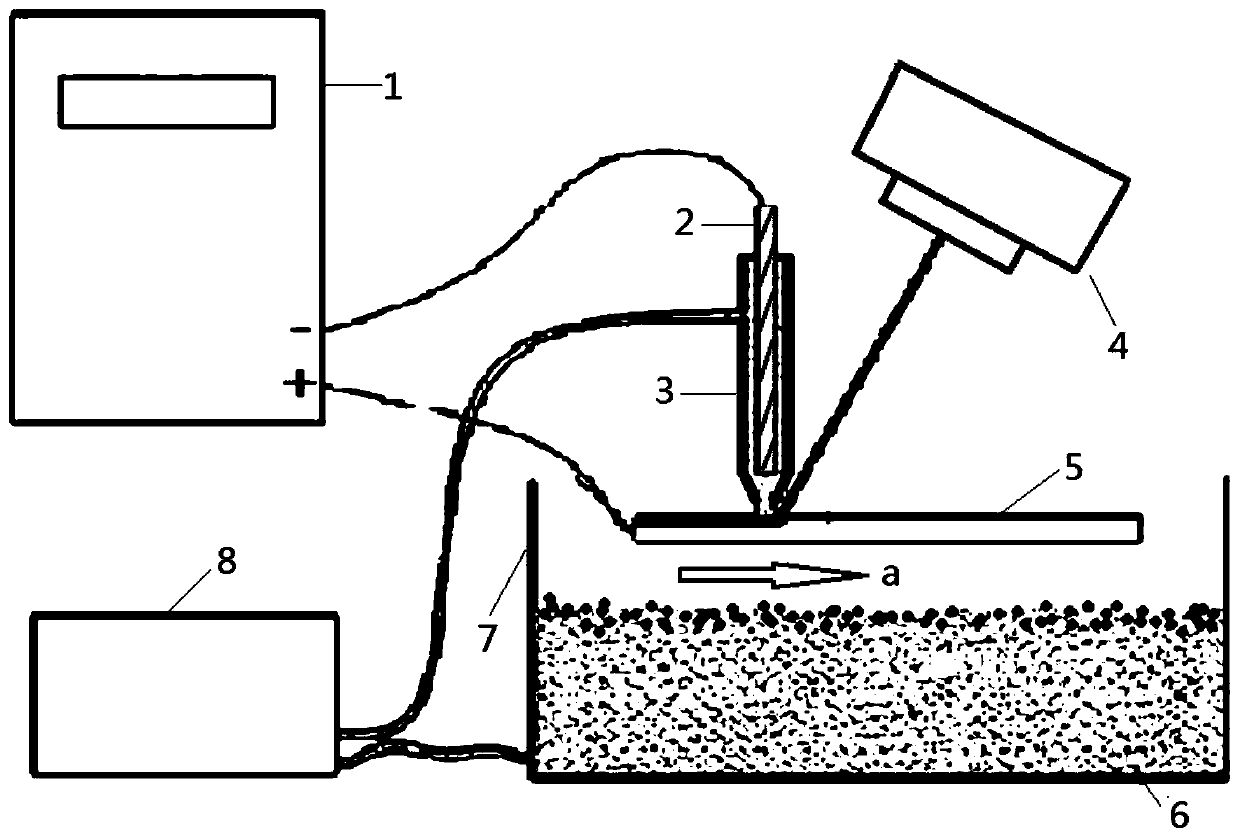

Scanning type laser-assisted micro-arc oxidation device and method

A micro-arc oxidation, laser-assisted technology, applied in anodizing, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of difficult to achieve local repair on site, inability to handle large workpieces, and reducing the fatigue life of substrates. Area effect and tip discharge phenomenon, the effect of improving the ability of atomic diffusion, and improving the quality of surface strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Pretreatment: Use wire cutting to cut the workpiece base into 60mm*20mm*20mm rectangular slices, and polish the rectangular slices, remove the surface oxide film and place them in alcohol solution, ultrasonic cleaning for 5 to 10 minutes, take out the sample after the ultrasonic is finished, and use Rinse with deionized water and dry naturally after rinsing;

[0030] The workpiece is a titanium alloy, and the specific method for grinding and removing the surface oxide film layer of the workpiece is: the workpiece is polished with 240#, 400#, 800#, and 1200# metallographic sandpaper to remove the surface oxide film and surface scratches.

[0031] First, the surface of the workpiece 5 is scanned by a laser, and then the workpiece 5 is subjected to micro-arc oxidation treatment.

[0032] Laser scanning: Aim the laser at the surface of the sample, the distance difference between the laser and the surface of the workpiece is about 280-300mm, the area to be processed is 40mm*...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com