Patents

Literature

36results about How to "Promote electrode reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

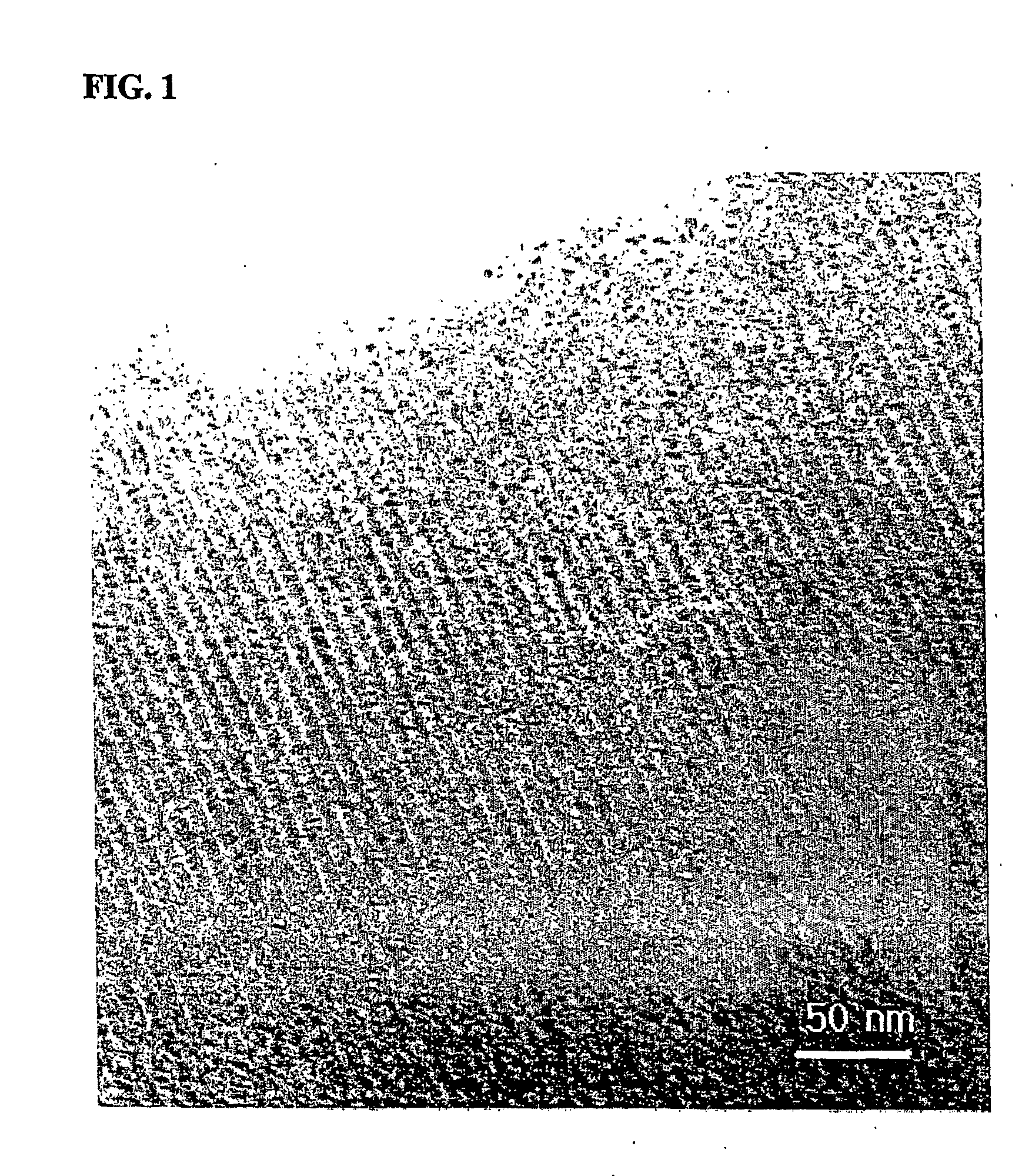

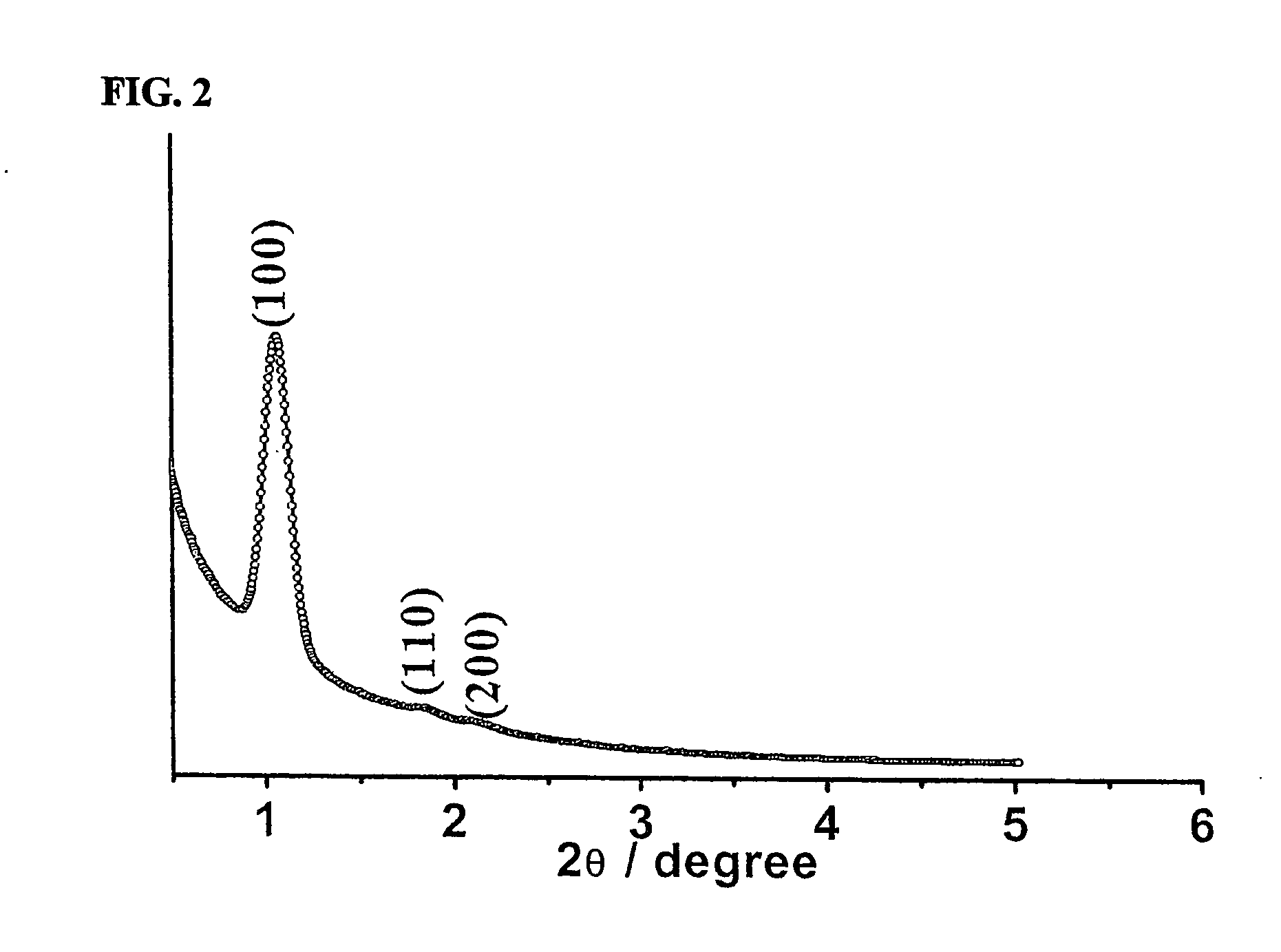

Nano-structured metal-carbon composite for electrode catalyst of fuel cell and process for preparation thereof

InactiveUS20060194097A1Improve featuresImprove reaction speedMaterial nanotechnologyActive material electrodesCarbon compositesFuel cells

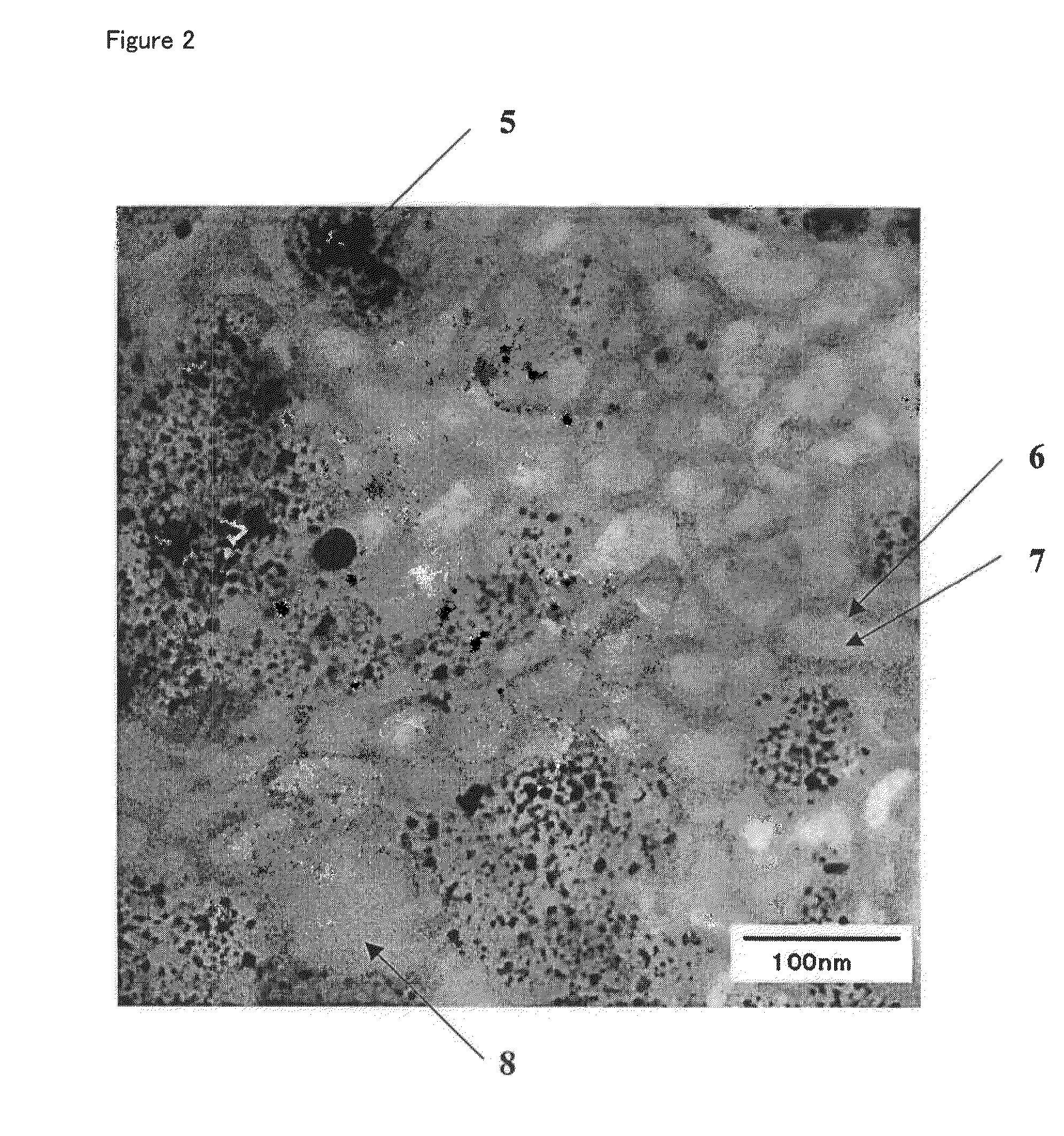

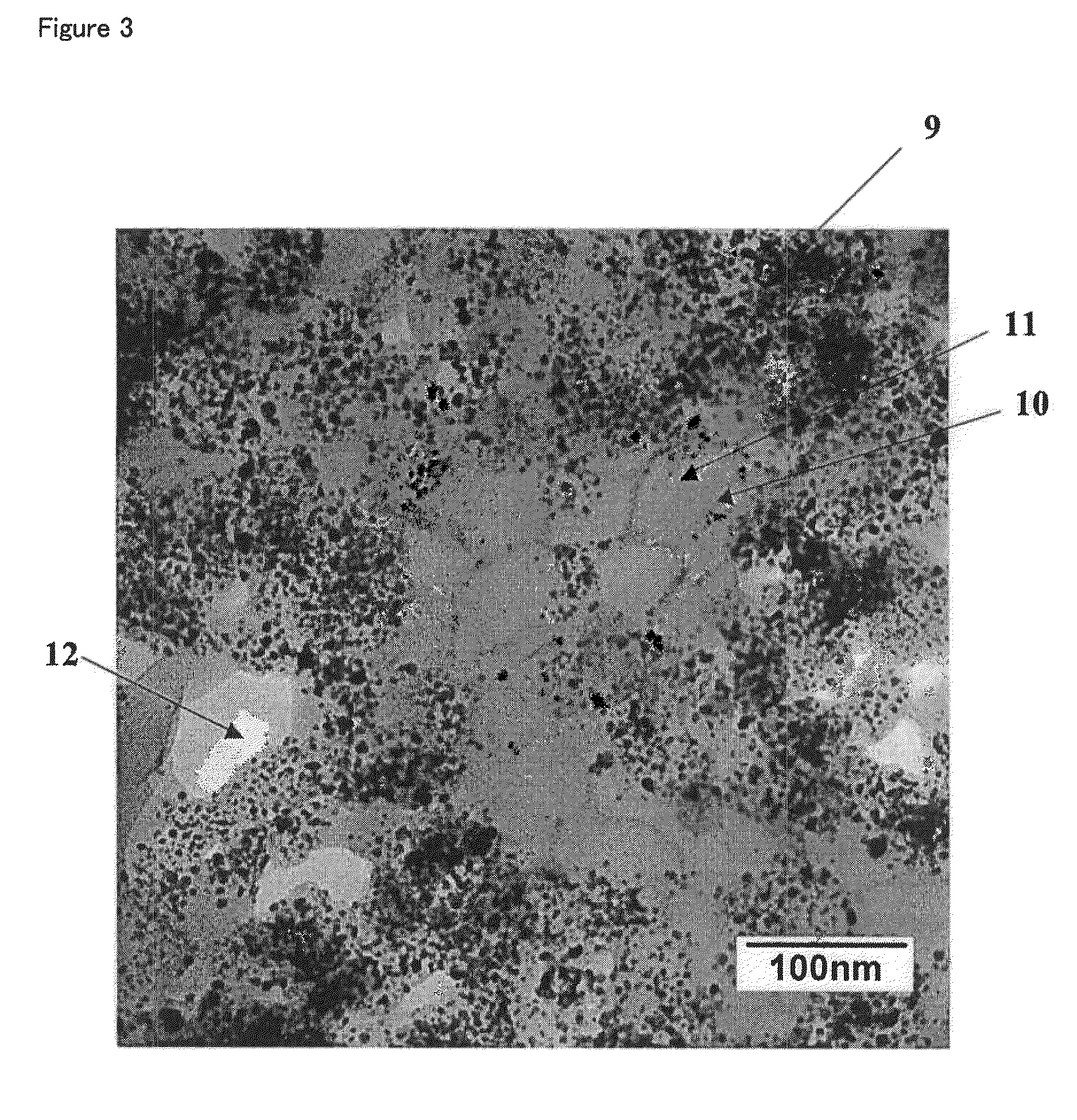

The present invention relates to a nano-structured metal-carbon composite and applications thereof, and more specifically, to a nano-structured metal-carbon composite obtained by consecutively impregnating a transition metal precursor and a carbon precursor in a nano frame and reacting the precursors at high temperature. In the metal-carbon composite of the present invention, metal is orderly polydispersed with less than 1 nanometer within a mesoporous carbon, and metal is chemically combined with carbon. Therefore, the metal-carbon composite is useful for electrocatalyst of fuel cells.

