Integrated three-dimensional ordered porous thin film electrode material and its preparation method and application

A porous film, three-dimensional ordered technology, applied in the field of electrochemistry, can solve the problems of sodium-ion batteries that cannot be directly applied, the disintegration of the electrode structure of sodium-ion batteries, and the decline of battery cycle life, and achieves unique pore distribution and high integrity. , the effect of high pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

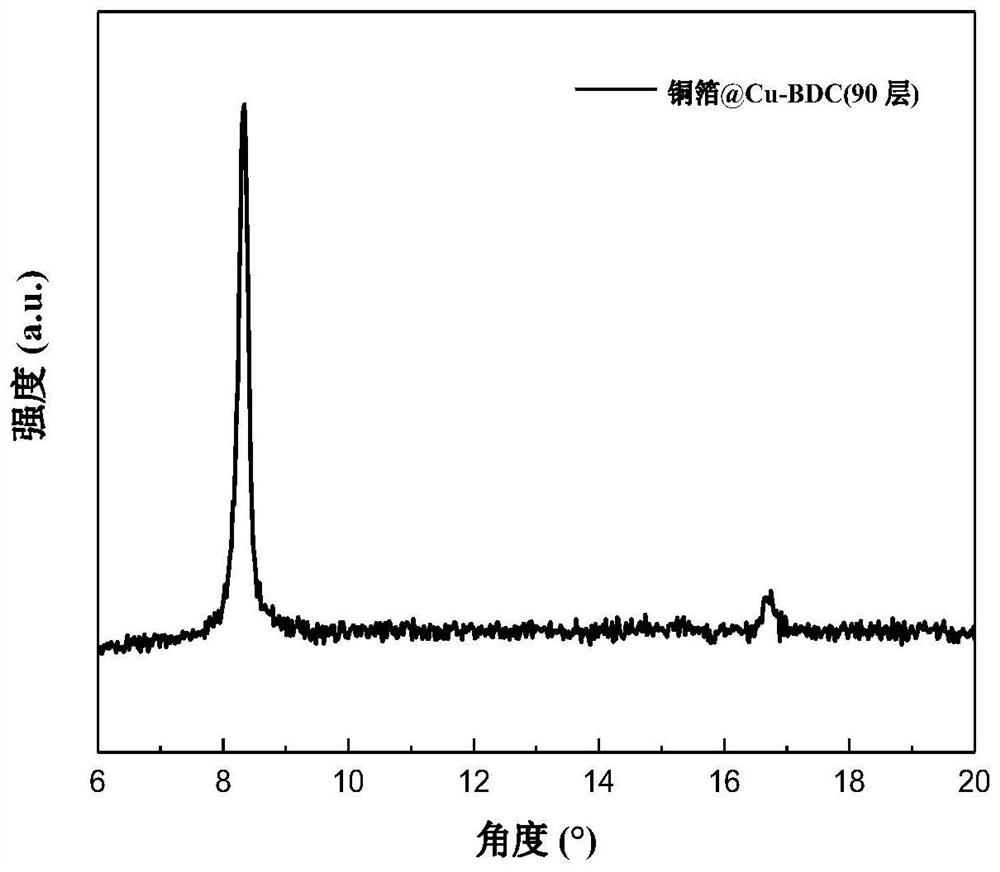

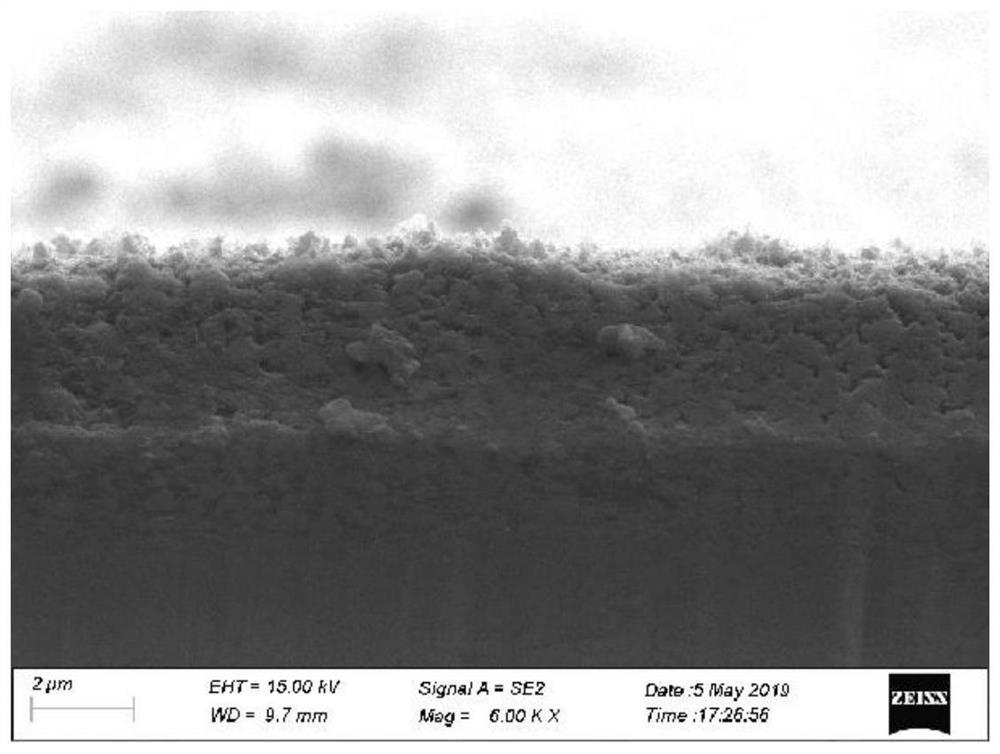

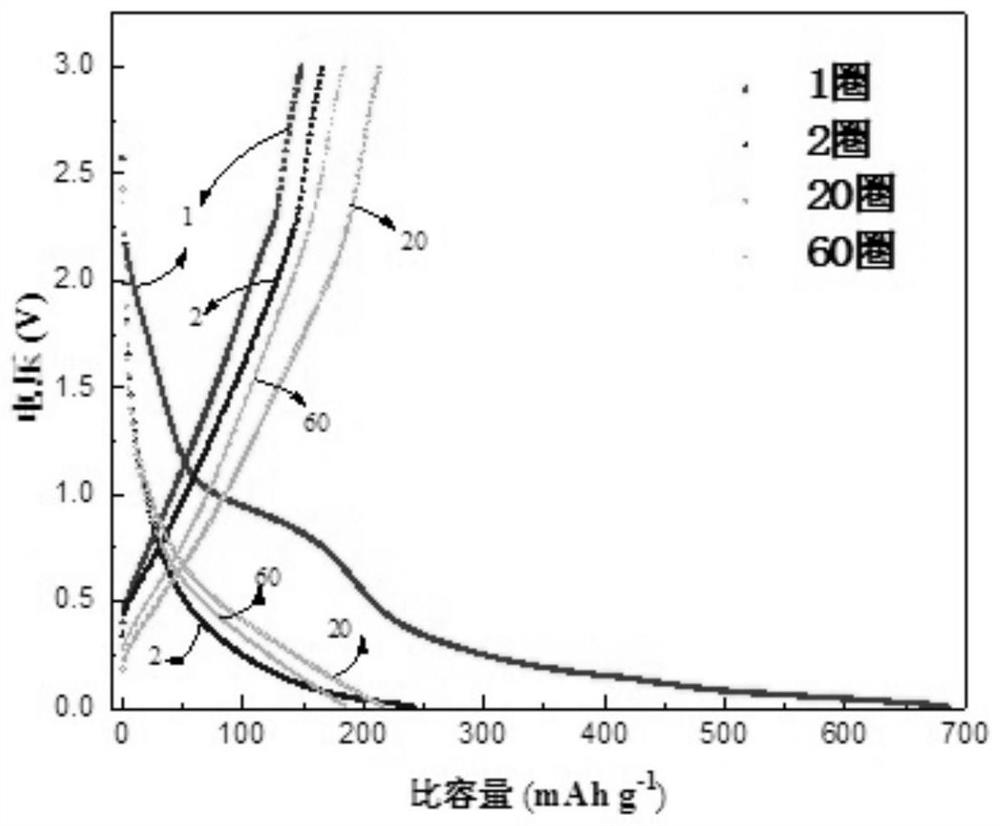

[0032]The integrated three-dimensional ordered porous film electrode material and its preparation method and application mainly include the following steps:

[0033](1) Preparation of metal organic framework solution:

[0034]Mix the metal salt copper acetate (0.0618g, 1mmol / L) with solvent ethanol (300ml), and ultrasonically disperse for 30 minutes to obtain the metal salt copper acetate solution;

[0035]Mix the organic ligand terephthalic acid (0.0099g, 0.2mmol / L) with solvent ethanol (300ml), and ultrasonically disperse for 30 minutes to obtain the organic ligand terephthalic acid solution;

[0036](2) Pretreatment of inorganic support:

[0037]Expose the surface of the inorganic support copper foil to ultraviolet light for 5 minutes, and then soak the surface in a 1mmol / L 16-mercaptohexadecyl acid ethanol solution for 24 hours for surface modification treatment;

[0038](3) Using liquid phase epitaxy self-assembly method to prepare metal organic frame film on inorganic support:

[0039]The surface ...

Embodiment 2

[0052]The integrated three-dimensional ordered porous film electrode material and its preparation method mainly include the following steps:

[0053](1) Preparation of MOF metal organic framework solution:

