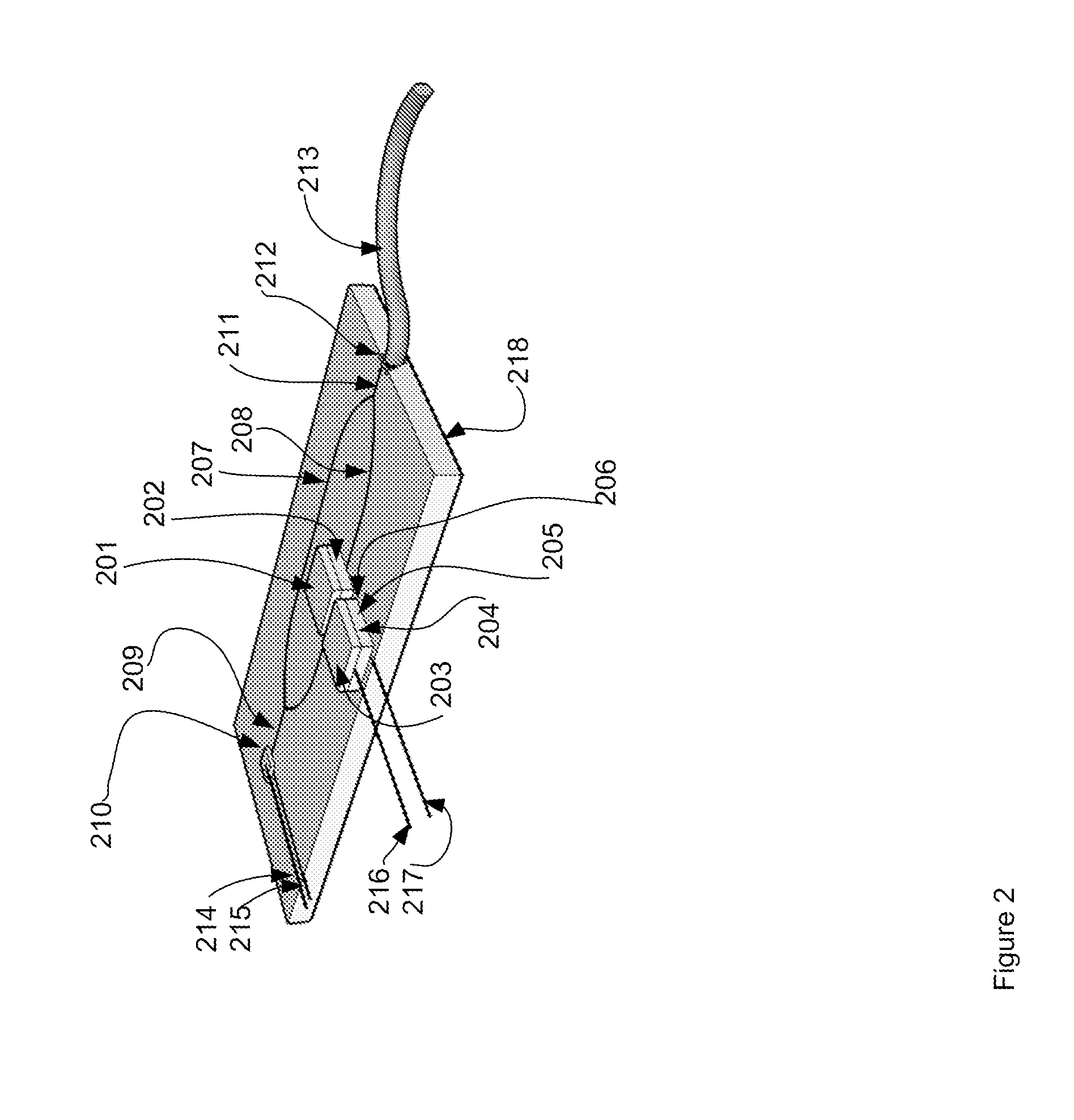

A new optical ultrasonic analysis transducer is described. The device includes a new detection means for the reflected ultrasound signal. The detector may be incorporated into a microchip design. The detector is compatible with a variety of material and design geometries that may be optimized for the particular application. Versions of the device may optionally include both excitation and receiving elements on the same device or these elements may be separate. Example designs are shown with applications to continuous wave ultrasound analysis useful for example in Doppler fluid flow measurements. Other designs are shown with multiple arrays and multiple excitation transducers to allow flexible three-dimensional imaging apparatus to be built. An equivalent circuit analysis of the frequency response and signal sensitivity provides means to customize material selection and other design parameters for particular applications.