Owner:KYUNGWON ENTERPRISES +1

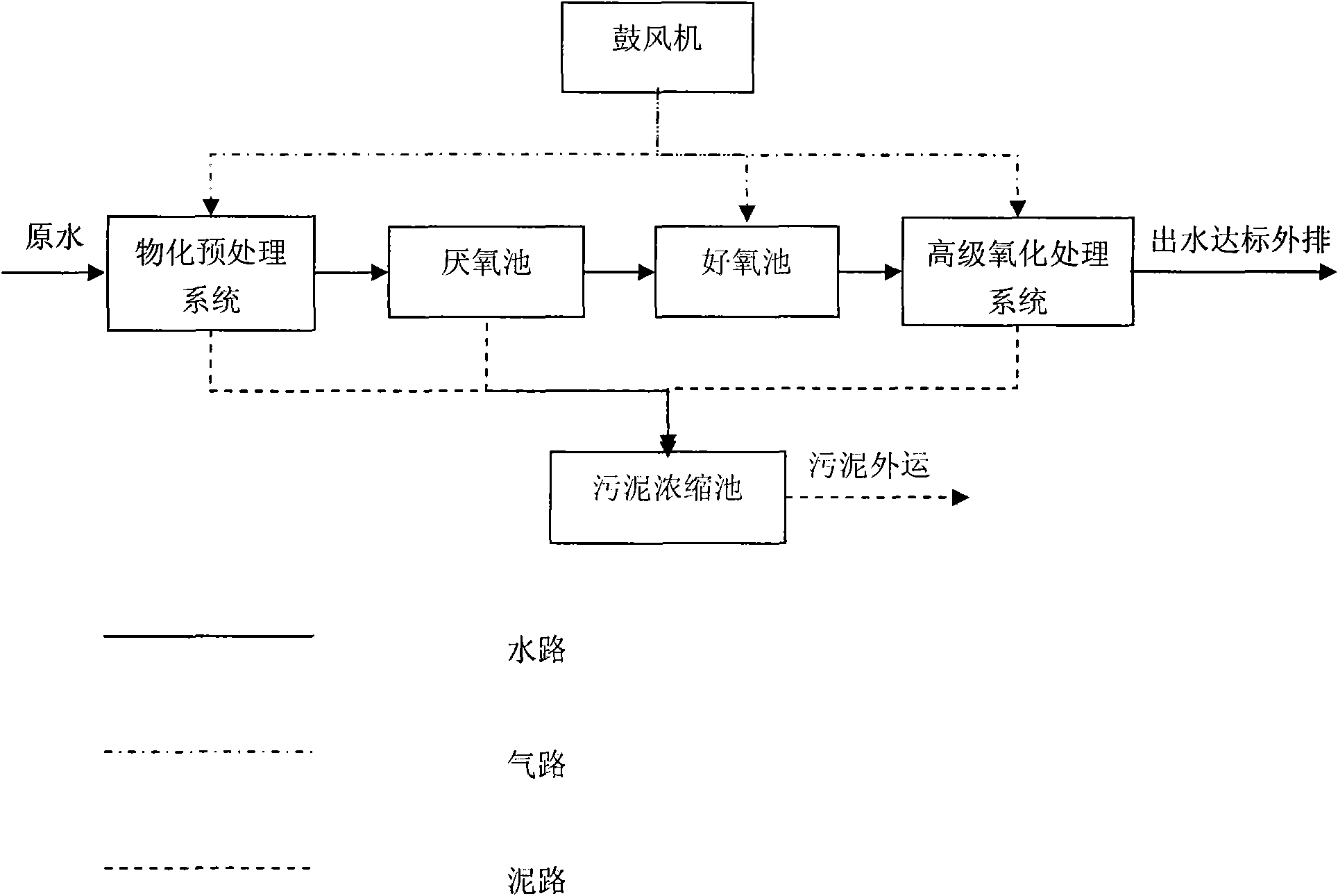

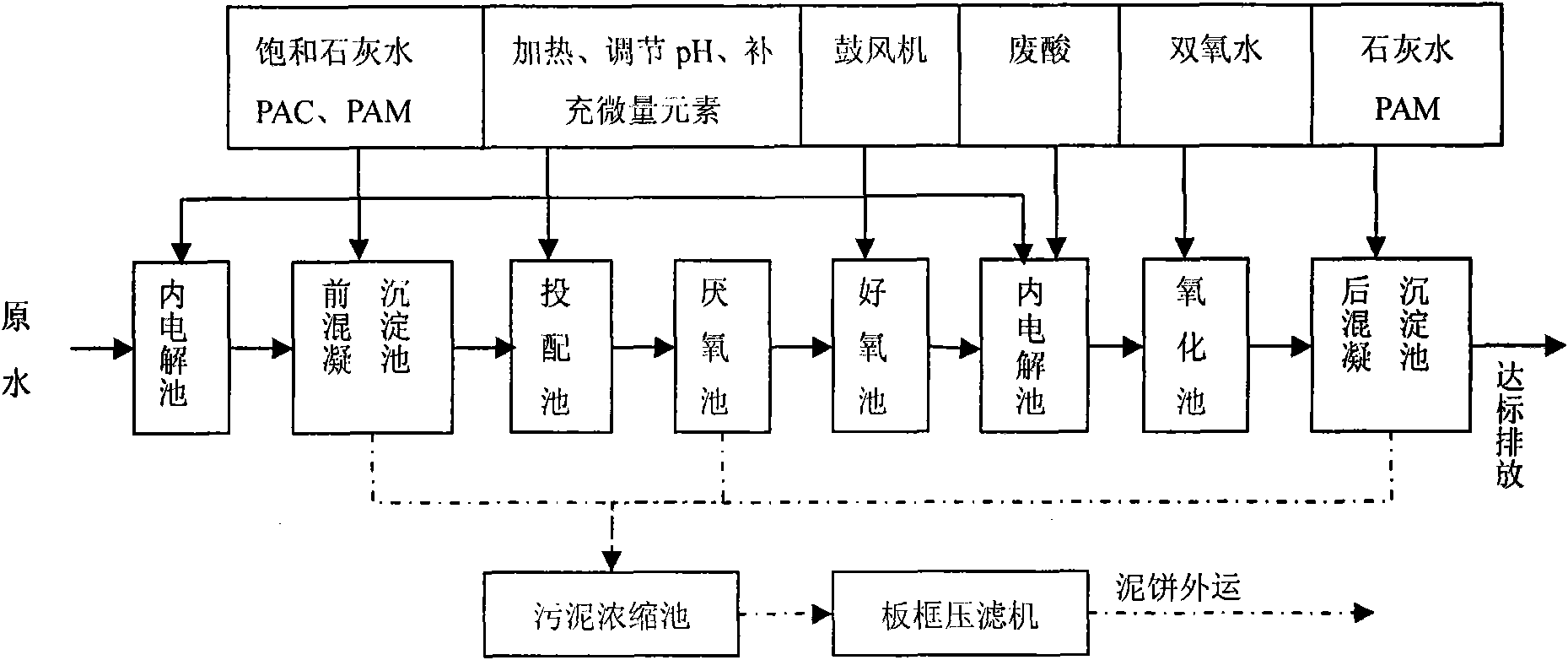

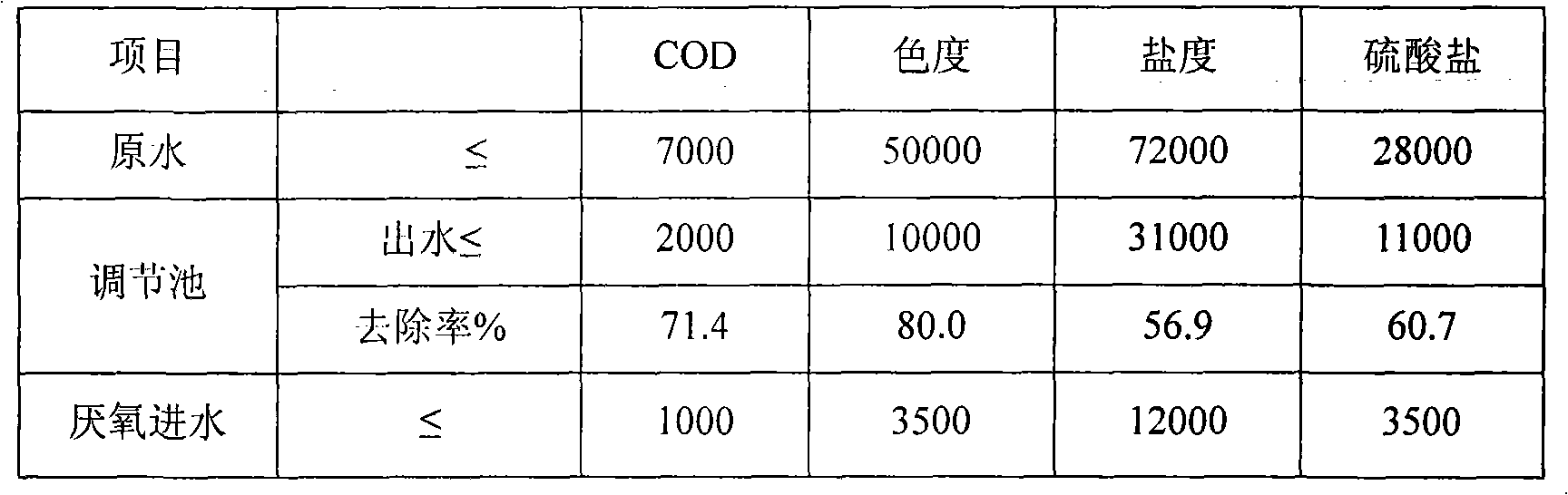

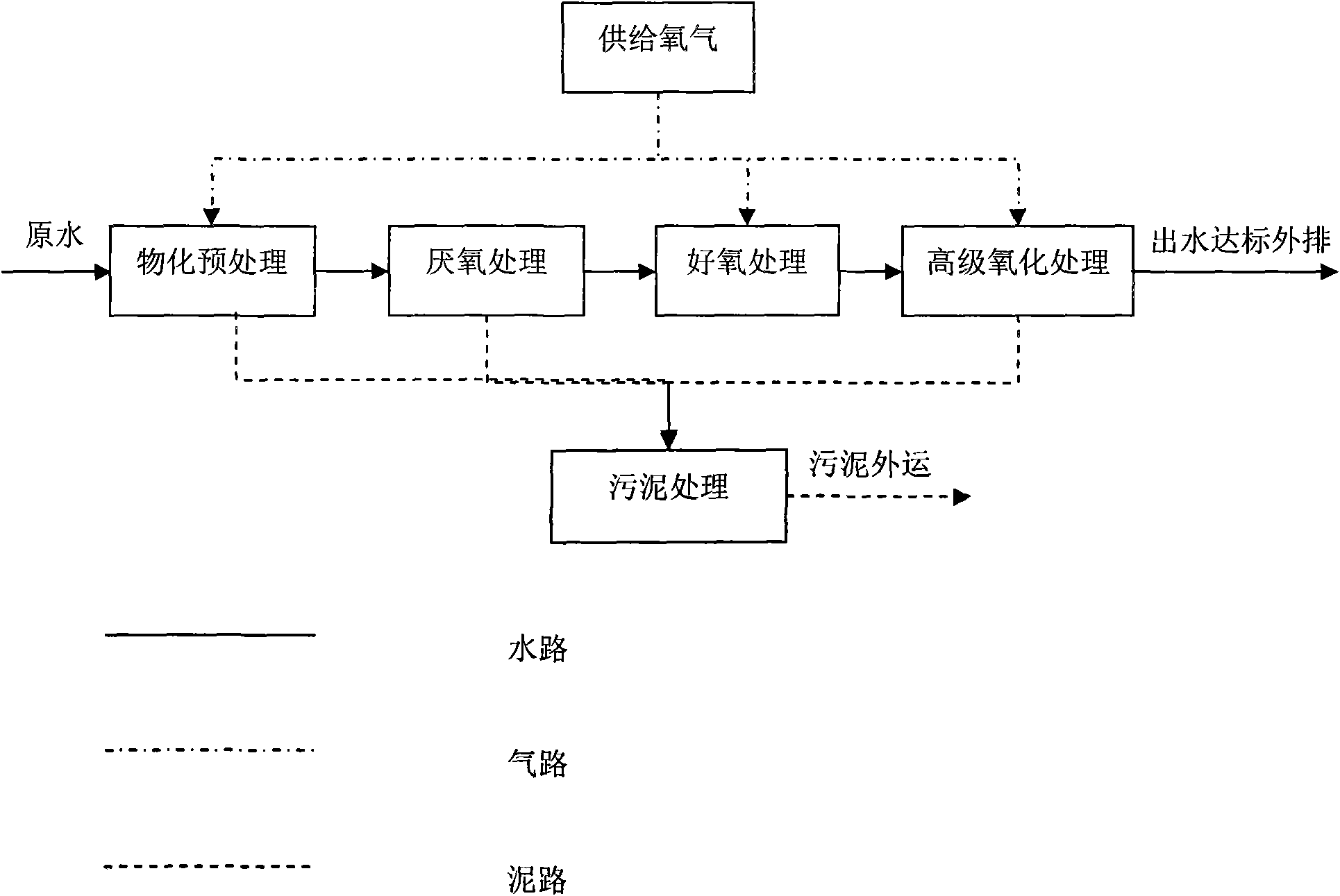

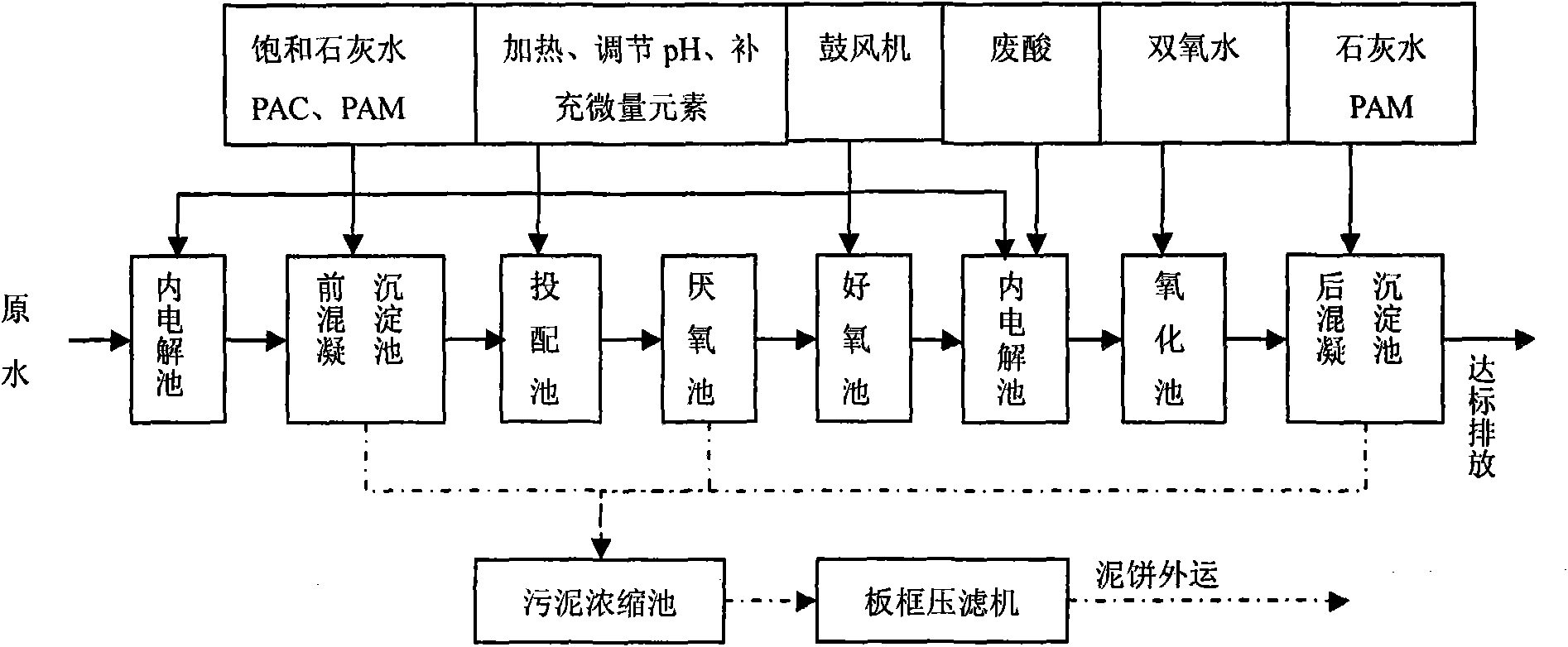

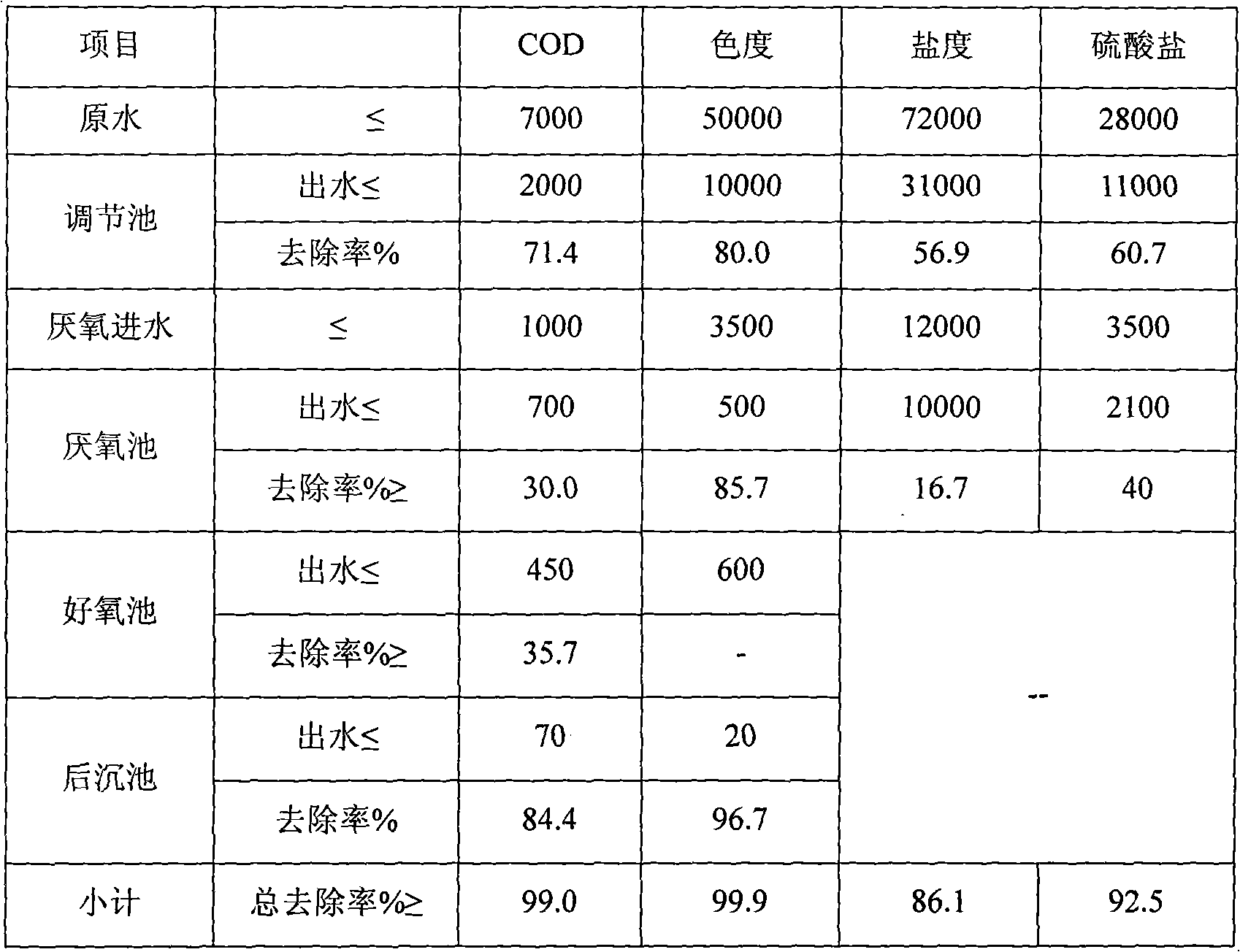

Dye waste water treatment system

InactiveCN101659500ARealize resourcesAchieve the goal of energy saving and emission reductionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationMetabolite

The invention provides a dye waste water treatment system which sequentially comprises a physico-chemical pretreatment system, an anaerobic tank, an aerobic tank and an advanced oxidation treatment system; dye waste water to be treated firstly enters into the physico-chemical pretreatment system to remove part chromaticity, sulphate and COD in the dye waste water, so as to ensure the pH, the alkalinity and the proper sulfate concentration which are needed by high-efficiency and stable running of later stage of anaerobic technique; after that, the dye waste water enters into the anaerobic tankto have anaerobic reaction and then enters the aerobic tank to have aerobic reaction; finally, the dye waste water enters into the advanced oxidation treatment system to remove the residual chromaticity and organic matter hard to degraded in the aerobic effluent as well as intermediate metabolite generated in the process of biological treatment. When being used for treating the dye waste water, especially the waste water having high salinity, sulfate, chromaticity and COD as well as higher concentration organic matter hard to degraded, the combined system has good treating effect and ensures the finally yielding water to reach the first-grade standard in GB4287-92 pollutant emission standards for textile dyeing and finishing industry.

Owner:北京盖雅技术中心有限公司

Suspended electrobiological filler for removing ammonia nitrogen from water, preparation method for suspended electrobiological filler and application of suspended electrobiological filler

ActiveCN102674530AQuick releaseImprove productivityWater contaminantsBiological water/sewage treatmentAdhesiveMicrosphere

The invention discloses a suspended electrobiological filler for removing ammonia nitrogen from water and a preparation method for the suspended electrobiological filler. The suspended electrobiological filler comprises the following components in percentage by weight: 10 to 20 percent of iron powder, 10 to 20 percent of graphite powder or activated carbon powder, 1 to 2 percent of alumina, 1 to 2 percent of nickel oxide, 1 to 2 percent of titanium oxide, 1 to 2 percent of thallium oxide, 1 to 2 percent of iridium oxide, 20 to 30 percent of molecular sieve material, 5 to 10 percent of adhesive and 20 to 30 percent of hollow glass microspheres. The preparation method comprises the following steps of: mixing the raw materials, putting into a reaction kettle, mixing, stirring uniformly, adding the adhesive and water, preparing paste with the water content of about 20-30 percent, granulating by using a granulator or pressing into granules and blocks in a molding machine, demoulding, feeding into a baking oven, and drying at the temperature of 100 to 180 DEG C for 3 to 4h to obtain the suspended electrobiological filler. The invention also provides application of the suspended electrobiological filler. The suspended electrobiological filler can effectively remove the ammonia nitrogen from the water; and in the upgrading reconstruction of industrial wastewater treatment stations, water works and municipal sewage treatment plants, the removal efficiency of the ammonia nitrogen in the water can be improved by 15 to 40 percent, and the total discharge amount of the ammonia nitrogen and nitrate nitrogen can be controlled.

Owner:深圳市地大东江环境研究院

Method for producing aluminum-magnesium alloy by utilizing liquid aluminum cathode method

The invention discloses a method for producing an aluminum-magnesium alloy by utilizing a liquid aluminum cathode method. The method is used for high-efficiently producing the high-quality aluminum-magnesium alloy. The method comprises the following steps of dissolving the high-purity magnesium oxide (MgO) in an electrolyte system consisting of Na3PO3-MgF2-NaCl in an electrolytic cell under the electrolytic temperature of 850DEG C to 900DEG C, wherein the aluminum liquid which is formed by melting a high-purity aluminum ingot is used as a liquid cathode; and applying a coil magnetic field with the intensity of 30mT to 40mT outside the electrolytic cell so as to enable the aluminum liquid to rotate under the electrolytic conditions that the anode current density is 0.47 to 0.52A / cm<2> and the high-purity graphite is adopted as an anode, reducing the magnesium ions on the rotating aluminum liquid cathode into elemental magnesium under the electromagnetic stirring effect to be uniformly dispersed into the aluminum liquid so as to form the aluminum-magnesium alloy product, and producing CO2 gas on the anode. The alloy prepared through the method is uniform in components and contains no impurity. The production process is continuous and easy to control.