[0054]Mix zinc nitrate hexahydrate (1.6899g, 10mmol / L) with solvent ethanol (400ml), stir and disperse for 1 hour to obtain a metal salt hexahydrate zinc nitrate solution;

[0055]Mix organic ligand dimethylimidazole (0.6268g, 20mmol / L) with solvent ethanol (400ml), stir and disperse for 1 hour to obtain organic ligand dimethylimidazole solution;

[0056](2) Pretreatment of inorganic support:

[0057]Expose the surface of the copper foil of the inorganic support to ultraviolet light for 5 minutes, and then soak the surface of the inorganic support in a 1mmol / L 11-mercapto-1-undecol ethanol solution for 24 hours for surface modification treatment;

[0058](3) The metal organic frame film is prepared on the inorganic support by the self-assembly method of pulling and coating:

[0059]The surface of th...

Embodiment 3

[0063]The integrated three-dimensional ordered porous film electrode material and its preparation method mainly include the following steps:

[0064](1) Preparation of metal organic framework solution:

[0065]The metal salt copper acetate (0.0419 g, 1 mmol / L) was mixed with solvent ethanol (200 ml), and ultrasonically dispersed for 30 min to obtain a metal salt copper acetate solution.

[0066]The organic ligand trimellitic acid (0.0088g, 0.2mmol / L) and solvent ethanol (200ml) were mixed, and ultrasonically dispersed for min to obtain the organic ligand trimellitic acid solution.

[0067]The metal salt solution and the organic ligand solution are mixed.

[0068](2) Pretreatment of inorganic support:

[0069]Expose the surface of the copper foil of the inorganic support to ultraviolet light for 20 minutes, and then soak the surface of the inorganic support in a 1mmol / L 16-mercaptohexadecyl acid ethanol solution for 12 hours for surface modification;

[0070](3) The metal organic frame film is prepared o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com