Owner:GARDNER JUDD

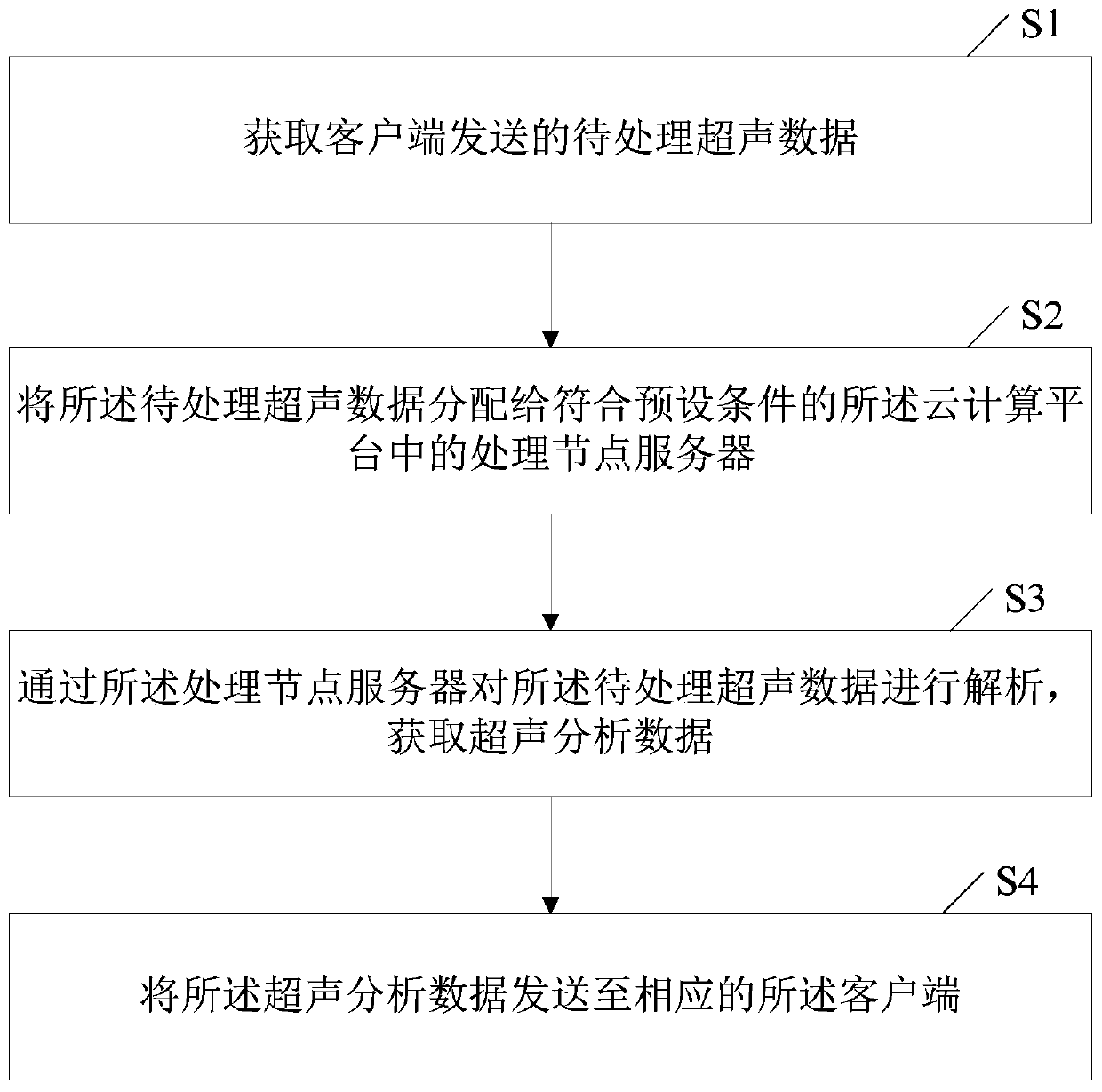

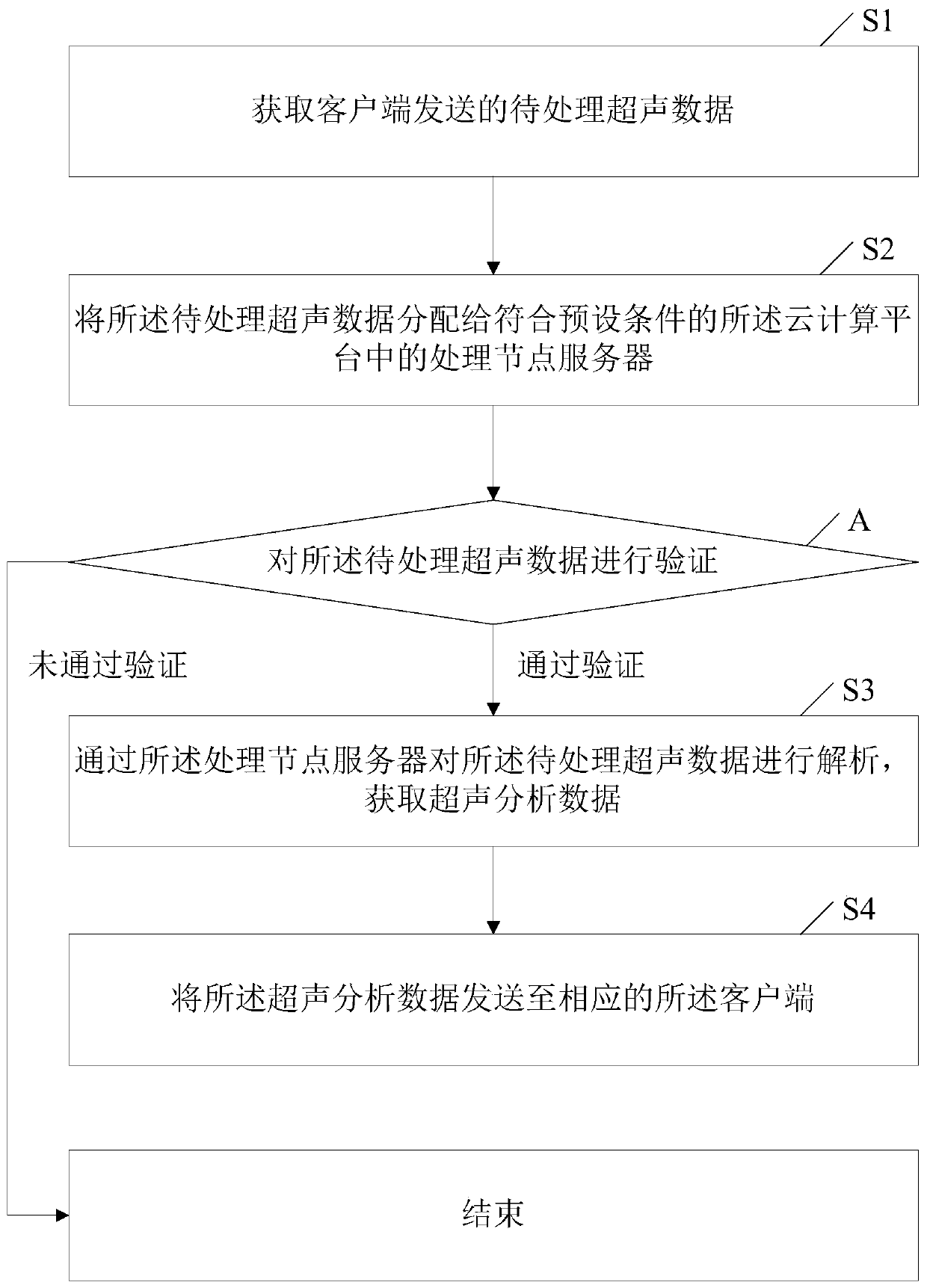

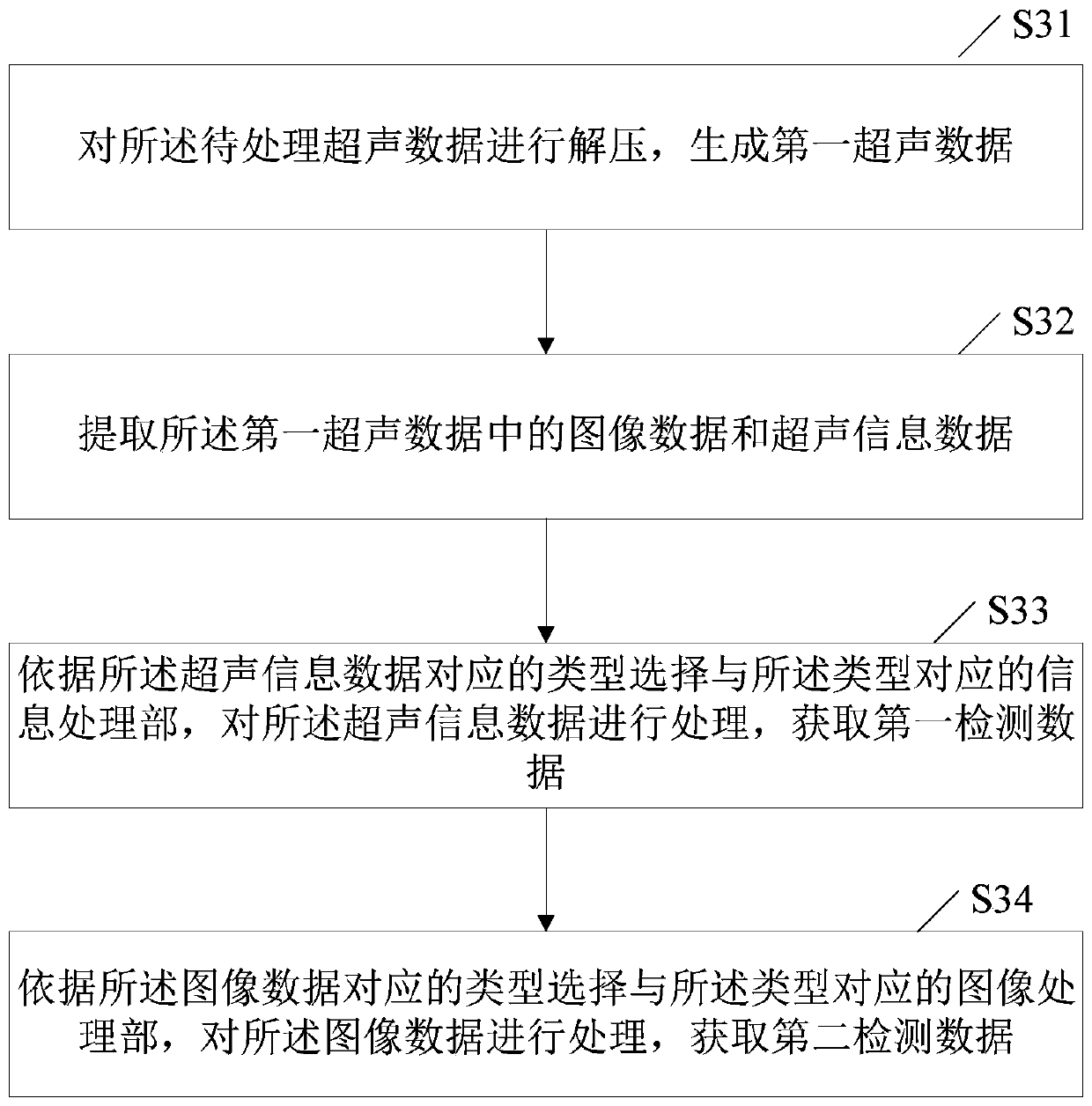

Ultrasonic image processing method and system

PendingCN111105863ARealize automatic identificationSmall amount of calculationMedical automated diagnosisMedical imagesComputer hardwareEngineering

The invention discloses an ultrasonic image processing method and system, and belongs to the field of data management. The ultrasonic image processing method comprises the following steps that to-be-processed ultrasonic data sent by a client is distributed to a processing node server in a cloud computing platform meeting a preset condition; the processing node server analyzes the to-be-processed ultrasonic data, obtains the ultrasonic analysis data and sends the ultrasonic analysis data to the corresponding client, so that the purpose of automatically identifying the ultrasonic data is achieved, manual identification is not needed, and the condition of missed diagnosis is avoided. Meanwhile, the cloud computing platform is adopted for ultrasonic data analysis, so that the calculated amountof local equipment (such as ultrasonic equipment, workstations or PACS of hospitals and the like) is reduced.

Owner:上海深至信息科技有限公司

Test device used for measuring partial discharge signal attenuation in ultrasonic method

ActiveCN104142177ATesting dielectric strengthSubsonic/sonic/ultrasonic wave measurementUltrasound attenuationCoaxial cable

The invention relates to the technical field of partial discharge detection, in particular to a test device used for measuring ultrasonic partial discharge signal attenuation in an ultrasonic method. The test device comprises a high-voltage lead terminal, a horizontal bus sleeve and a vertical bus sleeve, a horizontal high-voltage conductor is arranged in the horizontal bus sleeve, a vertical high-voltage conductor is arranged in the vertical bus sleeve, the high-voltage lead terminal is connected with the horizontal high-voltage conductor, the vertical high-voltage conductor is connected with the horizontal high-voltage conductor through an isolation switch, the connection portion of the isolation switch and the vertical high-voltage conductor is of an L-type structure, the portion of the L-type structure between the high-voltage lead terminal and the horizontal high-voltage conductor is provided with a discharge pointed end, ultrasonic sensors are arranged in the horizontal bus sleeve, on the isolation switch and in the vertical bus sleeve respectively, and the ultrasonic sensors are all connected with an oscilloscope through coaxial cables identical in length. The test device can provide a theoretical basis for best installation positions and the number of the ultrasonic sensors in a partial discharge online monitoring system.