Owner:UNIV OF SCI & TECH LIAONING

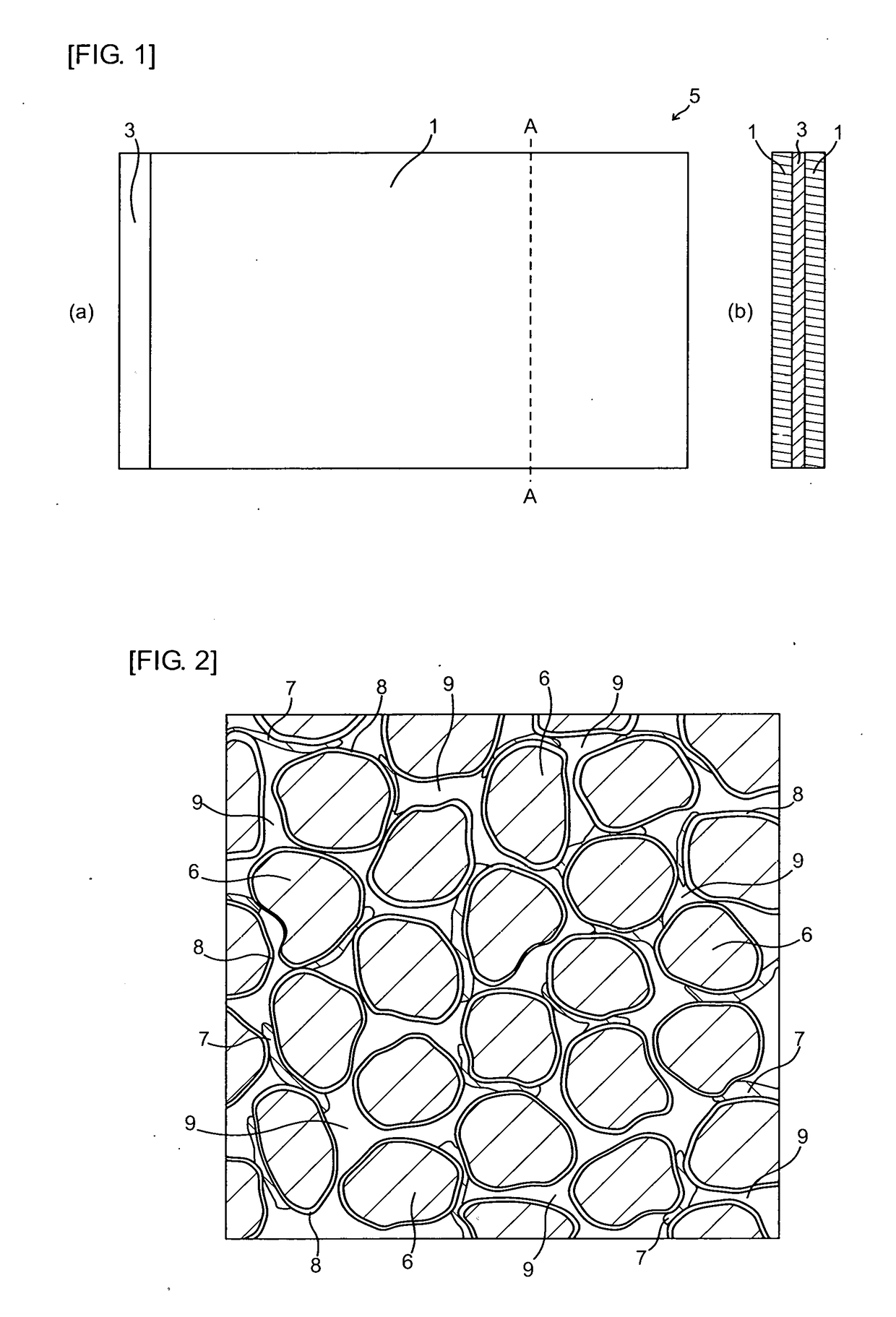

Lithium polymer battery

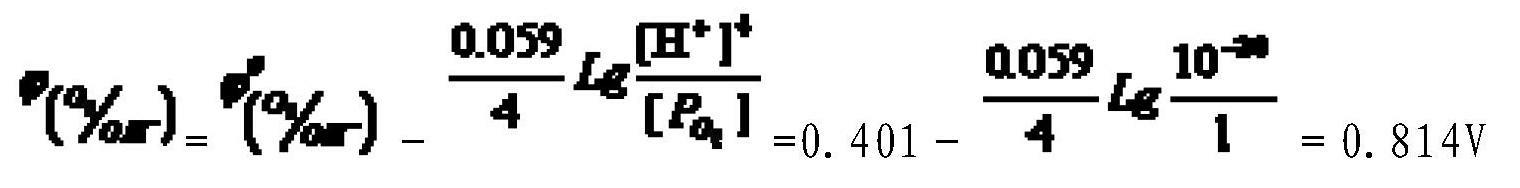

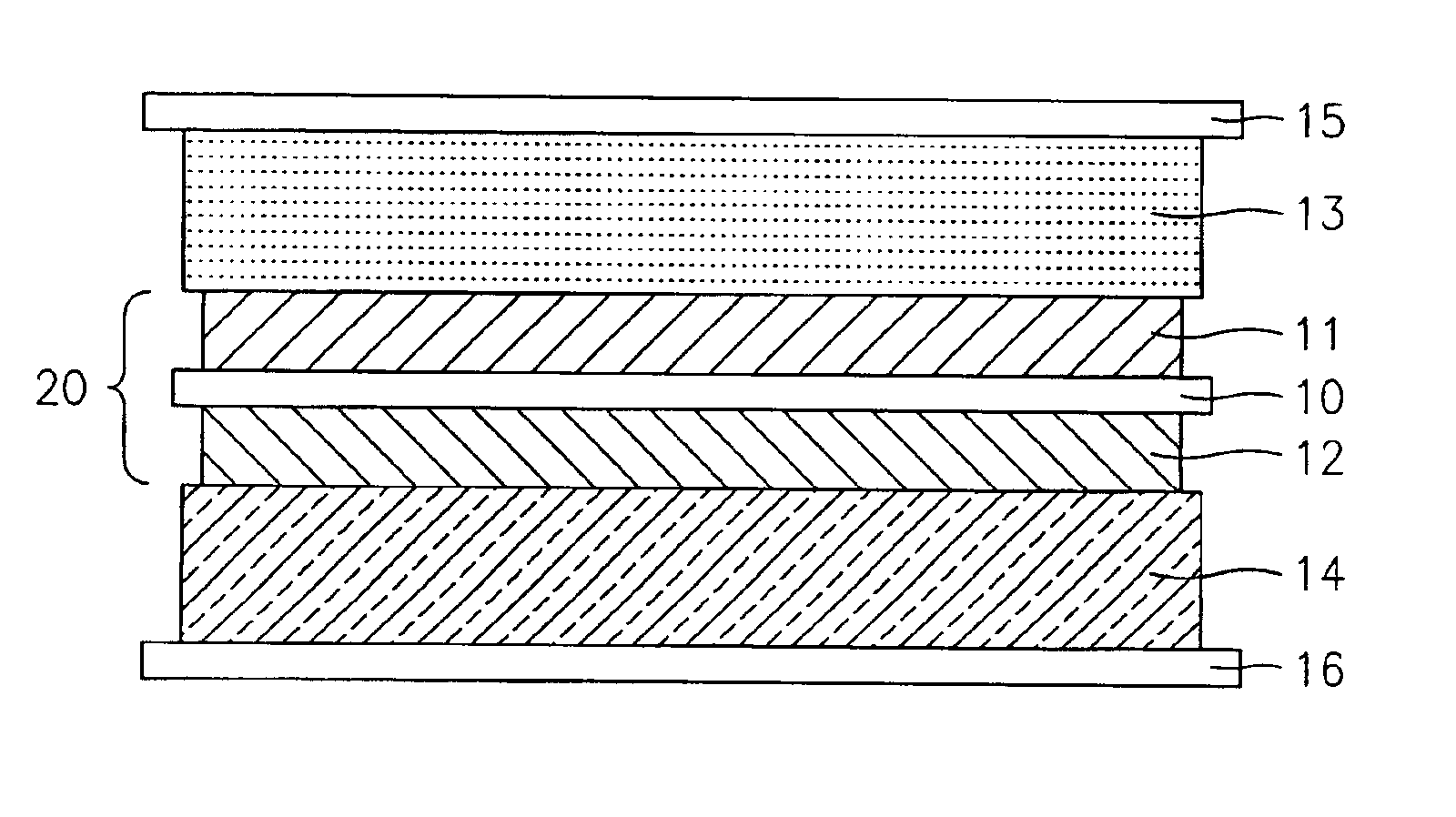

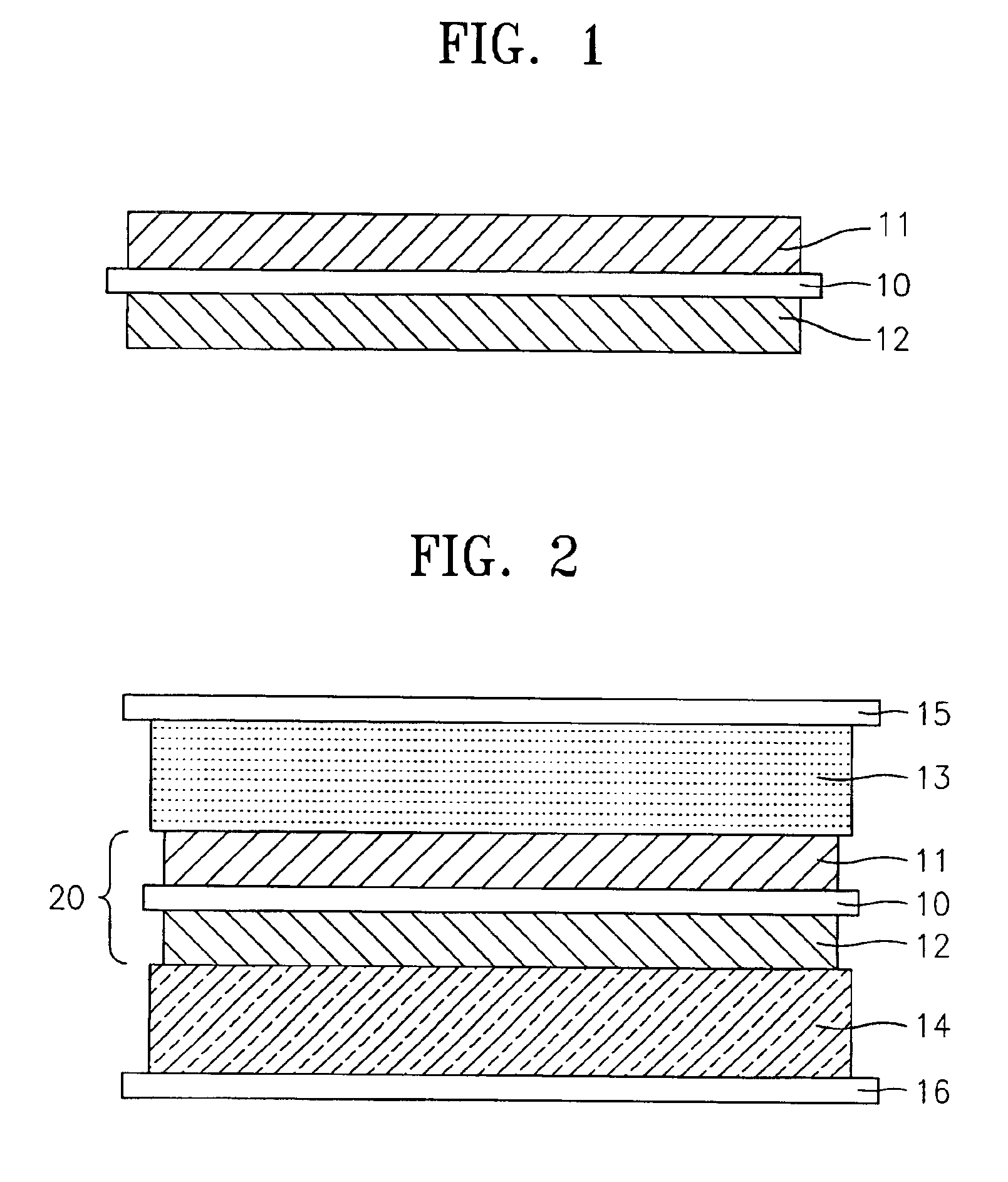

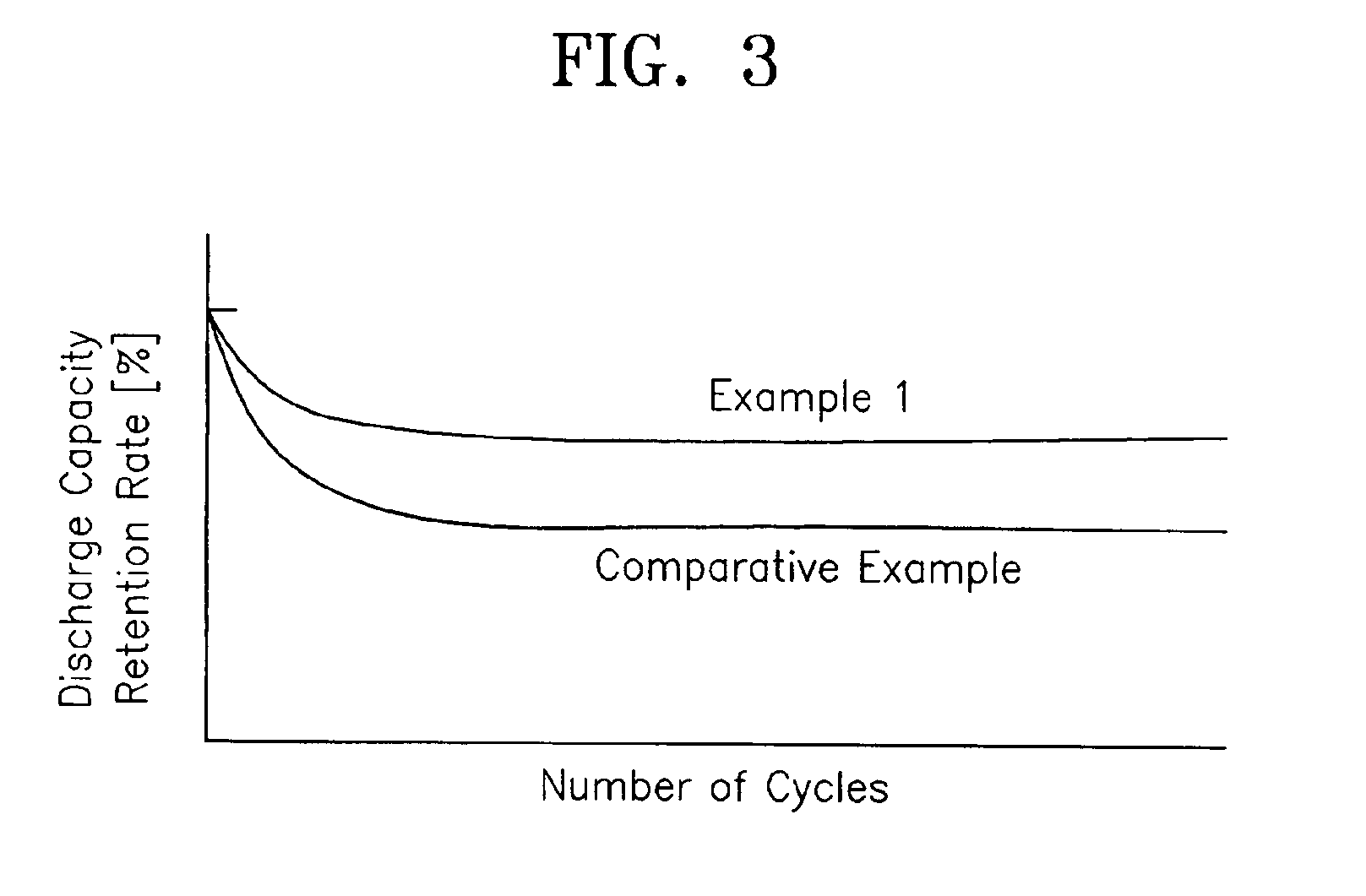

ActiveUS6884547B2Improved charging/discharging efficiency and life-cycle characteristicPromote electrode reactionSolid electrolytesFinal product manufactureLithium polymer cellAqueous solution

A lithium polymer battery includes a cathode, an anode and a porous separator disposed between the cathode and the anode. A first polymeric electrolyte is positioned on a first surface of the separator in contact with the cathode. A second polymeric electrolyte is positioned on a second surface of the separator layer in contact with the anode. The first and second polymeric electrolytes use host polymers having different pH levels in an aqueous solution extracted using water.

Owner:SAMSUNG SDI CO LTD

Dye waste water treatment method

InactiveCN101654314AHigh chromaIncrease concentrationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentEmission standardRefractory

The invention provides a dye waste water treatment method, comprising a materializing pre-treatment, an anaerobic treatment, an aerobic treatment, and an advanced oxidation treatment carried out in sequence, wherein the method comprises the steps of conducting a materializing pre-treatment to the object dye waste water to get rid of a part of chromaticity and COD for the anaerobic treatment and aerobic treatment, and then conducting an advanced oxidation treatment to the water discharged from the aerobic treatment to finally remove the degradation-refractory pollutant at the end of the waste water treatment and the intermediate metabolized substances produced in the process of biological treatment. Through the combined process of materializing pre-treatment, anaerobic treatment, aerobic treatment and advanced oxidation treatment, the invention can effectively treat difficultly degraded dye waste water and reduce the operation cost, thereby being capable of standardizing the indexes such as COD and chromaticity of the discharged water to the national norm simultaneously, solving the domestic current situation of difficulties in treating dye waste water, and being capable of meetingthe requirements of upgrading and restructuring the sewage treatment plant according to the increased standard of environment protection in the future.

