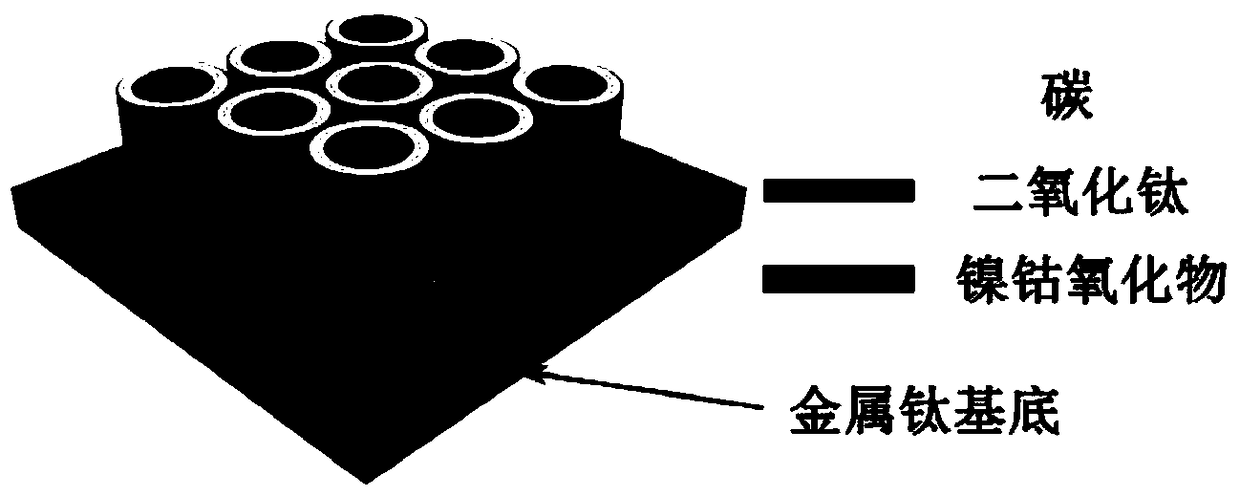

Preparation method of nickel-cobalt oxide electrode material supported by titanium dioxide nanotube array

A nanotube array, titanium dioxide technology, used in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of limited application, poor electrochemical activity and conductivity, and achieve the effect of overcoming poor conductivity and optimizing electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Sonicate a 1.5cm×5cm titanium sheet with a purity greater than 99.7% in acetone, absolute ethanol, and deionized water for 20 minutes to remove surface oil and oxides, and dry it in an oven for use;

[0033] 2) Put the cleaned and dried titanium sheet as the anode, and the high-purity graphite sheet as the cathode in 0.25mol / L NH 4 F, 7vol%H 2 In the ethylene glycol solution of O, react at a voltage of 60V for 6h; through this step, an array of titanium dioxide nanotubes arranged in order is prepared;

[0034] 3) Calcining the titanium dioxide nanotube array obtained in step 2) under the protection of an argon atmosphere for 3 hours, the heating rate is 2°C / min, and the firing temperature is 450°C, to obtain an amorphous carbon-coated and oxygen vacancy-modified titanium dioxide nanotube array;

[0035] 4) Immerse the amorphous carbon-coated and oxygen-vacancy-modified titania nanotube arrays obtained in step 3) into a solute composition of 1 mmol / L Ni(NO 3 ) 2 +5...

Embodiment 2

[0039] 1) Sonicate a 1.5cm×5cm titanium sheet with a purity greater than 99.7% in acetone, absolute ethanol, and deionized water for 20 minutes to remove surface oil and oxides, and dry it in an oven for use;

[0040] 2) Put the cleaned and dried titanium sheet as the anode, and the high-purity graphite sheet as the cathode in 0.25mol / L NH 4 F, 7vol%H 2 In the ethylene glycol solution of O, react at a voltage of 60V for 6h; through this step, an array of titanium dioxide nanotubes arranged in order is prepared;

[0041] 3) Calcining the titanium dioxide nanotube array obtained in step 2) under the protection of an argon atmosphere for 3 hours, the heating rate is 2°C / min, and the firing temperature is 450°C, to obtain an amorphous carbon-coated and oxygen vacancy-modified titanium dioxide nanotube array;

[0042] 4) Immerse the amorphous carbon-coated and oxygen-vacancy-modified titania nanotube arrays obtained in step 3) into a solute composition of 2 mmol / L Ni(NO 3 ) 2 +4...

Embodiment 3

[0046] 1) Sonicate a 1.5cm×5cm titanium sheet with a purity greater than 99.7% in acetone, absolute ethanol, and deionized water for 20 minutes to remove surface oil and oxides, and dry it in an oven for use;

[0047] 2) Put the cleaned and dried titanium sheet as the anode, and the high-purity graphite sheet as the cathode in 0.25mol / L NH 4 F, 7vol%H 2 In the ethylene glycol solution of O, react at a voltage of 60V for 6h; through this step, an array of titanium dioxide nanotubes arranged in order is prepared;

[0048] 3) Calcining the titanium dioxide nanotube array obtained in step 2) under the protection of an argon atmosphere for 3 hours, the heating rate is 2°C / min, and the firing temperature is 450°C, to obtain an amorphous carbon-coated and oxygen vacancy-modified titanium dioxide nanotube array;

[0049] 4) Immerse the amorphous carbon-coated and oxygen-vacancy-modified titania nanotube arrays obtained in step 3) into a solute composition of 3 mmol / L Ni(NO 3 ) 2 +3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com