Owner:STATE GRID CORP OF CHINA +2

Optical ultrasound device

InactiveUS7812960B2Minimizes electronic interferenceCompact designMaterial analysis using sonic/ultrasonic/infrasonic wavesPhase-affecting property measurementsUltrasound deviceSonification

A new optical ultrasonic analysis transducer is described. The device includes a new detection means for the reflected ultrasound signal. The detector may be incorporated into a microchip design. The detector is compatible with a variety of material and design geometries that may be optimized for the particular application. Versions of the device may optionally include both excitation and receiving elements on the same device or these elements may be separate. Example designs are shown with applications to continuous wave ultrasound analysis useful for example in Doppler fluid flow measurements. Other designs are shown with multiple arrays and multiple excitation transducers to allow flexible three-dimensional imaging apparatus to be built. An equivalent circuit analysis of the frequency response and signal sensitivity provides means to customize material selection and other design parameters for particular applications.

Owner:GARDNER JUDD

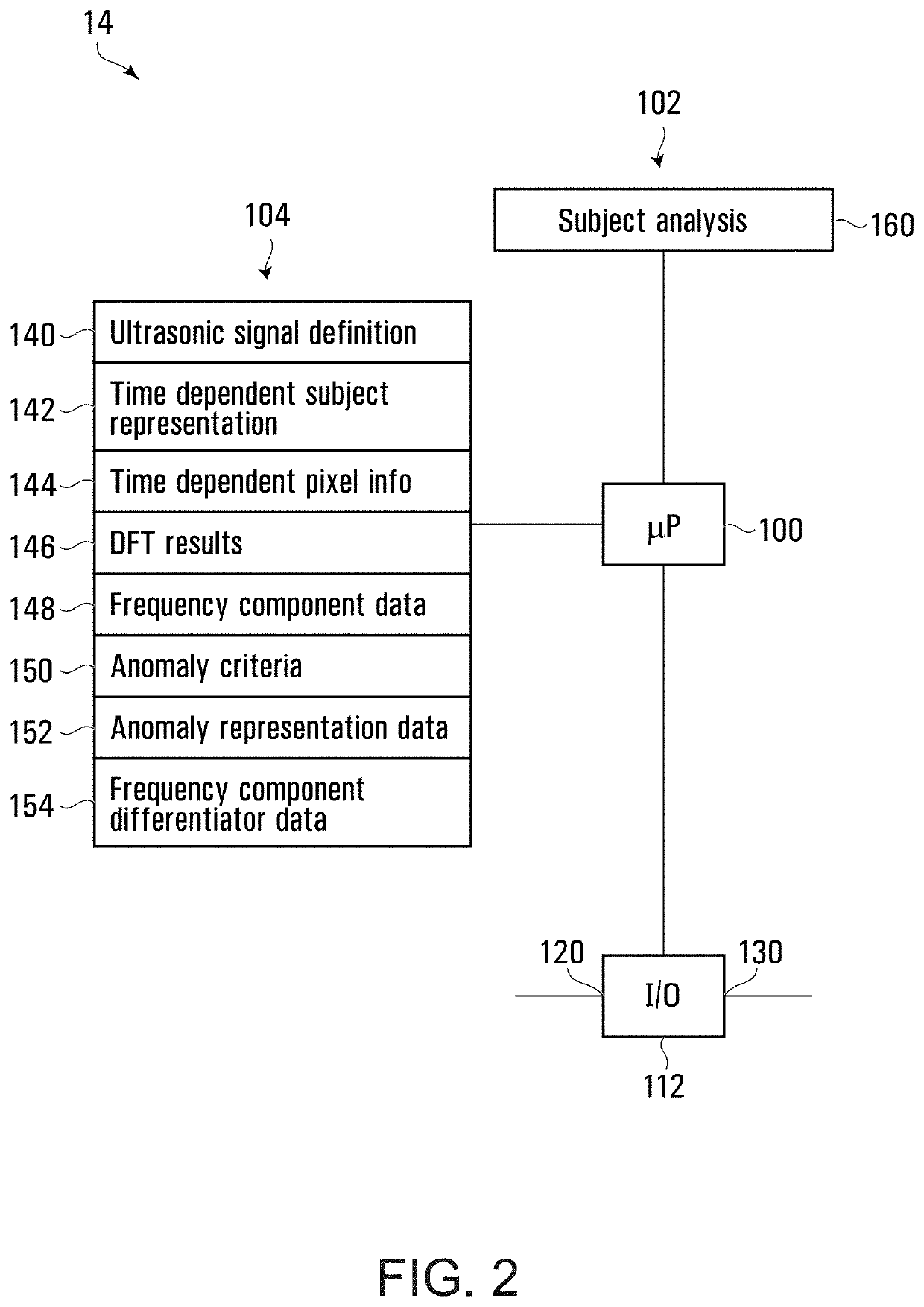

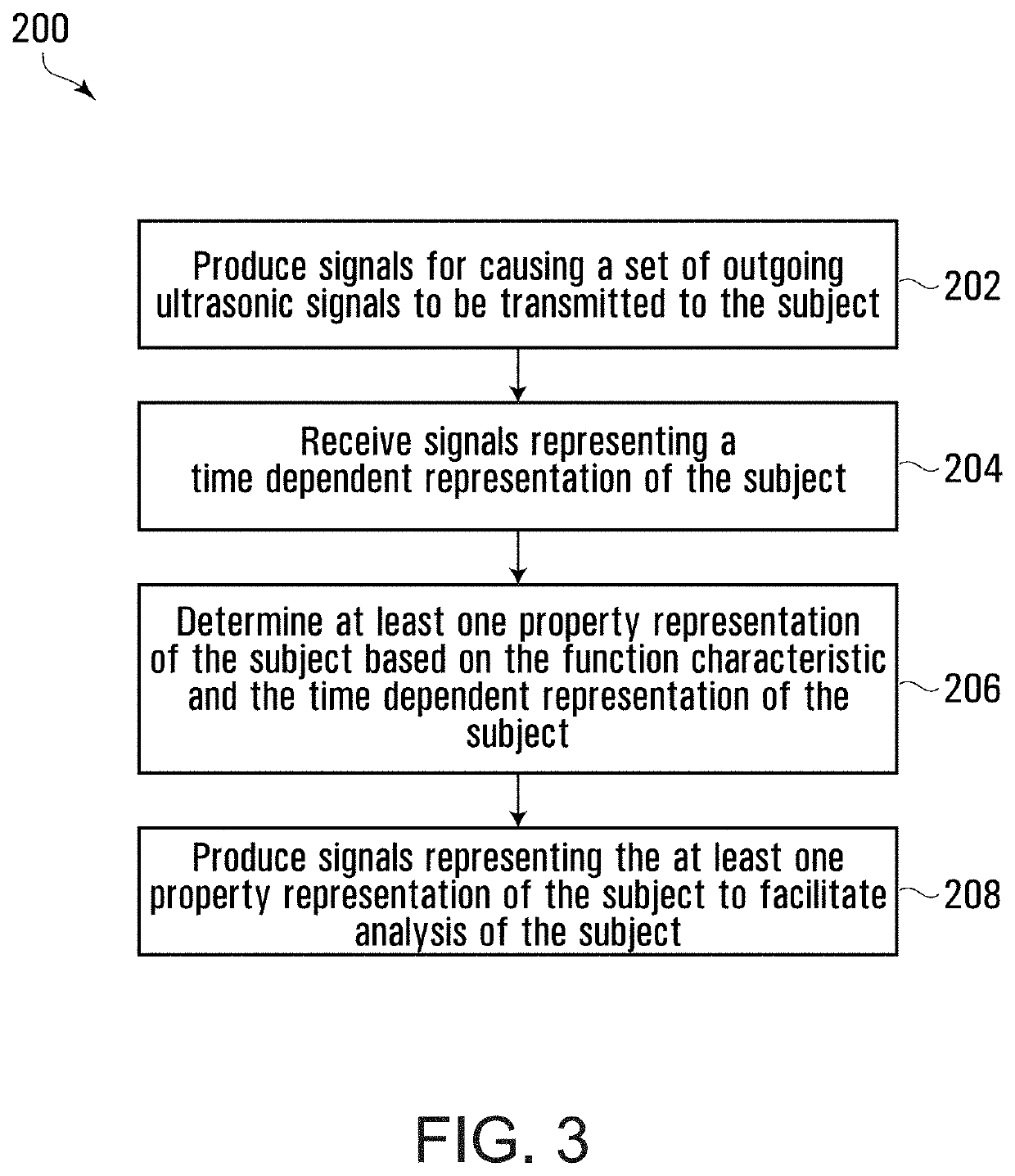

Ultrasonic analysis of a subject

ActiveUS11131650B2Easy to analyzeAnalysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionAcousticsComputer science

A method of facilitating ultrasonic analysis of a subject is provided. The method involves producing signals for causing a set of outgoing ultrasonic signals to be transmitted to the subject, wherein the set of outgoing ultrasonic signals is defined at least in part by a variable imaging parameter that varies over time in accordance with a variable imaging parameter function, the variable imaging parameter function represented or representable at least in part by a function characteristic, receiving signals representing a time dependent representation of the subject generated from a set of received ultrasonic signals scattered by the subject, determining at least one property representation of the subject based on the function characteristic and the time dependent representation of the subject, and producing signals representing the at least one property representation of the subject to facilitate analysis of the subject. Systems, non-transitory computer readable media, and other methods are also provided.