Owner:北京盖雅技术中心有限公司

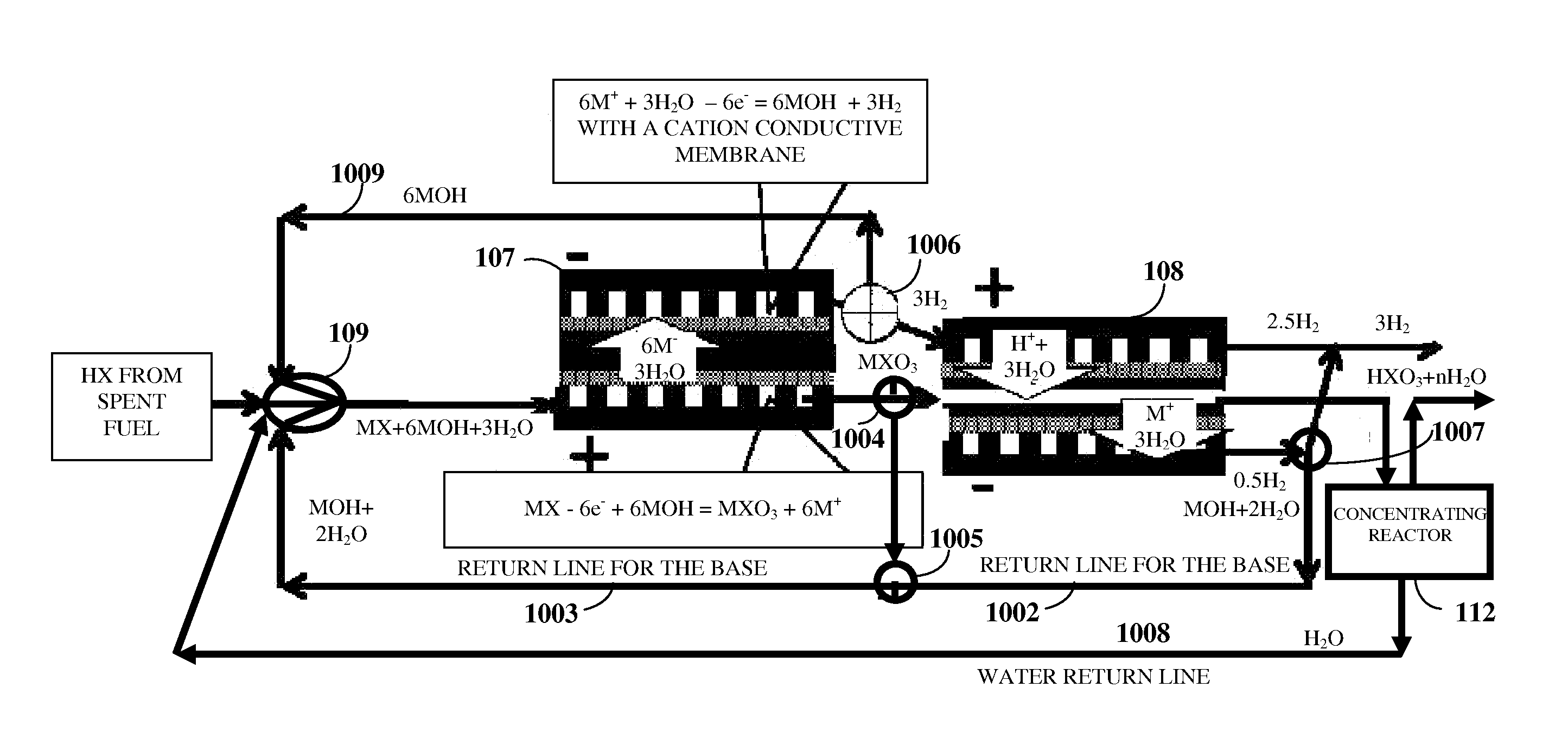

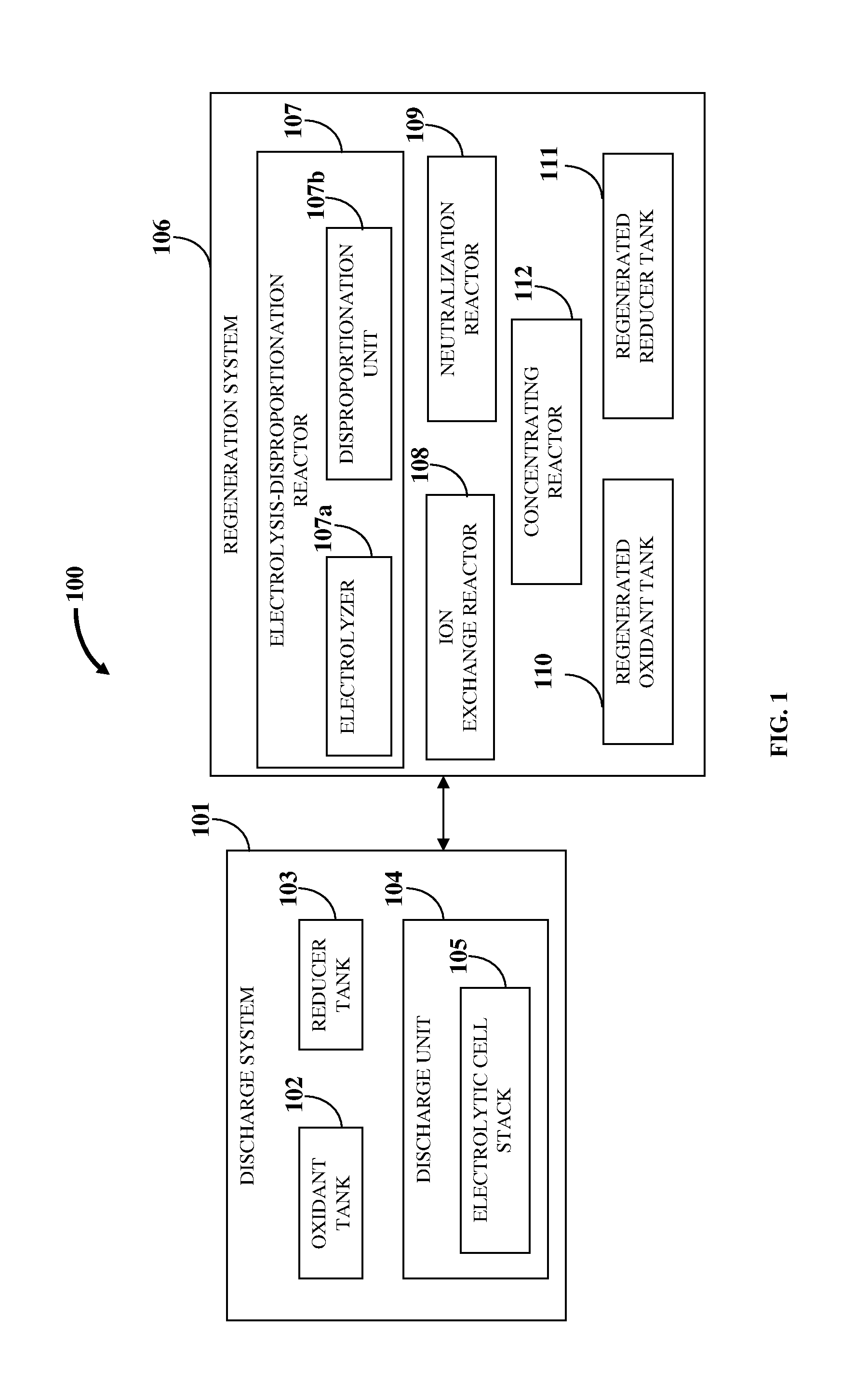

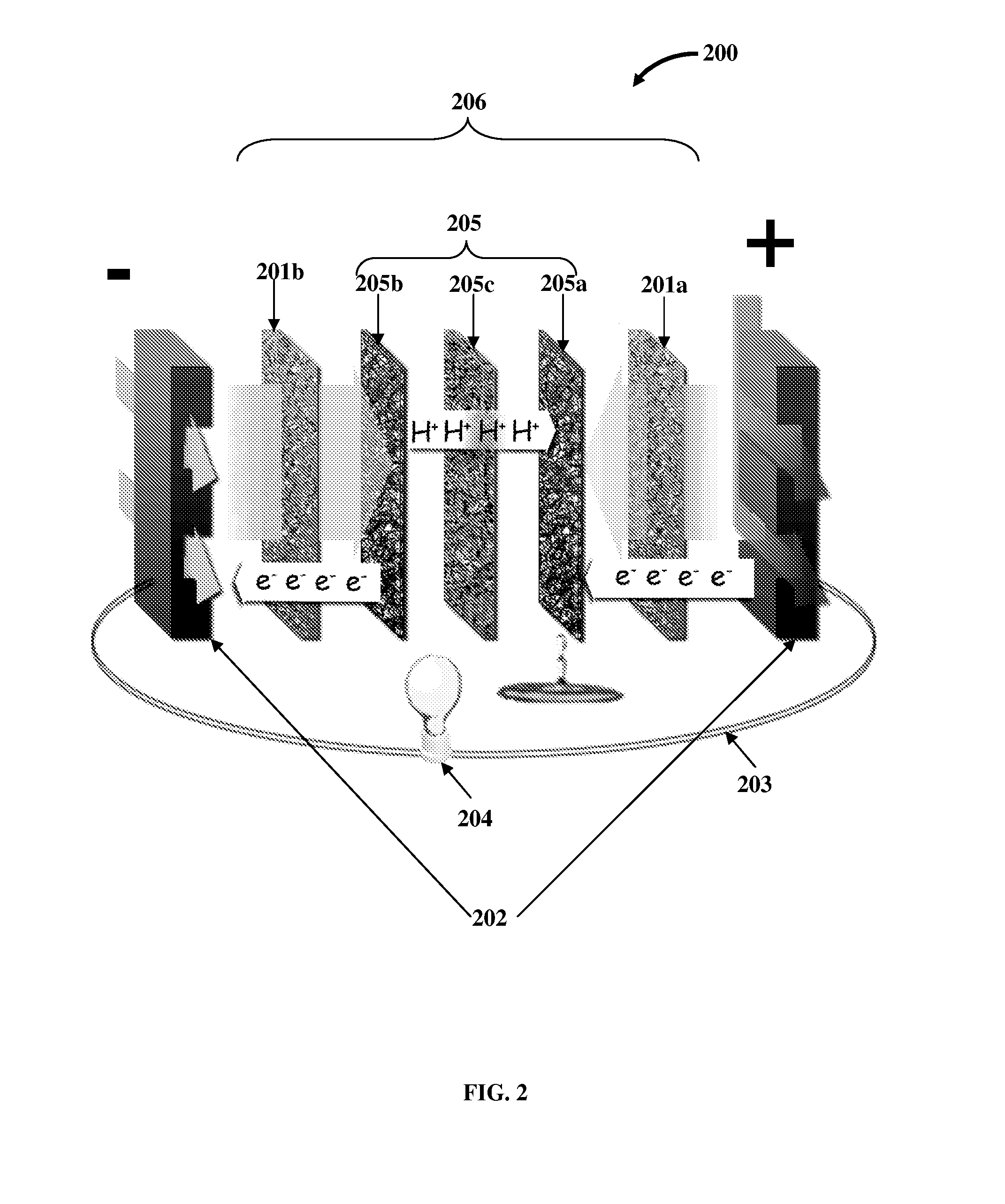

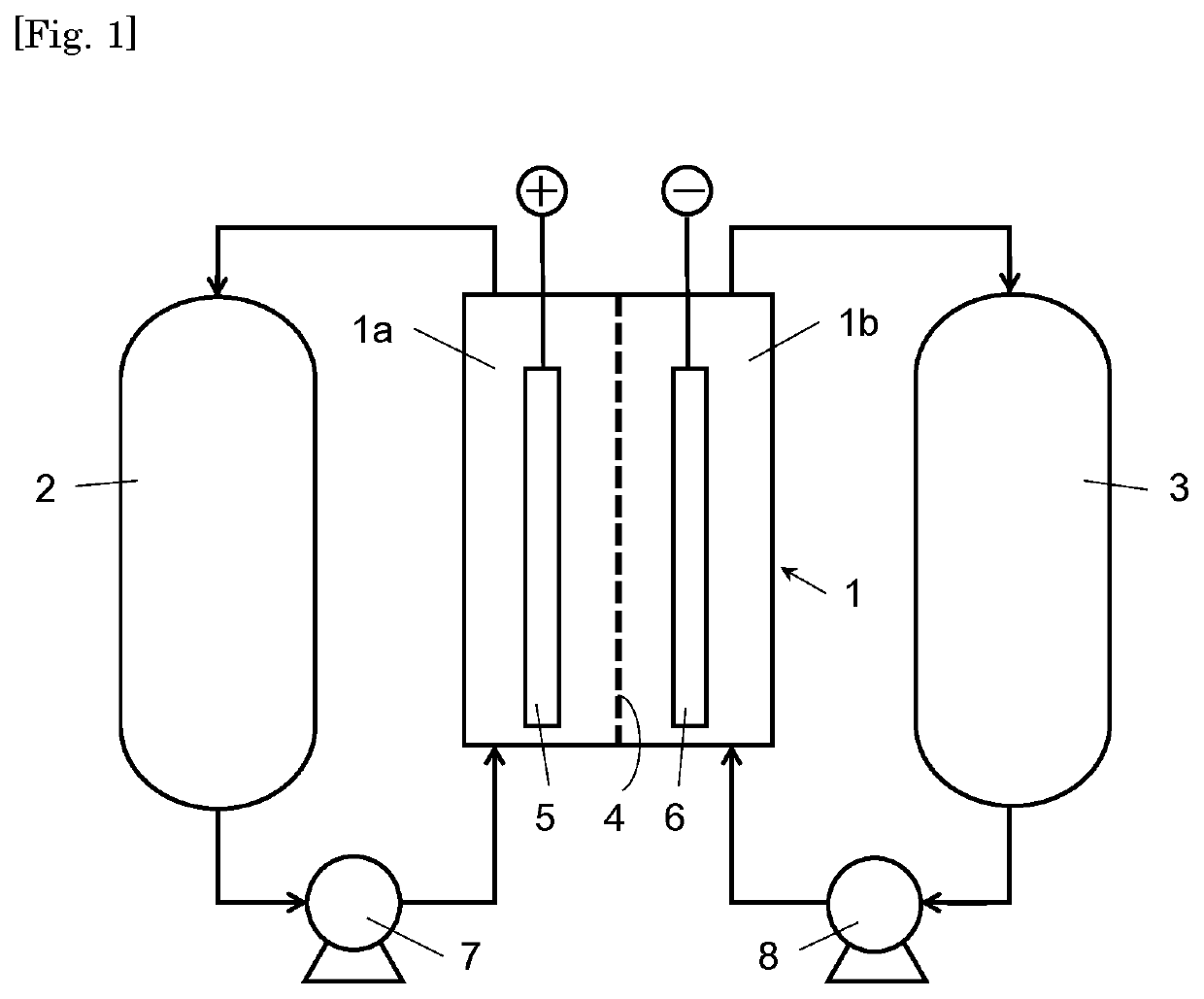

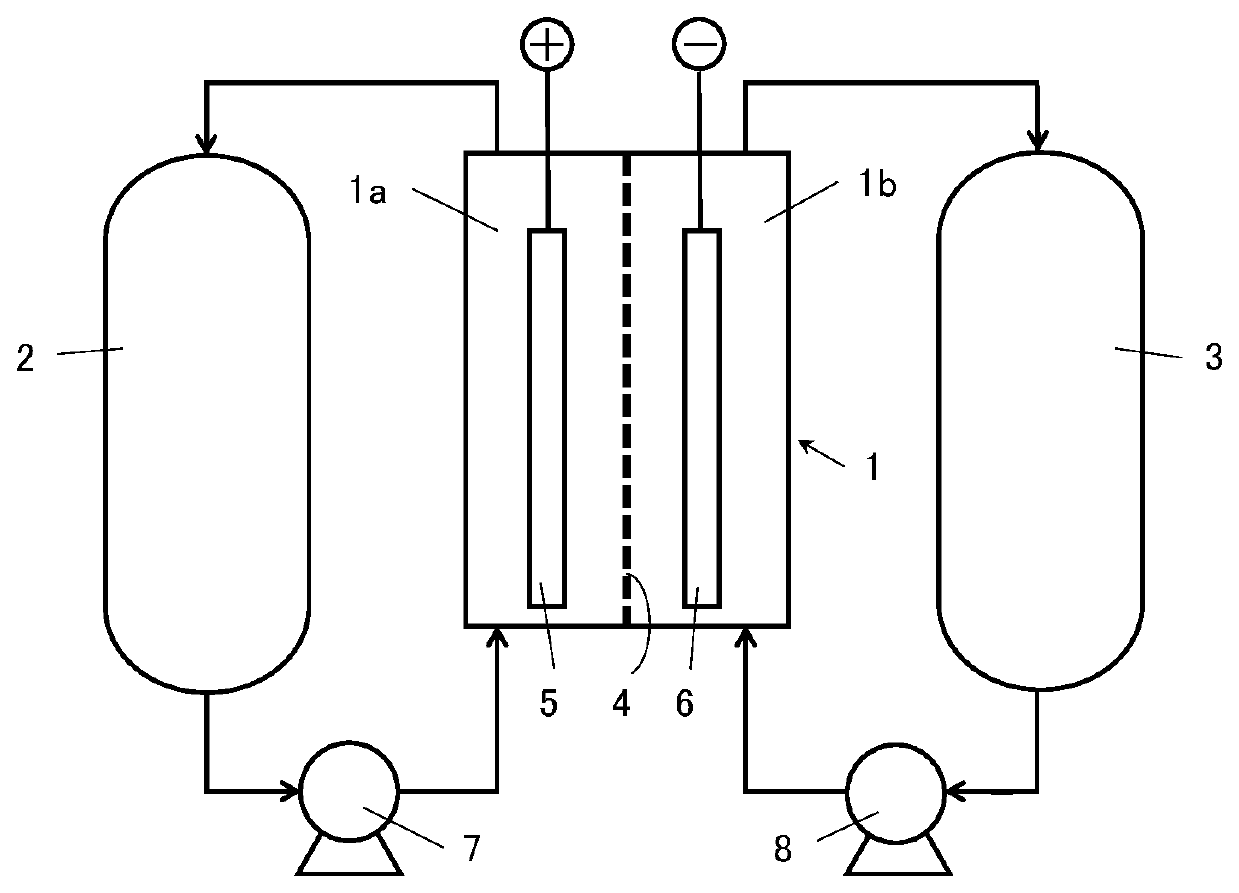

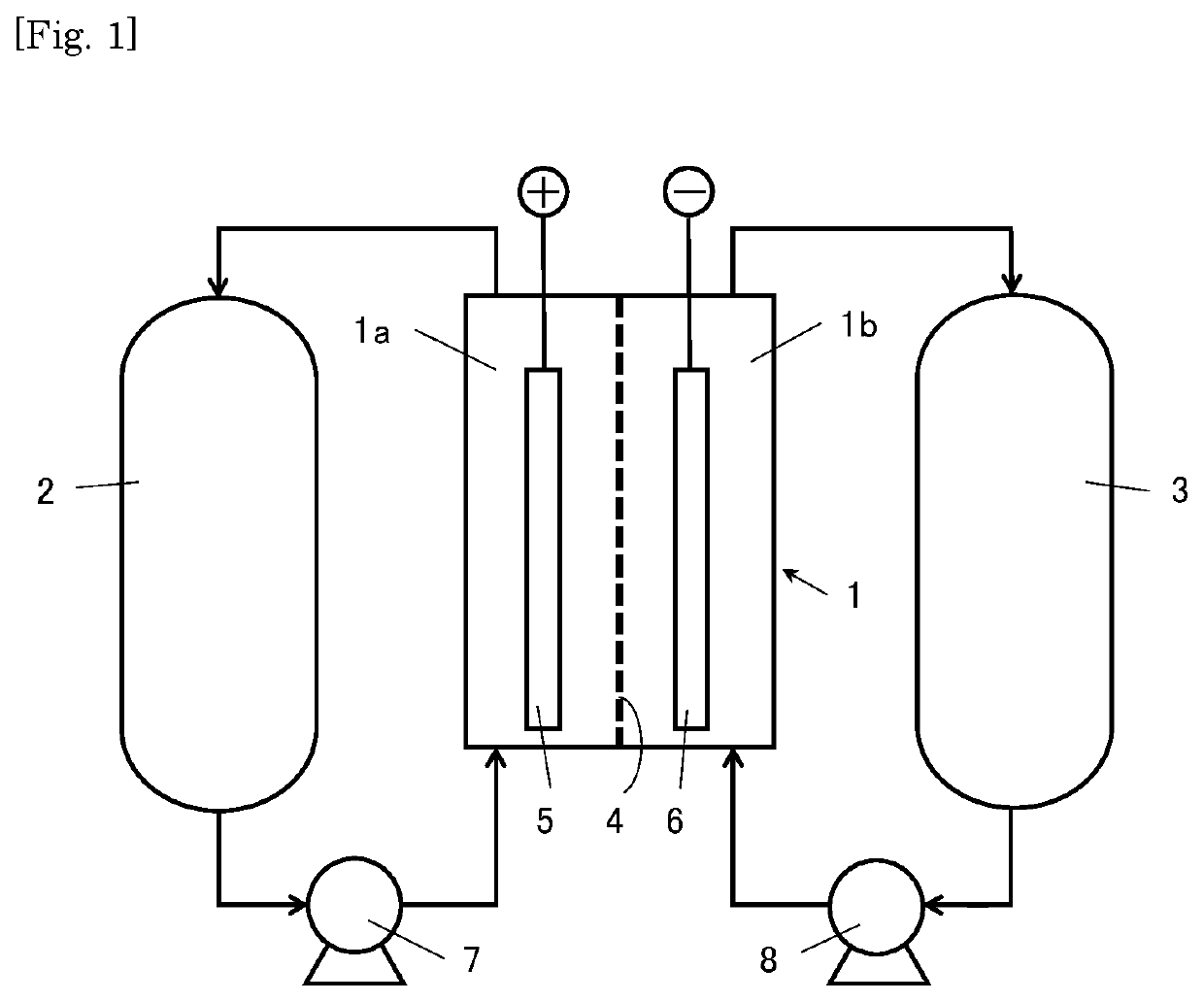

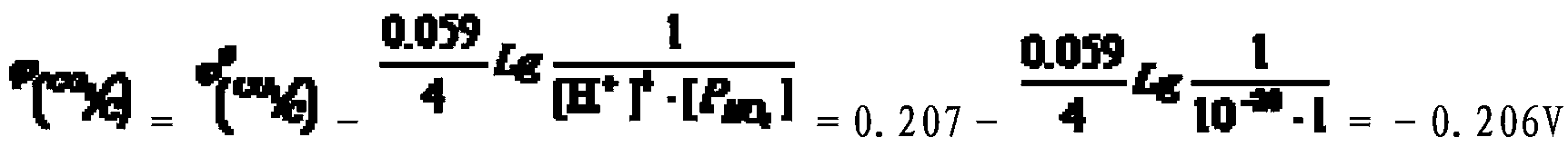

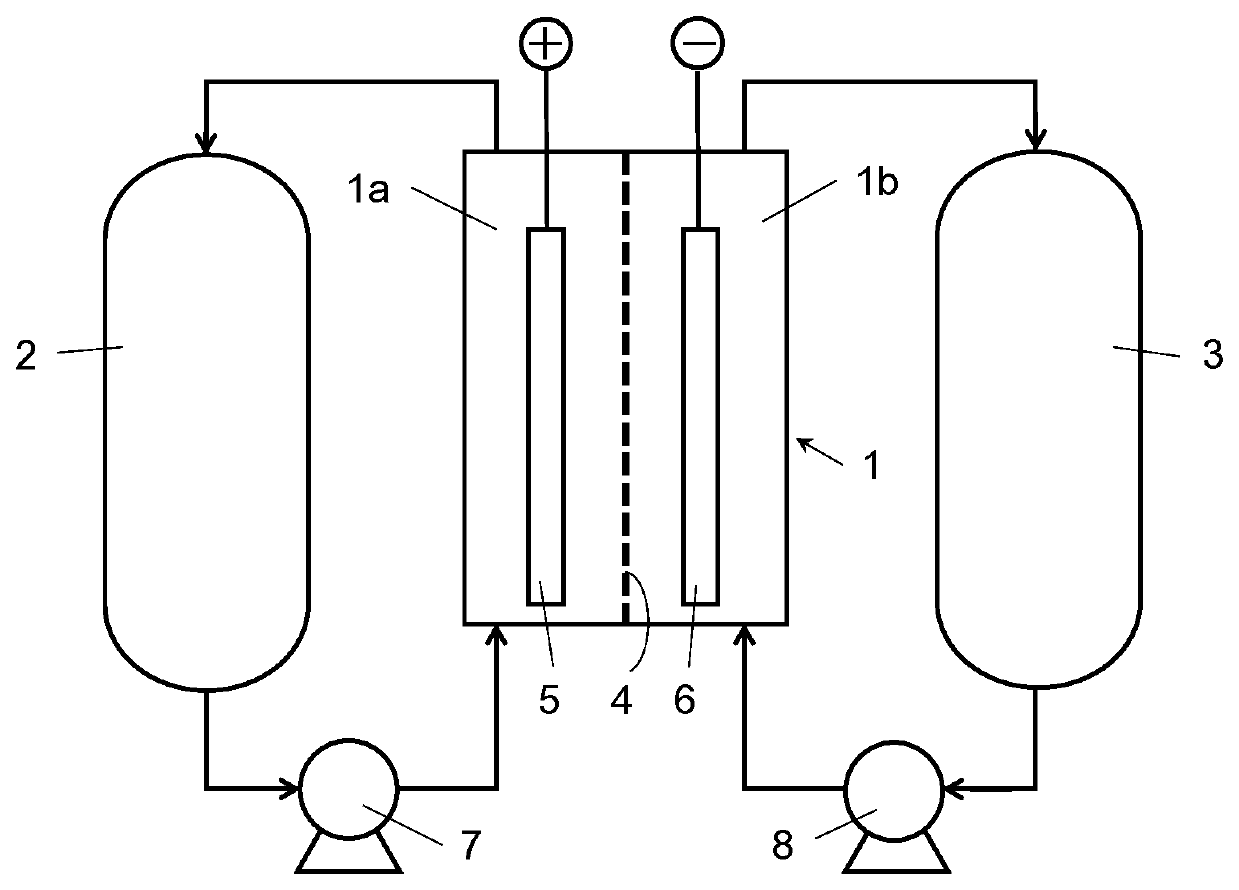

Flow Battery And Regeneration System

InactiveUS20140050999A1Improve energy efficiencyShort filling timeFuel cells groupingRegenerative fuel cellsElectrolysisIon exchange

Methods for generating electric power and a discharge fluid from an oxidant and a reducer using a discharge system, and regenerating an oxidant and / or the reducer from the discharge fluid using a regeneration system are provided. A discharge unit of the discharge system generates electric power and the discharge fluid by transferring electrons from a positive electrode of a 5-layer electrolyte-electrode assembly (5EEA) to an aqueous multi-electron oxidant (AMO) and from a reducer to a negative electrode of the 5EEA. The regeneration system neutralizes the discharge fluid to produce a salt form of the discharge fluid. The regeneration system electrolyzes the salt form of the discharge fluid into an intermediate oxidant in an electrolysis-disproportionation reactor and releases the reducer, while producing the AMO by disproportionating the intermediate oxidant. The regeneration system converts a salt form of the AMO into an acid form of the AMO in an ion exchange reactor.

