Preparation method of carbon-modified nano Li4Ti5O12-porous graphene composite electrode material

A technology of porous graphene and composite electrodes, which is applied in battery electrodes, nanotechnology, circuits, etc., can solve the problems of poor electronic conductivity of lithium titanate and limit high-rate performance, and achieve low cost, high efficiency, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

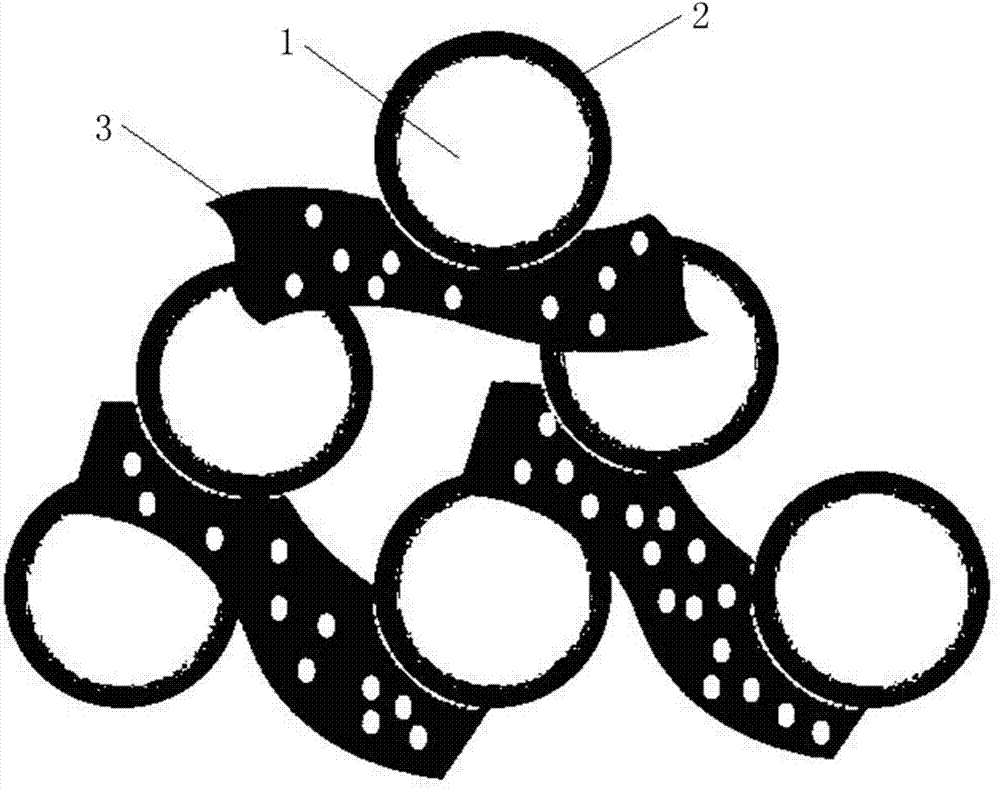

Image

Examples

Embodiment 1

[0027] (1) Carbon-modified nano-Li 4 Ti 5 o 12 Preparation: Weigh 1.3gLi 4 Ti 5 o 12 Nanomaterials are placed in the reaction zone of the reaction furnace, heated under a nitrogen atmosphere, the first heating is started at a heating rate of 5°C / min, the heating is stopped when the temperature rises to 400°C, and hydrogen gas is introduced at a flow rate of 400ml / min. After the completion of the hydrogen gas, start the second heating at a heating rate of 20°C / min, and at the same time, feed the mixed gas of hydrogen and carbon monoxide at a volume ratio of 3:10, raise the temperature to 1000°C and keep it for 1 hour. The above processes are all carried out under a nitrogen atmosphere. , and then stop heating and cool with nitrogen at a flow rate of 50ml / min to obtain carbon-modified nano-Li 4 Ti 5 o 12 . Microscopic characterization shows that the prepared carbon-modified nano-Li 4 Ti 5 o 12 , in spherical Li 4 Ti 5 o 12 The thickness of the carbon layer on the s...

Embodiment 2

[0035] (1) Carbon-modified nano-Li 4 Ti 5 o 12 Preparation: weigh 2.5gLi 4 Ti 5 o 12 The nanomaterials are placed in the reaction zone of the reaction furnace, heated under a helium atmosphere, the first heating is started at a heating rate of 20°C / min, the heating is stopped when the temperature is raised to 500°C, and hydrogen gas is introduced at a flow rate of 300ml / min. After the hydrogen flow is completed, start the second heating at a heating rate of 5°C / min, and at the same time, pass in a mixture of hydrogen and hydrocarbons at a volume ratio of 1:2, and raise the temperature to 800°C for 3 hours. Carry out under gas atmosphere, then stop heating and pass into nitrogen gas cooling at the flow rate of 100ml / min, obtain carbon-modified nano-Li 4 Ti 5 o 12 . Microscopic characterization shows that the prepared carbon-modified nano-Li 4 Ti 5 o 12 , in spherical Li 4 Ti 5 o 12 The thickness of the carbon layer on the surface of the nanometer material is 100-2...

Embodiment 3

[0043] (1) Carbon-modified nano-Li 4 Ti 5 o 12 Preparation: weigh 2.0gLi 4 Ti 5 o 12 The nanomaterials are placed in the reaction zone of the reaction furnace and heated under an argon atmosphere. The first heating is started at a heating rate of 30°C / min, and the heating is stopped when the temperature is raised to 450°C, and hydrogen gas is introduced at a flow rate of 200ml / min. After the completion of the hydrogen flow, start the second heating at a heating rate of 30°C / min, and at the same time, pass in a mixture of hydrogen and carbon dioxide at a volume ratio of 1:10, and raise the temperature to 1200°C and keep it for 10 minutes. The above processes are all in an argon atmosphere. , and then stop heating and pass through nitrogen cooling at a flow rate of 200ml / min to obtain carbon-modified nano-Li 4 Ti 5 o 12 . Microscopic characterization shows that the prepared carbon-modified nano-Li 4 Ti 5 o 12 , in spherical Li 4 Ti 5 o 12 The thickness of the carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com