Owner:QUEENS UNIV OF KINGSTON +1

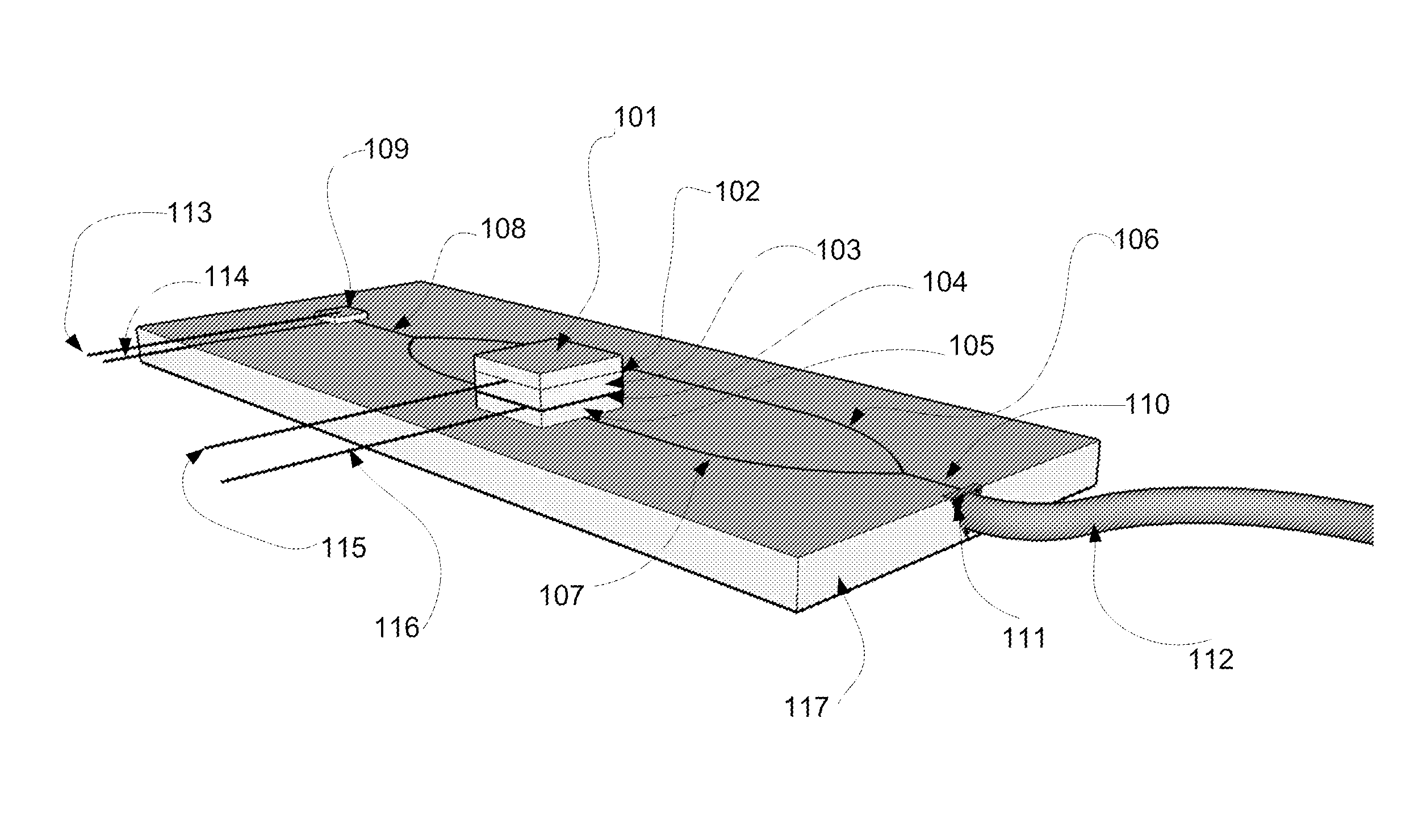

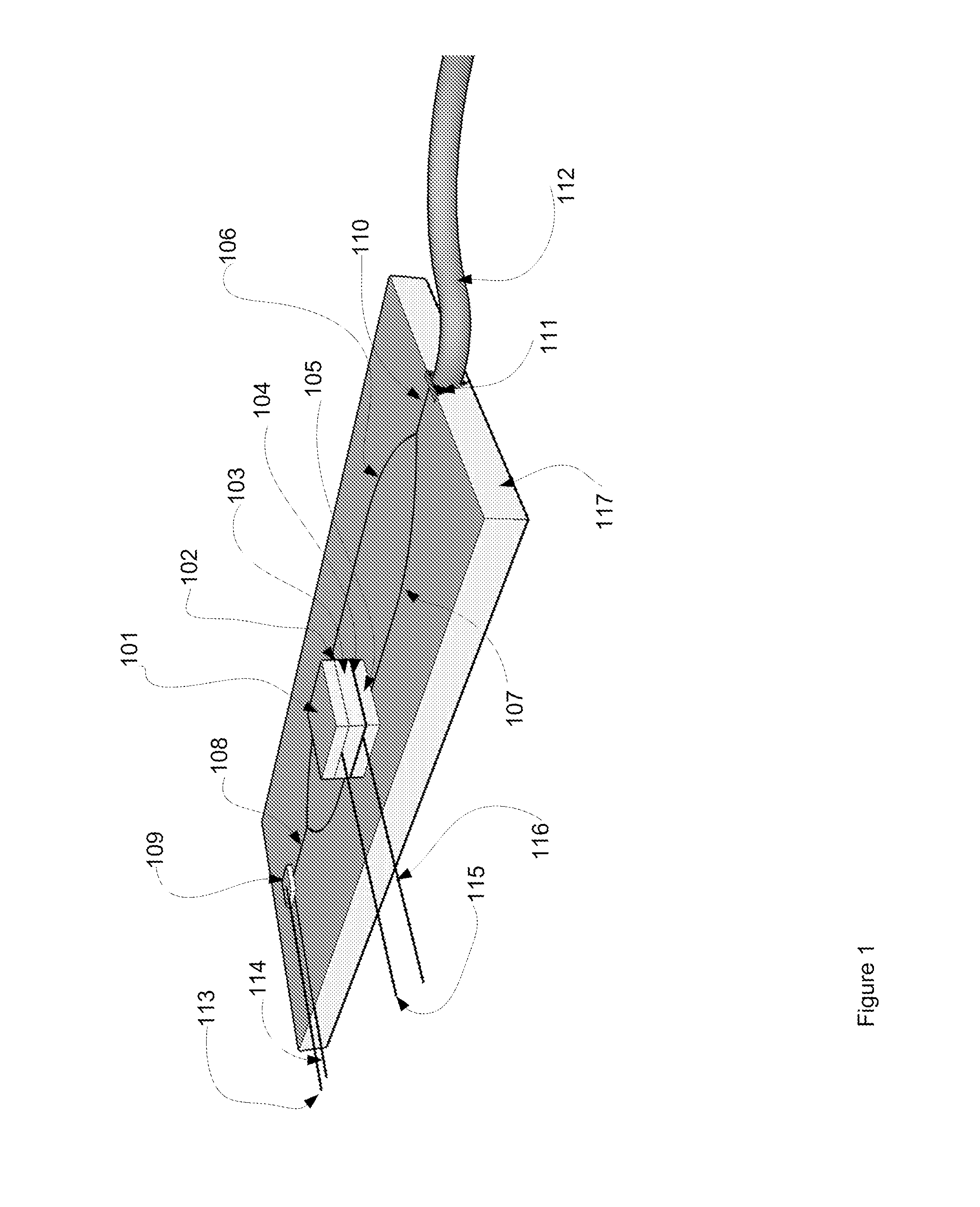

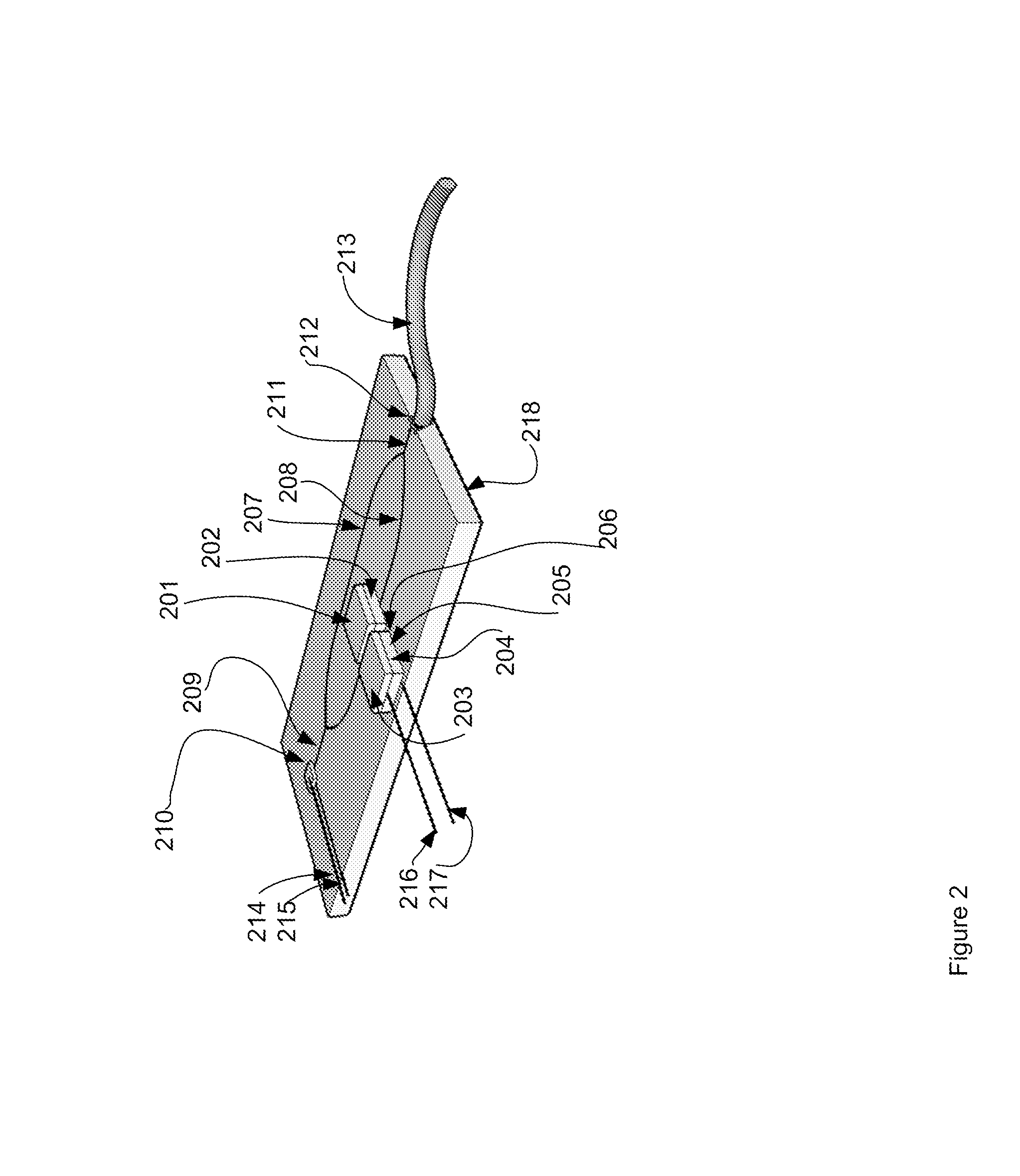

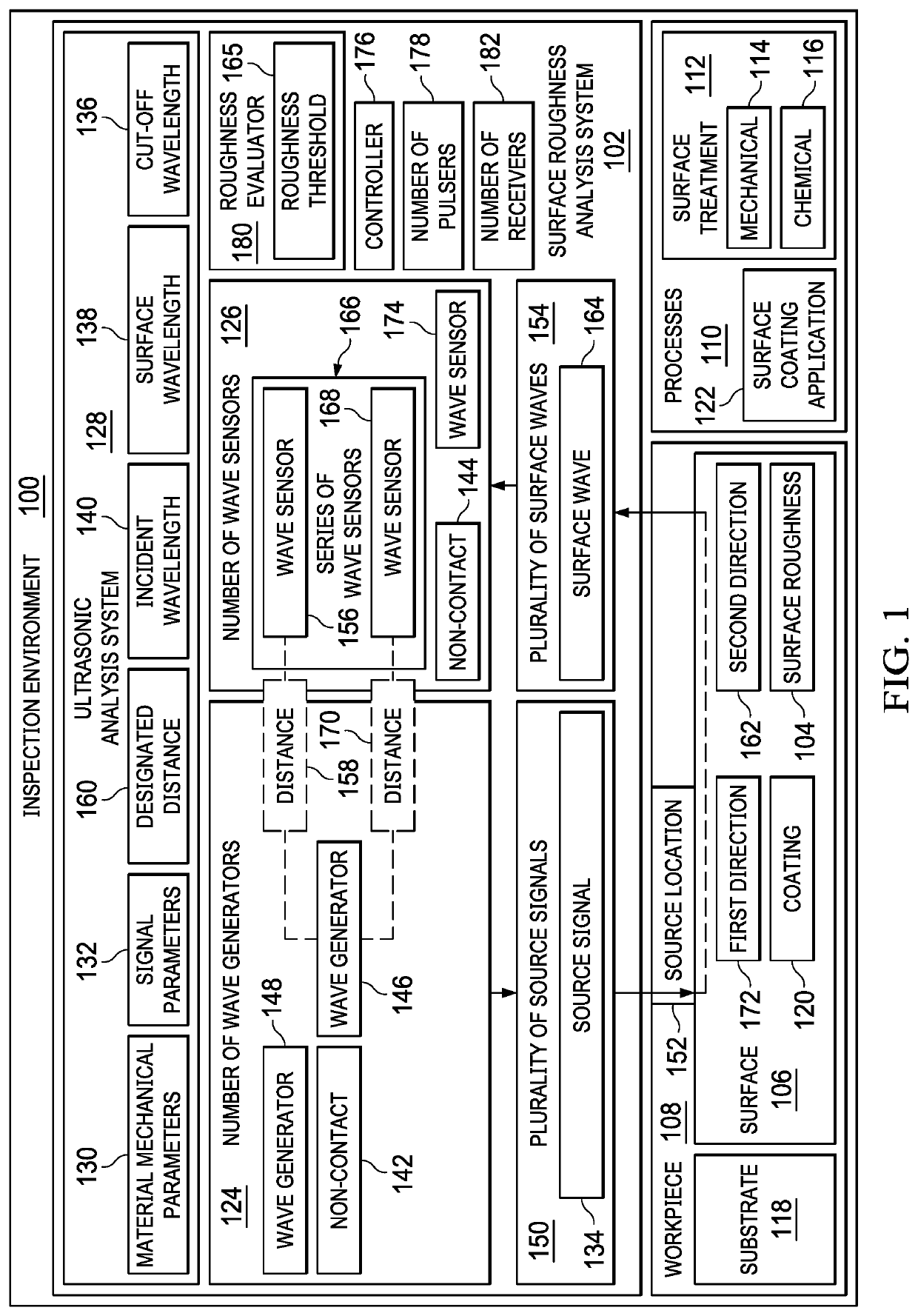

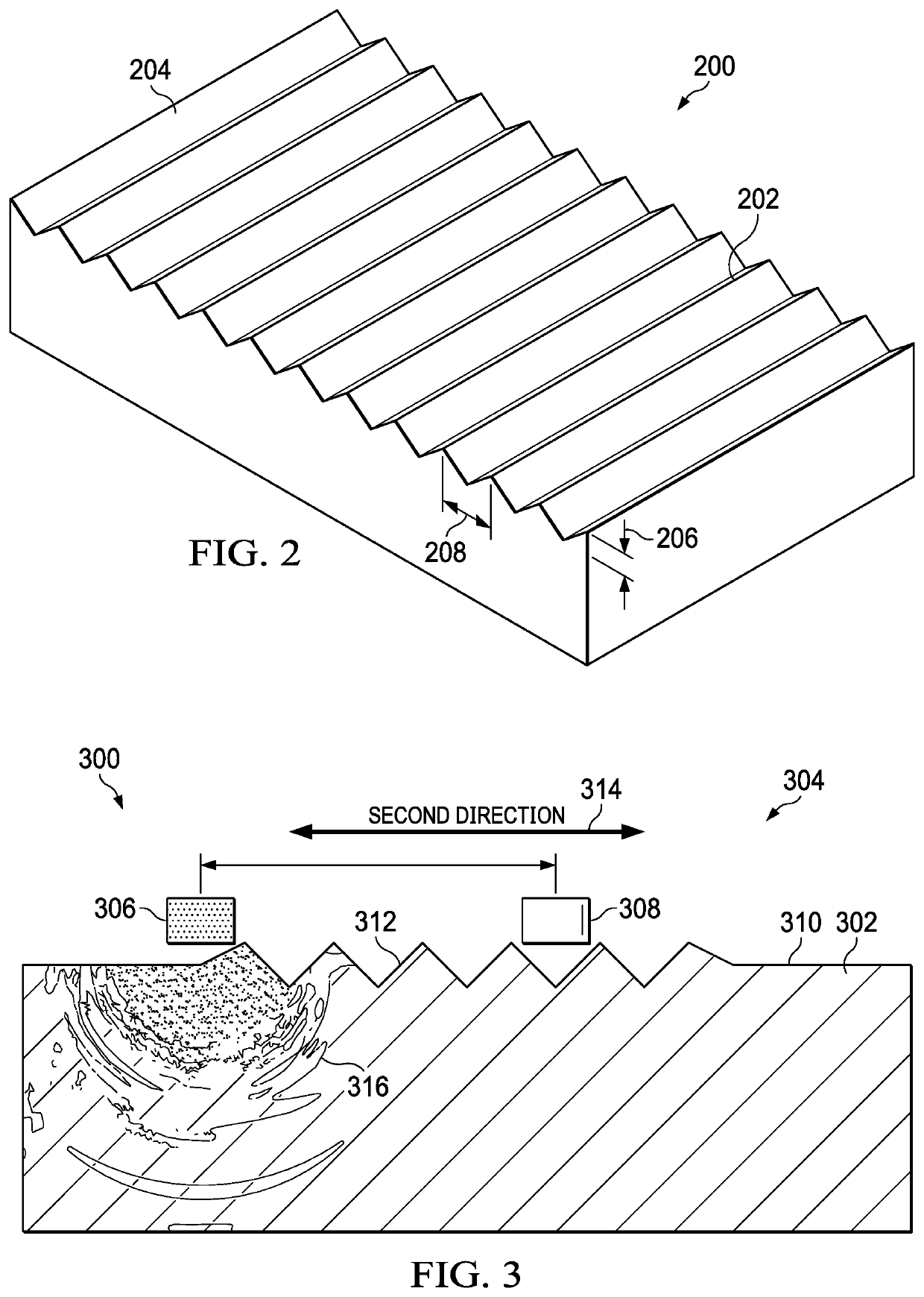

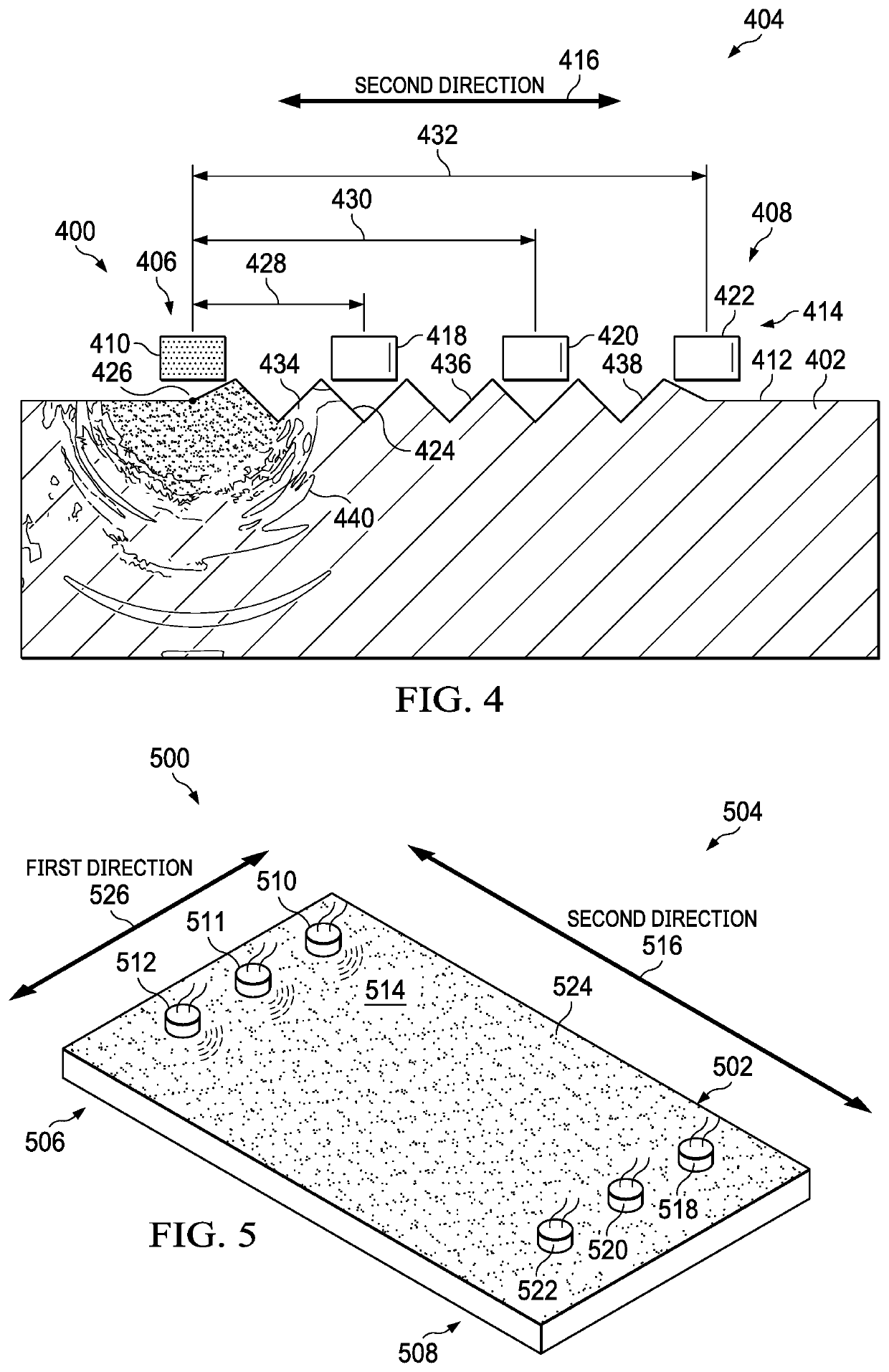

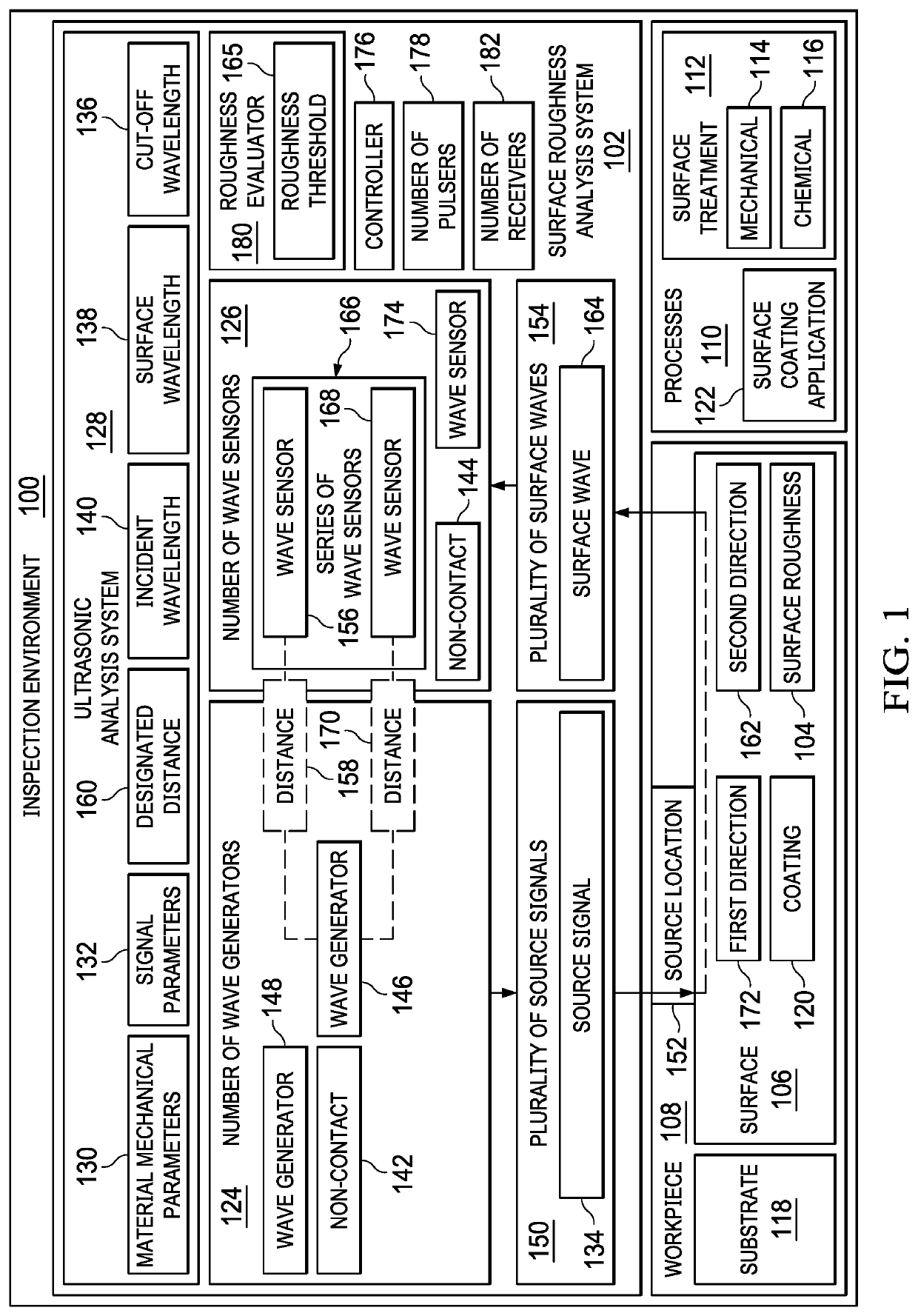