Owner:FTORION

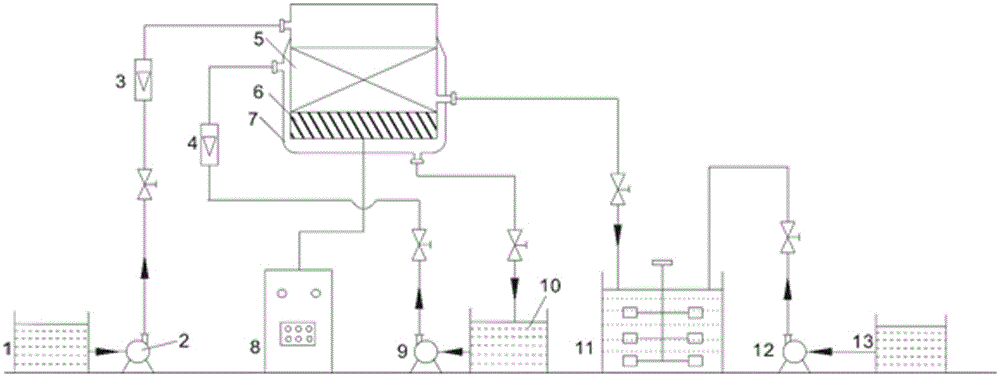

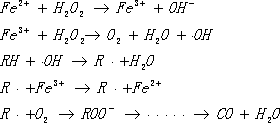

Method and device for treating nitrobenzene wastewater through ultrasonic wave/iron-carbon micro-electrolysis-Fenton oxidation method

PendingCN105884098APromote passivationAvoid churnWater/sewage treatment with mechanical oscillationsWater contaminantsElectrolysisFenton reagent

The invention belongs to the technical field of treatment of nitrobenzene wastewater, and particularly relates to a method and device for treating nitrobenzene wastewater through an ultrasonic wave / iron-carbon micro-electrolysis-Fenton oxidation method. The problems in the prior art that efficiency is low when organic pollutant in wastewater is treated only through ultrasonic waves, when a traditional iron-carbon micro-electrolysis-Fenton method is directly used for treating wastewater, along with delay of treating time, due to passivation of iron-carbon micro-electrolysis filler, the treating efficiency is greatly lowered, and anodic reaction is weakened are solved. The method comprises the steps that nitrobenzene wastewater is treated through ultrasonic waves and iron-carbon micro-electrolysis, and nitrobenzene difficult to degrade is reduced to be aniline easy to degrade; after micro-electrolysis is finished, wastewater is placed into a stirring reaction pool, H2O2 is added into wastewater to be combined with Fe2+ in wastewater to form a Fenton reagent, and wastewater is further oxidized and degraded. The reaction speed of iron-carbon micro-electrolysis is improved by 6-10 times on the whole, the concentration of free Fe2+ in wastewater is improved by 5-8 times, and H2O2 needed by the follow-up Fenton oxidization method is greatly reduced.

Owner:ZHONGBEI UNIV

Lithium ion battery with adoption of secondary electrolyte injection

ActiveCN102255105AImprove conductivityReduce restrictionsSecondary cellsCell component detailsPropionitrileEthyl propionate

The invention discloses a lithium ion battery with adoption of secondary electrolyte injection, comprising a positive pole, a negative pole, a diaphragm, an electrolyte and an outer package. In the process of manufacturing the battery, the secondary electrolyte injection is adopted; the electrolyte solvent in the first electrolyte injection is one or a combination of more than one of EC (ethylene carbonate), PC (propylene carbonate), DMC (dimethyl carbonate), DEC (diethyl carbonate), EMC (ethyl methyl carbonate), Gamma-BL (butyrolactone), MF (methyl formate), MA (methyl acetate), EP (ethyl propionate) and THF (tetrahydrofuran) and does not contain acetonitrile and propionitrile; the secondary electrolyte injection is conducted after the formation; and the used electrolyte in the secondary electrolyte injection contains at least one of the acetonitrile and the propionitrile. The electrolyte containing the at least one of the acetonitrile and the propionitrile has the advantage of high normal-temperature conductivity (10-50mS / cm) and low-temperature conductivity (4-20mS / cm at the temperature of -20 DEG C), thereby exceeding the level of an existing electrolyte.

Owner:DONGGUAN AMPEREX TECH +1

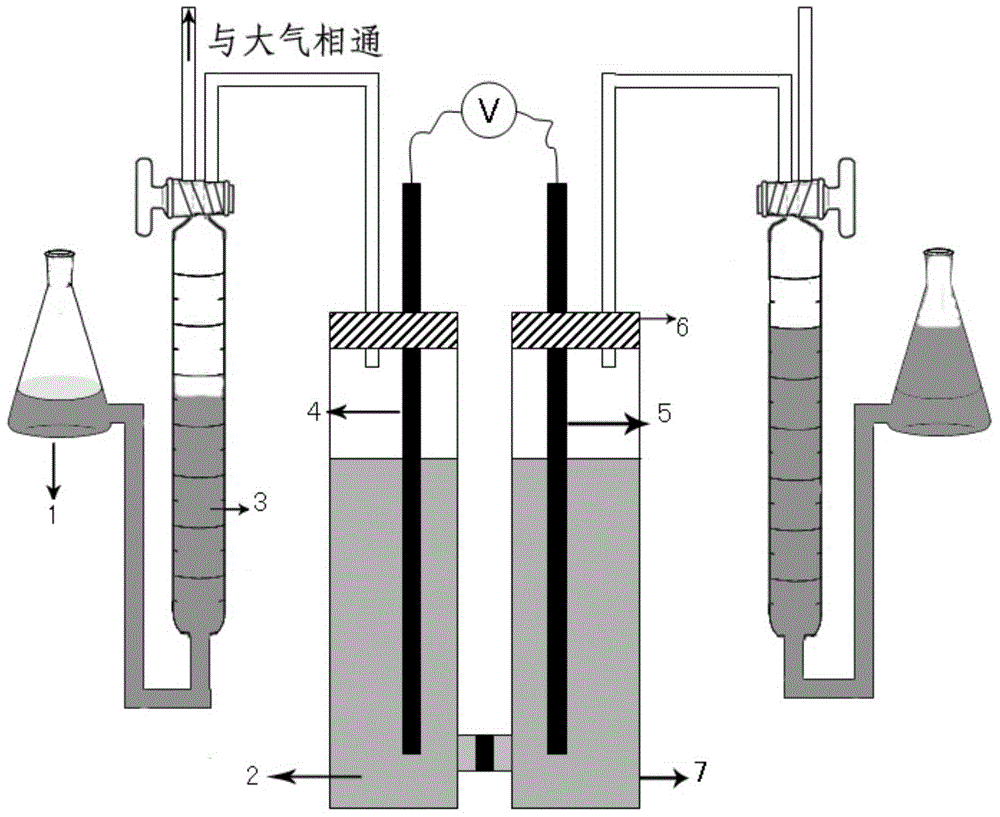

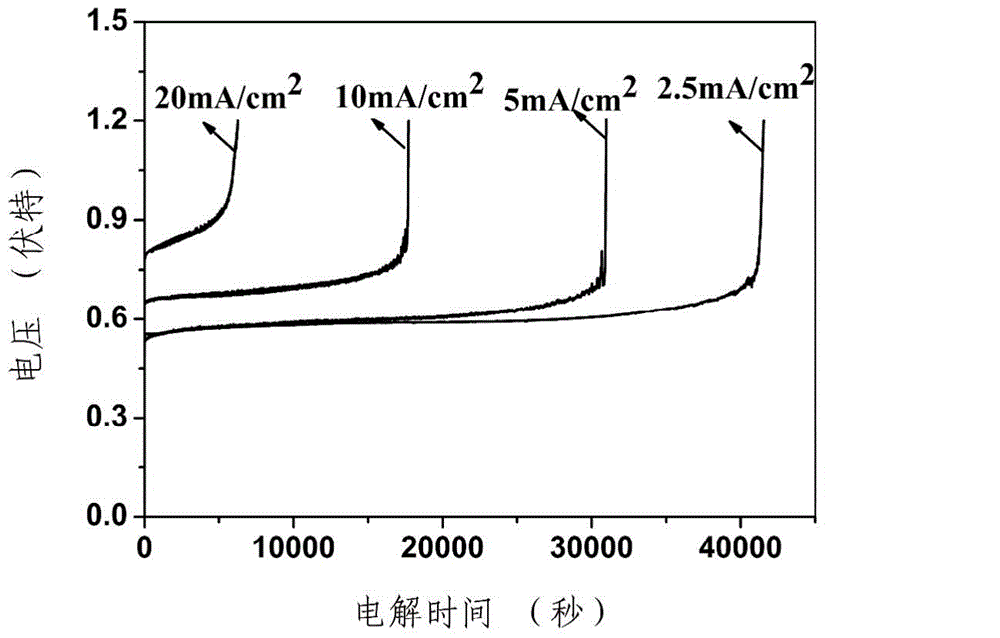

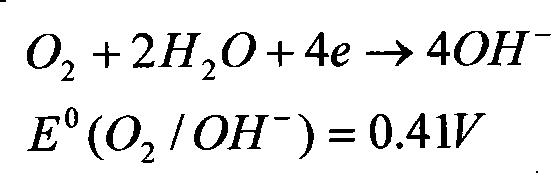

Method and device for preparing hydrogen by electrolyzing ammonia

InactiveCN104419945AReduce energy consumptionImprove efficiencyCellsElectrode shape/formsElectrolytic agentNitrogen gas

The invention belongs to a preparation method of hydrogen and specifically relates to a method and a device for preparing the hydrogen by electrolyzing ammonia. Ammonia is taken as a raw material and foamed nickel on which different noble metals are deposited is taken as an anode and a cathode for an electrolytic hydrogen production reaction; specifically, the cathode and the anode are simultaneously inserted into an ammonia-containing electrolyte, and the external voltage of 0.6-0.8V is applied between the cathode and the anode so that ammonia has an oxidizing reaction to generate nitrogen and water has a reduction reaction to generate hydrogen. The temperature of the electrolytic reaction is controlled between 50 and 60 DEG C. The method for preparing hydrogen by electrolyzing ammonia has the advantages that the electrolytic voltage can be controlled below 0.8V and hydrogen can be prepared economically and effectively.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Method for oxidation treatment of sewage by novel Fe-C microelectrolysis-Fenton reagent

ActiveCN101704596AReduce utilizationIn line with the principle of treating waste with wasteMultistage water/sewage treatmentWater/sewage treatment by oxidationFenton reagentSlag

The invention relates to a sewage treatment method, in particular to a method for comprehensively utilizing heavy slag and gas ashes of a blast furnace. The method is characterized in that a novel Fe-C microelectrolysis-Fenton reagent consisting of the heavy slag and gas ashes of the blast furnace is used for oxidation treatment of the organics in sewage; subsequently the exposure of gas is utilized to effectively remove the suspension organics and colloid generated due to the oxidation treatment of the Fe-C microelectrolysis-Fenton reagent, thus removing the contamination in the sewage and resolvable organics difficult for biodegradation. The method reduces the production cost for sewage treatment, simultaneously utilizes the heavy slag and gas ashes of the blast furnace comprehensively, is environment-friendly and economical, and has greater application and development prospects.

Owner:杨忠刚

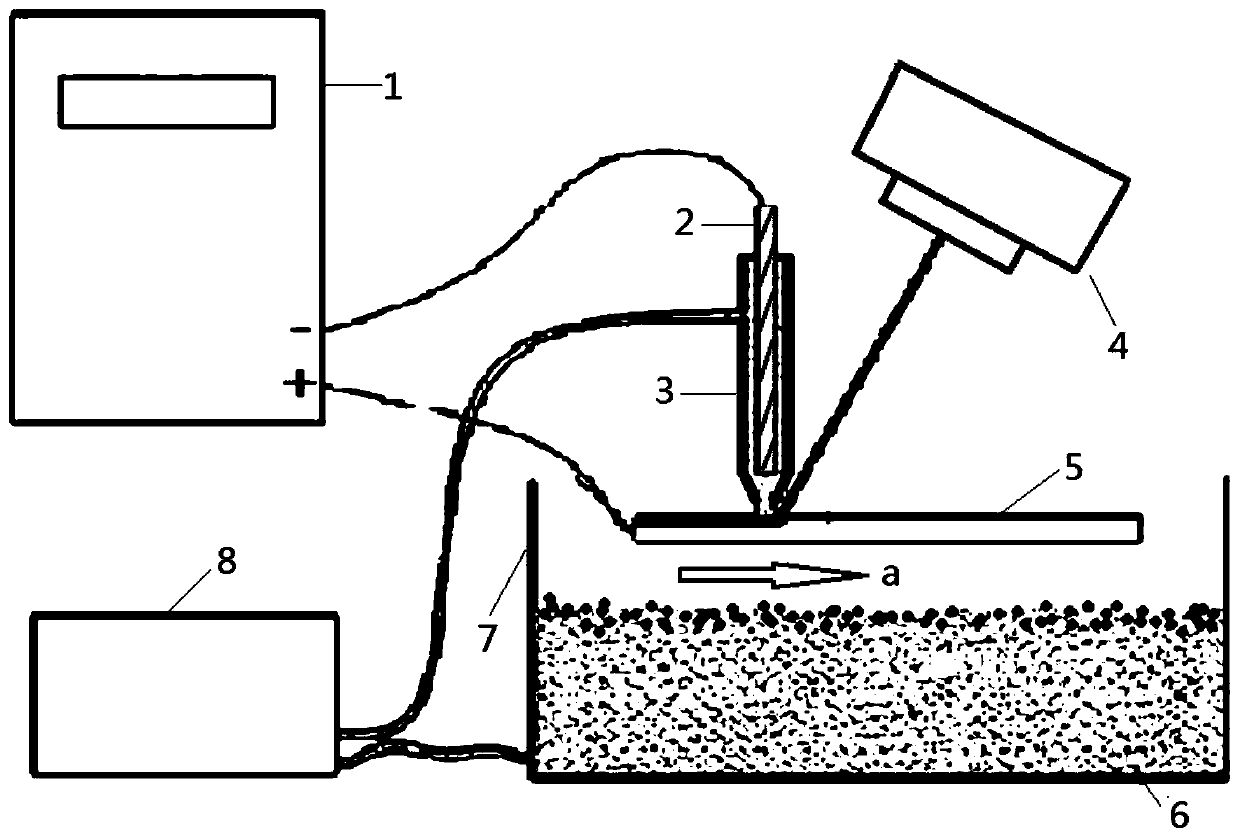

Scanning type laser-assisted micro-arc oxidation device and method

The invention provides a scanning type laser-assisted micro-arc oxidation device and method. The device is not limited by the size of the electrolytic cell and does not require power supply of ultra-high power and can perform local strengthening or repairing treatment so as to reduce the energy consumption, improve the film forming efficiency and the film layer quality, reduce micro-arc oxidationarcing voltage and energy consumption, perform micro-arc oxidation more easily and enter a film forming stage more quickly, realize machining of large-size workpieces or workpieces with complex moldedsurfaces, solve the problems of the area effect and point discharge in the traditional machining device, the reduce limitation of the workpiece size on the power output power and realize micro-arc oxidation of a specific area controlling an inter-electrode electric field.

Owner:ZHEJIANG UNIV OF TECH

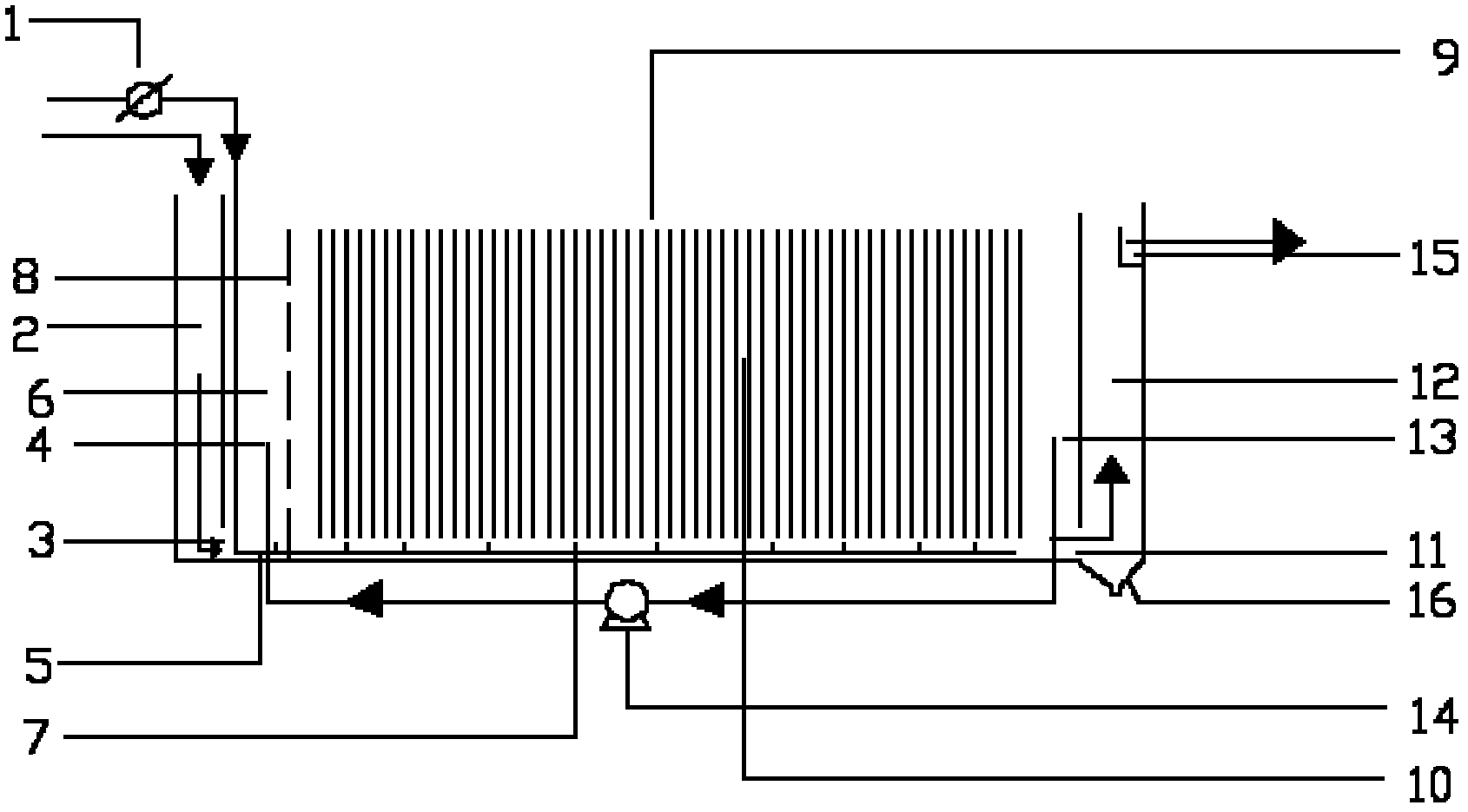

Iron-copper microelectrolysis reaction tank and preparation method for copperized iron wire net plate

The invention relates to an iron-copper microelectrolysis reaction tank and a preparation method for a copperized iron wire net plate. Both ends of a tank body of the iron-copper microelectrolysis reaction tank are provided with a water inlet chamber and a water outlet chamber, a microelectrolysis reactor is arranged between the water inlet chamber and the water outlet chamber, sewage enters a water distribution area from the water inlet chamber via a water inlet and then the microelectrolysis reactor via a water distribution buffer plate, and is electrolyzed, the microelectrolysis reactor comprises a plurality of parallel copperized iron wire net plates, and both opposite edges of each copperized iron wire net plate are respectively arranged on both opposite sidewalls of the tank body. The electrolyzed sewage overflows a water outlet weir of the water outlet chamber. The structure of the iron-copper microelectrolysis reaction tank is simple, the applicable water quality range is wide, the cost is low, the service life is long, the chroma, toxicity and CODCr of organic waterwater can be effectively decreased, and the biodegradability of sewage can be enhanced. Copper can be firmly attached on the surfaces of the iron wire nets, and cannot easily come off, and low cost and low energy consumption are truly realized in the process of sewage treatment.

