Preparation method of iron tetroxide-carbon nanotube lithium battery negative electrode material

A technology of ferroferric oxide and carbon nanotubes, which is applied in the direction of battery electrodes, negative electrodes, nanotechnology, etc., can solve the problems of poor conductivity and achieve the effects of maintaining stable performance, improving cycle performance, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

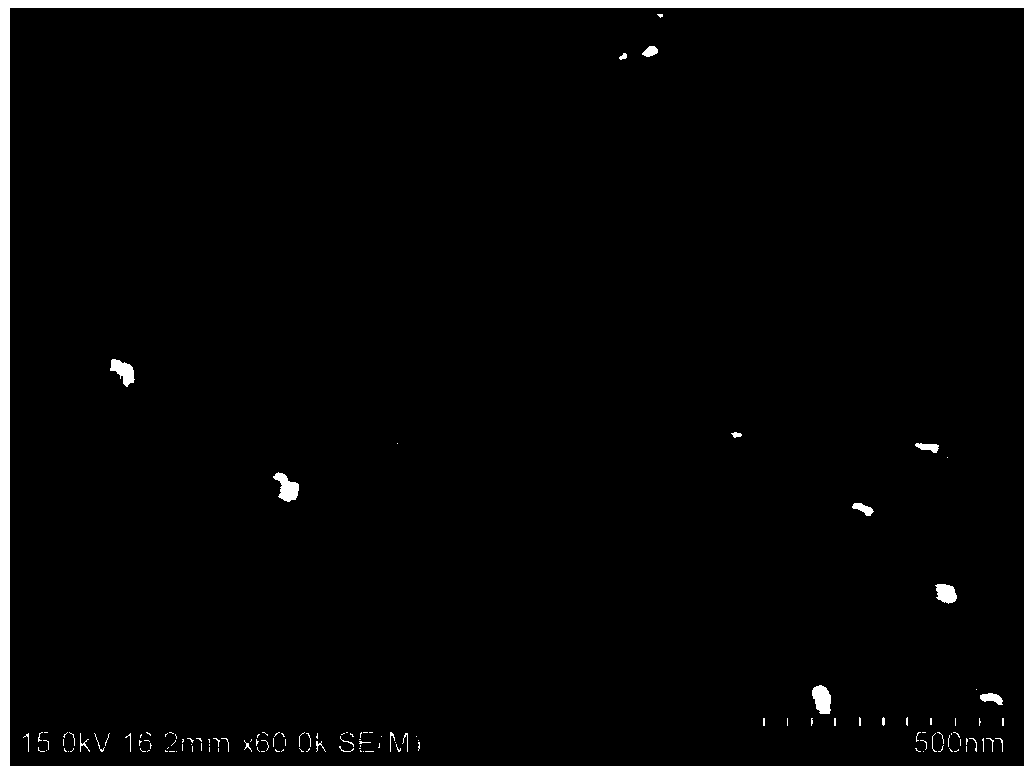

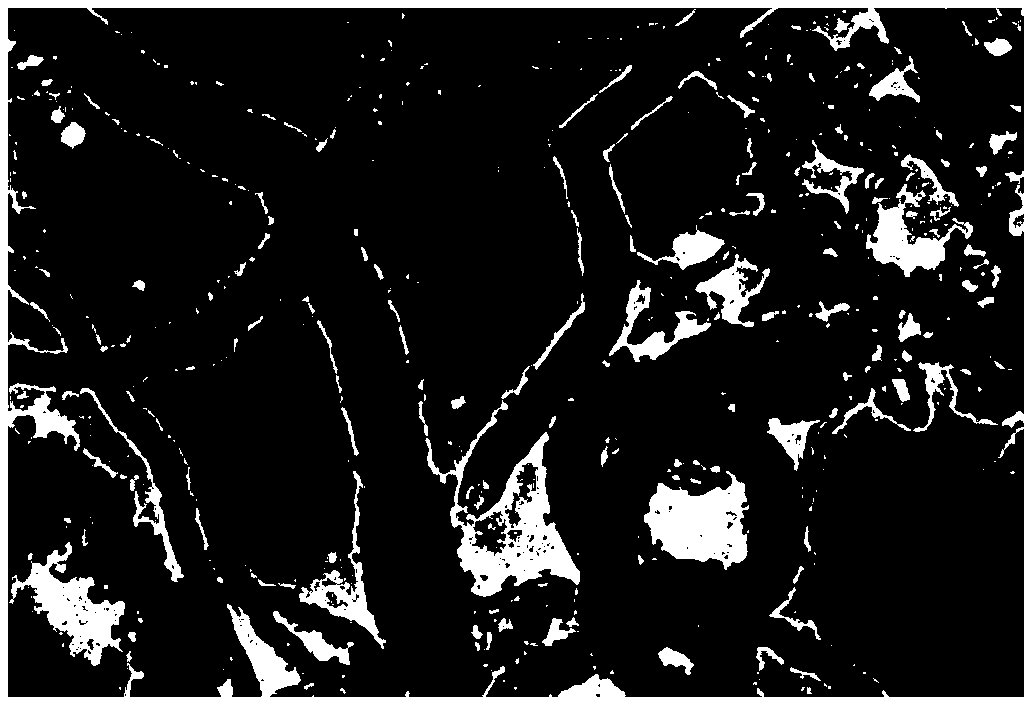

Image

Examples

preparation example Construction

[0027] A preparation method of ferroferric oxide-carbon nanotube lithium battery negative electrode material, comprising the following steps:

[0028] Step 1: Disperse the purchased carbon nanotubes in concentrated nitric acid (65%-68% in mass fraction), perform high-temperature acid treatment, and then wash and dry for subsequent use;

[0029] Step 2: dispersing acid-treated carbon nanotubes into deionized water;

[0030] Step 3: Add ferric chloride hexahydrate, urea, and polyvinylpyrrolidone into the mixed solution obtained in step 2, then add sodium potassium tartrate as a reducing agent, stir and dissolve fully, wherein ferric chloride hexahydrate: urea: sodium tartrate The mass ratio of potassium is 3.8~4.5:8~11:5~7; ferric chloride hexahydrate is used as the raw material of magnetic ferric oxide, and the input amount determines the magnetic ferric oxide particles attached to carbon nanotubes The thickness of urea provides an alkaline environment for the conversion of fe...