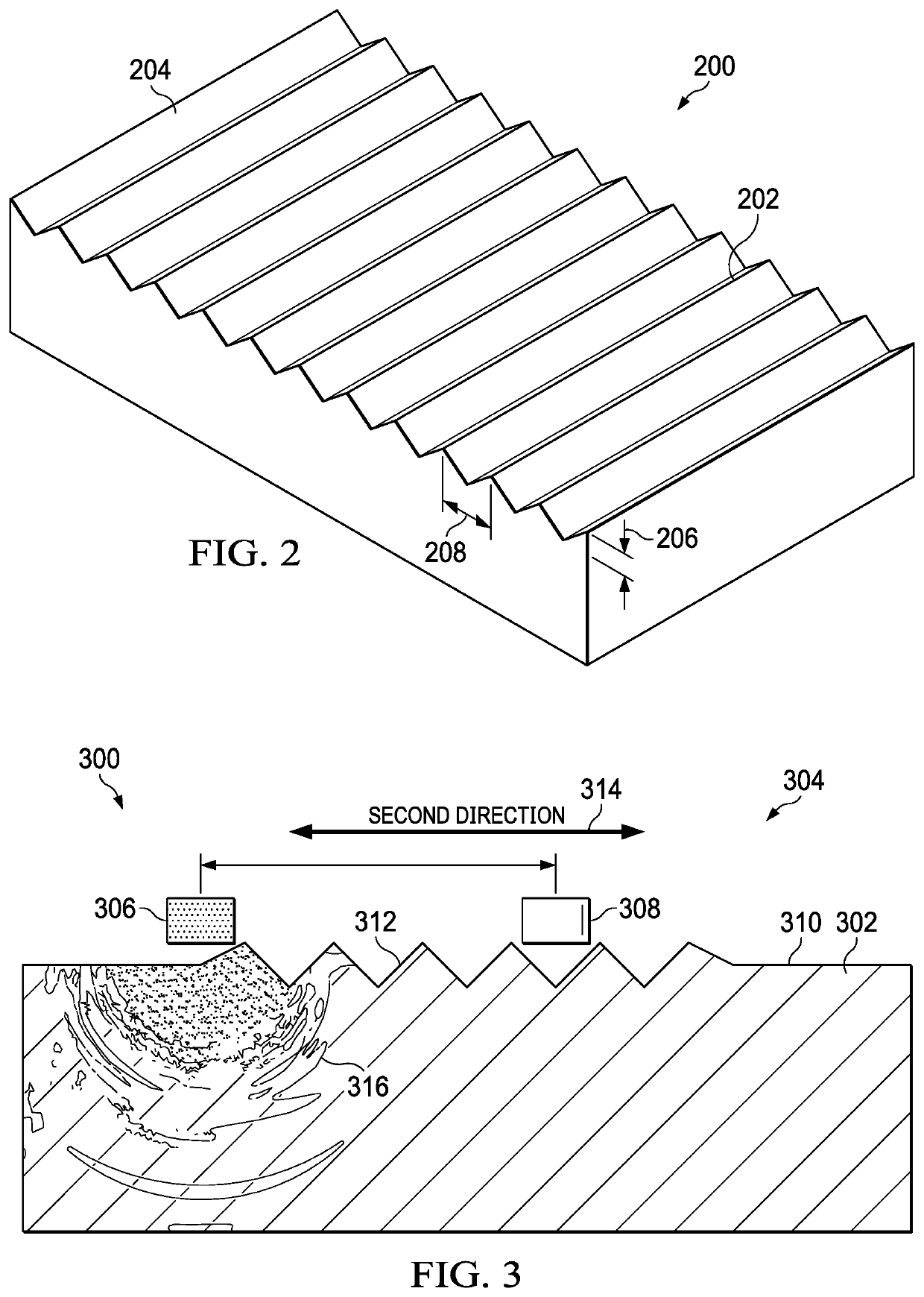

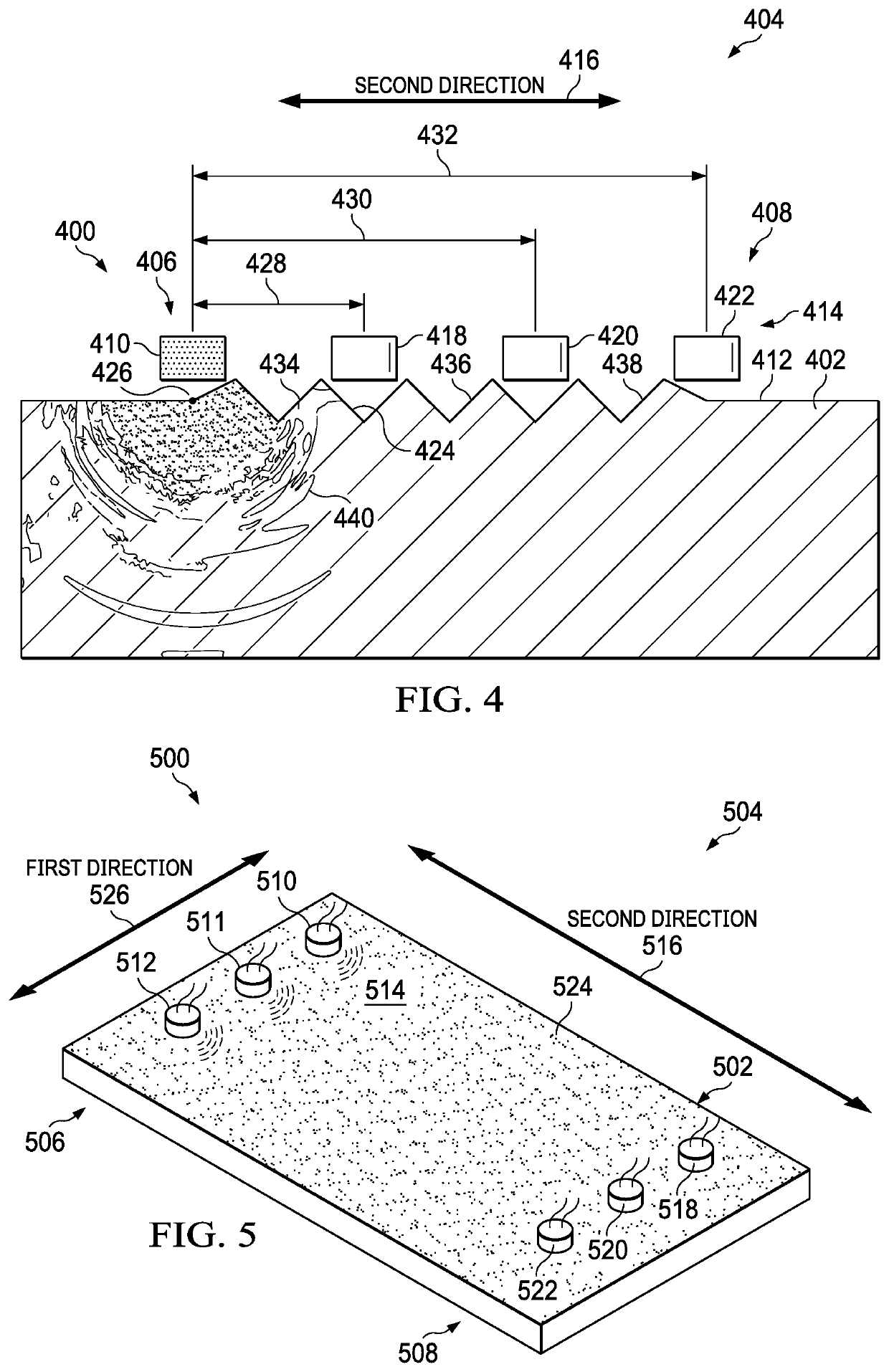

Surface roughness analysis system and methods of analyzing surface roughness of a workpiece

ActiveUS11262195B2Analysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationSurface roughnessIncident wave