Owner:SHANDONG UNIV

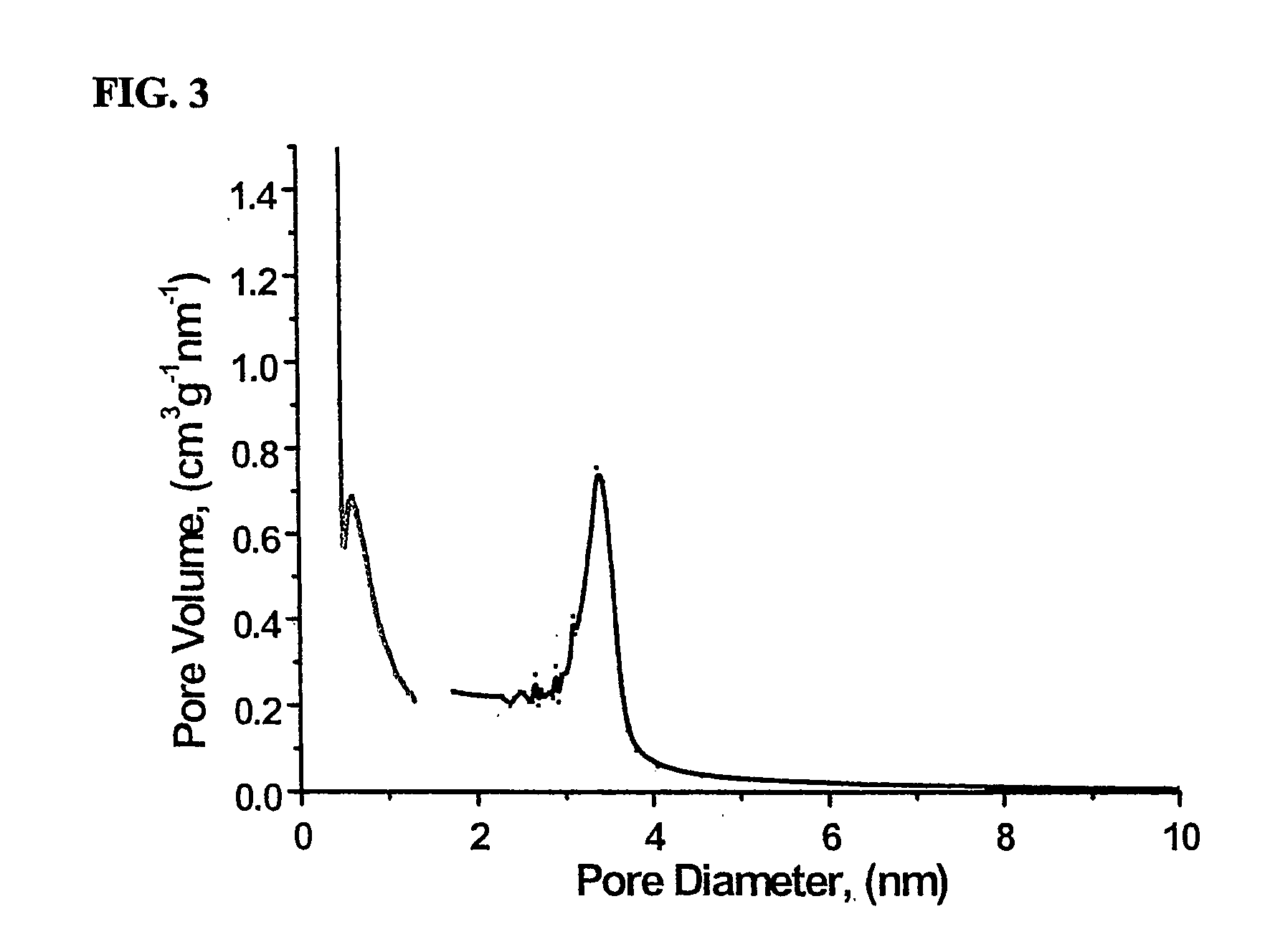

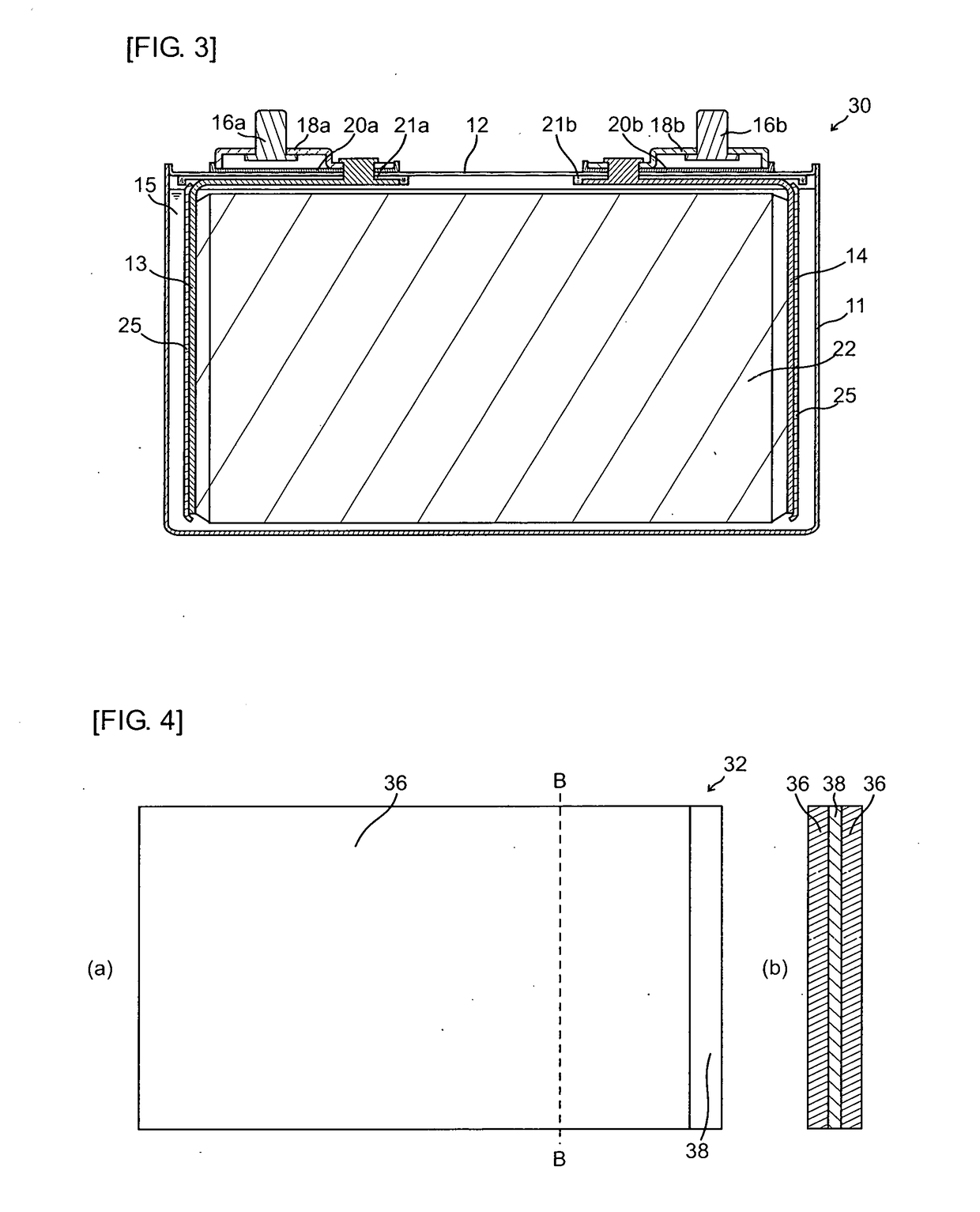

Positive electrode for nonaqueous electrolyte secondary battery, and nonaqueous electrolyte secondary battery

InactiveUS20170244096A1Promote reactionReaction surface of be increaseFinal product manufactureSecondary cellsPore diameterElectrolyte

A positive electrode for a nonaqueous electrolyte secondary battery according to the present invention is provided with a porous positive electrode active material layer that contains a positive electrode active material. The positive electrode active material layer is formed so that a logarithmic differential pore volume distribution curve thereof, which shows the relation between pore diameter and pore volume of pores in the positive electrode active material layer, is a single-peak type curve. The distribution curve has a main peak having a full width at half maximum of from 0.001 μm to 0.05 μm inclusive, and the sum of the pore volumes of the pores within a pore diameter range corresponding to the full width at half maximum is 70% or more of the total pore volume.

Owner:ELIIY POWER

Method for treating sewage by industrial solid wastes

ActiveCN101704563AReduce utilizationIn line with the principle of treating waste with wasteWater/sewage treatmentActivated carbonElectrolysis

The invention relates to a method for treating sewage, which comprises the comprehensive utilization of blast furnace heavy slag and blast furnace iron-containing slag. The method is characterized in that the blast furnace heavy slag is used as a bedding layer; coke, the blast furnace iron-containing slag and activated carbon are overlapped from bottom to top to form a sewage iron-carbon treatment layer; and the iron-carbon treatment layer utilizes a micro-electrolysis theory to treat the sewage. The method solves the problem that the efficiency of treating the sewage only by a coke treatment layer is low, reduces production cost for treating the sewage only by an activated carbon treatment layer, makes the blast furnace heavy slag and the blast furnace iron-containing slag comprehensively utilized simultaneously, is environmentally-friendly and economical, and has wider application and development prospect.

Owner:杨祺

Method for treating sewage by blast furnace heavy slag and blast furnace gas ash

ActiveCN101704562AIncrease the potential differencePromote electrode reactionWater/sewage treatmentSlagActive carbon

The invention relates to a method for treating sewage, which comprises the comprehensive utilization of blast furnace heavy slag and blast furnace gas ash. The method is characterized in that the blast furnace heavy slag is used as a bedding layer; coke and the blast furnace gas ash are overlapped from bottom to top to form a sewage iron-carbon treatment layer; and the iron-carbon treatment layer utilizes a micro-electrolysis theory to treat the sewage. The method reduces production cost for treating the sewage only by an iron dust-active carbon treatment layer, makes the blast furnace heavy slag and the blast furnace gas ash comprehensively utilized simultaneously, is environmentally-friendly and economical, and has wider application and development prospect.

