Preparation method of gas sensitive material based on graphene/molybdenum disulfide composite

A gas-sensitive material, molybdenum disulfide technology, applied in the direction of material resistance, etc., can solve the problems of poor solubility of nanoparticles, and achieve the effects of improving gas-sensing performance, high selectivity and sensitivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

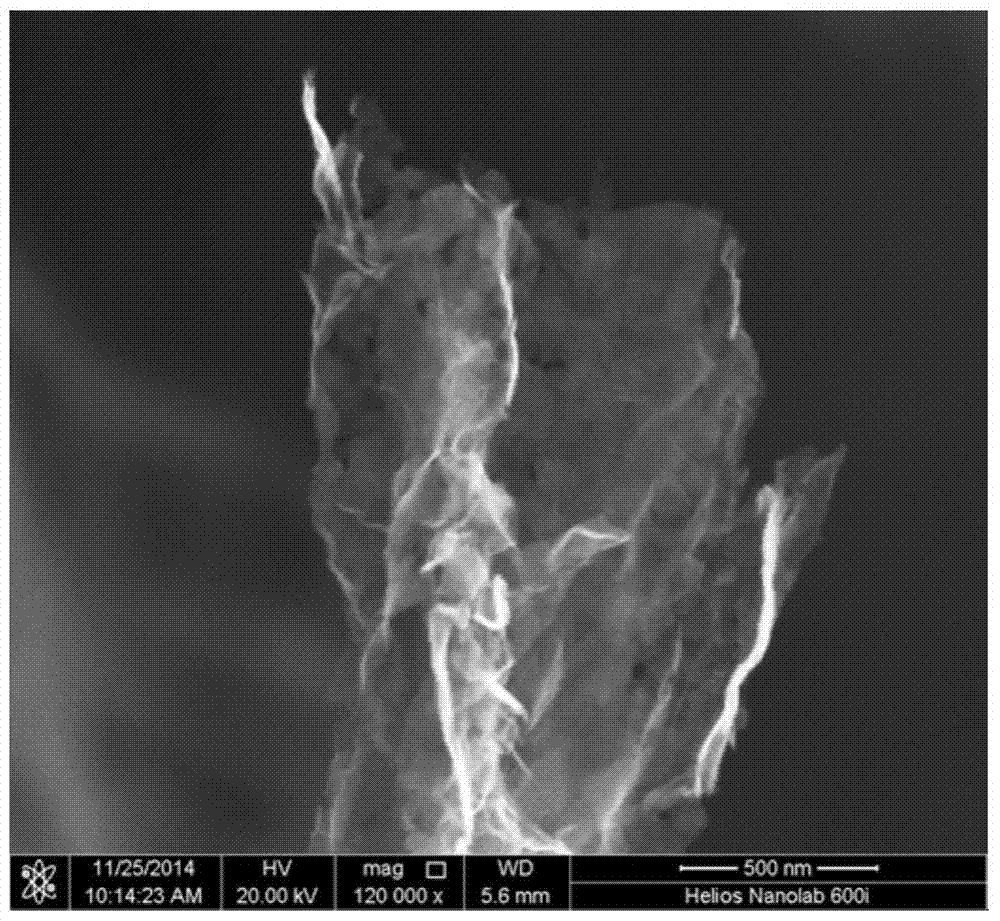

[0019] Specific Embodiment 1: In this embodiment, the molar ratio of molybdenum atoms to carbon atoms in the gas-sensitive material based on graphene / molybdenum disulfide composite is 1:1-5, molybdenum disulfide is wrapped on the outer surface of graphene, and molybdenum disulfide The number of layers is 5-20, and the distance between each layer is 0.62-0.65nm.

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the molar ratio of molybdenum atoms to carbon atoms in the gas-sensitive material based on graphene / molybdenum disulfide composite is 1:3. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the distance between each layer is 0.64 nm. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com