Iron-copper microelectrolysis reaction tank and preparation method for copperized iron wire net plate

A micro-electrolysis, reaction tank technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc. , reduce organic load, accelerate the effect of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

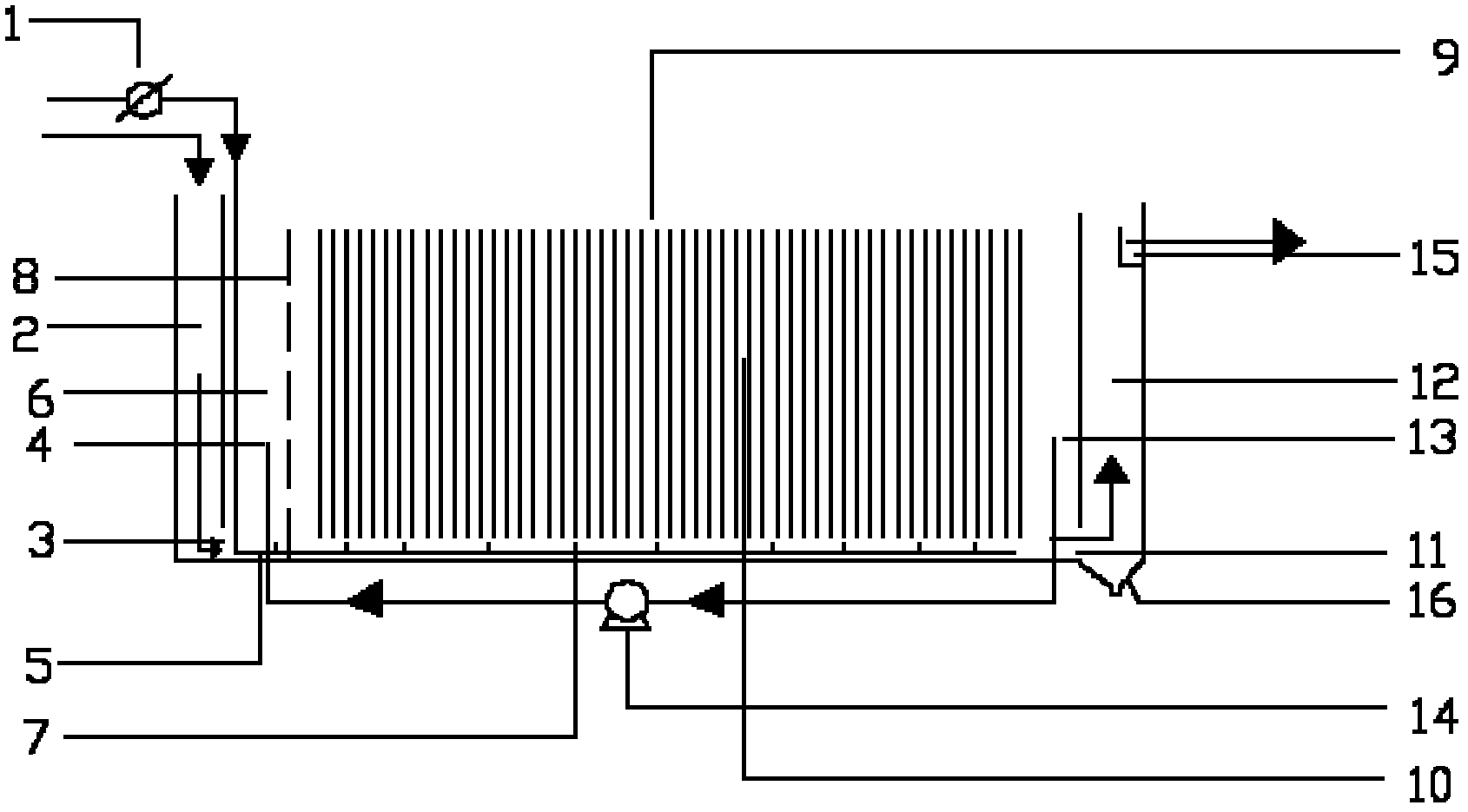

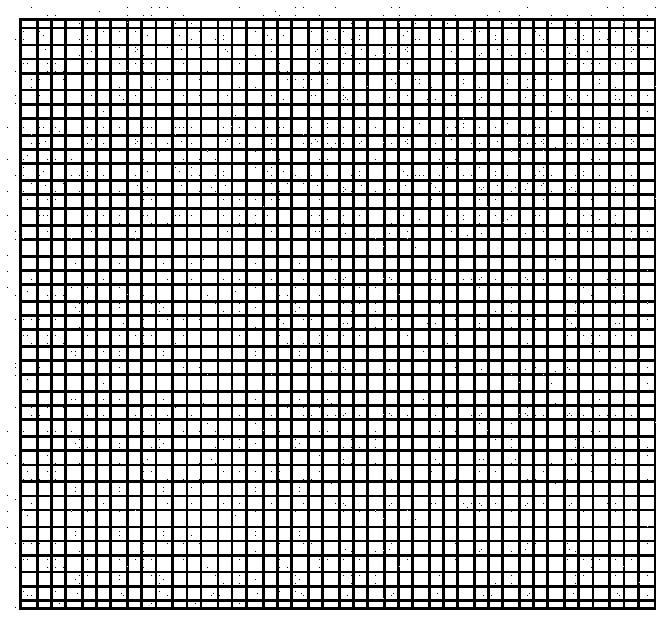

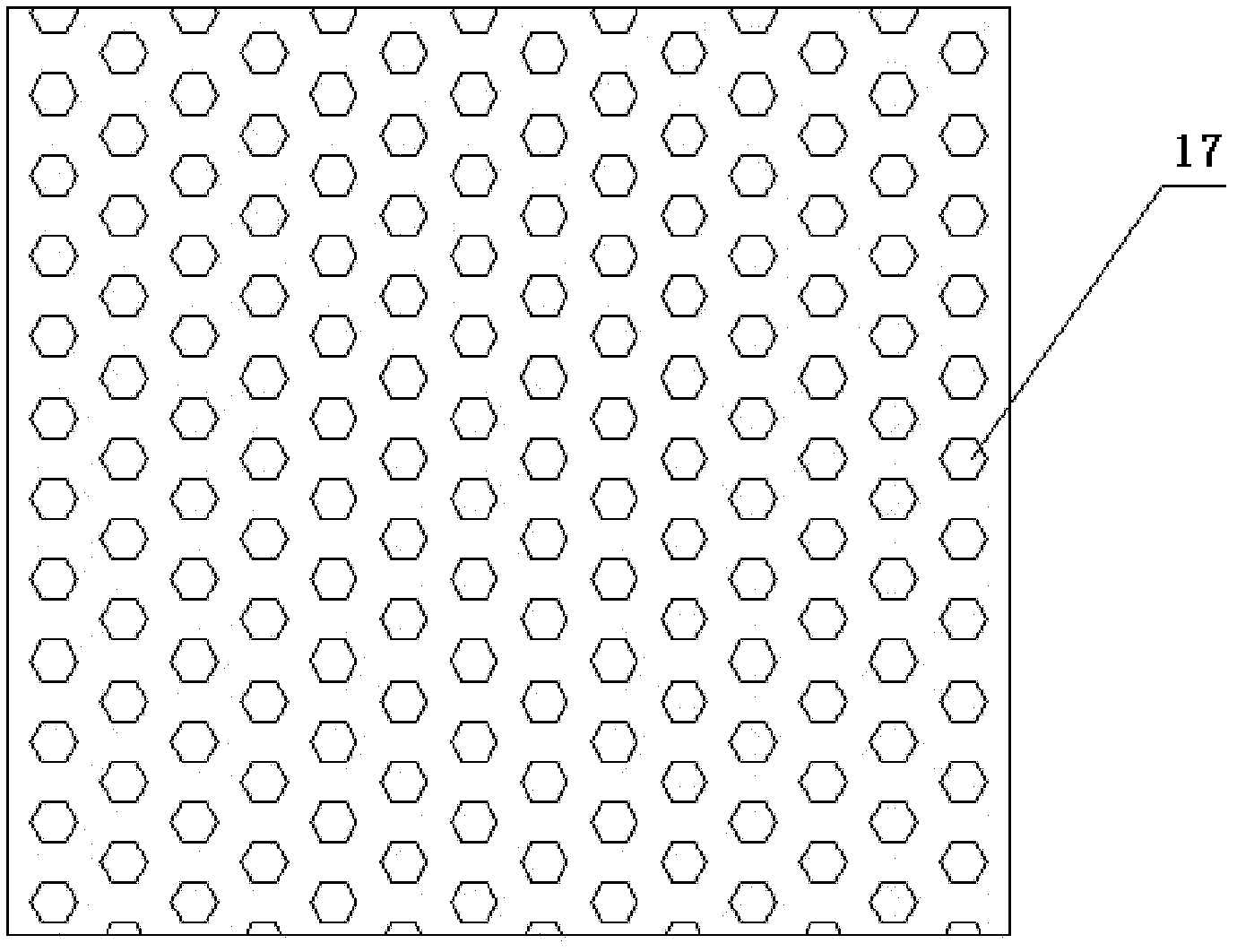

[0035] structured as figure 1 As shown, the iron-copper micro-electrolysis reaction tank of the present invention includes a tank body, and a water inlet chamber 2 and a water outlet chamber 12 are respectively arranged at opposite ends of the tank body, and a micro The electrolytic reaction device is provided with a water distribution buffer plate 8 between the water inlet chamber 2 and the micro-electrolysis reaction device, and the water distribution buffer plate 8 is provided with water distribution holes 17, and the water distribution holes 17 are evenly distributed on the water distribution buffer plate 8, The shape of water distribution hole 17 is preferably hexagonal, and the structure is as image 3shown. The area between the water inlet chamber 2 and the water distribution buffer plate 8 is the water distribution area 6, the water inlet chamber 2 communicates with the water distribution area 6 through the water inlet 3 arranged at the bottom of the water inlet chamb...

Embodiment 2

[0046] The structure of the iron-copper micro-electrolysis reaction tank is as described in Example 1, and the difference is:

[0047] There are 80 copper-plated wire mesh panels 9, and the distance between two adjacent copper-plated wire mesh panels 9 is 0.6cm. The size of the copper-plated wire mesh panels 9 is 65cm×40cm, and there are dense wire mesh holes on the copper-plated wire mesh panels. , The size of the wire mesh hole is 0.8cm×0.8cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com