Owner:杨忠刚

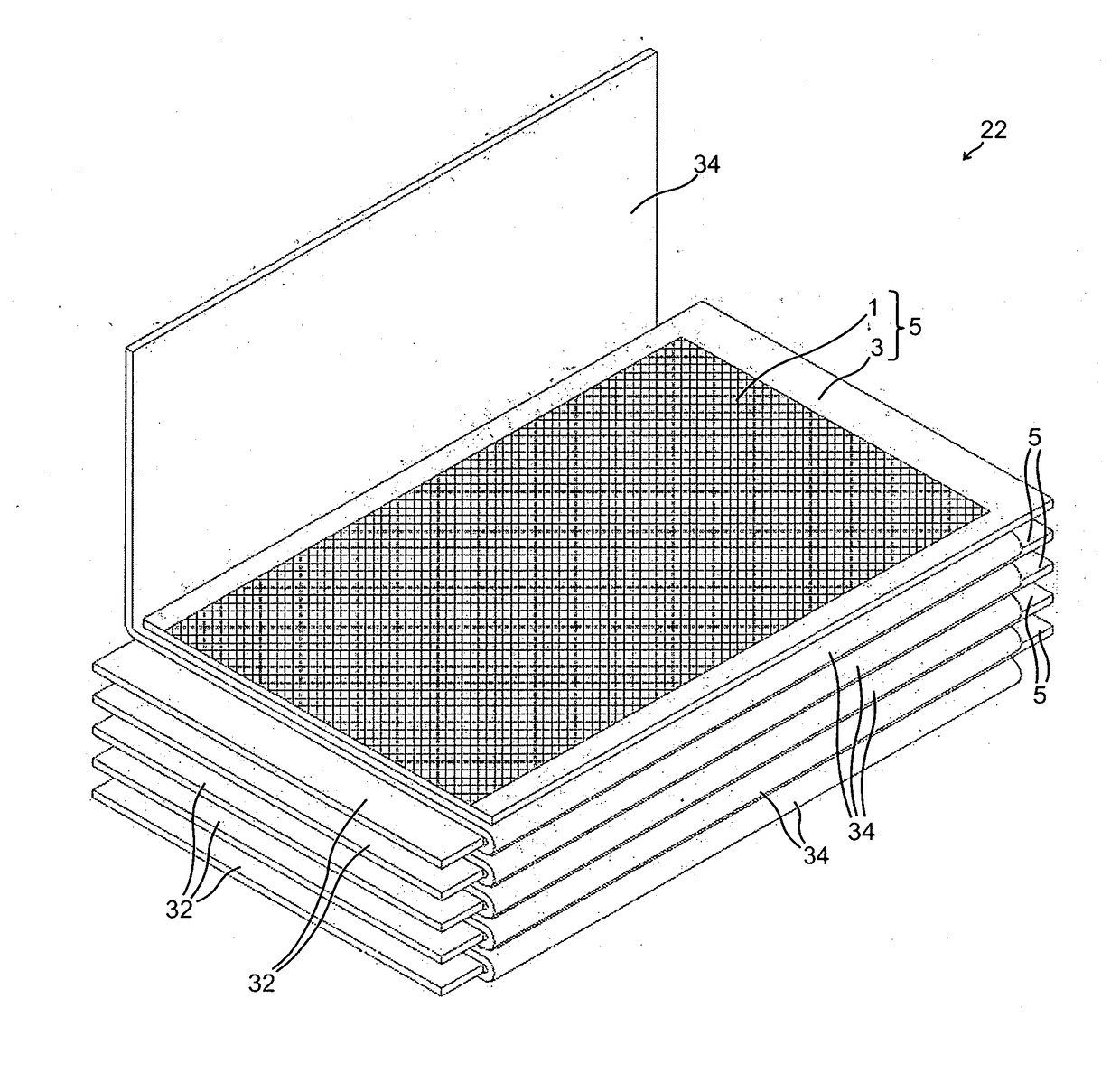

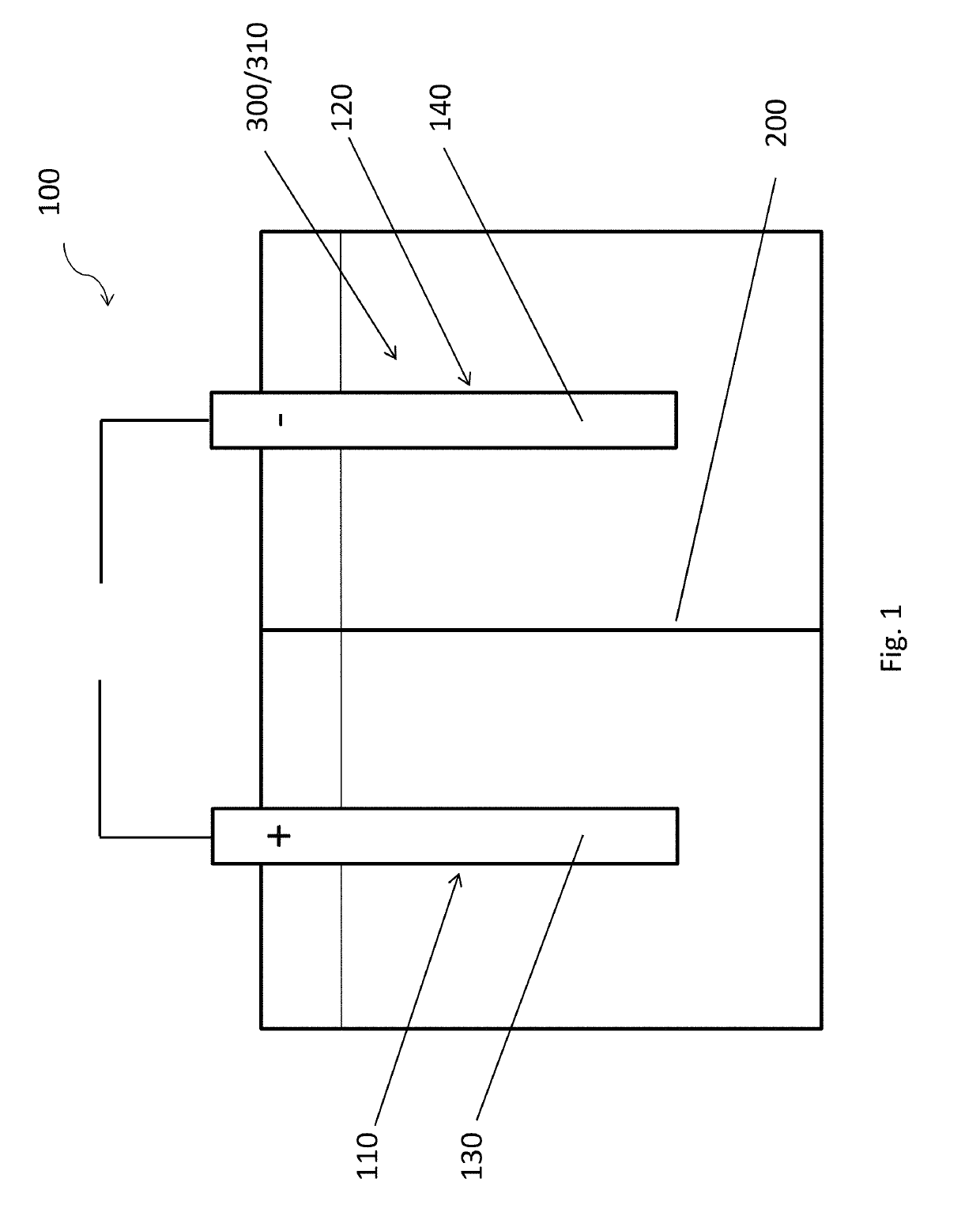

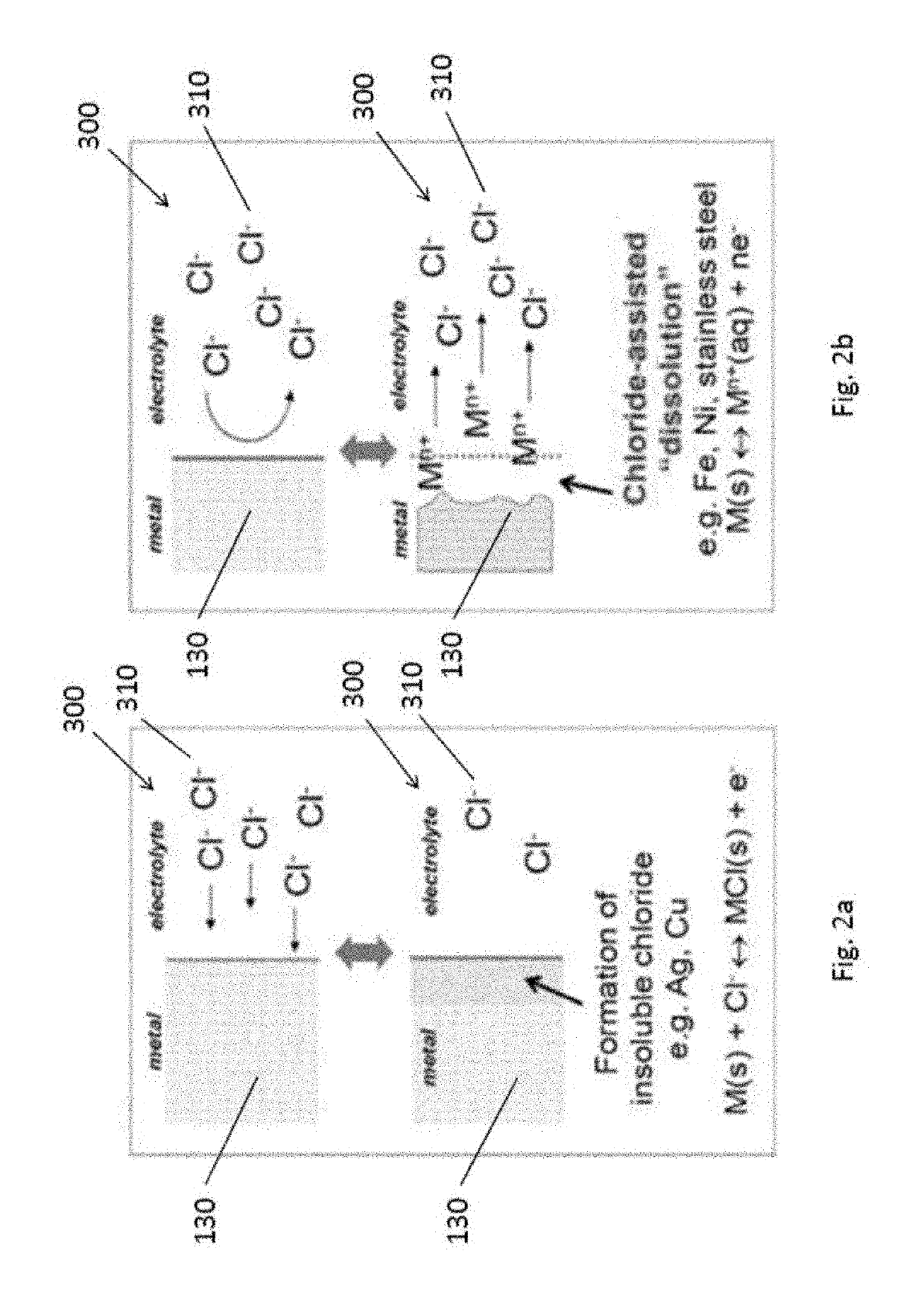

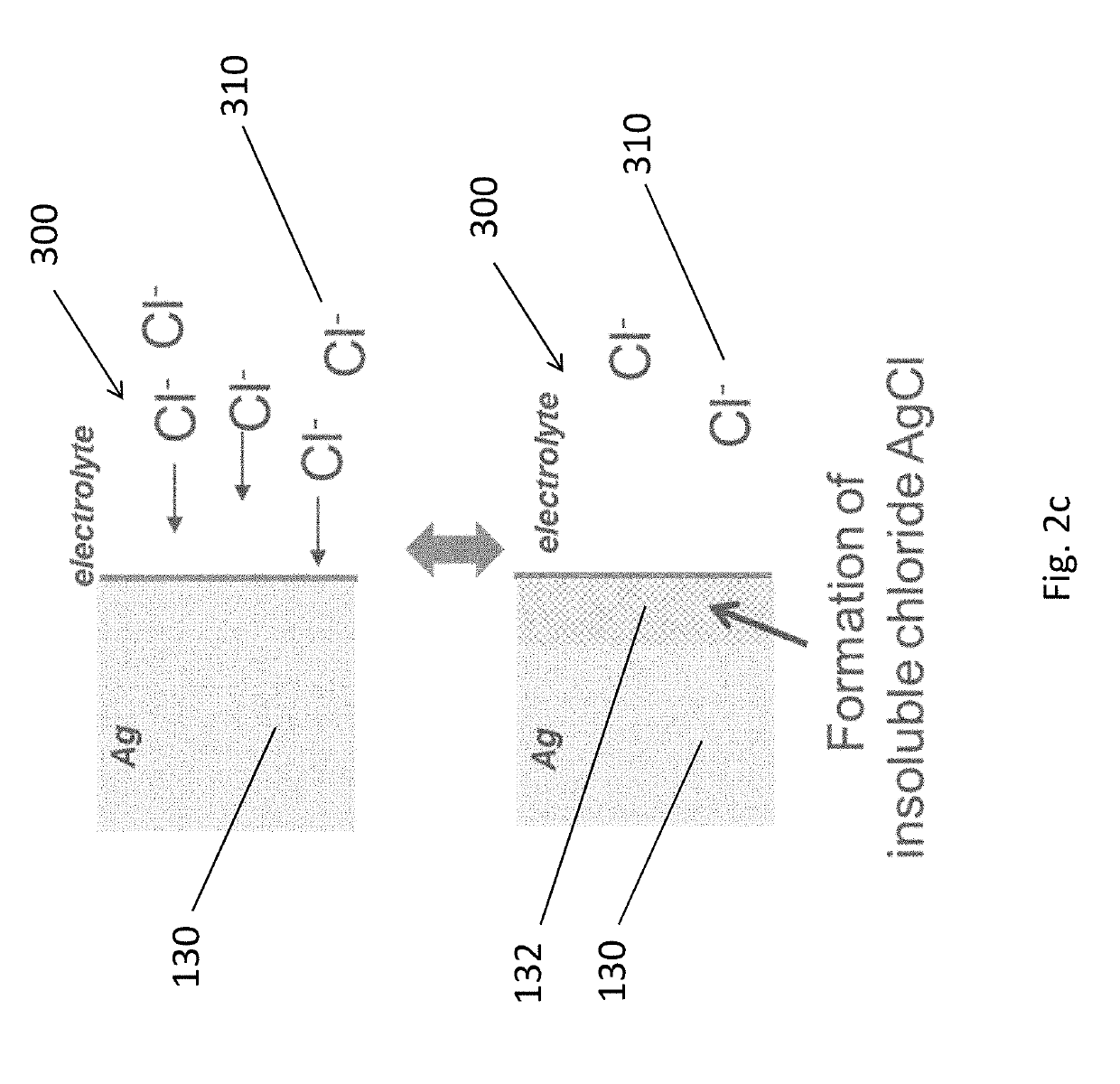

Battery system and a method of forming a battery

ActiveUS20190229363A1Promote electrode reactionCell electrodesFinal product manufactureChemical reactionCharge carrier

A battery system includes a positive electrode having a first material arranged to undergo chemical reaction during charging and / or discharging of the battery, a negative electrode having a second material arranged to undergo chemical reaction during charging and / or discharging of the battery, a separator disposed between the positive electrode and the negative electrode; and an electrolyte having a charge carrier, wherein the charge carrier is arranged to facilitate the chemical reaction of the first material during charging and / or discharging of the battery.

Owner:CITY UNIVERSITY OF HONG KONG

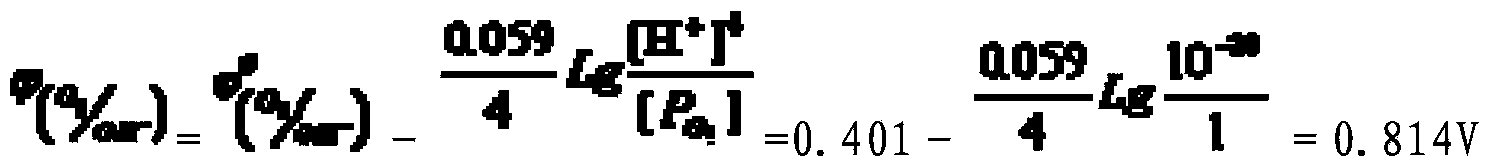

Carbon catalyst for redox flow battery electrodes

ActiveUS20190341626A1Promote electrode reactionIncreased durabilityPhysical/chemical process catalystsCell electrodesRedoxOxygen

An electrode for redox flow batteries is produced using a carbon catalyst for redox flow battery electrodes, wherein a ratio of the number of oxygen atoms to the number of carbon atoms (O / C ratio) is 0.05 to 0.20 as measured by surface analysis using X-ray photoelectron spectroscopy.

Owner:HISSHINBO HOLDINGS INC

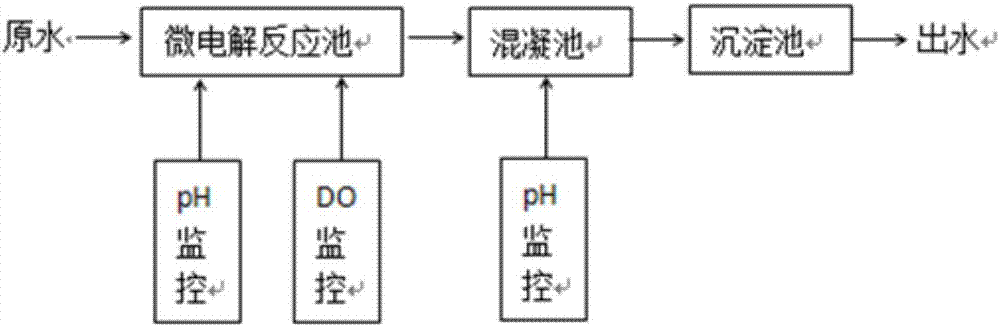

COD pollutant treatment method

InactiveCN109279723AHigh removal rateShorten the timeWater treatment parameter controlWater treatment compoundsAeration systemSludge

Disclosed is a COD pollutant treatment method. The COD pollutant treatment method is characterized in that the method is to pass to-be-treated liquid through the following functional units in order: an iron-carbon tank which is provided with a water inlet and an automatic pH adjusting device at the top to adjust incoming water to be acidic and an aeration system at the bottom, a Fenton tank whichis provided with an automatic drug adding device at the water inlet to add hydrogen peroxide and an aeration system at the bottom, a coagulation tank which is provided with an automatic pH adjusting device at the water inlet to adjust incoming water to be alkaline and an automatic drug adding device at the water inlet to add a coagulant, and a sedimentation tank which is provided with a sludge discharge port at the bottom.

Owner:周尧

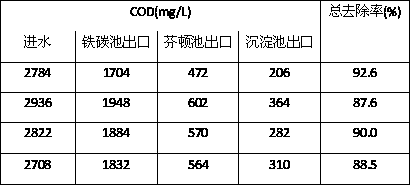

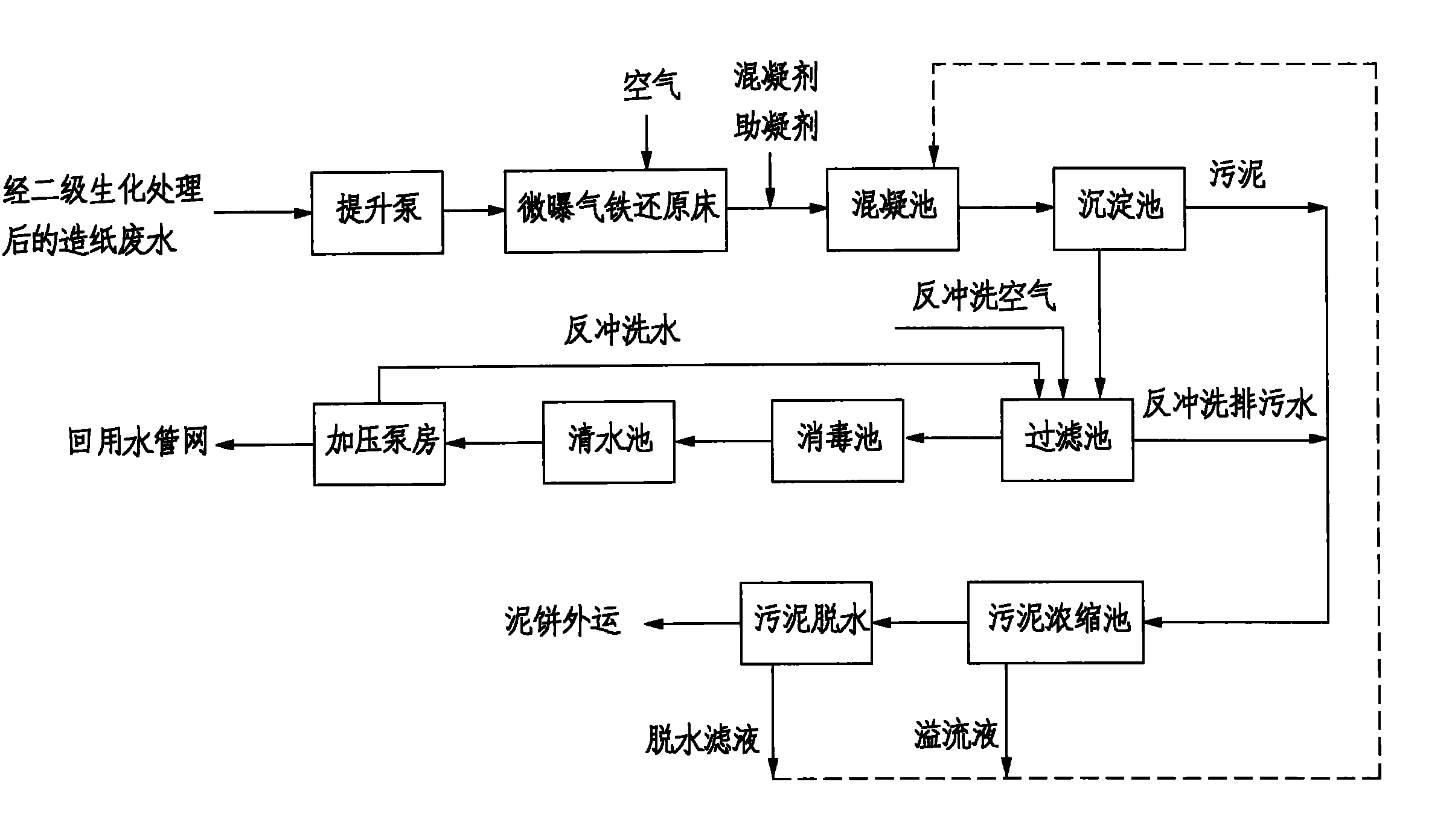

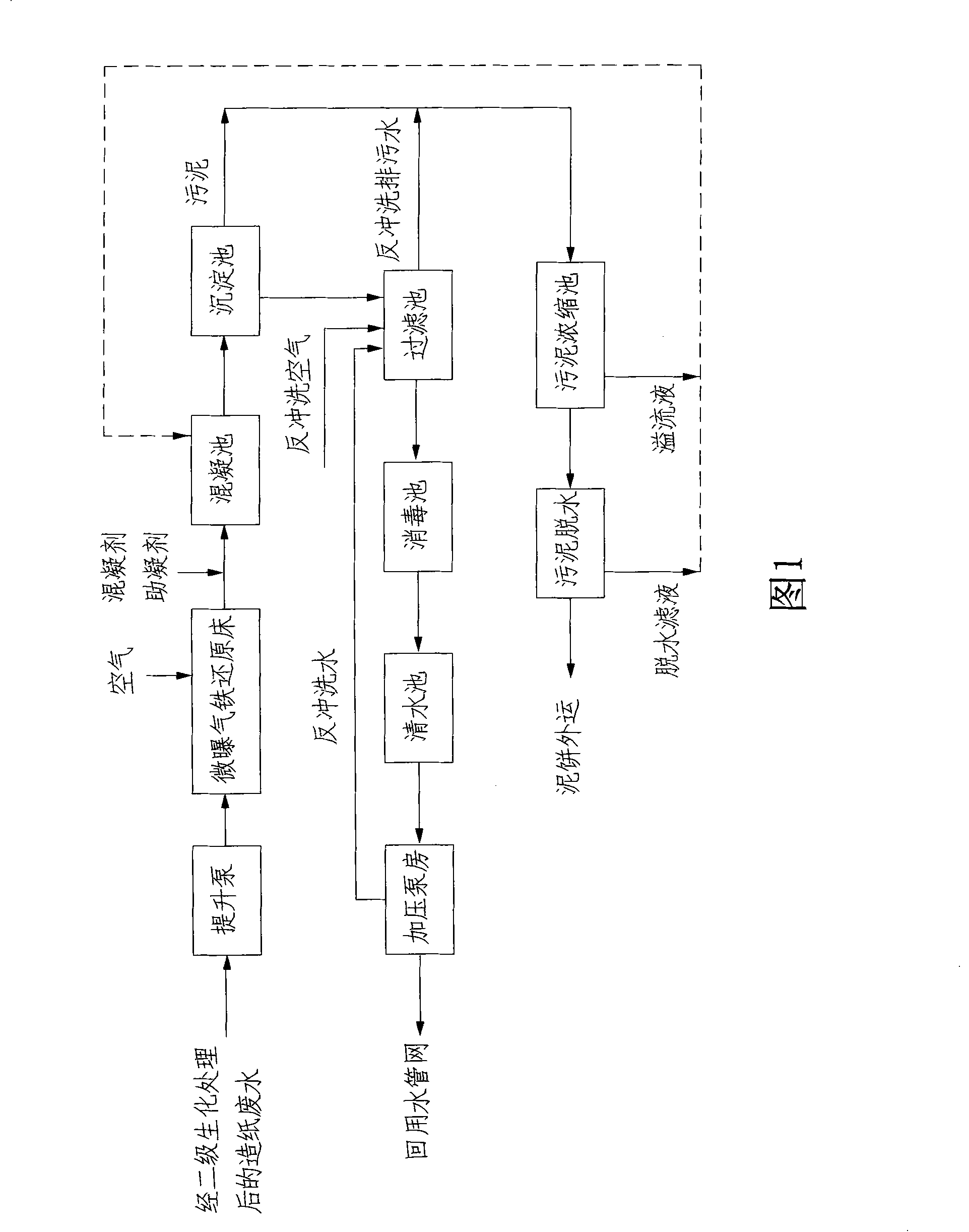

Advanced treatment process for paper-making waste water

ActiveCN101337752BHigh salt contentImprove conductivitySludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSludgeWastewater

The invention discloses an advanced treatment process of paper-making wastewater. The process comprises the following steps: introducing the paper-making wastewater after being subjected to secondary biochemical treatment into a micro-aeration iron reduction bed, backfilling iron chips in the micro-aeration iron reduction bed, and carrying out reducing reaction to the paper-making wastewater in the micro-aeration iron reduction bed; introducing effluent water after being processed according to step one into a coagulation basin, and adding a coagulating agent and a coagulant aid to the coagulation basin, so as to promote grains in the water to be agglomerated; introducing effluent water after being processed according to step two to a sedimentation tank for sludge separation; introducing the effluent water in the sedimentation tank into a filter basin for being filtered; introducing the effluent water filtered after being sterilized and disinfected into a reusing water pipe network; introducing sludge in the sedimentation tank and back washing blow-off water in the filter basin into a sewage thicker, and outwardly transporting the sludge and the back washing blow-off water after being dehydrated for disposal; and meanwhile, introducing dehydrate filtrate solution and overflowing liquid in the sewage thicker into the coagulation basin for re-treatment. The process has the advantages of simple process, good decoloration effect and cheap cost.

Owner:HUATIAN ENG & TECH CORP MCC

Carbon catalyst for redox flow battery electrodes

ActiveUS10903504B2Promote electrode reactionIncreased durabilityPhysical/chemical process catalystsCell electrodesPtru catalystRedox

An electrode for redox flow batteries is produced using a carbon catalyst for redox flow battery electrodes, the carbon catalyst being a particulate carbon catalyst and consisting of carbonaceous particles having a specific surface area of 800 to 2000 m2 / g and an average particle size of 100 to 1000 nm.

Owner:HISSHINBO HOLDINGS INC

Microelectrolysis filler and process for treating printing and dyeing wastewater

InactiveCN107089705AReduce usageSimple processWater contaminantsMultistage water/sewage treatmentActivated carbonDyeing wastewater

The invention discloses a microelectrolysis filler for treating printing and dyeing wastewater. The microelectrolysis filler is a ternary filler based on Fe, C and Al and contains the following components in percentage by weight: 15%-25% of iron, 30%-40% of activated carbon, 15%-25% of aluminum, 20%-30% of clay and 0-10% of sodium carboxymethylcellulose. The ternary microelectrolysis filling based on Fe, C and Al is used for directly treating the printing and dyeing wastewater, so that the technical process is simplified, meanwhile, the use amounts of acid-base reagents are reduced, and the cost is effectively saved.