Owner:THE BOEING CO

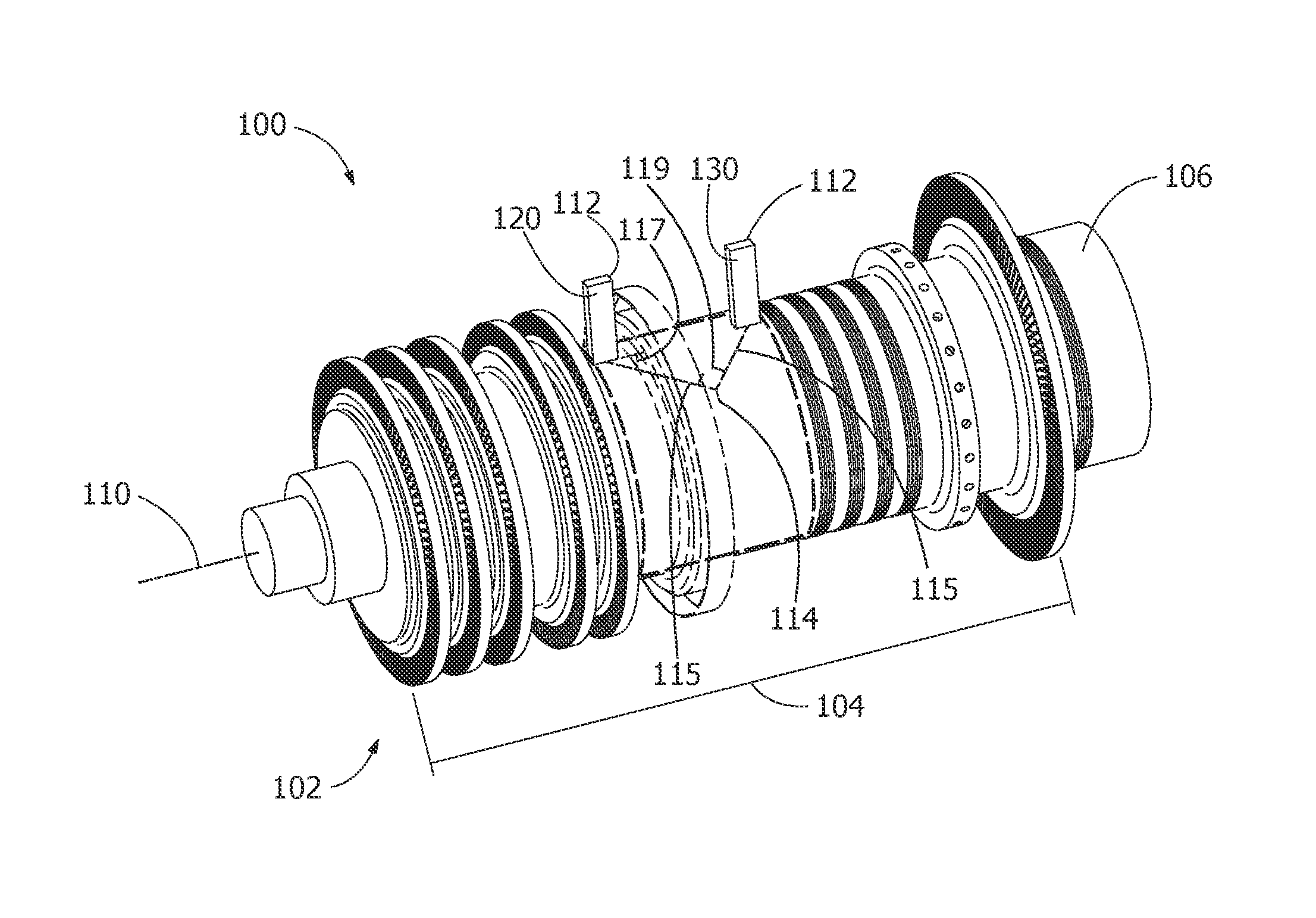

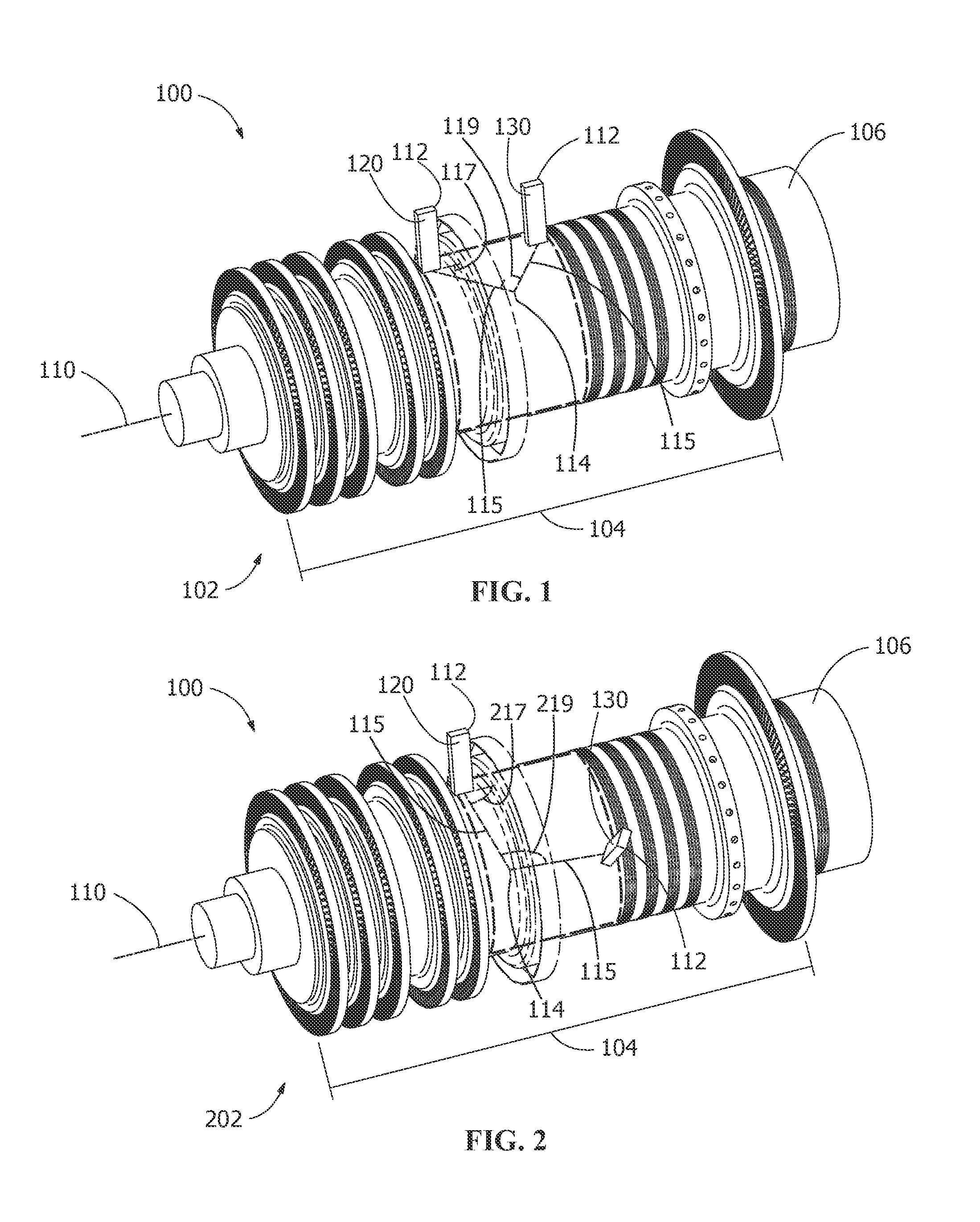

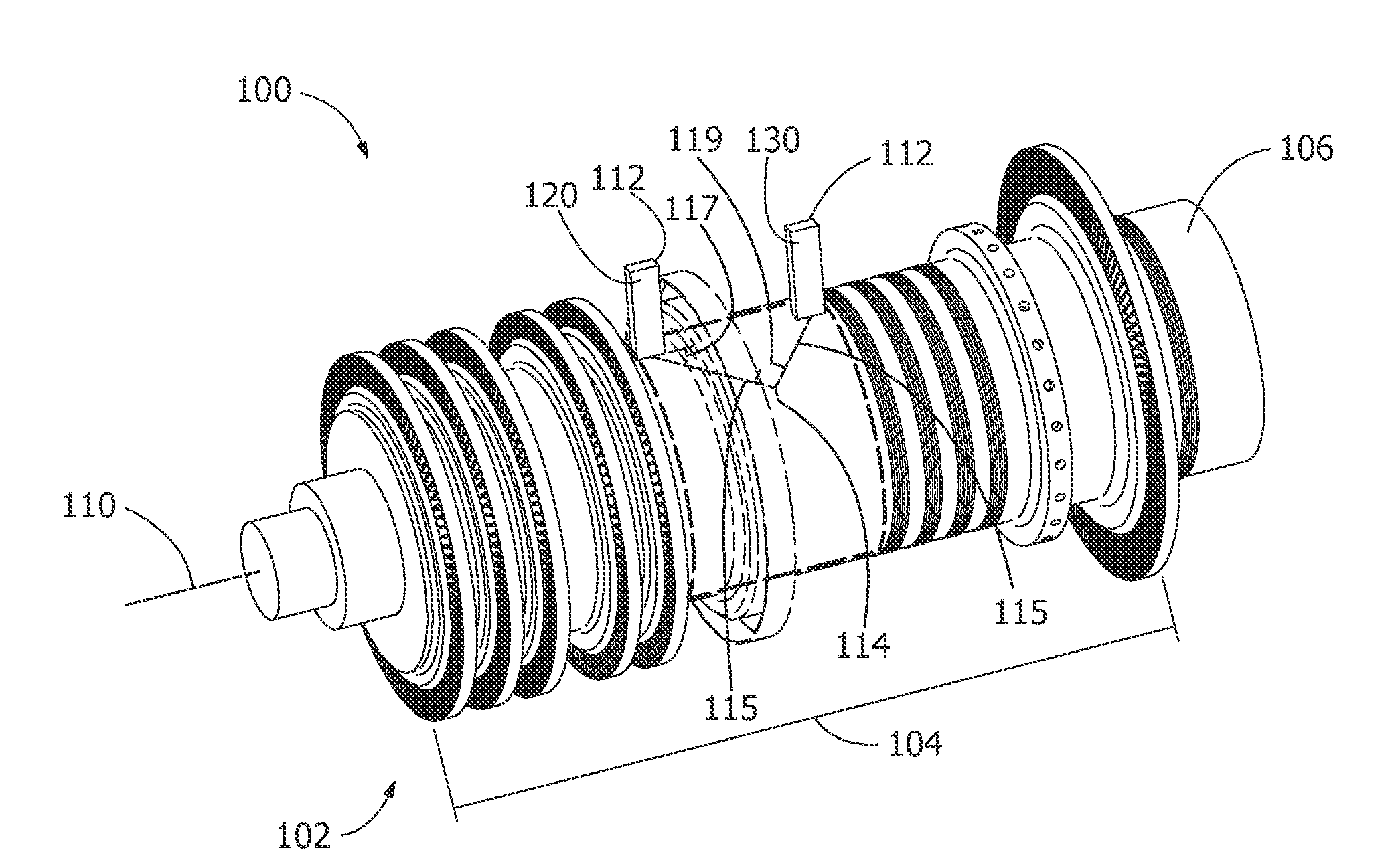

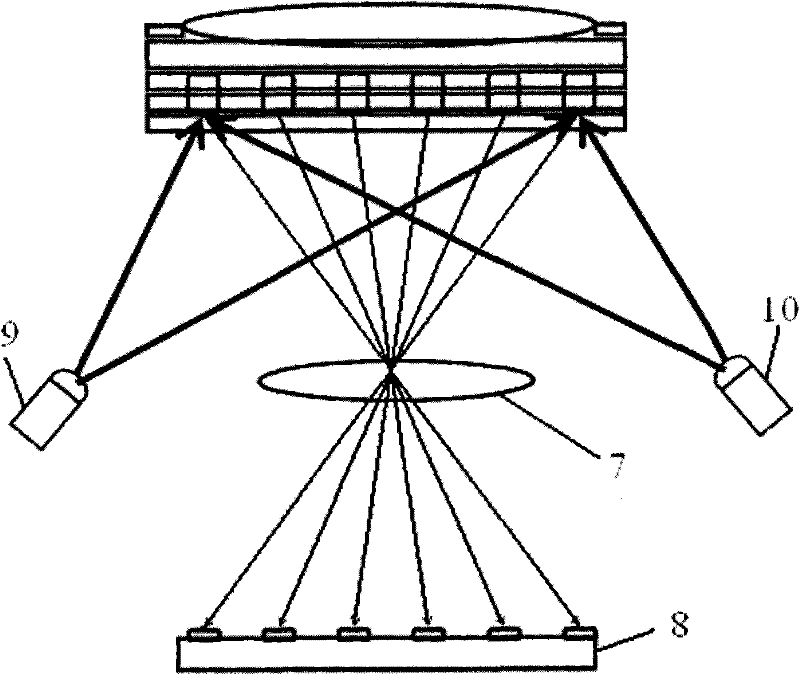

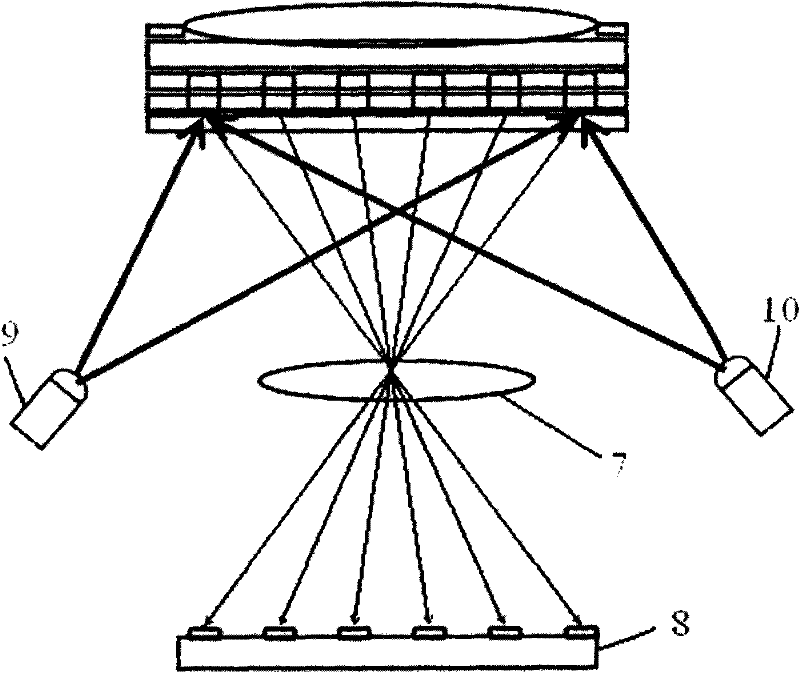

Ultrasonic detection method and ultrasonic analysis method

ActiveUS9482645B2Analysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic attenuationPhased array

Ultrasonic detection methods are disclosed. The method includes providing an ultrasonic detection system having a transmitting phased array device and a receiving phased array device. A phased array wave is transmitted through a revolutionary body from the transmitting phased array device to the receiving phased array device, thereby obtaining ultrasonic detection information about the revolutionary body. In another embodiment, the method includes positioning the transmitting phased array device and the receiving phased array device on a periphery of a turbine rotor, transmitting a phased array wave into the turbine rotor, the phased array wave not reflecting off of a reflecting feature, adjusting the positioning of the transmitting phased array devices on the periphery of the turbine rotor, and transmitting the phased array wave into the turbine rotor, the phased array wave reflecting off of a reflecting feature. The reflected phased array wave is received by the receiving phased array device.

Owner:GE INFRASTRUCTURE TECH INT LLC

Ultrasonic detection method and ultrasonic analysis method

ActiveUS20140338456A1Analysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsUltrasonic testingPhased array

Ultrasonic detection methods are disclosed. The method includes providing an ultrasonic detection system having a transmitting phased array device and a receiving phased array device. A phased array wave is transmitted through a revolutionary body from the transmitting phased array device to the receiving phased array device, thereby obtaining ultrasonic detection information about the revolutionary body. In another embodiment, the method includes positioning the transmitting phased array device and the receiving phased array device on a periphery of a turbine rotor, transmitting a phased array wave into the turbine rotor, the phased array wave not reflecting off of a reflecting feature, adjusting the positioning of the transmitting phased array devices on the periphery of the turbine rotor, and transmitting the phased array wave into the turbine rotor, the phased array wave reflecting off of a reflecting feature. The reflected phased array wave is received by the receiving phased array device.

Owner:GENERAL ELECTRIC CO

A vacuum pulsation method for extracting and purifying ursolic acid in rosemary

The invention discloses a vacuum pulse type method of extracting and purifying ursolic acid of rosemary. The method comprises the following steps: (1) drying and crushing a raw material medical material rosemary; (2) carrying out vacuum pulse type reflux extraction on the material by taking 20-90% of ethanol as a solvent, and concentrating the extracting liquor for later use; and (3) carrying out ultrasonic analysis on the concentrated ursolic acid extracting liquor after being adsorbed by D101 macroporous resin, and then, concentrating, crystallizing twice and drying to obtain a 90-98% ursolic acid product. The method provided by the invention efficiently and greenly extracts ursolic acid in the whole technical process under a condition that no organic solvents except ethanol are used, and the finally obtained ursolic acid product has the activities of bacteriostatic action, tumor resistance, inflammation dimishing and the like and is wide in application prospect.

Owner:JISHOU UNIVERSITY

Method and apparatus for analyzing elastography of tissue using ultrasound waves

A method and apparatus for analyzing elastography of tissue using ultrasound waves, wherein elastography information of tissue in a region of interest (ROI) is analyzed by irradiating ultrasound waves for diagnosis towards the ROI to which a shear wave is induced from an ultrasound probe, receiving echo ultrasound waves, and acquiring three-dimensional (3D) ultrasound images with respect to the ROI.

Owner:SAMSUNG ELECTRONICS CO LTD

Cable defect detection system

InactiveCN109557427ADefect detectionImprove detection success rateTesting using acoustic measurementsAcoustic waveEngineering

The invention discloses a cable defect detection system. A cable is clamped by a clamping portion. An ultrasonic sensor is provided at a place which is further than the safety distance of the cable, transmits a pressure wave signal which is generated by the partial discharge, due to cable core defects, of the cable which is running online, by an optical fiber, and sends the detected signal to an ultrasonic analyzer for detecting and analyzing. And finally comparing it with the pre-calibrated result to determine the defect degree of the cable. The cable defect detection system adopts a specialcable clamper to safely detect the defects of the cable when the cable is running online, and conducts sound waves by the optical fiber, and the detection success rate thereof is much higher than thetest result under the cable offline state.