Embodiment 1

[0039] Weigh 0.11g of acid-treated carbon nanotubes obtained by acid treatment, disperse them in 40ml of deionized water, add 0.4g of ferric chloride hexahydrate to dissolve, add 0.9g of urea and 2g of polyvinylpyrrolidone, and continue to After stirring for 1.3 hours, 0.6 g of sodium potassium tartrate was added to dissolve. Then the mixture was poured into a polytetrafluoroethylene-lined stainless steel reaction kettle, sealed and heated to 190°C for 12 hours. After it was cooled to room temperature, it was repeatedly centrifuged and washed with deionized water and ethanol for more than 5 times, and the obtained magnetic black product was dried in a vacuum oven at 60° C. for 30 hours to obtain the target product.

Embodiment 2

[0041] Weigh 0.1g of acid-treated carbon nanotubes obtained by acid treatment, disperse them in 40ml of deionized water, add 0.38g of ferric chloride hexahydrate to dissolve, add 0.8g of urea, add 1.8g of polyvinylpyrrolidone, and stir under magnetic force Stirring was continued for 1 hour, and then 0.5 g of sodium potassium tartrate was added to dissolve. Then the mixture was poured into a polytetrafluoroethylene-lined stainless steel reaction kettle, sealed and heated to 180°C for 10 hours. After it was cooled to room temperature, it was centrifuged and washed with deionized water and ethanol repeatedly 5 times each, and the obtained magnetic black product was dried in a vacuum oven at 55° C. for 24 hours to obtain the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com