Owner:江苏艾特克环境工程设计研究院有限公司 +1

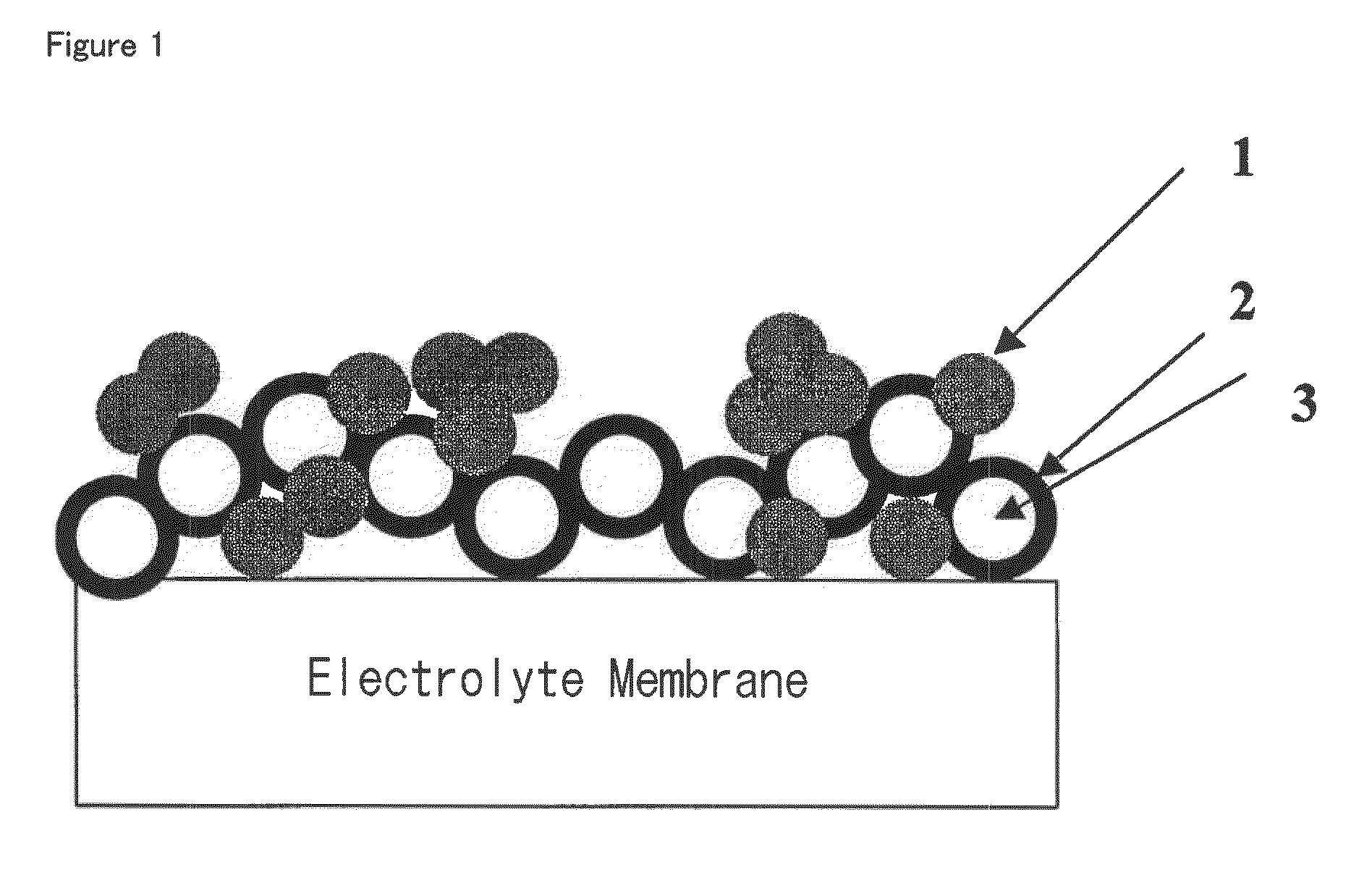

Catalyst layer and preparation process thereof, and membrane-electrode assembly and polymer electrolyte fuel cell using the catalyst layer

InactiveUS8420276B2Promote electrode reactionImprove battery efficiencyCell electrodesOrganic-compounds/hydrides/coordination-complexes catalystsPolymer electrolytesFuel cells

In a membrane-electrode assembly for polymer electrolyte fuel cells comprising a polymer electrolyte membrane and two gas diffusion electrodes being bonded to the membrane so that the membrane can be between them, at least one catalyst layer constituting the gas diffusion electrodes characterized in that the ion-conductive binder comprises a block copolymer having a particle size of 1 μm or less comprising a polymer block (A) having ion-conductive groups and a polymer block (B) having no ion-conductive group, both polymer blocks phase separate from each other, polymer block (A) forms a continuous phase, and the contact parts of the block copolymer with catalyst particles are comprised of polymer block (A) having ion-conductive groups; a membrane-electrode assembly and a polymer electrolyte fuel cell.

Owner:KURARAY CO LTD

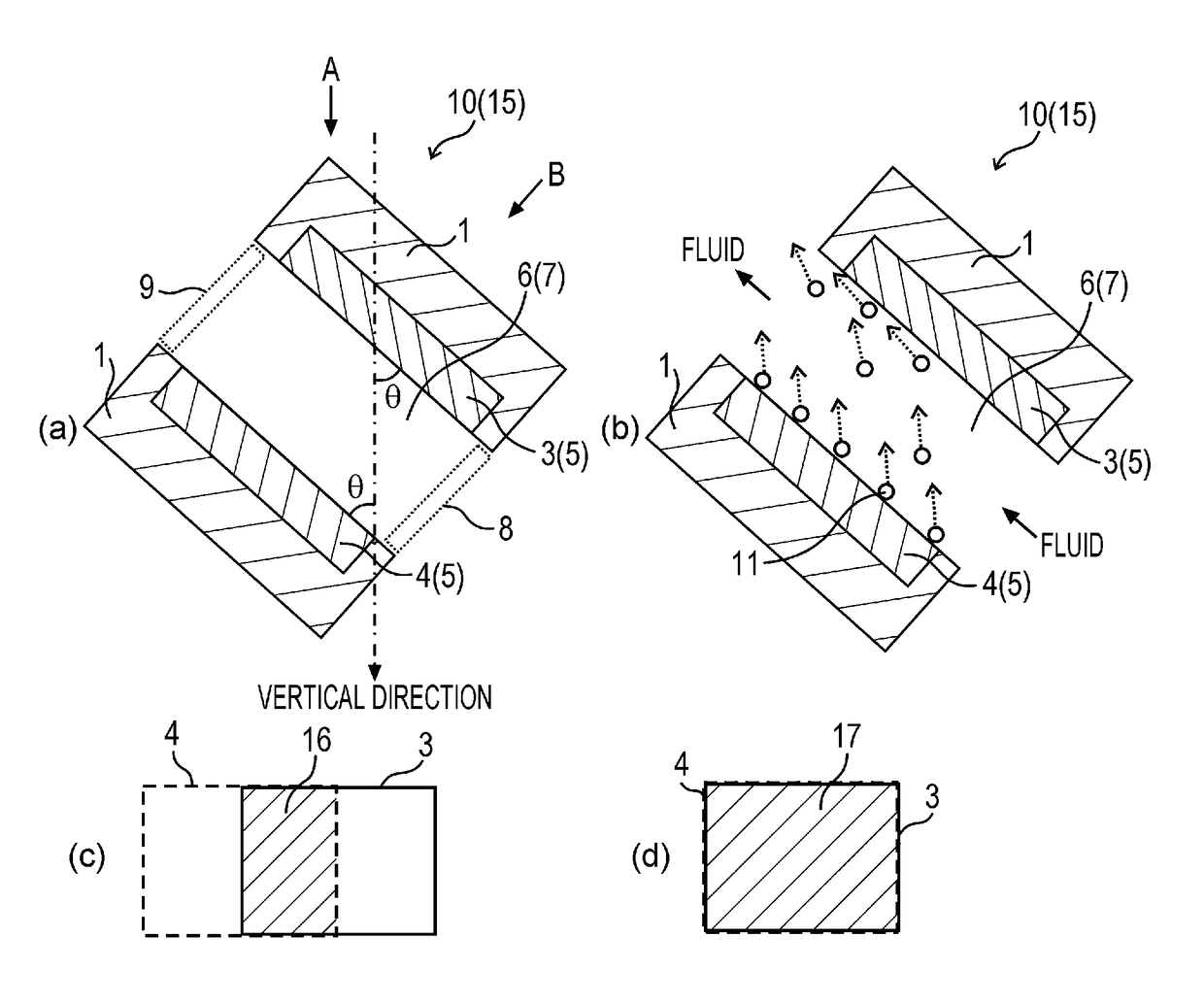

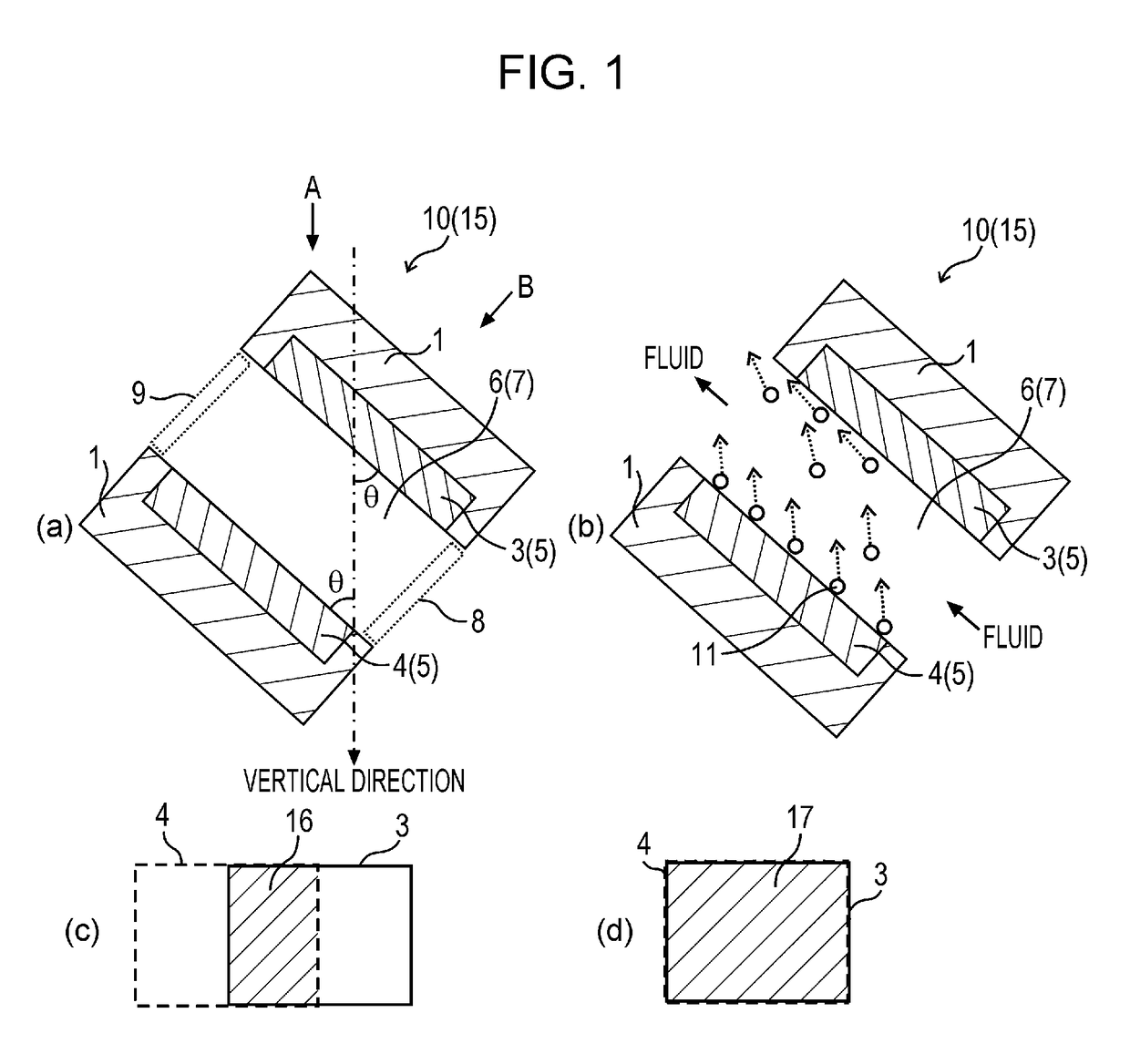

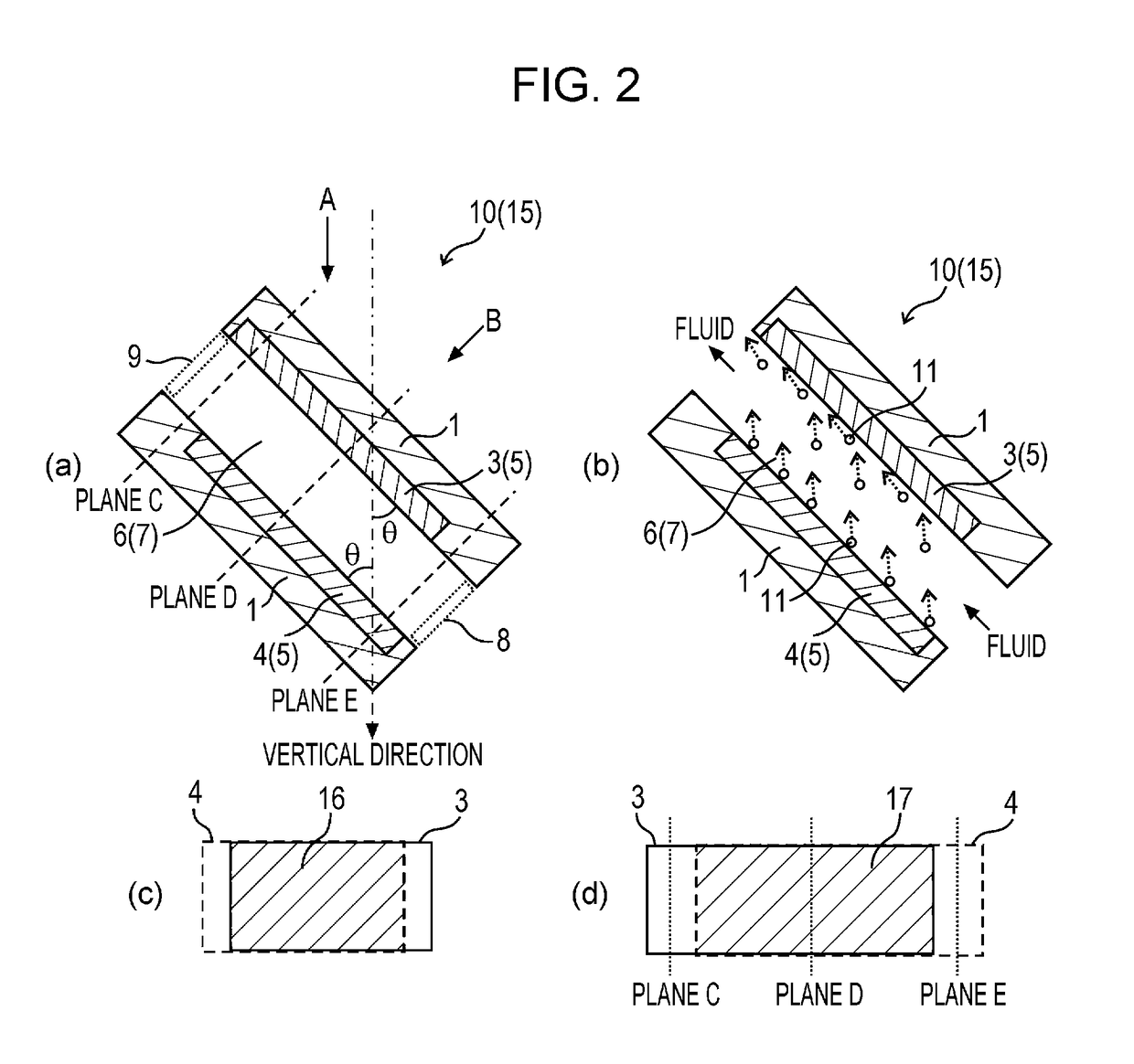

Electrolysis device

InactiveUS20170145571A1Continuous productionEfficient productionCellsWater treatment parameter controlElectrolysisEngineering

An electrolysis device of the present invention includes an electrolysis unit. The electrolysis unit includes a channel for fluid to be treated, at least one electrolysis electrode pair, a flow inlet, and a flow outlet. The electrolysis electrode pair is disposed so as to incline with respect to a vertical direction and includes an upper electrode and a lower electrode disposed so as to face each other. The channel for fluid to be treated is disposed so that a fluid that has flowed in from the flow inlet flows through an interelectrode channel between the upper electrode and the lower electrode from a lower side to an upper side and flows out from the flow outlet.

Owner:SHARP LIFE SCI CORP

Carbon catalyst for redox flow battery electrodes

ActiveUS20190341625A1Promote electrode reactionIncreased durabilityPhysical/chemical process catalystsCell electrodesParticulatesRedox

An electrode for redox flow batteries is produced using a carbon catalyst for redox flow battery electrodes, the carbon catalyst being a particulate carbon catalyst and consisting of carbonaceous particles having a specific surface area of 800 to 2000 m2 / g and an average particle size of 100 to 1000 nm.

Owner:HISSHINBO HOLDINGS INC

Suspended electrobiological filler for removing ammonia nitrogen from water, preparation method for suspended electrobiological filler and application of suspended electrobiological filler

ActiveCN102674530BPromote electrode reactionImprove adsorption capacityWater contaminantsBiological water/sewage treatmentAdhesiveMicrosphere

The invention discloses a suspended electrobiological filler for removing ammonia nitrogen from water and a preparation method for the suspended electrobiological filler. The suspended electrobiological filler comprises the following components in percentage by weight: 10 to 20 percent of iron powder, 10 to 20 percent of graphite powder or activated carbon powder, 1 to 2 percent of alumina, 1 to 2 percent of nickel oxide, 1 to 2 percent of titanium oxide, 1 to 2 percent of thallium oxide, 1 to 2 percent of iridium oxide, 20 to 30 percent of molecular sieve material, 5 to 10 percent of adhesive and 20 to 30 percent of hollow glass microspheres. The preparation method comprises the following steps of: mixing the raw materials, putting into a reaction kettle, mixing, stirring uniformly, adding the adhesive and water, preparing paste with the water content of about 20-30 percent, granulating by using a granulator or pressing into granules and blocks in a molding machine, demoulding, feeding into a baking oven, and drying at the temperature of 100 to 180 DEG C for 3 to 4h to obtain the suspended electrobiological filler. The invention also provides application of the suspended electrobiological filler. The suspended electrobiological filler can effectively remove the ammonia nitrogen from the water; and in the upgrading reconstruction of industrial wastewater treatment stations, water works and municipal sewage treatment plants, the removal efficiency of the ammonia nitrogen in the water can be improved by 15 to 40 percent, and the total discharge amount of the ammonia nitrogen and nitrate nitrogen can be controlled.

Owner:深圳市地大东江环境研究院

A kind of method that utilizes liquid aluminum cathode method to produce aluminum-magnesium alloy

The invention discloses a method for producing an aluminum-magnesium alloy by using a liquid aluminum cathode method, which can produce high-quality aluminum-magnesium alloy with high efficiency. The content of the method includes: taking high-purity magnesium oxide as raw material, dissolving MgO in an electrolyte system composed of Na3PO3-MgF2-NaCl at an electrolysis temperature of 850-900° C. in an electrolytic cell, using high-purity aluminum ingots The molten aluminum is used as a liquid cathode; high-purity graphite is used as the anode, and under the condition of electrolysis with an anode current density of 0.47-0.52A / cm2, a coil magnetic field with a strength of 30-40mT is applied outside the electrolytic cell to make the molten aluminum rotate. Under the action of electromagnetic stirring, magnesium ions are reduced to elemental magnesium on the rotating aluminum liquid cathode and evenly diffused in the aluminum liquid to form an aluminum-magnesium alloy product, and at the same time, CO2 gas is generated at the anode. The alloy formed by the invention has uniform composition and no inclusions. And the production process is continuous and easy to control.

Owner:UNIV OF SCI & TECH LIAONING

Method for reducing surface microdefects of titanium metal bipolar plate of fuel cell

PendingCN114284520APromote electrode reactionLess micro defectsFinal product manufactureCollectors/separatorsCarbon coatingTitanium metal

A method for reducing surface microdefects of a titanium metal bipolar plate of a fuel cell comprises the following steps: firstly, carrying out ultrasonic oil removal on the titanium metal bipolar plate, then adding an H2SO4 solution with the concentration of 30-60g / L, an HF solution with the concentration of 2-10g / L and methanol with the concentration of 20-40g / L into distilled water, uniformly stirring and mixing to prepare a polishing solution, and then carrying out electrochemical polishing on the titanium metal bipolar plate to obtain the surface microdefects of the titanium metal bipolar plate. The purpose of micro-leveling the surface of the titanium metal bipolar plate gradually is achieved, micro-defects on the surface of the titanium metal bipolar plate can be reduced, such as micro-cracks generated in the rolling process or defects of a conductive corrosion-resistant carbon coating on the surface of the bipolar plate, the service life of the bipolar plate coating is remarkably prolonged, and the reliability of the bipolar plate coating is remarkably improved. A specially-made polishing solution is used during electrochemical polishing, the polishing solution is simple in component, stable in performance and good in effect, the polishing process is reasonably set, and the method is suitable for large-scale production and application.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Carbon catalyst for redox flow battery electrodes

ActiveUS10903505B2Promote electrode reactionIncreased durabilityPhysical/chemical process catalystsCell electrodesPtru catalystPhysical chemistry

An electrode for redox flow batteries is produced using a carbon catalyst for redox flow battery electrodes, wherein a ratio of the number of oxygen atoms to the number of carbon atoms (O / C ratio) is 0.05 to 0.20 as measured by surface analysis using X-ray photoelectron spectroscopy.

Owner:HISSHINBO HOLDINGS INC

Refillable lithium-ion battery

ActiveCN102255105BImprove conductivityReduce restrictionsSecondary cellsCell component detailsPropionitrileEthyl propionate

The invention discloses a lithium ion battery with adoption of secondary electrolyte injection, comprising a positive pole, a negative pole, a diaphragm, an electrolyte and an outer package. In the process of manufacturing the battery, the secondary electrolyte injection is adopted; the electrolyte solvent in the first electrolyte injection is one or a combination of more than one of EC (ethylene carbonate), PC (propylene carbonate), DMC (dimethyl carbonate), DEC (diethyl carbonate), EMC (ethyl methyl carbonate), Gamma-BL (butyrolactone), MF (methyl formate), MA (methyl acetate), EP (ethyl propionate) and THF (tetrahydrofuran) and does not contain acetonitrile and propionitrile; the secondary electrolyte injection is conducted after the formation; and the used electrolyte in the secondary electrolyte injection contains at least one of the acetonitrile and the propionitrile. The electrolyte containing the at least one of the acetonitrile and the propionitrile has the advantage of high normal-temperature conductivity (10-50mS / cm) and low-temperature conductivity (4-20mS / cm at the temperature of -20 DEG C), thereby exceeding the level of an existing electrolyte.

Owner:DONGGUAN AMPEREX TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com