Owner:南京龙贞自控科技发展有限公司

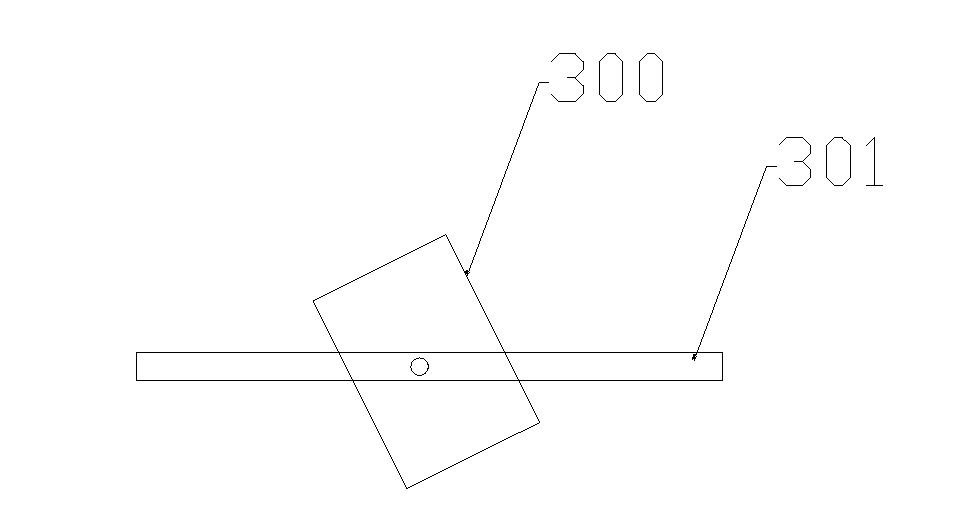

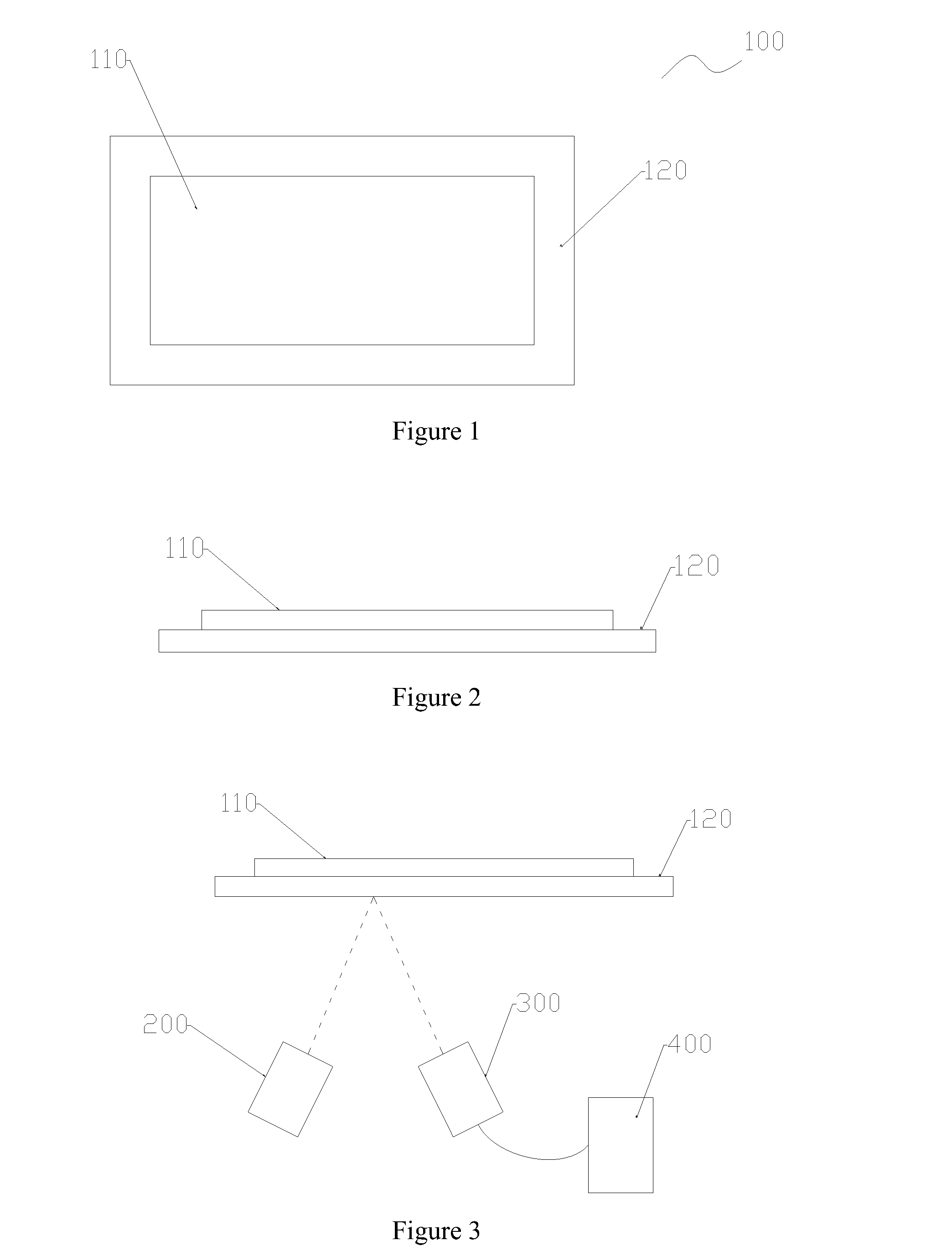

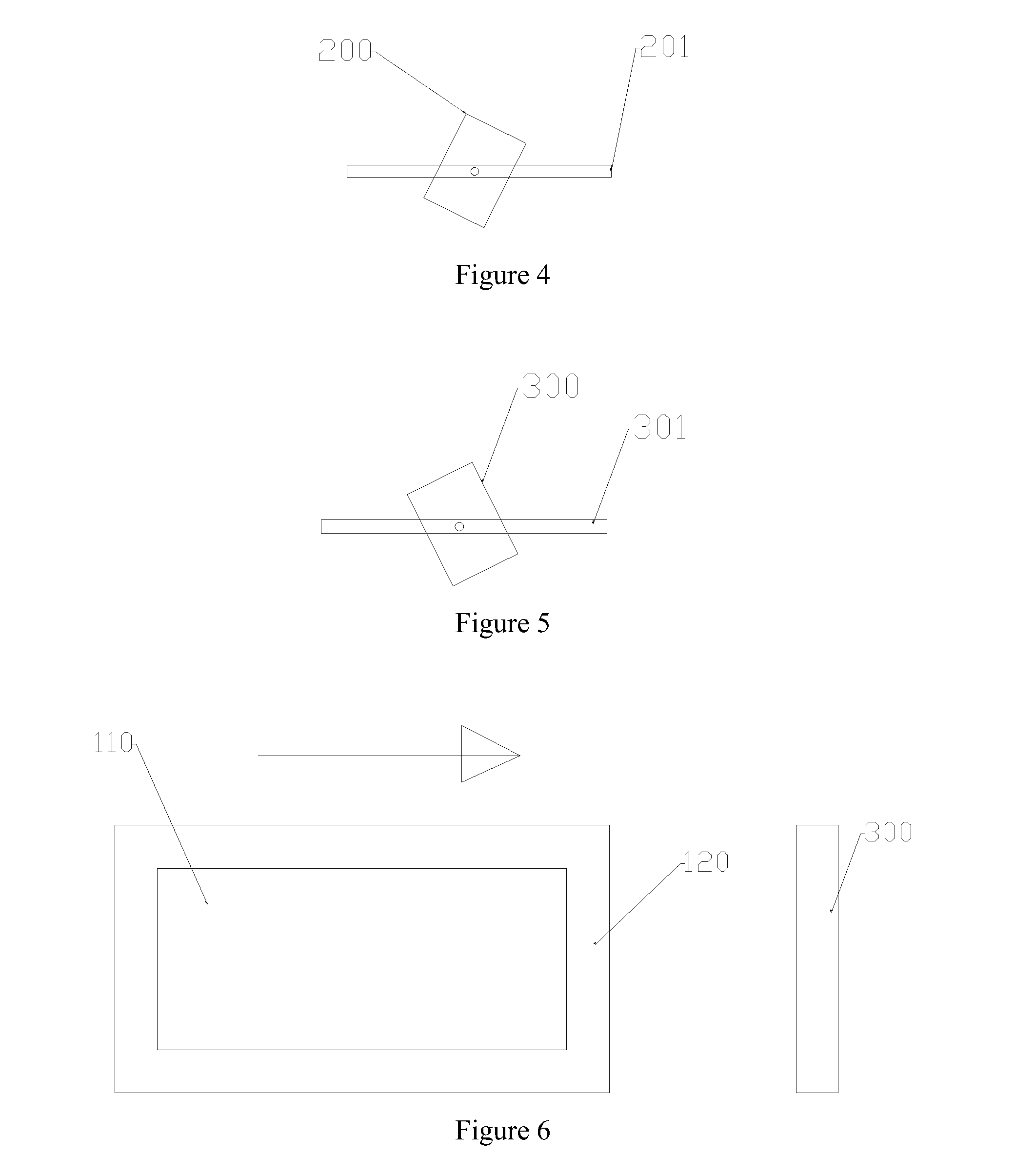

Device and method for testing the quality of a display substrate

InactiveUS20140345383A1Damage to production lineEasy maintenanceAnalysing solids using sonic/ultrasonic/infrasonic wavesManufacturing lineUltrasonic analysis

A method and device for testing the quality of a display substrate are provided to detect whether the substrate has been broken. The device comprises an ultrasonic emitter and an ultrasonic receiver, both of which are set on the side opposite to the processing area, and it further comprises an ultrasonic analyzer connected to the ultrasonic receiver. The ultrasonic emitter emits ultrasonic waves for testing to the substrate, the ultrasonic receiver receives the ultrasonic waves reflected from the substrate, and the ultrasonic analyzer connected to the ultrasonic receive analyzes the received ultrasonic waves to determine whether the substrate has been broken. In the present invention, the fragment on anywhere comprising the processing area and the non-processing area of the substrate can be detected, the broken substrate can be picked out overall, and thus preventing the broken substrate from damaging the production line and the products.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

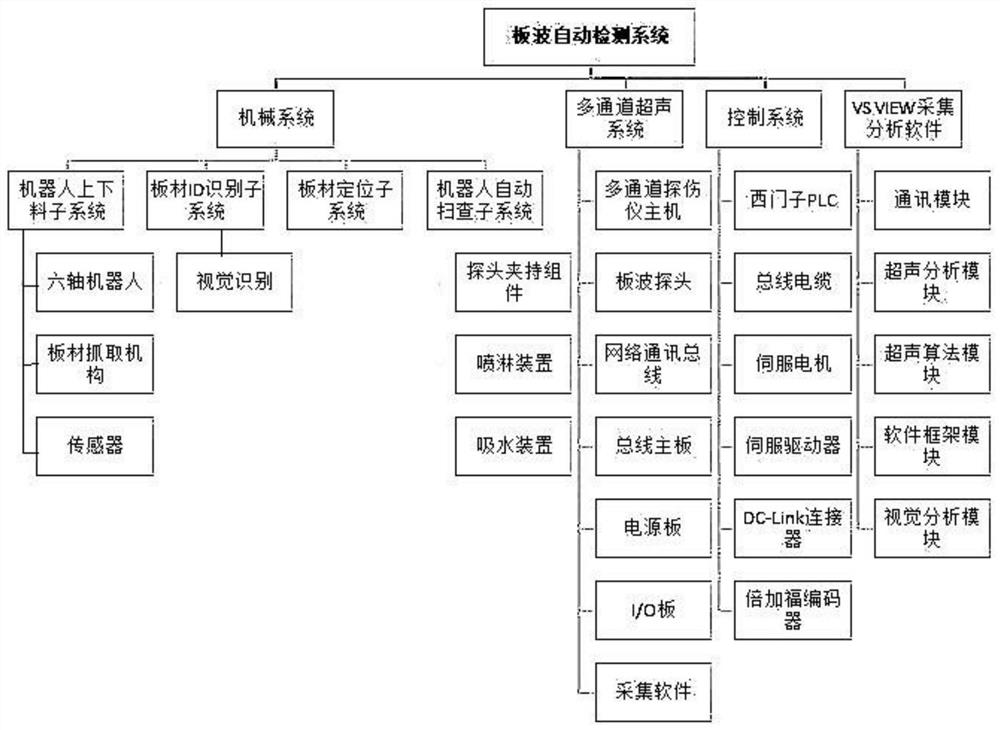

Ultrasonic plate wave automatic detection system

PendingCN112051330AAnalysing solids using sonic/ultrasonic/infrasonic wavesSortingNetwork communicationElectric cables

The invention provides an ultrasonic plate wave automatic detection system, which comprises a mechanical system, a multi-channel ultrasonic system, a control system and acquisition analysis software;the mechanical system comprises a robot feeding and discharging subsystem, a plate ID identification subsystem, a plate positioning subsystem and a robot automatic scanning subsystem; the multi-channel ultrasonic system comprises a multi-channel flaw detector, a plate wave probe, a network communication bus, a bus main board, a power supply board, an IO board and acquisition software; the controlsystem comprises a PLC part, a bus cable, a servo driver, a DC-Link connector and an encoder. The acquisition and analysis software comprises a communication module, an ultrasonic analysis module, anultrasonic algorithm module, a software framework module and a visual analysis module. The system is applied to a production line. The whole system comprises a mechanical scanning device, an electrical control system, a multi-channel ultrasonic instrument and signal acquisition and analysis software, and the system adopts a plate wave inspection technology to complete the automatic working processof feeding, detecting, discharging and sorting of plates.

Owner:四川云卓创新科技有限公司

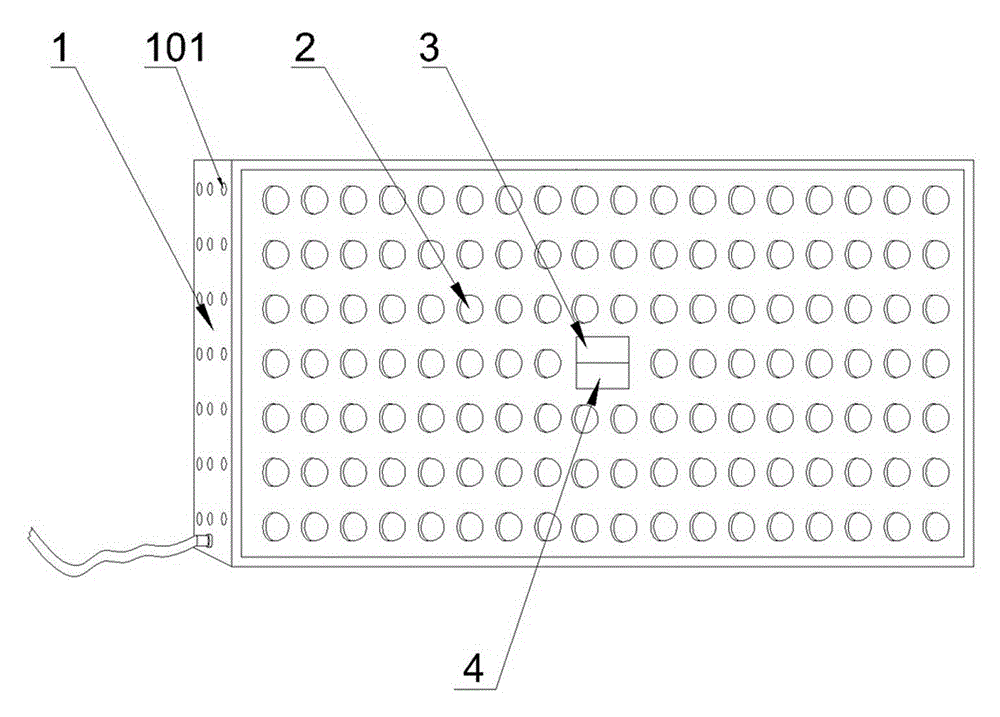

High flux multipurpose liquid sample rapid ultrasonic analyzer

InactiveCN102455325AAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis by observing effect on chemical indicatorControl systemHigh flux

The invention relates to a high flux multipurpose liquid sample rapid ultrasonic analyzer. The ultrasonic analyzer contains test paper, a quantitative pipette liquid feeding device, a liquid flow modulation and demodulation control system, an ultrasonic detection sensing head, a signal conversion processor, an analog-to-digital converter and a computer. The above seven parts cooperate with each other to complete the liquid sample rapid analysis and detection process. The ultrasonic analyzer through ultrasonic signal inductive transmission is endowed with a rapid, high-efficiency, accurate andreliable detection technology.

Owner:杨晓波

LED lamp switched on and off through ultrasonic wave

InactiveCN104879662AReduce distractionsExtended service lifePoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

Owner:遵义市义阳光电有限公司

Surface Roughness Analysis System and Methods of Analyzing Surface Roughness of a Workpiece

ActiveUS20210270604A1Analysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationSurface roughnessEngineering

A surface roughness analysis system and methods of analyzing surface roughness of a workpiece are presented. The surface roughness analysis system comprises a number of wave generators; a number of wave sensors; and an ultrasonic analysis system configured to receive material mechanical parameters for a workpiece, determine incident surface wave signal parameters for a source signal to be sent by the number of wave generators, and determine a cut-off wavelength using the material mechanical parameters, wherein the cut-off wavelength is a ratio of surface wavelength over incident wavelength.

Owner:THE BOEING CO

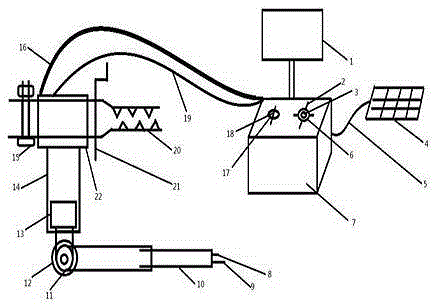

Novel portable oil tank detection device capable of remote control

InactiveCN105352684ARealize all-round detectionRealize remote control conditionsLarge containersFluid-tightness measurement using lightDisplay deviceLED lamp

The present invention provides a novel portable oil tank detection device capable of remote control. The novel portable oil tank detection device of remote control comprises a detection system, a control system and auxiliary components. The detection system includes a camera with a LED lamp, an ultrasonic tester, an ultrasonic analyzer, a computer host device and a display. The control system includes two braking motor with two protective housings, a hydraulic gauge rod, a fixed base, a universal driving shaft, a sleeve, a clamp, a hydraulic oil pipeline, an electric hydraulic oil pump and a braking motor control device. The auxiliary components includes a power shift switch, a device main switch, a storage battery, a solar panel and a soft spring. The novel portable oil tank detection device capable of remote control is configured to detect leak sources and defects in an oil tank through the camera with the LED lamp and an ultrasonic system; the display is configured to display the condition in the oil tank; the solar panel is configured to supply electric energy for a motor; remote control conditions may be realized through the braking motor control device and the electric hydraulic oil pump; and multi-angle detection in the oil tank may be realized through the hydraulic gauge rod and the universal driving shaft. The novel portable oil tank detection device capable of remote control is convenient and practical and has a high practical value.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

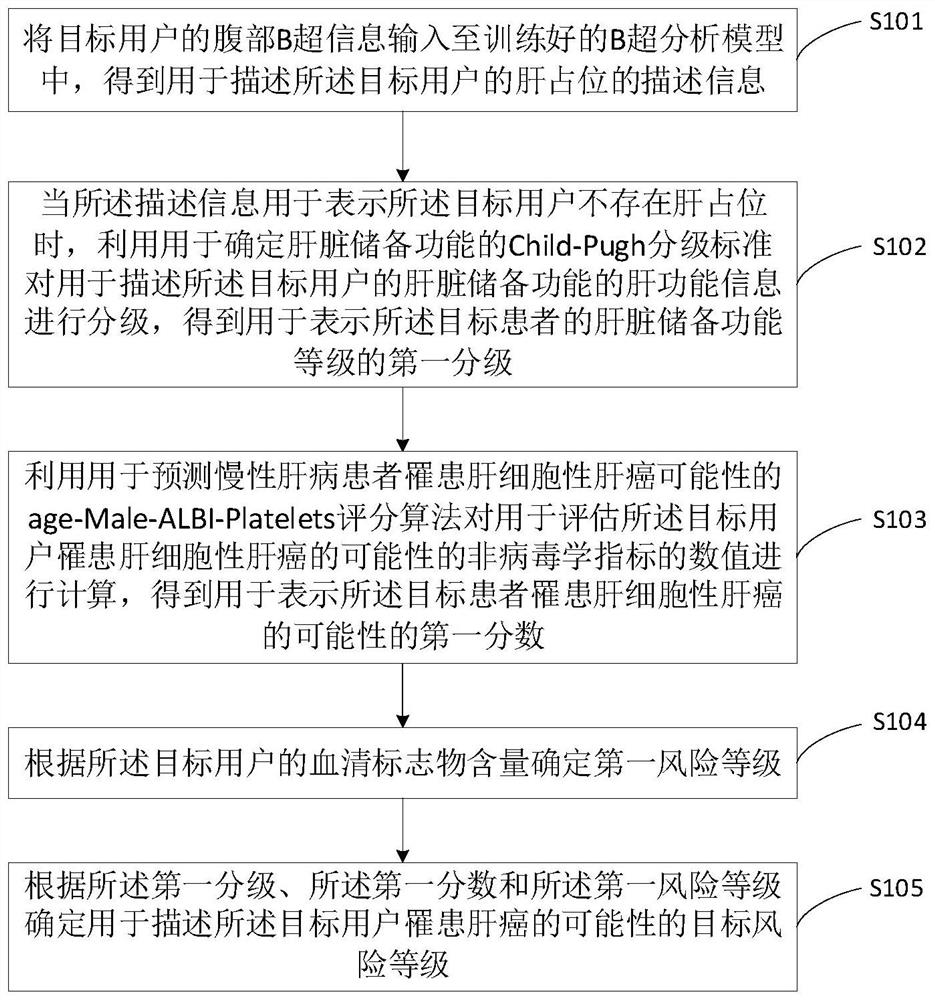

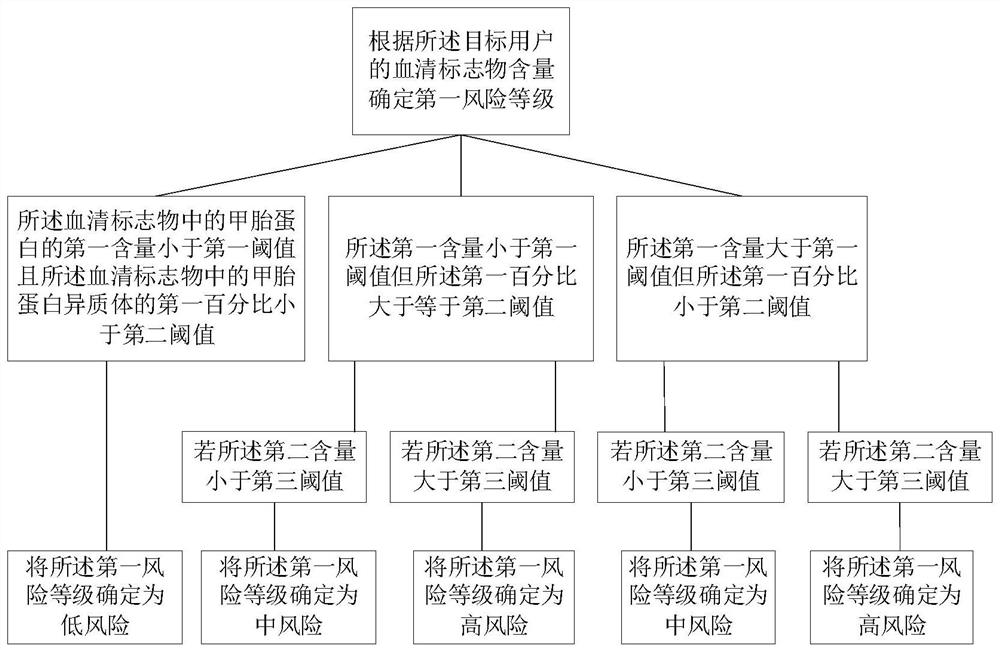

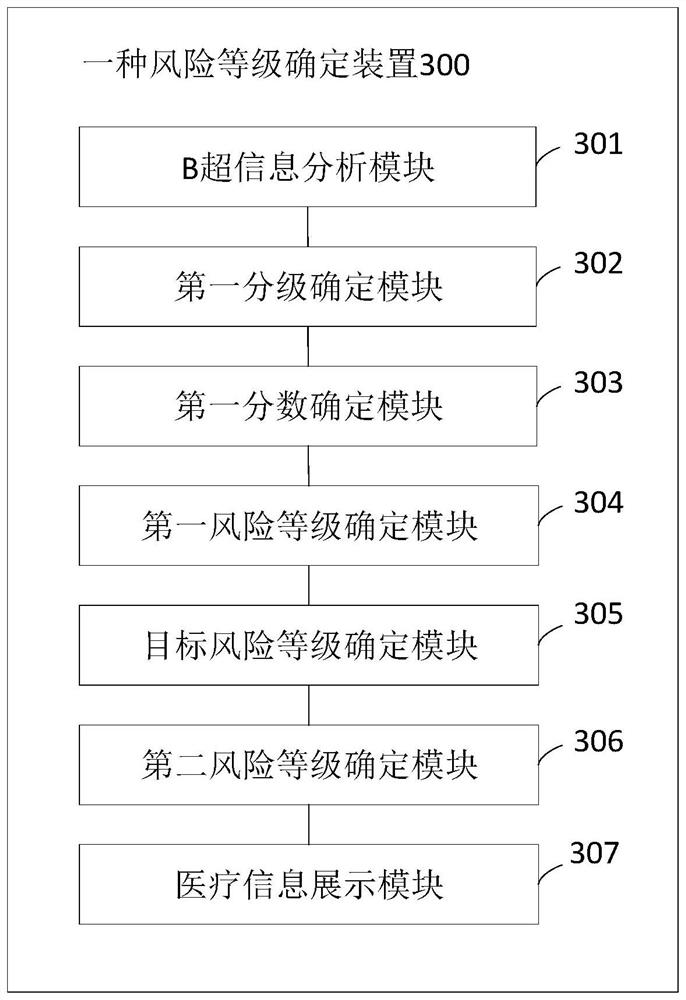

Risk level determination method and device, computer equipment and storage medium

PendingCN114694831AAvoid the influence of human factorsImprove accuracyMedical data miningMedical automated diagnosisHepatocyteUltrasonic analysis

The invention provides a risk level determination method and device, computer equipment and a storage medium, and the method comprises the steps: inputting the abdomen B-ultrasonic information of a user into a B-ultrasonic analysis model, and obtaining the liver occupation information of the user; grading the liver function information of the liver reserve function of the user by using a Child-Pugh grading standard to obtain a first grade for representing the liver reserve function grade of the target user; using an age-Male-ALBI-Plate scoring algorithm to obtain a first score used for representing the possibility that the target user suffers from the hepatocellular carcinoma; determining a first risk level according to the serum marker content of the target user; and according to the first grade, the first score and the first risk level, determining a target risk level for describing the possibility that the user suffers from the liver cancer. By adopting the method, various body indexes of the user are analyzed, so that the accuracy of risk level determination is improved.

Owner:NANFANG HOSPITAL OF SOUTHERN MEDICAL UNIV +1

Test device for measurement of partial discharge signal attenuation by ultrasonic method

ActiveCN104142177BTesting dielectric strengthSubsonic/sonic/ultrasonic wave measurementElectrical conductorCoaxial cable

The invention relates to the technical field of partial discharge detection, in particular to a test device for measuring the attenuation of partial discharge signals by an ultrasonic method. The test device includes a high-voltage lead terminal, a horizontal busbar sleeve and a vertical busbar sleeve. The horizontal busbar sleeve is equipped with a horizontal high-voltage conductor, and the vertical busbar sleeve is equipped with a vertical high-voltage conductor. Connection, the vertical high-voltage conductor and the horizontal high-voltage conductor are connected through an isolating switch, the connection between the isolating switch and the vertical high-voltage conductor forms an L-shaped structure, and the L-shaped structure between the high-voltage lead terminal and the horizontal high-voltage conductor is provided with a discharge tip , the horizontal busbar sleeve, the isolating switch, and the vertical busbar sleeve are respectively equipped with ultrasonic sensors, and the ultrasonic sensors are connected to an ultrasonic analyzer through coaxial cables of equal length. It provides a theoretical basis for setting the best installation position and quantity in the online monitoring system.

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com